By Jeff W. Zimba

Photos by Dan Shea

All AK47s are not created equal and it could not be more apparent than when you handle your first rifle manufactured by Arsenal, Inc. of Las Vegas, Neveda.

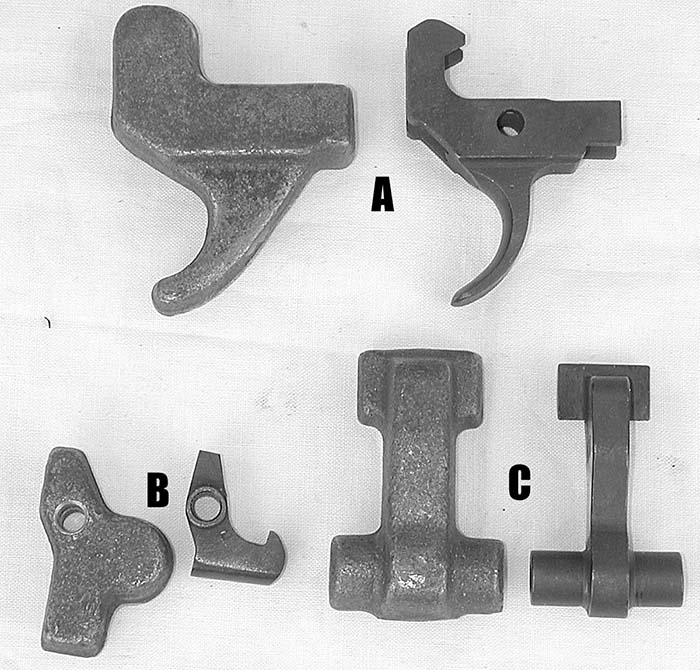

The first thing you will notice about the SA M7 is that every line is perfectly straight and smooth. Every piece fits perfect with others around it. The hammer, trigger and disconnector are in absolute sync and all have a perfect relationship with their home in the receiver. If you have any hands-on experience with or have even owned an AK47 you must be asking yourself how this can be possible, and I will tell you right now. Arsenal, Inc manufactures their own parts and receivers.

There is not one single part in an Arsenal, Inc rifle that is used or surplus. Every part is brand new. The parts they manufacture in house are done to exacting tolerances. Their quality requirements are so stringent that the only way to guarantee them is to actually forge and CNC mill each receiver, hammer, trigger and disconnector. The barrel is even hammer forged and chrome lined. There is an immediate and obvious benefit to the tight tolerances in the relationship between the hammer, trigger and disconnector as soon as you fire it.

Where several AK variants on the market are built with surplus parts, their loose relationship can disallow them to work in harmony. One common telltale symptom of a poor relationship between these parts is the painful forward trigger slap caused by the hammer hitting the trigger when the bolt carrier comes rearward. Another may be an occasional double tap caused by the hammer following the carrier forward. This is particularly dangerous as there is a chance it will fire out of battery causing damage to the rifle or even harm to the shooter.

When forging parts, as opposed to casting, the metal is poured from a single stock and actually pressed to shape. Forging compresses the density of the molecules and actually forces out bubbles and imperfections. This greatly adds to the strength of the finished product.

Due to the fact that each part is manufactured to such exacting specifications, the relationship between these parts is also nothing short of exacting, guaranteeing them to function in harmony and reduce wear over time even further. The rifles are assembled and quality assured by factory trained master craftsmen who are passionate about the product they ship out. Just like the staff here at Small Arms Review, the crew at Arsenal, Inc. are true gun enthusiasts and collectors. A genuine interest in your line of work always shows in the finished product and is obvious in this case as well.

Before these rifles leave the factory they are inspected, test fired and laser sighted for a distance of 100 yards. If a rifle is sighted in the traditional way by one person, the group may consistently be two inches high and right for a different shooter, and two inches low and left for yet another. Laser sighting completely eliminates any human error that is evident when sighting in with live ammo. The process uses two lasers. One laser is attached to the sights and the other in the bore. They are aligned with each other at 100 yards. Just as a testimonial to the quality of these rifles, of the thousands they have manufactured, none of Arsenal, Inc’s firearms has ever failed to fire or has been improperly head-spaced at this stage.

As with most other products the quality of an item usually dictates the pricing. Before handling one of these rifles people often inquire about the price being approximately double that of many other AK variants. Over and above all the manufacturing details outlined above, These methods take considerably more time than other methods. Just for an example, once you are set up to build stamped receivers it is not unreasonable to have the ability to manufacture hundreds of units per day. On the opposite end of this spectrum it may take several hours to CNC mill only one receiver. What is lost in time is certainly gained in quality.

One question that immediately comes to mind whenever dealing with any post-ban “assault rifle” is the ability to legally accept an imported pre-ban high capacity magazine. Congress has dictated that a specific number of parts in these firearms must be domestically produced. In some cases the magazine, or parts of it, must be utilized in order to meet this quota, actually making the insertion of a foreign made magazine illegal. In the case of the Arsenal, Inc firearms there are so many domestically manufactured parts included in this rifle that the magazine is not at issue. Any pre-ban high capacity magazine may be legally used with this firearm.

Our range time with the SA M-7 was well spent. The rifle is well balanced and very comfortable to shoot. The trigger is smoother than any Kalashnikov trigger I have ever felt. Recoil was very light and much of that can be contributed to the unique muzzle brake. The magazines locked in easily and very positive with no forceful motion necessary. The stock set is a composite material that is both comfortable and durable.

The SA M-7 is, without a doubt, the nicest AK style firearm I have ever seen. The workmanship is second to none. The detail that has gone into every aspect of manufacturing this rifle, from forging the parts to final inspection and assembly is obvious over every inch of this rifle. There is no doubt in my mind that any AK enthusiast could be no less than impressed by the SA M-7.

Arsenal, Inc manufactures four AK variant firearms. The SA M-7, the SA M-7S which employs the features of the M-7 as well as being equipped with a scope rail mount, and the SA M-7 Classic which is 100% identical to the original Kalashnikov as it was introduced in 1955. Just like the original, the classic has the sling swivel on the receiver and has a little heavier barrel. It also has no compensator but a barrel nut. Less than 250 of the Classic were manufactured and there are still a few available. Suggested retail on the Classic is $875.00. Arsenal, Inc also manufacturers the SA RPK-7 which has a longer barrel and the latest variation of the bipod which has the cleaning kit in the leg.

SA M7 Specifications

Caliber: 7.62×39

Total Length: 900 mm

Barrel Length: 415 mm

Twist Rate: 1 / 240 mm

Weight without Magazine: 3.835 Kg

Muzzle Velocity: 715 m/s

Rate of Fire: 40 rds/min

Effective Range: 400 m

Maximum Range: 2000 m

SA M-7 is a gas operated, magazine fed, air-cooled and semi-automatic shoulder fired sporting rifle. It operates via the long stroke gas system designed by Mikhail Kalashnikov.

A Rich History

In December of 2000, Arsenal, Inc. opened in their present location in Las Vegas, Nevada but this is far from a new company. Many of their engineers actually learned in TULA and the company history actually goes back as far as 1878. Below is a brief outline of the company.

Arsenal, Ltd’s history dates back to 1878 when a special factory was required to fill the needs of the newly created Bulgarian army. It was named “Artillery Arsenal” of Rousse. Russian Officers originally managed the Artillery Arsenal until 1884 when Professor General Simeon Nikolov Vankov was appointed the first Bulgarian director.

In 1891 the factory was transferred in Sofia and was established the Sofia Artillery Arsenal. In 1924 the factory was moved to Kazanlak under the name “State Military Factory”. Its basic function was simply “to produce and repair all military equipment necessary for the army, the police, the border troops and all state security organs as well as the testing of new models”. At that time several items including rifles, pistols, ammo and even gas masks were manufactured in Kazanlak.

After WWII, just like our own factories, it was time to retool and start manufacturing a more diverse product base. At that time they were producing plows, harrows, batteries, diesel engines, electronic motors and several other items. In 1948 the State Military Factory passed from the Defense Ministry to the Ministry of Industry & Crafts and was designated “Factory 10”.

Between 1956 and 1958 Factory 10 started producing a recoilless cannon (B-10) as well as the Kalashnikov AK-47 under Russian license. The first AK47 came off the assembly line in 1958 and they would go on to produce their 1,000,000th unit in 1982.

In 1964 the plant was again renamed, this time United Industrial Plant “Friederich Engels”. Production facilities built at this plant included a factory to build springs, a workshop for CNC machines, a computing center and a facility to produce powders, primers and pyrotechnic products.

From 1977 to 1989 the Bulgarian factory “F. Engels” added the licensed production of the following products:

- 1971-72 9x18mm pistol cartridge

- 1971-73 7.62mm Kalashnikov machine gun PK

- 1972-74 9mm Makarov pistol

- 1976-78 7.62mm Kalashnikov tank machine gun PKT

- 1983 23mm anti-aircraft system Zu-23-2

- 1984-86 5.45mm Kalashnikov assault rifle AK-74, AKS-74

- 1985-87 5.45x39mm cartridges

- 1986-87 122mm howitzer

Arsenal, Inc is currently the only new manufacturer of the Kalashnikov family of firearms outside of the group of nations under the former Warsaw Pact.

The suggested retail price for the SA M-7 is $700.00. The contact information is:

ARSENAL INC.

5015 W. Sahara Ave. #125

Las Vegas, NV 89146

TEL: 888-539-2220

FAX: 702-643-2088

Web: www.arsenalinc.com

| This article first appeared in Small Arms Review V6N2 (November 2002) |