By Al Paulson

HK’s Mark 23 pistol is an accurate and robust weapon that was designed from the very beginning to be silenced. This is a rarity in the annals of weapon design. This is a big handgun firing a big cartridge, so a fairly large suppressor is required for effective sound suppression. Adding a suppressor of conventional size to the Mark 23 pistol requires adding a recoil enhancement device (known as an impulse device in Europe and a Nielsen Device to industry insiders) to temporarily negate the inertia created by the mass of the suppressor hanging off the end of the barrel. Balancing the timing and forces of a Nielsen Device is high art, and this is an especially unforgiving art when applied to polymer frame pistols. According to a source at Heckler & Koch, only two suppressor manufacturers have fielded suppressors with properly engineered Nielsen Devices for the Mark 23 pistol. Operators in the United States and a few of its allies have had access to the Model OHG suppressor from Knight’s Armament Company of Vero Beach, Florida. And armed professionals in Europe, the Middle East and elsewhere have had access to the Impuls IIA suppressor from Brügger and Thomet AG of Spiez, Switzerland. Now B&T silencers are being manufactured under license in the States, giving the U.S. marketplace some very interesting options. The following discussion will provide a hands-on evaluation of the Impuls IIA suppressor being manufactured by CCF/Swiss Inc., which is an offshoot of Capital City Firearms in Richmond, Virginia.

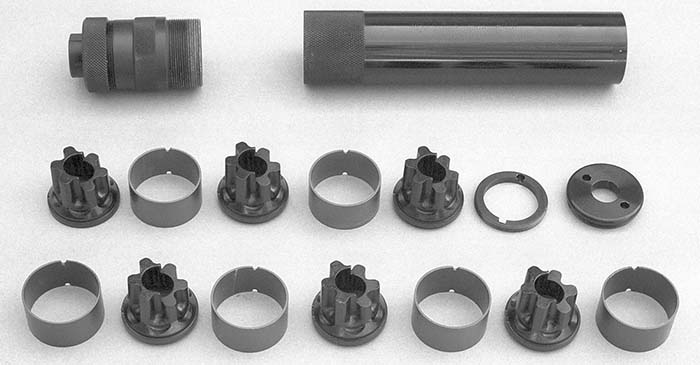

Each baffle of the Impuls IIA suppressor indexes with a spacer (made from aluminum alloy in pistol caliber suppressors) using a tongue and groove arrangement possibly inspired by the tongue and groove indexing structures used in the cast baffles with integral spacers developed for the Vaime suppressors in Finland during the 1980s. The B&T design uses tongues on the front and back faces of the baffle base, which mate with grooves cut on each end of the spacers. This feature ensures that asymmetric structures on the baffles align properly for optimum performance.

The metallurgy used in the B&T designs is unusual. The baffles are now machined from an exotic steel alloy not available in the States. This steel has its atypical structural and harmonic properties because of the rather surprising elements that are added to the alloy. Originally, the baffles were machined from an esoteric aluminum alloy with an Inconel blast baffle, but HK (Oberndorf) wanted a suppressor that would give a longer service life to the HK pistols than the original military requirement of 5,000 rounds. B&T changed the material used in the baffles, and redesigned the Nielsen Device for the new suppressor mass, producing a silencer that now gives a pistol and silencer service life of 10,000+ rounds.

What’s the actual lifespan of the suppressor itself? I don’t know of anyone who has tested one to destruction yet. One user has 14,000+ rounds through the system. The rearmost baffle sustained enough sandblasting by unburned powder and primer particulates after about 8,500 rounds that the user moved the rearmost baffle to just behind the front-most position. Since five of the suppressor’s six baffles can be rearranged, this implies a baffle life for the system of 5 x 8,500 = 42,500 rounds. Unpublished data from Europe suggest the suppressor tube should have a minimum lifespan of 15,000 to 20,000 rounds.

The suppressor tube is made from an exotic aluminum alloy not available in the States, and it requires a proprietary heat treatment to provide an unusual mix of strength and elasticity. It appears that, if either the baffles or the suppressor tube were made with the aluminum and steel alloys commonly used in the U.S. firearms industry, these components would experience structural failure. The lifespan of the tube might be increased dramatically by reheating the tube to the aforementioned proprietary temperature to “normalize” the work-hardened alloy every 10,000 rounds (thereby removing the brittleness that slowly accumulates with use). This is an area that has received no research to date, however, and there would appear to be little financial incentive to conduct such a study.

Since the requisite steel and aluminum alloys are not available in the States, CCF/Swiss goes to the significant expense of air-freighting its tube stock and bar stock into the country from Switzerland to ensure the necessary durability of these critically engineered systems. CCF/Swiss manufactures these baffles to very close tolerances on a $0.312 million six-axis CNC indexing machine and the complex fluted structure requires considerable machine time per baffle.

The basic Impuls IIA suppressor is available for pistols in the following calibers: 9x19mm, .40 S&W, 10mm Auto, and .45 ACP. A variety of impulse or Nielsen devices are specifically engineered to the timing and force requirements of the following pistols: Heckler & Koch Mark 23, USP (Universal Self-Loading Pistol), and USP45 Tactical; Glock 17, 19, 20, 21, 26, 27, 29, 30; SIG 226, 228, 229; and SIG Pro. Nielsen Devices are also available for the 9x19mm and .40 S&W variants of HK’s USP Tactical Pistol, which are not available in the United States at this time.

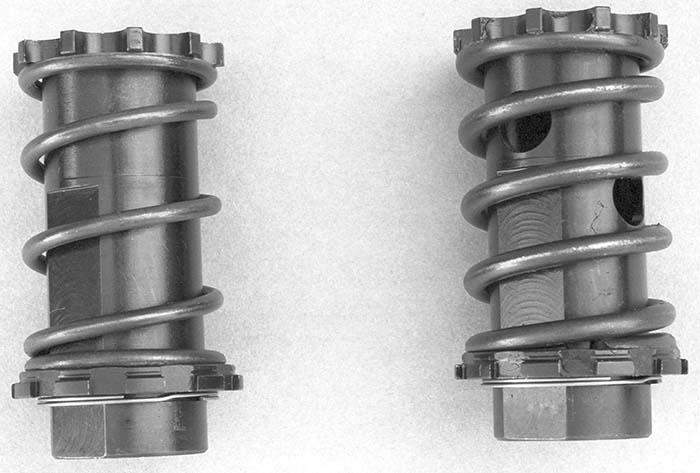

As designed for the HK Mark 23 pistol, the Impuls IIA is 7.83 inches (19.9 cm) long and has a diameter of 1.38 inches (3.5 cm). With six proprietary steel baffles, the .45 caliber Impuls IIA weighs 14.9 ounces (421 grams). Steel components are finished in a matte black oxide, the aluminum spacers are anodized, and the suppressor tube, Nielsen tube and front-end cap are finished in a black hardcoat anodizing. The rear of the suppressor tube is knurled, as are the Nielsen Device tube (attached to the rear of the suppressor tube) and the rear end cap of the Nielsen Device, so the both the suppressor and impulse device can be fully disassembled for cleaning or servicing, although this is not required very often. At the insistence of HK (Oberndorf), B&T’s Nielsen Device incorporates the alignment indexing system developed at Knight’s Armament Company, although the different manufacturing techniques and specifications used to build the Impuls IIA make any such adjustments unnecessary.

Cleaning and Maintenance

While the Impuls IIA suppressor comes with a disassembly tool and manual, I do not recommend disassembly for routine cleaning and maintenance. After a shooting session, simply unscrew the rear end cap and remove the Nielsen Device piston with its captive spring. Place the suppressor with the rear end down in a metal tennis ball can or similar vessel filled with WD-40. Soak along with the rear end cap and piston for one hour. Drain and blow-dry with an air hose. No other routine maintenance should be required. If you have a Dillon CV-2001 Vibratory Case Cleaner, an acquaintance informs me that you can transform a pair of metal tennis ball cans into a poor-man’s ultrasonic suppressor cleaner in a few minutes. You’ll need a hole cutter for your electric drill sized to the cans, a board wider than a can and as long as the diameter of the vibratory cleaner’s lid, a roll of picture hanging wire, and some dry wall screws and screw eyes. Drill a can-sized hole in the middle of the board and then one on each side of that hole equidistant from the center hole. Remove the lid from the vibratory cleaner, and screw it onto the board with drywall screws so that the central hole gives clearance for the lid’s wing-knob. Set the cans in the two outlying cutouts in the board and secure with guy wires wrapped several times around the top of the cans (leaving enough room to fit the can lids), securing the guy wires to screw eyes appropriately spaced in the board. Buy a gallon can of WD-40, place suppressors in the cans and then fill with WD-40. While this may not be as effective as a $3,000 ultrasonic cleaner, it’s a whole lot better than a simple soaking on the workbench.

Performance

The milspec version of the Mark 23 (engraved “MK 23” on the slide) features a match-spec chamber, enabling it to deliver 2-3 inch groups at 50 yards using Black Hills 230 grain FMJ ammunition (with or without a CCF/Swiss Impulse IIA suppressor installed). The commercially available version of the Mark 23 pistol (engraved “Mark 23” on the slide) features a looser SAAMI-spec chamber, which might be a contributing factor as to why these pistols seem to deliver somewhat less accuracy than the milspec “MK 23” pistols. That said, the SAAMI-spec chambers make more sense for civilian end-users because they will digest a wider range of ammunition.

The Mark 23 barrel is threaded 16x1mm RH, while the barrel on its smaller sibling, the USP45 Tactical, is threaded 16x1mm LH. Left-hand threading was used by HK on the 9x19mm, .40 S&W and .45 ACP variants of the USP Tactical as a simple way for organizations or individuals fielding both the Mark 23 and USP45 Tactical pistols to avoid accidentally installing a recoil enhancement module designed for the Mark 23 on the smaller pistol, or vice versa. This is a consideration because the same Impuls IIA sound suppressor can be used for either the Mark 23 or USP45 Tactical pistol by changing the piston in the Nielsen Device. Simply swap out the piston with its captive spring for the piston required for a particular pistol. It’s easy to keep track of which piston goes with which gun. The piston without holes in its side is used with the Mark 23 (either the milspec or commercial variants), while the piston with large holes drilled in its side must be used with the USP45 Tactical.

To evaluate the performance of the sound suppressor, I tested CCF’s Impuls IIA on HK’s Mark 23 pistol and USP45 Tactical pistols using Black Hills 230 grain FMJ ammo (Black Hills Ammunition, Inc., Dept. SAR, P.O. Box 3090, Rapid City, SD 57709-3090; phone 605-348-5150; fax 605-348-9827; URL http://www.black-hills.com). The Impuls IIA can be used as a dry can for maximum convenience or as a wet can for maximum sound suppression. When using in wet mode, the Impuls IIA uses a tablespoon of water as the coolant medium. To add coolant, simply pour some water from your canteen into the rear of the Impuls IIA, shake a few times to distribute the water, and allow any excess to drain. This entire procedure takes about five seconds. Then mount the suppressor on the gun. The Impuls IIA will retain this water for about a day at moderate temperatures without shooting or for at least a full magazine of shooting.

The sound pressure levels of suppressed and unsuppressed pistols are reported as decibels in Table 1, and net sound reductions appear in Table 2. The Black Hills ammunition averaged 829 fps using the HK Mark 23 pistol and 821 fps using the HK USP45 Tactical pistol. All tests were conducted on the same day at a temperature of 72 °F. When fired dry, the Impuls IIA produced a mean (average) sound signature that was just above the pain threshold of 141 dB on the Mark 23, and just below the pain threshold on the USP45 Tactical. If maximum stealth or hearing protection is required, adding a bit of water to the rear of the can drops the mean sound signature by 11-13 decibels, which is a bunch when you recall that the decibel scale is logarithmic rather than linear. The CCF/Swiss Impuls IIA fired wet provided a net sound reduction of 29 dB on the Mark 23 and 30 dB on the USP45 Tactical.

This is very good performance. What the numbers don’t show is the butter-smooth operation of the CCF/Swiss Nielsen Device. It is perfectly tuned to the force and timing requirements of the Mark 23. When this smoothness of operation is combined with the fact that the suppressor eliminates about half of the perceived recoil, placing rapid follow-up shots is addictively easy. The elevated sights on the Mark 23 and the USP45 Tactical provide excellent sight pictures over the suppressor, so the speed of target acquisition and precision of shot placement are outstanding. Whether mounted on a Mark 23 or an HK USP45 Tactical pistol, the Impuls IIA from CCF/Swiss operates more smoothly than any Nielsen Device I’ve ever used on a .45 ACP sound suppressor. This makes me a better and a more confident shooter. The Nielsen Device is also very well designed to tolerate the grit and grime encountered during military operations in the real world.

It is also interesting to note that the Impuls IIA was quieter on the USP45 Tactical than the Mark 23. The fact the Impuls IIA was quieter on the pistol with the shorter barrel implies that the baffle design “likes” higher velocity gases. This, in turn, suggests that the suppressor might actually be more effective if it were redesigned to a smaller diameter so the asymmetric baffles could work the gases even harder.

Final Thoughts

It is safe to say that the Impuls IIA is a tough, user-friendly suppressor that provides acceptable sound suppression when fired dry and very good sound suppression when fired wet. If you count all caliber variants, the Impuls IIA is probably issued in greater numbers to elite military, security and law-enforcement units outside of the United States than any centerfire pistol suppressor in history. Thanks to CCF/Swiss Inc. (Dept. SAR, P.O. Box 29009, Richmond, VA 23242; phone 804-740-4926; fax 804-740-9599; URL http://www.ccfa.com), agencies and qualified individuals within the United States now can obtain this impressive technology for their own demanding applications. Mounting the CCF/Swiss Impuls IIA suppressor on the Mark 23 or USP45 Tactical pistol provides an accurate, quiet, and robust system that should satisfy both the armed professional and the qualified civilian.

| This article first appeared in Small Arms Review V5N4 (January 2002) |