By Charles Q. Cutshaw

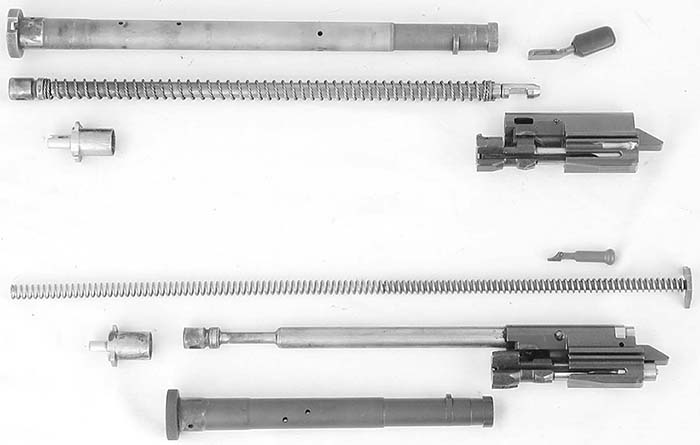

SIGARMS’ 5.56x45mm (.223 Remington) SG550 and SG551 have been in production for nearly 20 years, but they have not been readily available in the United States until recently. The SG550 and SG551 were adopted by the Swiss Army in 1984 as the StGw (Sturmgewehr) 90. A relative newcomer to the SG550 family is the SG552 Commando, introduced into Swiss military inventory in 1998. Swiss citizens are fortunate enough to be able to purchase either the SSG550 or the SG551 carbine in semiautomatic only. Some 20,000 of these superb rifles have been sold to Swiss citizens at the time this was written (late 2002). Unfortunately, inane US gun laws preclude sale of the SG550/551 semiautomatic in this country. SIGARMS is now marketing the SG551 and SG552 to law enforcement agencies. There are no individual officer sales as of this time.

SAR recently had the opportunity to test both the SG551 SWAT carbine and SG552 Commando subcarbine (Subcarbines constitute a new class of small arms that are submachine-gun-sized, but fire rifle-caliber cartridges.) along with SIGARMS’ P229 pistols, which we will cover in a later article. Since these carbines are intended for police use, we engaged the services of the Florence, Alabama SWAT team to help test the rifles. The team practiced entries, clearing and tactical drills with the carbines and then fired them for evaluation on the department’s range. The carbines performed flawlessly and with remarkable accuracy in all testing, both the formal range testing which we conducted and the informal shooting by the Florence SWAT Team, who were enthusiastic about the overall capabilities of the carbines.

SIGARMS’ SG551 and SG552 are made with emphasis on light weight and reliability. The design makes extensive use of plastic and alloys, while maintaining the rugged durability for which SIG manufactured firearms have always been noted. The folding stock is of plastic material and has an optional cheekrest for use with optical sights that necessitate a raised cheek weld for proper eye relief. Magazines are available in 5-, 20- and 30-round capacities. The magazines are of translucent plastic with built in clips and studs on each side to allow magazines to be locked together for quick reloads. Clipping more than three magazines together is not recommended. The “clip and stud” method of fastening magazines together is extremely simple and more positive than any “add on” mechanism. Clips are on one side of the magazine and studs on the other. To fasten two magazines together, magazines are held at 90 degrees, the top stud from one magazine snapped down into the top vertical clip of the other and then the magazines rotated to seat the stud into the lower horizontal clip. Once fastened together, magazines do not move or rattle. Magazines pivot into place in the magazine-well by hooking the magazine’s forward lip into the magazine-well and simply pulling to the rear. Although we had never before operated a SG551 or 552, we never had a misfeed with these magazines; insertion is much easier than either an AK or M14. Even with two or three magazines clipped together, changes were quick and simple.

The carbines we tested had a number of options. Both had optical sights. The SWAT Carbine was equipped with a Leupold CQT 1-3x variable, while the Commando subcarbine mounted a Trijicon ACOG Reflex II sight. Leupold’s CQT gives the user the benefit of both a 1x CQB sight with low power magnification for longer range work. The Trijicon ACOG Reflex II is one of the best available reflex sights, requires no batteries and is in widespread use by military and police forces. Both carbines also had Surefire WeaponLights(tm) Installed. The SWAT carbine was equipped with Surefire’s M500A which has a high intensity xenon light as an integral component of the handguard, while the Commando had a Surefire M952 Universal Tactical Light mounted on the front handguard. These lights offer superior brightness, beam focus and rugged reliability.

Both carbines had four fire control options: “Safe,” “1” (semiautomatic); “3” (three-round burst) and “20” (full auto). In the “3” mode, the burst selector resets, so that a burst is obtained each time the trigger is pulled, rather than an unpredictable number of rounds between one and three, like some burst control mechanisms. The SG551 is available in semiautomatic only for those agencies that do not desire a select-fire carbine, while the SG552 is available only in select-fire. If a department or organization wishes to block the full-auto function, limiting the carbine to burst fire, an integral block that prevents the selector from being placed into the full-auto position can be rotated and locked into place. The ambidextrous selector switch is large and easily manipulated by gloved hands. Also, the positioning of the selector is such that the natural downward movement of the thumb takes it from “safe” to semiautomatic. Pressing the switch forward a “click” selects “burst” and finally full-auto. The engagement of the selector at each point is positive and not subject to inadvertent movement from one position to another. As mentioned, the three-round burst resets to fire a full three rounds with each pull of the trigger.

The sights consist of a rear diopter rotating drum with markings from “1” through “4” equating to 100 through 400 meters. The 100-meter battlesight is a square notch with tritium dots on either side for night use. The rear sight is adjustable for windage and elevation. The front sight is a square post protected by a ring and has a folding tritium-illuminated night sight that remains in the “down” position until it is needed. The carbines tested, however, were equipped with optical sights and we did not require the use of the “iron sights.” That said, the open sights are standard for the Swiss military and since we have used such sights in the past, we expect that they are as good as, or better than, the “backup iron sights” used by some other manufacturers.

Fit and finish of these rifles is of the legendary SIGARMS quality. Although these are in essence military assault rifles in the true sense of the term, they exude quality throughout. There were no visible machining marks and the finish was an even matte green – grey. The polymer grip, stock and handguard mated to the metal components almost perfectly. The care that went into the manufacture of these carbines was obvious.

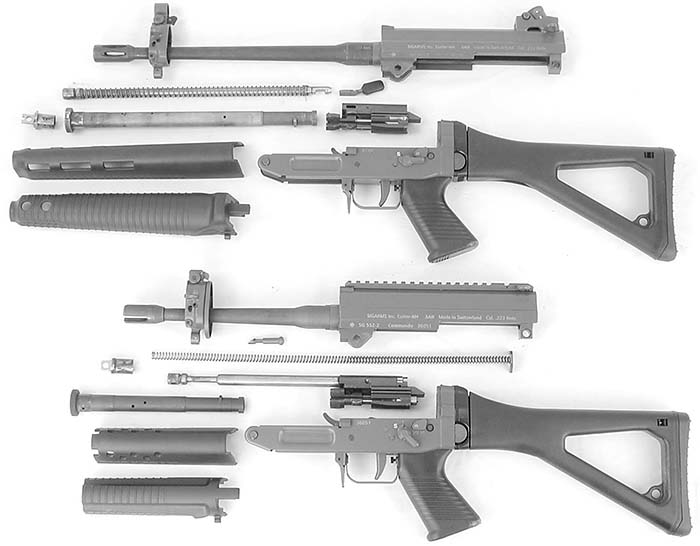

The carbines are gas-operated using a system similar to that of the Kalashnikov (AK). The SG551 and SG552, however, each use a slightly different system. The SG551 incorporates an operating rod that is retained in the bolt carrier by the operating handle, thus making the two essentially a single unit. The recoil spring surrounds the operating rod inside the gas tube. Thus, while the SG551 system is similar to the Kalashnikov, it is not identical. The SG552, on the other hand, is virtually identical to the AK system. All gas system components are made of stainless steel for ease of cleaning and longevity. The SG552’s bolt carrier and operating rod are integral, with the operating spring contained inside the operating rod and impinging against the rear of the receiver. This necessitates slightly different disassembly procedures for the two carbines.

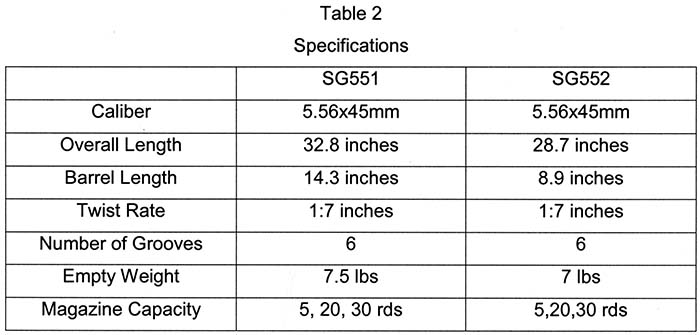

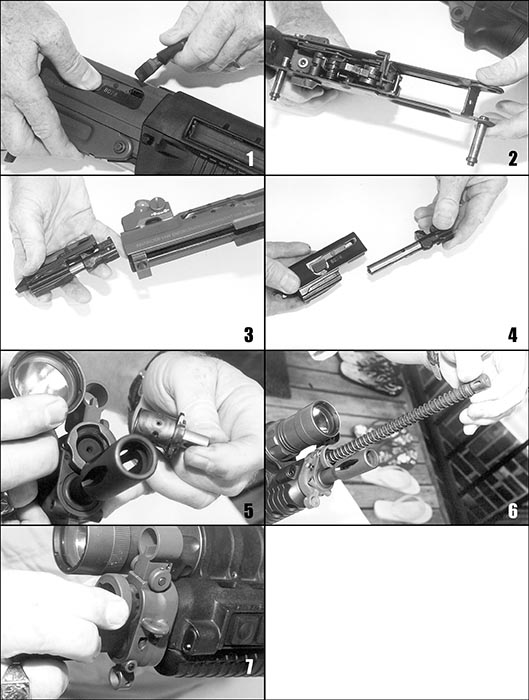

The SG551 is disassembled for cleaning by first pressing the charging handle retaining clip and removing the charging handle. This frees the operating rod for removal. The gas regulator is twisted and removed to allow withdrawal of the operating rod, which is under slight spring pressure. The gas cylinder can then be twisted a quarter turn and removed. The rear receiver retaining pin is removed, freeing the rear of the upper receiver, which is then pivoted upward similar to the AR-15. If it desired, the front pin can be removed to completely separate the upper and lower receivers. This pin also retains the handguards. Once the pin is withdrawn, the bolt, bolt carrier and handguards can be removed and separated. No further disassembly is required for routine maintenance.

Field stripping the SG552 is slightly different due to its operating system. The bolt carrier and operating rod of the SG552 are unitary like those of the AK. The operator first presses in on a pin at the rear of the lower receiver that frees the upper receiver to be rotated upwards. As the upper receiver is rotated up, the recoil spring is controlled with the thumb and allowed to fully expand. It is then removed. The charging handle is then removed like that of the SG551. The unitary bolt carrier and operating rod can then be withdrawn. Gas valve and tube removal is the same as the SG551.

Optical sights are available for the rifles, but a production MIL-STD-1913 rail was not available at the time of testing, although a MIL-STD-1913 receiver rail should be available by the time this article goes to press. SIGARMS’ system is ingenious and ensures a return to zero when optics are changed, but it is not MIL standard and thus is being redesigned. The existing system consists of a forward receiver stud that engages a receptacle in the removable mount. The mount has a spring-loaded heavy pin that engages a receptacle in the rear sight base. To install optics, the spring loaded stud is pressed back into the sight base, rotated down and then allowed to move forward to engage the receiver stud. Removal is the reverse of installation. During our testing, which involved the use of several types of optical sights, this proved to be a very strong mount and satisfactory system. We changed optics several times and the SIGARMS system always returned to zero. SIGARMS realizes that the MIL-STD-1913 rail is the prevalent system in the United States and thus has designed a rail that is permanently attached to the upper receiver, with a backup rear sight for emergency use.

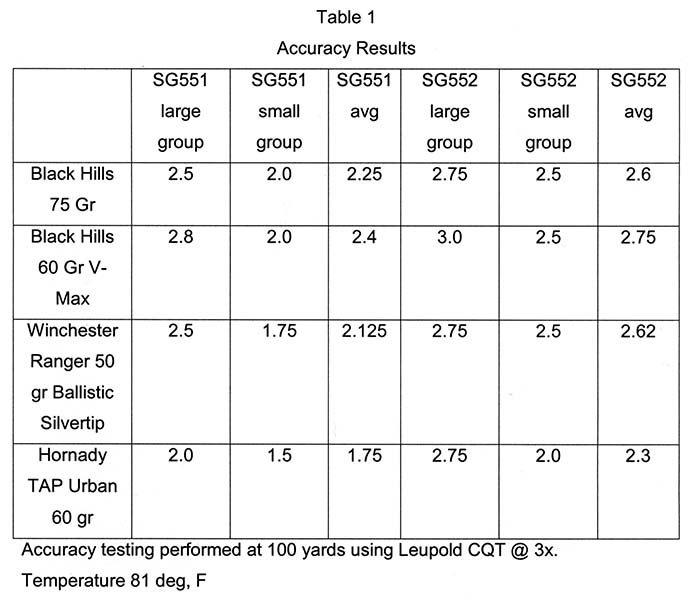

Shooting the SG551 and SG552 brought some surprises, primarily dealing with the carbines’ accuracy, which was better than we had any right to expect from such short-barreled carbines that are essentially close quarters battle (CQB) guns. (See Table 1 for accuracy results.) Handling was excellent; both carbines balanced and pointed well. Trigger pull weight was approximately 6 pounds and was the same in every fire control option. The trigger is typical “European military” with a relatively long takeup and then a crisp “break” as the sear releases the hammer. The optical sights enhanced accuracy and target acquisition, especially for individuals such as the author, whose middle-aged eyes have difficulty focusing on both front and rear sights and a target. We tested the SWAT Carbine with Leupold’s 1-3x CQT and the Commando with Trijicon’s ACOG Reflex II. SIGARMS’ optional cheekrest was a definite advantage for the author when using the CQT due to the height of the optic mount, which prevented a good cheek weld without the raised cheekrest. Functioning was typical SIGARMS – flawless. Spent cases were ejected very forcefully, which carried them about 10 yards to the right front of the shooter. Muzzle climb on full-auto was notable but manageable due to the light felt recoil inherent in the 5.56x45mm cartridge, the efficient muzzle brake/flash suppressor, and the overall design of both carbines, which places recoil forces low on the stock and in virtually direct alignment with the barrel. These factors also contribute to quick follow-up shots in semiautomatic fire.

In sum, these carbines arguably represent the highest quality weapons of their type. They incorporate excellent ergonomics, and include many features that are to be found in no other firearms. They are surprisingly accurate. From a shooter’s standpoint, these are outstanding firearms. The sole detriment is their price, which is almost twice that of some alternative 5.56mm carbines. There is an old saying, however, that “You get what you pay for.” The price of admission to the SIGARMS SG551 and SG552 is high, but for the department that can afford them and wants the best for their officers, there are few alternatives.

Note: These carbines are 5.56mm caliber, not .223 Remington. Chamber and cartridge dimensions are slightly different for 5.56mm and .223. 5.56mm is slightly longer in the leade, the unrifled portion of the bore just in front of the chamber. In practical terms, 5.56mm firearms will accept .223 ammunition, while guns chambered for .223 may not accept military 5.56mm cartridges.

SIGARMS, Inc.

18 Industrial Dr.

Exeter, NH 03833

Tel: 603-772-2302

www.sigarms.com

Leupold & Stevens, Inc

PO Box 688

Beaverton, OR 97075

Tel: 503-646-9171

www.leupold.com

Trijicon, Inc.

PO Box 930059

Wixom, MI 28393

Tel: 248-960-7700

www.trijicon-inc.com

Surefire

18300 Mt. Baldy Circle

Fountain Valley, CA 92708

Tel: 714-545-9444

www.surefire.com

Black Hills Ammunition

PO Box 3090

Rapid City, SD 57709-3090

Tel: 605-348-5150

Fax: 605-348-9827

Email: BHAmmo@rapidnet.com

Hornady Manufacturing

PO Box 1848

Grand Island, NE 68803

Tel: 308-382-1390

Fax: 308-382-5761

www.hornady.com

| This article first appeared in Small Arms Review V6N5 (February 2003) |