By Charles Brown

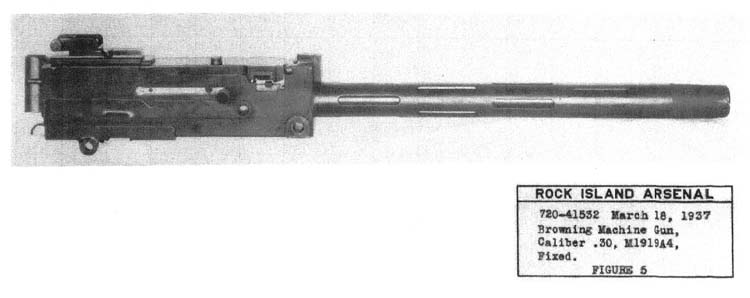

When the U.S. Army decided to adopt the M1919A4 air cooled .30 caliber Browning machine guns for use by Calvary, Infantry and Armored units it was felt that it should be in two basic forms. The Fixed model Major Item 51-83 for mounting in tanks and the Flexible model Major Item 51-84 for ground and vehicle applications.

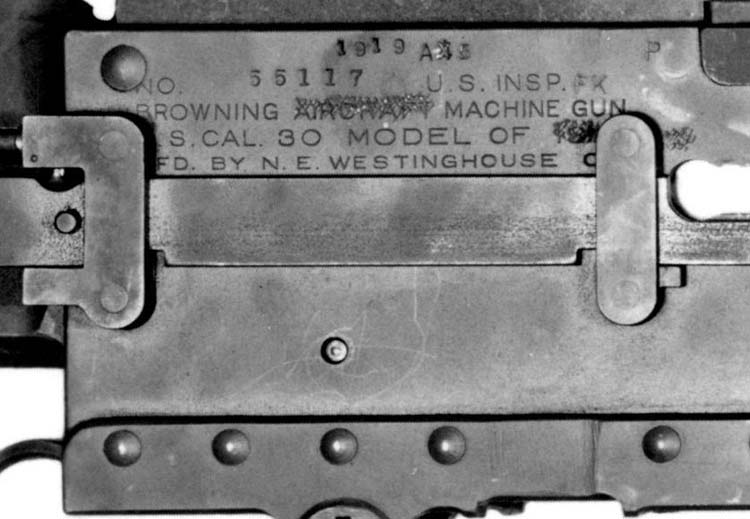

As a peacetime economy measure all of the available weapons such as the Tank guns, M1919A2, M1918 and M1919 .30 caliber Aircraft guns, and excess M1917 water cooled guns left over from WWI and not being converted to M1917A1 configuration were rounded up and converted to something deemed useful: the M1919A4.

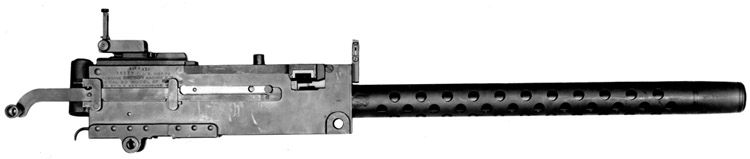

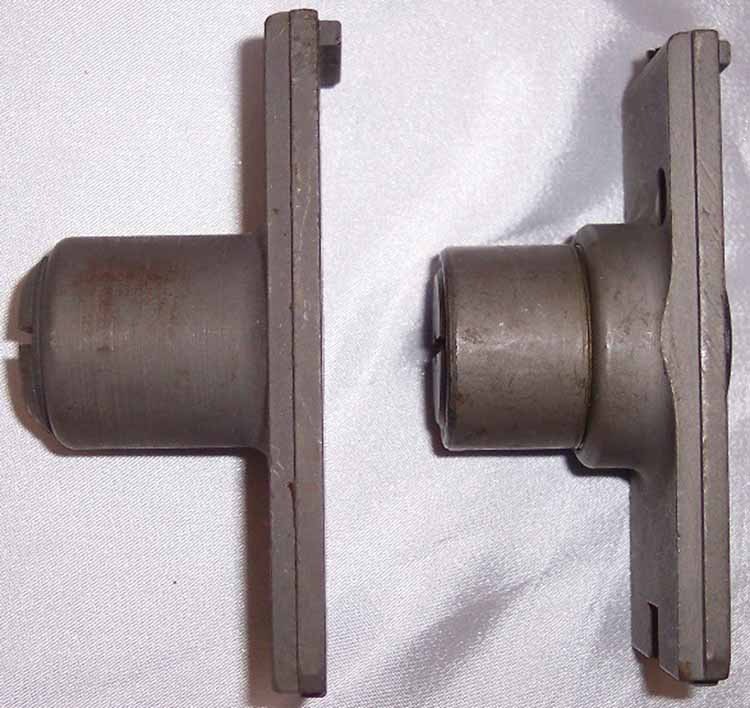

The only difference between the M1919A4 Fixed and Flexible models was the back plate assembly. The Flexible had the familiar pistol grip with horizontal buffer system and the Fixed used the vertical buffer back plate assembly without the grip used on the Browning M1918M1 aircraft machine gun. Both Fixed and Flexible were equipped with the bolt latch to help prevent cook-offs – a feature left over from the M1919 Tank Machine Gun. Using the vertical buffer system without the pistol grip cut about 4 inches off the overall length of the weapon: a good thing in the close confines of a tank turret.

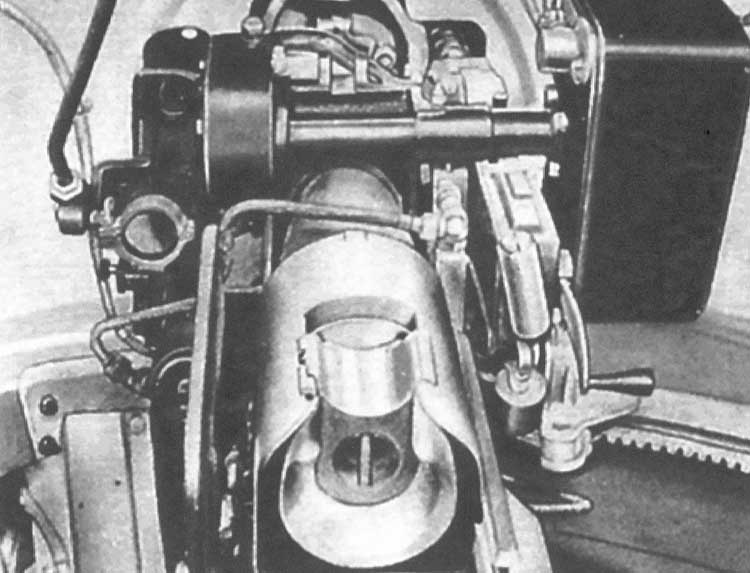

The M1919A4 Fixed differed from the earlier M1919Tank Machine Gun in that it had a 24 inch barrel and no pistol grip back plate or auxiliary grip and trigger. Tank combination mounts where the main gun and the machine gun were laid on using the same sighting system were also equipped with solenoid remote firing devices that allowed the gunner to fire the machine gun without actually touching the trigger.

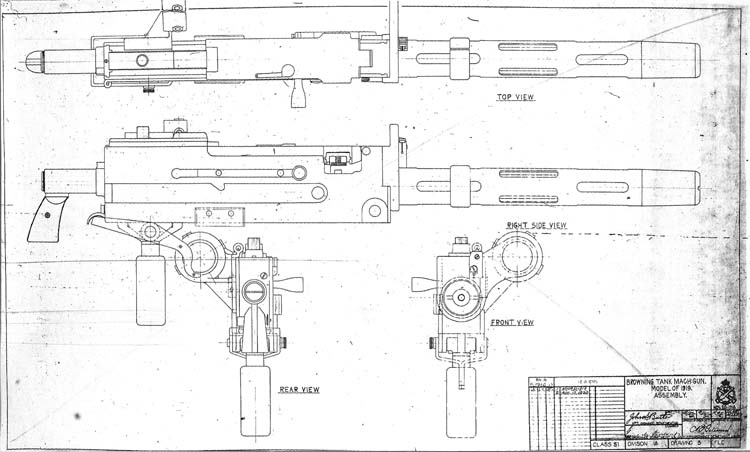

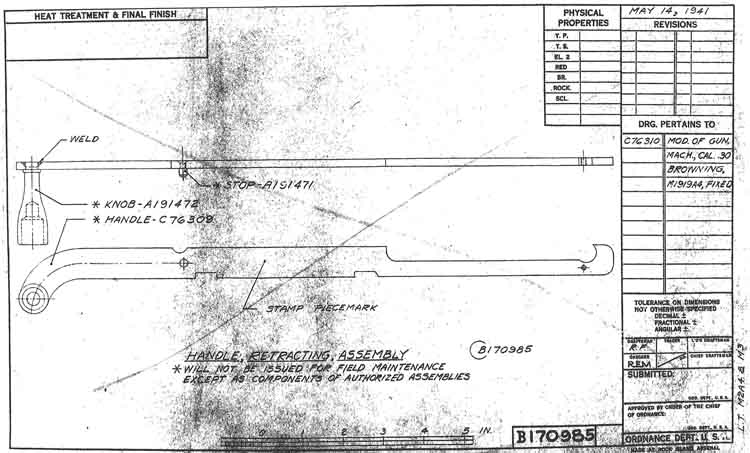

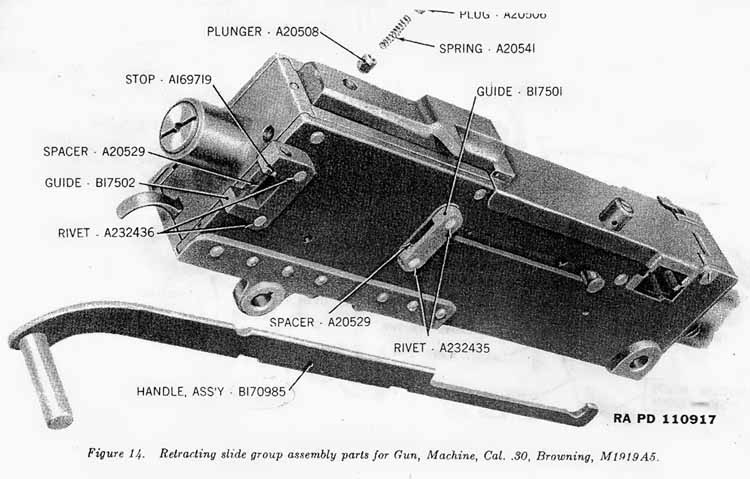

As the combination mounts M22 and M23 for the M5 37mm main gun used in the M2A4 and M3A1 Stewart tank came into service, problems developed with fitting the standard M1919A4 Fixed model into the mount. In these applications there wasn’t enough room for the gunner to reach the bolt handle and the newly developed M1919A4 top cover hold open device bolt protruded too far to the right.

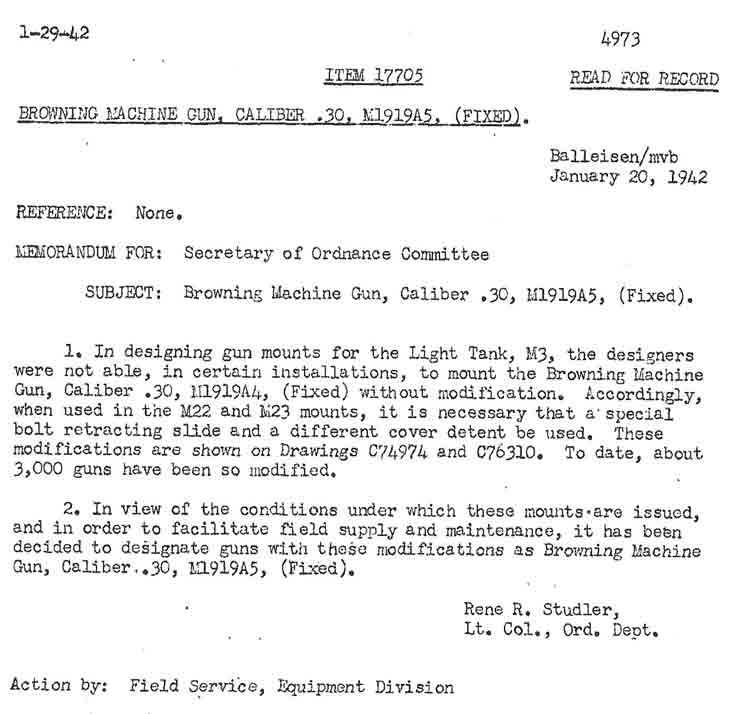

The Ordnance Department solved this dilemma in May of 1941 by having the Rock Island Arsenal develop a new style of bolt retracting handle assembly, a modified top cover hold open device and swapping out the original bolt handle for the cocking stud from the Aircraft guns. These changes were applied to standard M1919A4 Fixed weapons having front and rear sights which produced a custom built application. The problem was that because they were custom built there was no way to differentiate between the standard Fixed model A4 and the modified ones or any way to stock or order parts.

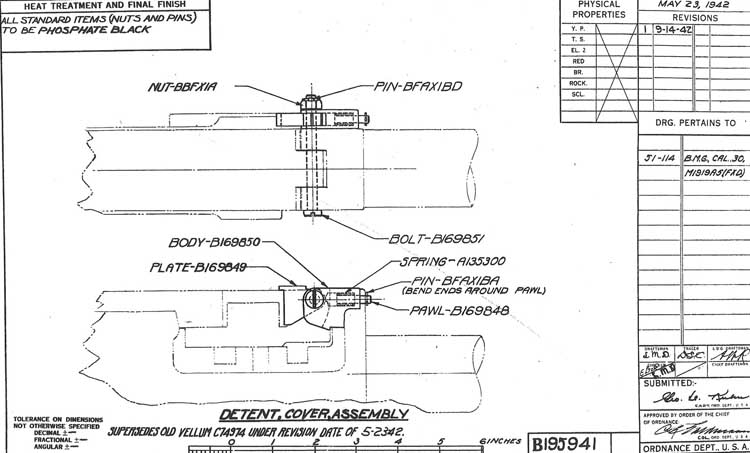

In early 1942, after building about 3,000 of these customized weapons and with need for them increasing with war demands, the Ordnance Department decided to identify them with their own standard nomenclature, M1919A5 Fixed and their own Major Item number 51-114. While this solved the problem for future production it created a situation where there were M1919A4 Fixed hybrid weapons in the field.

The September, 1943 Standard Nomenclature List A-6 lists the M1919A5 parts but the first SNL illustration of a purpose built A5 didn’t appear until April 1947 in ORD 9 SNL A-6. By this late date the A5 had been obsolete for four years. According to figures published in Goldsmith’s Volume 1 of The Browning Machine Gun there were about 14,000 purpose built M1919A5s constructed between May of 1942 and May of 1943. Most if not all of the purpose built A5s seem to have been produced at RIA. Production of the A5 ceased because its principal user the M3A1 Stewart tank was declared obsolete in November of 1943. The purpose built weapons are easy to spot as they have the original model designation die stamped on the right side plate.

The A5s borrowed M1918 aircraft vertical buffer back plate was replaced by a short horizontal buffer tube design with two variations: one a two piece and the other a single piece. Both used an 8 fiber disc buffering system and the standard M1919A4 buffer system parts with the exception of the adjusting screw. Changing the design of the back plate from the M1918 aircraft style to the horizontal versions simplified fabrication.

Now the situation was reversed; instead of having too few M1919A5s, Ordnance had too many of them with no foreseeable demand. However, there was a demand for the M1919A4 and M1919A6. The excess M1919A5s were reworked into something more useful. So far, we haven’t located any samples of a purpose built unaltered M1919A5, perhaps one of the readers may know of one, if so the author would like to know its whereabouts.

| This article first appeared in Small Arms Review V16N1 (March 2012) |