Sten Mk II submachine gun and magazines.

By Frank Iannamico

During World War II there were an estimated forty-two million magazines produced for the British Sten submachine gun. Today, Sten magazines are very easy to find on the surplus market and usually very inexpensive. Because of their availability and low price, Sten magazines have been adopted for use in a number of modern firearms, both as issued and in modified form. With such a proliferation of Sten magazines one has to wonder just why anyone would choose to make new ones.

During 1940, the British were in dire need of small arms. The British Lanchester submachine gun and its magazine were a close copy of the German MP28 II submachine gun. The reason for choosing that particular weapon was the manufacturing drawings had been made earlier from two weapons that were in British hands. The existing German magazine and the submachine gun were copied instead of designing a new one to save precious time. The German’s MP28II magazine was the same basic configuration later used for their MP38-MP40 magazines. A similar magazine, in a 32-round configuration, was adopted for the British Sten submachine gun for the same reason. The double-stack single-feed magazine design is a configuration that requires a strong spring in order to force the cartridges into a single row at the top. The spring makes the single feed magazine difficult to load by hand, requiring the use of a loading tool, and places a lot of force on the magazine feed lips. The double-stack double-feed design, as was used in the Thompson submachine gun, is far more reliable and much easier to load by hand.

Sten magazines were produced by a large number of contractors and subcontractors. The magazines were fabricated from sheet metal, with the manufacturing process of the body varying slightly by manufacturer. A thick steel collar was spot welded to the top of the magazine’s body to form the feed lips. The floor plate was made of sheet metal and bent to slide onto the rails formed on the bottom of the magazine body. The floor plate was held in place by a protrusion on a plate attached to the bottom of the magazine spring.

Early Sten magazines proved problematic and were redesigned by eliminating the holes in the rear of the magazine (used to determine how many rounds were in the magazine) and adding a cross brace to connect the legs of the follower to keep them from spreading apart and dragging on the magazine body. The new magazines were designated as the Mk2 design. Many of the earlier magazines were upgraded when processed through a British Factory Thorough Repair program (FTR).

The primary contributing factor of the Sten magazine’s functioning problems is the feed lips’ propensity to spread apart when loaded, changing the critical feed angle of the top cartridge. The condition exists because of the stiff spring inherent of the design.

After Market Sten Magazines

This brings us back to the question of just why aftermarket Sten magazines exist. One of the primary problems with original Sten magazines is that they are 70 plus years old. Springs have a finite life, and the sheet metal parts can suffer from metal fatigue and corrosion. The new manufacture Sten magazines are made of modern materials and to closer tolerances than possible during World War II. When the Sten magazine conversions for the M11/Nine submachine gun were introduced, there was a small run of Sten new magazine springs produced in an attempt to make the magazines more reliable. As a general rule, aftermarket magazines are not as reliable as original factory production. However, the reproduction Sten magazines seem to be the exception. Currently there are two known sources for new manufacture Sten magazines.

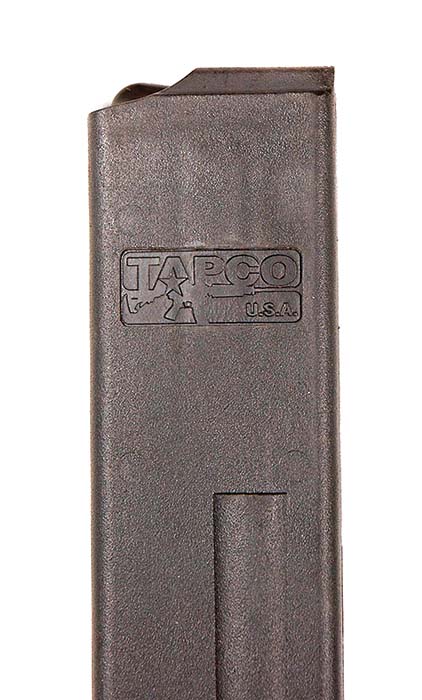

TAPCO is a well-known wholesale company based in Georgia that specializes in the accessory market for firearms. One of the products the company offers is a U.S. made, 32-round Sten magazine made from a modern composite polymer material. The spring is made of corrosion resistant stainless steel, the floor plate is steel and the follower is made from the same polymer as the body. The magazines were originally designed for MasterPiece Arms’ 9mm Defender Series of semiautomatic MAC type pistols. The Defender pistols were originally designed to use metal Sten magazines, but as suitable surplus magazines could no longer be found in the quantity needed, the Company persuaded TAPCO to manufacture new ones. They also offer a magazine loader, although the magazines used in the evaluation could be loaded with an original Sten box type loading tool. According to their website, all TAPCO products have a lifetime guarantee.

The TAPCO logo is molded into the magazine body. According to their website the magazines are made in the USA.

Disassembled TAPCO Sten magazine. The magazines are made from polymer composite except for the spring and floor plate that are steel. The magazines were originally designed for the MasterPiece Arms 9mm Defender series of MAC style pistols.

The second source of new manufacture Sten magazines is an online company called KeepShooting.com. The company, in business since 2002, is located in southern Maryland and sells firearms, firearm accessories, military surplus and ammunition. The Sten magazines offered by Keep Shooting are all steel and exact reproductions of the originals. The company website states: “The magazines are guaranteed to fit and function reliably in any Sten submachine gun, including the Sten Mk I and each of its many variants. This magazine is also compatible with the MPA-30. The body of the magazine, which is designed to hold and feed 32-rounds of 9x19mm Parabellum ammunition to your firearm, is constructed from hardened steel that has been fully heat treated. It also boasts a black Teflon-based finish for enhanced protection against rust and corrosion. Additionally, both the steel spring and follower are precision manufactured to provide for reliable feeds on a consistent basis. The Keepshooting.com Sten magazine is a reproduction of the original Sten magazine, which was a direct copy of the MP-38 magazine. As such, it may still suffer from the reliability issues characteristic of the original design, as our modern manufacturing techniques are not capable of correcting inherent design flaws. If properly maintained, your Keepshooting.com Sten magazine should perform well.”

As advertised, the Sten magazines appear to be very well made. The company website lists the manufacturer as the KeepShooting.com products house-brand. Several efforts were made to contact the company by both phone and email to inquire where the magazines were manufactured. No one answering the phone at the company knew the answer, nor could locate anyone that did. There were no replies to several emails. Judging from the construction and finish of the magazines an educated guess would be South Korea, based on features and construction of other magazines known to be produced there. There are some magazines advertised on the Keep Shooting website that specifically state “not Korean made.” The Sten magazines ad on the site did not include that statement. These particular Sten magazines seem to be only available from this company, so not revealing their source is understandable.

The Field Test

Both the TAPCO and Keep Shooting magazines were tested in a British Mark II Sten, Mark V Sten, Sterling and a Lanchester submachine gun – weapons all designed to use Sten magazines. Ammunition for the test varied from reloads to new full metal jacket with a variety of 115, 125 and 147 grain bullets.

Fit

The Lanchester submachine gun could not be used for the operational test because none of the aftermarket magazines being evaluated would fit into the brass magazine well. Original World War II manufactured 32-round Sten and 50-round Lanchester magazines fit with no problem. During World War II, Sten submachine guns and magazines were assembled from parts supplied by numerous manufacturers both large companies and small workshops. As such the parts were made to generous tolerances. To expand the magazine fit-test beyond the four test guns, the new magazines were then checked in several Sten magazine housings from parts sets and the magazines fit with no problem. One of the magazine housings was from a Lanchester part set. The Keep Shooting magazines fit, but the TAPCO mags did not.

Function

As stated earlier, the primary problem with original Sten magazines is the spreading of the feed lips, which changes the feed angle and leads to failure to feed stoppages. Loading the magazines to full capacity will aggravate this condition. If you leave original Sten magazines fully loaded over an extended period of time, you will probably encounter functioning problems. The feed lips of the new magazines were measured and the feed angle checked. The magazines were then loaded to capacity and stored for several months. The magazines were removed from storage and measured again. The feed lips of all the magazines remained in spec. The acid test was to test fire them. Seven of the Keep Shooting and four of the TAPCO magazines were loaded and tested twice. They were fired in two different Sten variants and a Sterling submachine gun. There were a few stoppages encountered in firing 700-plus rounds, but none could be directly attributed to a magazine malfunction.

Summary

The aftermarket magazines functioned very well in the test; they proved to be more reliable than original World War II magazines. The cost of the new manufacture magazines is comparable with original 32-round surplus mags, and there is no storage grease or Cosmoline to remove.

Sources

TAPCO

www.tapco.com/

Keep Shooting

Phone (877) 703-2767

www.keepshooting.com/

| This article first appeared in Small Arms Review V19N6 (July 2015) |