By Folke Myrvang

As the Second World War ended, large quantities of small arms became surplus material in the countries where they had been brought by the fighting armies. In the author’s native country, Norway, the number of small arms were according to the more than 350,000 German soldiers that surrendered in May of 1945. These soldiers had brought Russian, Belgian, French, Dutch, Polish, Czech and other captured weapons as well as large quantities of German infantry weapons. In addition to this came the Norwegian weapons from the pre war period, weapons air dropped or smuggled in to supply the resistance forces, as well as weapons brought from Sweden and England by the returning Norwegian soldiers when the fighting was over. As if this was not enough, the Norwegian army received quantities of British weapons in the late 40s and early 50s as well as a full scale re-arming after Norway received yet another large quantity of weapons in the U.S. weapons aid program of the 1950s.

This situation made the Norwegian army and the newly founded Home Guard a virtual circus as far as weapons types and ammunition was concerned for the first years after the war. The Home Guard would in its early years use any gun they could get their hands on, whether 2 or 200 were available seemed to matter little as long as they could arm their soldiers with it. The author’s father served in His Majesty the Kings Guard in 1950 and remembered that there was a vast selection of weapons available for shooting and plenty of ammunition.

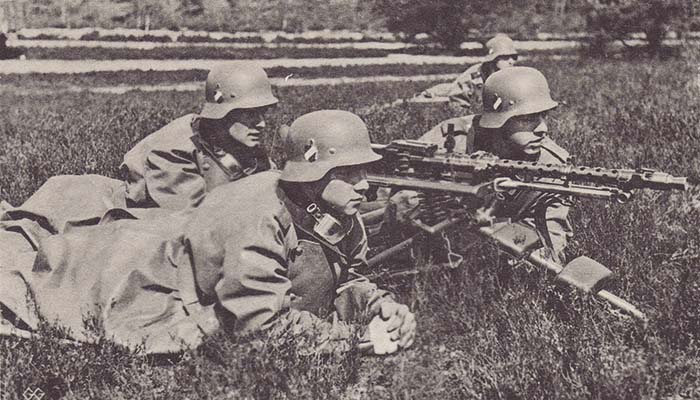

For reasons of logistics, the Norwegian military authorities soon had to make some choices of direction for their vast arsenal, and the quantities available soon made it clear that it was the ex-German MG34 that was the most likely weapon for a good many years to come as the Norwegian Armed Forces’ LMG. Personally I used the MG34 for many years as a machine gunner in a competition team and it was an interesting experience. Many officers and soldiers in the Home Guard had good knowledge of the working parts of the MG34 and how to make the guns run.

430,000 MG34s had been manufactured between 1936 and 1945, and a large quantity of these survived the war in serviceable condition. The MG34 was used by a few countries after the war, most notably Yugoslavia, Israel (who bought the remaining stock of finished and unissued guns from the Czech BRNO factory), Romania and Norway.

Norway was not only the longest official user of the MG34, but also the only country where the MG34 was officially converted and used in other calibers. First .30-06 and later 7.62×51. Officially taken out of service in 1993, the MG34 served for almost 50 years with a mixed popularity among the soldiers. There are some rumors of Israeli conversions to 7.62×51, but the author has never seen any parts that can confirm this.

As early as 1950, the MG34 had a mixed reputation in the Norwegian army, as witnessed by a memo from the Distriktskommando Nord (Army Command North) dated March 15 1950. The Northern part of Norway was considered strategically the most important from 1945 to 1990 because of the joint borders with the Soviet Union and most of the regular army was based in this area.

The memo is three pages long and concludes that the MG34s in use are quite worn and no longer have the matching parts that were considered essential for their reliability. Also to blame is the minimal knowledge amongst the operators of these rather complicated weapons. These factors seem to be the reason for about 50% of the stoppages and malfunctions, while the rest were credited to the various stages of deterioration of the ex-German ammunition was in after years of poor storage. Another cause of problems that was pointed out was the soldiers’ seemingly careless treatment of the belts and the fact that many did not seem to care if the belts were dirty, rusty or generally in poor shape.

With the forming of NATO, of which Norway was an early member, it was decided that the standard rifle and machine gun cartridge was to be the U.S. cartridge of 1906, the .30-06, in Norway known as the 7.62×63. For a while it was still debated if the 7.92×57 should remain as the official Home Guard cartridge as vast stocks of this ammunition was in depots all over the country. In 1948-50 the Norwegian ammunition company Raufoss Ammunisjonsfabrikker (Raufoss ammunition factories) manufactured the 7.92 sS heavy ball ammo to supply the ex-German weapons. Unfortunately this ammunition is plagued by misfires, especially the 1948 vintage ammunition has slightly deep primer pockets. To successfully fire this ammunition, a long firing pin and a powerful firing pin spring is necessary.

When it was clear that the .30-06 was going to be the only serious rifle and MG cartridge in NATO, the Norwegian Chief of Ordnance and his staff decided to rebuild some of their ex-German weapons to the NATO cartridge instead of scrapping them. In theory, this should not pose much of a problem, as the .30-06 cartridge is only approximately 4mm longer than the 7.92. The K98k rifle was an easy choice for the rifle, as the numbers of these were staggering, as was the availability of bayonets (every German soldier had been issued a bayonet as part of his field equipment whether he was a rifleman, machine gunner or a chauffeur), ammunition pouches as well as spare parts. Machine guns considered for conversion were the MG34 and the MG42.

As an interesting footnote we can add that the Norwegian Police received all the available G33/40 Gebirgsjäger carbines and also a small number of MG13s. These guns were kept in their original 7.92 caliber. The G33/40 was in service until the 1970s; while the MG13s were probably never taken out of their transit cases. The MG13s were all converted to MG13k standard by shortening the barrels and barrel jackets at some point.

The first documents regarding the conversion of the ex-German machine guns to .30-06 were dated in the fall of 1952, when the quantities of 3,500 barrels for MG42 and 6,000 barrels for MG34 were ordered by the Chief of Ordnance from the State Rifle Factory, Kongsberg Våpenfabrikk, all barrels in .30-06 caliber of course. The barrels were ordered without locking pieces, as locking pieces were to be salvaged from the ex-German barrels. Later, the number of MG34 barrels were enlarged to 12,000, 3 for each of the 4,000 guns that were to be converted. It is possible that there was a shortage of locking pieces, as the majority of MG34F1 barrels found today are lacking these.

MG34F1

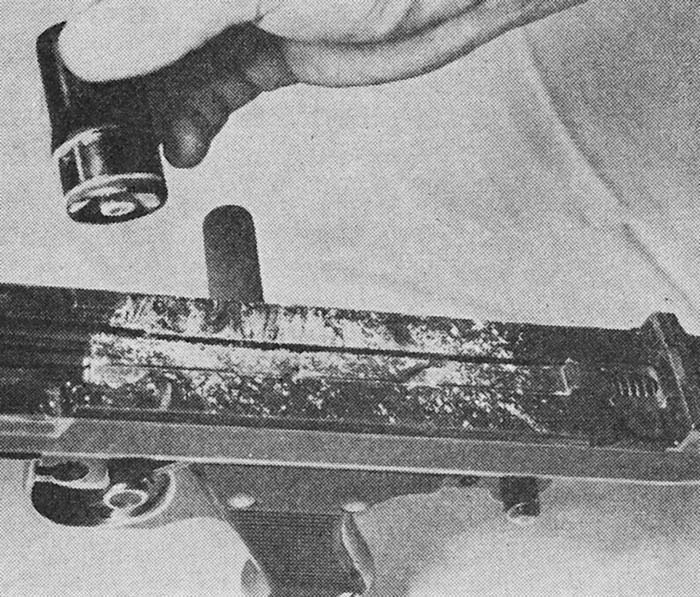

The conversion of the MG42 seems to have been delayed for quite some time, probably because it was not desirable to work on more than one project at a time. The conversion of the MG34 was not very complicated. The ejection port was to be lengthened slightly, and the receiver was cut slightly to accommodate the longer cartridge. Subsequently, the feed tray had to be formed for the cut in the receiver by heating and bending it. The feed tray would be weakened by this operation, and it was later found that some of the feed trays had to be hand fitted to the guns in order to make them work. The feed trays were numbered to their guns so they would not get mixed up. After the drawings for the MG34 conversion were completed at the Army Ordnance Corps, they were sent to the company Brødrene Fossum at Ski for a price estimate of the conversion of the receiver and feed tray at a rate of 200 weapons a month for a total of 4,000 weapons. Brødrene Fossum did not seem to get further involved in the conversion, and all the work seems to have been done at Kongsberg. The conversions at Kongsberg were priced at 250 nok each, approximately 35 US$, excluding ammunition for test firing and the barrels, which were priced at 72 nok each, or 10 US$.

The first test firings of the converted MG34F1 (Forandring 1 – Alteration 1) were held at Kongsberg on September 9 1953 with the results being encouraging, although a few stoppages occurred. The next recorded sessions were held in August of 1954. In the meantime, the Rustmester (Chief Armorer) of the Army Ordnance Corps, Captain Oscar Øvern had been able to locate the ex-German apparatus for tightening the connection between the receiver and barrel jacket of the MG34. His enthusiastic memo of October 26 1954 describes the apparatus and the advantages and necessities of employing it to the ongoing conversion routines for a large number of weapons that showed considerable play between the barrel jacket and the receiver. Unfortunately, only the description remains, as it has not been possible to find any specimens of the apparatus itself. This procedure was to be included in the conversion and rebuild of the MG34 to MG34F1.

Flower of Sulphur The Magic Potion

Although the Germans had discontinued the use of Flower of Sulphur as a lubrication additive for the MG34 long before the war ended. The Bakelite container was dropped from the accessory lists by the HeeresWaffenamt on April 3 1944 because better lubricants had been developed that served the purpose without the addition of Flower of Sulphur. Still, the issue of Flower of Sulphur continued in the Norwegian Army until 1993 regardless of which oils were used with the small arms. This magic potion was regarded as essential for the functioning of the MG34 and Lord have mercy on the MG34 gunner who did not use it. In the test reports from the conversion of the MG34 to .30-06, several of them mention that the guns were sluggish and did not work reliably until Flower of Sulphur was added to the lubrication and VOILA! the guns worked. It is possible that the lubricants used in the Norwegian army in the 1950s may have been sub-quality and actually needed the addition of Flower of Sulphur, but this was certainly not the case in the 1980s and 1990s.

When the MG34F1 were converted, the following procedure was to be followed for marking the guns: The receiver was to have the serial number HÆR (army) nr 0000 engraved with 5mm fonts on the left side and painted white. The barrel jacket, top cover, feed tray. buffer, buttstock and booster cone were to be marked with the –0000- serial number in 3.5mm fonts and old serial numbers were to be removed. The bolts were to be serial numbered by electric pencil on both the bolt head and the carrier, spare bolts to be marked with an A. Barrels were to be marked with HÆR nr 0000, spare barrels to be marked with 1 or 2. Bolts and barrels also to be marked with 3.5mm fonts.

Test firing was done from the MG Lafette 34, the guns lightly oiled and lubed with Flower of Sulphur. In October 1955, 10 converted MG34F1 were test fired and found to be working flawlessly with the allotted spare barrels that were to be issued with each gun. With these promising results in mind, test firings were conducted all through 1956 with relatively good results. Throughout the spring of 1956 it became clear that the success of the conversion would rely entirely of the availability of spare replacement parts for the MG34 as many guns had parts that were almost worn out. Both the Army Ordnance Corps and the Army Material Command left no stone unturned and came up with impressive numbers of spare parts that were transferred to Kongsberg so the full scale conversions could begin.

As the weapons aid program from the U.S. unfolded, Norway received 1919A4 and 1918A2 BAR machine guns that were issued to the regular army units. The MG34 was then to become the only machine gun for the Home Guard. This decision seems to have been made after it was decided to convert the ex-German machine guns to .30-06 and may had been instrumental in making the decision to sell off the stocks of MG42s that were held awaiting conversion.

Throughout 1956 it became clear that most of the MG34F1 would never achieve a reliability of 100%. One test firing session was held at the Home Guard Academy of Dombås, HVSKD. Four MG34F1s fired 2,673 rounds, with a total of 24 stoppages. Most of the stoppages were cleared by working the cocking handle, and were decided to be acceptable as they were easy to clear. The relation between the ejector and the ejector plate was pointed out as essential for reliable functioning, as was the use of Flower of Sulphur. At this test a number of what was known in the Home Guard as Czech Bren guns – ZB vz 26 LMG’s, were test fired as well. It is not known whether these were converted to .30-06 or if they were in their original 7.92 caliber.

Later test reports pointed out that as many as 75% of the stoppages were related to the belts and the joints between the belts that sometimes were too much for the MG34F1. In 1958, 20,000 belts were cleaned in acid and oiled as a refurbishing process to help cure these problems. It was noted in a memo dated March 3 1958 that the availability of spare parts would be low after the conversion was completed.

As 1956 drew to an end, the first completed series of 100 MG34F1s were being test fired and the initial tests were also held with BFAs (blank firing adapters) for the MG34F1. The BFA was patterned after the BFA for the Madsen M/1922 BFA, and replaced the booster cone internally, and had a brass wheel screwed onto it from the outside. There seems to have been no interest at all in pursuing the original German two piece blank firing barrels at this time. The Norwegian company Bakelitfabrikken were marketing their red plastic body blank ammunition, and these were the only blanks that were used with the MG34F1. The BFA and the plastic ammunition seemed to cause a few problems, and were never as successful as one would have hoped. In comparison, the original 7.92 German blank firing barrels with the wooden bullet ammunition seems to have worked quite well. It is quite possible that the locking pieces from the blank firing barrels were already destined for the new.30-06 barrels, as it would otherwise have seemed like a logical choice to make new chamber ends for the original blank firing barrels.

In early 1957, a cutaway MG34F1 was machined out at Kongsberg for study and instructional purposes. At a later stage, this MG34 was filmed in action, showing how the mechanism worked with the 3 different calibers. Not surprisingly, the 7.92 set up seemed to be the smoothest by far. Unfortunately, this weapon was sold to England in the 1990s.

An invoice dated May 16, 1958 exists for three MG34s bought from Sidem International, Brussels, Belgium at the price of $192.50 each. The guns were to represent the highest, middle and lowest quality of the guns available from Sidem. According to the accompanying paperwork, it was seriously considered to acquire 1,000 MG34s from Sidem as an alternative to converting Bren guns (Both British 7.7 and Czech ZB 26 in 7.92 cal) to .30-06. It is not known whether these guns were acquired or not. In a memo dated October 22, 1959 it is mentioned that the Bren gun will be replaced by the 1918A2 BAR, so it is likely that this made the need for more LMGs less important.

As the conversions progressed, Arsenalet på Kongsgårdsmoen, close to Kongsberg Våpenfabrikk, became the central depot for gathering MG34s from all over Norway. The units were to send in half their stock of MG34s and to keep the other half in reserve. The Cold War was very much in effect. The shipments were slow and several reminders had to be sent out before the weapons started to show up. Kongsberg Våpenfabrikk were to convert the guns in batches of 100. The bipods were to be refurbished separately, and older type bipods (MG13 style) were to be scrapped. The stud for fastening the bipod to the barrel jacket was to be replaced if it was of the older style. By March, 1958, the conversions seemed to be well on their way, but the barrels may have been a little slower to manufacture, as a memo noted that the interchangeability of barrels from gun to gun was so good that it was ok to return the guns with just one barrel and send the last two barrels later.

The total number of MG34s seem to have been 4,296, and additionally 12 MG34F (almost certainly a mistake for MG34S) and 126 MG34 tanker guns were transferred from the main Arsenal in Oslo to Kongsgårdsmoen in May, 1958. The “F” and the tanker guns were to be held in storage until it was decided whether to convert them to .30-06 or to scrap them for parts. As Norway had scrapped its ex-German Panzer III tanks, there was no immediate need for tanker guns, and we must assume that the tanker guns were indeed scrapped. The Armed Forces Museum has three specimens of the MG34S in their reference collection.

According to Rustmester Øvern, the original wooden stocks were not to be used with the MG34F1 for some unknown reason. New buttstocks were manufactured in Beech at Kongsberg and painted with the same black finish as was found on the forend of the 1918A2 BAR. Bakelite stocks were used when available.

As the .30-06 cartridge was slightly longer than the 7.92, the basket drums for the 50-round belts and their carriers were scrapped during the conversion process. Very few of these have survived, and it was not until the surplus sale of MG34s from Portugal that Norwegian collectors could obtain these. Tests were carried out where the pressure plate in the lid of the drum was removed to make room for the longer cartridge, but they seemed to have been unsuccessful.

Original ammunition cans were converted by removing the left side of the can and adding on to it to make room for the longer cartridge. 8,710 aluminium cans were converted and repainted Olive Drab. Two companies converted these, A/S Stanseprodukter and N.Blomberg A/S at a price of 8.60 nok each. The first delivery of 1,400 cans had the wrong side extended, and was accepted at a reduced price. A number of Madsen M/1922 aluminium magazine cans were also converted into belt cans for the MG34F1 as specified on a drawing of November 22, 1956. The conversion consisted of removing the dividers for the magazines and moving the carrying handle to a different spot.

Of the two belt filling machines Gurtfüller 34 and Gurtfüller 41, only the earliest type was converted to .30-06, and this conversion was undertaken by two companies, most notably Vinghøg in Nøtterøy, who later marketed their famous soft mount for the .50 M2HB. A small alteration to the lid of the MG Patronenkasten 41 was necessary to make room for the slightly enlarged hopper of the Gurtfüller 34 after the conversion. Only steel ammo cans, and as noted, mostly the MG Patr.kast.41 were used for the belt filling machines. FG Pedersen of Sandefjord also converted belt filling machines, a total of 1,166 from both companies.

Gunner’s pouches were also manufactured as almost exact reproductions of the German originals, with the exception of the holder for the AA sight, which was omitted. At some point, the AA sight holder was removed from a majority of the ex-German pouches remaining in service as well. Both the AA sights and the AA mounts for the MG34 saw no use in the 1950s and were scrapped.

Some of the tools, the angled screwdriver, the Lafette tool (issued to all gunners whether needed or not), broken shell extractor (marked with a crown over K for Kongsberg), the hot barrel pad and the Bakelite container for Flower of Sulphur were all reproduced in Norway. Locally made oil cans were used as well.

The contents of the gunners pouch as issued in Norway was as follows: spare bolt, dust cap for the spare bolt (there is no such thing – this is an incorrect nomenclature for the late type muzzle cover), container for Flower of Sulphur, angled screwdriver, broken shell extractor, hot barrel pad, oil can, MG13 wrench, MG Lafette wrench.

Transport crates for each MG34F1, mechanism covers and carrying slings were also manufactured in Norway. The ex-German mechanism covers seem to have been discarded at some point, while the original carrying slings were used until the guns were scrapped, when available. A small plastic funnel for oil, and a cleaning rod was also part of the contents of the transport crate. Spare barrel carriers were repainted ex-German, and all the various Laufbehalter 34, Laufschützer 34 and Laufschützer 43 variations have been found repainted OD in the Home Guard stocks.

As a part of the conversion, the rear sight blade was milled down 2.5 mm and given a U-notch instead of the original V-notch. The front sight was milled down if necessary during the actual test firing to ensure that the point of impact was as close to the point of aim as possible with the lighter bullet of the .30-06. A number of booster cones with a 10.5 mm opening diameter (as opposed to the German spec 11 mm) were also made at Kongsberg for the MG34F1.

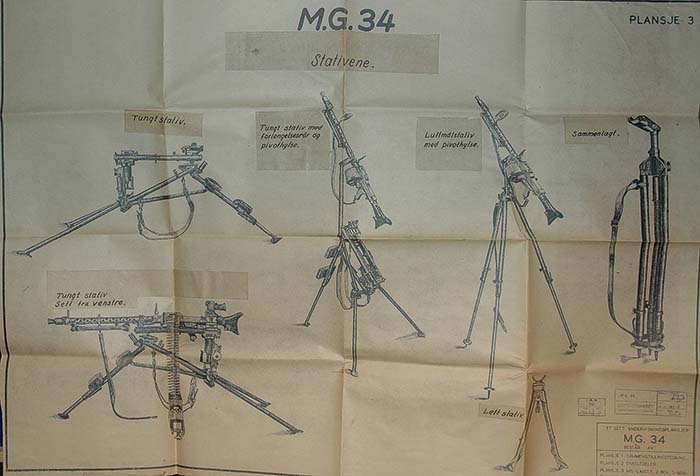

The MG Lafette 34s were quite numerous. Most of the Lafettes were repainted Olive Drab, but a few did survive this process and retain their original color. It is to be assumed that all Lafettes with Gebirgsjäger hind legs were altered to “normal” legs at some point, as the Gebirgslafette is unknown in the Norwegian Home Guard. The number of issued optical sights would possibly reflect the number of MG Lafette 34s in stock, while a total of 104 MG Lafette 34s were kept in reserve.

In 1958 it was decided that the Home Guard district of Greater Oslo should use the MG Z 40 optical sight for their Lafettes, while the rest of the country should use the MG Z. This must have changed later, as the author never saw any MG Z 40 in the Home Guard at all. The Air Force used some MG Z 40 for the aiming system of their Bofors L70 40mm AA guns. All remaining MG Richtaufsatz sights originally intended for indirect fire with the MG08, but also used with the MG34 were to be scrapped at this time (March 3, 1958). A total of 700 MGZ and MG Z 40 were held in stock at this time. The ZF12 does not seem to have been considered for use at all.

The following accessories were made for the MG34F1:

- Transport crates, supplied by Bakelittfabrikken at a price of 46 nok each.

- 1,200 Transport crates also from Eilif og Sigurd Stene at a final price of 51.90 nok each after adjustments of the specifications.

- 2,000 broken shell extractors (Winkelschraubenzieher, angled screwdrivers) from A/S Stanseprodukter at 2.85 nok each.

- 2,500 MG Lafette wrenches (Zapfenschlussel zur Zweilochmutter) from A/S Stanseprodukter at 3 nok each.

- Plastic funnels from Thiis & Co. at 0.52 nok each.

- 1,000 gunners pouches from A/S Kolbjorn Knutsen & Co at 22.76 nok each. (Later deliveries from Gresshoppa)

- 5,000 one piece cleaning rods, from A/S Roja at 5.34 nok each.

- 4,500 mechanism covers from A.Bockman A/S at 11.90 nok each.

- 2,500 carrying straps from N.Blomberg A/S at 4.85 nok each. Later the price was reduced to nok 2.60 ea as the first delivery proved to be of insufficient quality.

- 3,000 plastic boxes for the Flower of Sulphur from Steinar Larsen Plastic Fabric in Brummunddal at 1.35 nok each with an additional cost of 8.50 nok for the casting dies.

- 1,200 BFAs were made at Stansecompaniet 7.20 nok each.

BREN MkII F1

While going through the vast collection of rare and unique machine guns at the Armed Forces Museum in Oslo, Norway, we found an example of an Inglis manufactured Bren MkII converted to .30-06. The conversion was relatively simple; the barrel was locally made and the magazine well was slightly modified to take the magazine, which was a ZB26 magazine converted to the longer cartridge. As evidenced by the markings and the shape of the magazine well, the gun had originally been in .303 caliber and converted by the Army Ordnance Corps. The bolt was unmodified but there is some indication that the extractors used were from 7.92 caliber ZB26 machine guns.

ZB26F1 and ZB30F1

The Armed Forces Museum also holds two examples of ZB26 and one ZB30 converted to .30-06 as well. The conversion is similar to the one undertaken on the Bren MkII. One of these converted guns is actually a ZB30J, the only specimen in the museums collection.

MG42F1

It is common knowledge among machine gun enthusiasts that the MG42 was converted to .30-06 in the U.S. during WWII. The conversion was not very successful, most likely due to a rather optimistic goal of preferably reducing the cyclic rate to 350rpm by means of an extremely heavy bolt carrier. The fact that the MG42 was converted to the same caliber in the 1950’s in Norway was unknown to this author until recently, even after researching a book on the subject. As the conversion was a post WWII adventure, it would not have been relevant for the first edition of my book anyway, but it is always nice to find these neat pieces of machine gun trivia.

The 3,500 barrels mentioned previously were ordered in 1952, but the first order of converting the guns were not placed with Kongsberg Våpenfabrikk until September 6, 1956, when ten MG42s were to be converted to MG42F1. The converted guns were to be marked as follows: A serial number and prefix HÆR_____ was to be engraved on the left side of the receiver with fonts of 5 mm height. The original serial number and the year of manufacture were to be chiseled out, while the model designation MG42 was to be kept unaltered. It was soon discovered that most of the stock of approximately 2,000 MG42s had been sold to another country, and this of course made the whole project moot. According to a memo of October 10, 1957, only 2 MG42Fs1 were finished. Most likely the MG42s held in Norway were sold to Denmark or back to Germany. The German army refurbished WW2 vintage MG42s and converted them to 7.62×51 and reissued them under the model designation MG2.

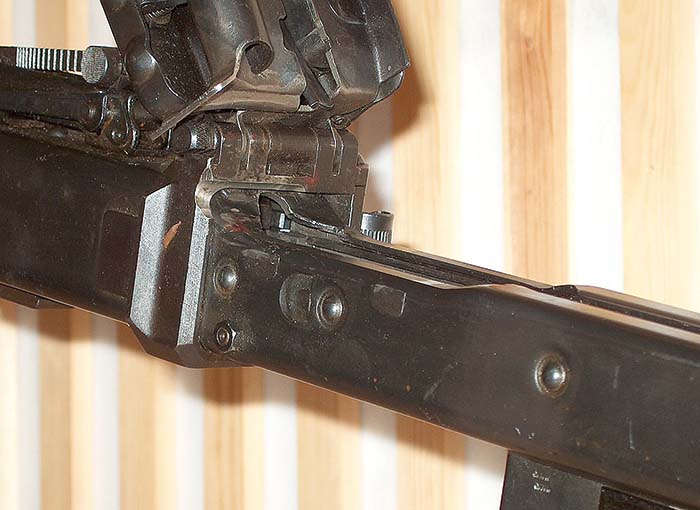

The conversion was simple, and only the feed tray and the camming piece had been slightly modified. As the conversion program was aborted, it is unlikely that heavy troubleshooting was performed on the two modified MG42s though there is no reason why these guns would not work reliably.

A total of 3,218 barrels had been finished by the time this slight “communication error” was discovered and tests and experiments were held to see if it was possible to convert these MG42F1 barrels to MG34F1 specifications. The tests seem to have been successful, but the author has not been able to find any trace of these barrels anywhere. The MG42 barrel is 53 cm long and the MG34 barrel is 60 cm long, so the conversion not only involved a re-profiling trip to the lathe, but a sleeve would have to be made and fitted to the shorter barrel as well in order to make it work. It must be assumed that the last 7 cm would have to be smooth-bored. The conversion of all the barrels was ordered in 1961, and test firings were undertaken in 1963 and 1964. No known specimens exist of these barrels today.

MG34F2

The MG34F1 was the Home Guards official machine gun until the mid 1970s, when it was decided that it was time to modernize it for the new NATO cartridge, the 7.62×51. As the years went by, the supplies of .30-06 ammunition were more and more expensive to keep up. The Home Guard Youth still used their K98k rifles until the 1990s but their ammunition expenditure was small compared to the machine gunners’ yearly allotment. At some point it was decided to equip the Home Guard in the northern part of the country with the MG3. As mentioned above, this was considered the most important part of the defence against the Soviet Union. It is also likely that the 1918A2 BAR was used in some quantity in the northern part of Norway.

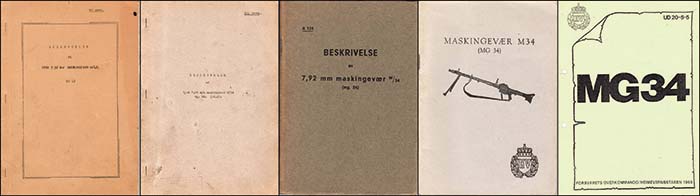

Up through the years the knowledge about the complicated MG34 was passed down in the units, but a lot of the finer points were lost, as were the specialized tools to work on it and exchange parts. Manuals were issued in 1949, 1956 and 1990, but the correct use of the optics and Lafette mounts was lost along the way, although these items were used until the final changeover to the MG3 in 1994. The MG34 was a mythical weapon that had its share of followers and enthusiasts, and a large group of members of the Home Guard simply hated the damn thing. The holy grail was to always keep the Flower of Sulphur at hand for many of the machine gunners. The MG34F1 was not bad, but as we shall see the conversion to 7.62×51 was to be everything but a success.

By the mid 1970s, the MG34F1s were starting to show a lot of wear. The supply of certain spare parts was starting to dry up. The knowledge once gathered at Kongsberg during the initial conversion from 7.92 to .30-06 had been lost in the meantime. The apparatus to adjust the connection between the barrel jacket and the receiver was nowhere to be found.

For the new conversion, it was decided to remove most of the markings from the barrel jacket of the MG34s to avoid all confusion regarding the serial numbers. The official Norwegian serial number was of course the one stamped on the left side of the receiver. The original German nomenclature on the barrel jacket was just ground off and then it was blued over. This makes the research on these weapons very difficult.

Although the conversion had been relatively simple from 7.92 to .30-06, the new conversion to the much shorter 7.62×51 proved to be a nightmare for the next 17 years. The drawings and plans for the conversion were drawn up in 1976. One of the most critical issues was that there was no longer a supply of original springs of any kind for the MG34. A contact was made with a spring factory in Sweden, and production began. Additionally, many parts had to be modified in the top cover for the new conversion. As the 7.62×51 cartridge is considerably weaker than the 7.92/.30-06 rounds it replaced, it was decided to make a lighter barrel for this conversion. This created another problem in the timing and unlocking of the mechanism.

The Feedway of the 7.62×51 Round

During the test firing of the first conversions to the 7.62×51 cartridge, the following stoppages were noted: incomplete feeding of the rounds and incomplete locking of the bolt/barrel connection

The centre line of the round was found to be at too much of an angle from the centre line of the chamber of the barrel during the feeding of the cartridges, therefore causing the stoppages mentioned above. The receiver of the MG34 has a curvature in the front end of the feedway that is intended to help guide the cartridge on its way into the chamber. The 7.92 and .30-06 are so similar in length that the first conversion did not cause any problems, but the much shorter 7.62×51 cartridge would not work well in the first converted MG34s.

To improve the feeding, the following suggestions were made: the forward cartridge pressure pawl was to be replaced with a newly made pressure pawl with an angled surface to help in adjusting the round in the correct direction. The rearward cartridge pressure pawl was also to be slightly adjusted and the feed pawl and feed pawl slide were also slightly altered in the process. The feed tray was also altered for the shorter cartridge.

With these corrected parts, test firings were held in April, 1976 and the cyclic rate was found to be around 850 rpm with new ejector plates installed. When the guns were sent in for conversion at Kongsberg, the following checklist was set up for the guns before the work was done on them:

- Serial number

- Trigger group

- Barrel jacket – straightness and dents

- Rear sight

- Connection between receiver and barrel jacket

- Receiver

- Buttstock

- Top cover

- Bolts, both the main bolt and the spare.

After the conversion of the guns themselves had been completed, the need for special equipment arose. A special blank firing barrel modeled after the German original was introduced by Bakelittfabrikken. This blank firing barrel had a heavy chamber end that caused a lot of unnecessary wear on the guns. In the 1988 manual for the MG34, several types of barrels for both blue plastic short range training ammunition and red plastic blanks are shown. These barrels have their own booster cones, but I never saw these issued to the troops. The belt loaders were also rebuilt for the shorter cartridge. The transport crates for the MG34F1 were remarked and read MG34F1F2, a black square stenciled over the original F1 marking.

The Kongsberg small arms factory went through all the Home Guards MG34F1s and rebuilt them into MG34F2s as a modernizing project. After a couple years of service it was obvious that this was far from the case. The rebuilt MG34F2s were less reliable than ever and the stoppages were many. A few local enthusiasts in the Oslo Home Guard analyzed the problem and found that on their weapons most of the problems were related to the ejector. Many of their bolts had ejectors that showed signs of having been ground off with no other purpose than to fit the bolt inside the receiver, instead of finely honing the ejector until the bolt fits in the gun and works perfectly as it is supposed to. The report from these enthusiasts was sent in to the General Staff of the Home Guard, but no attention was paid and no action was taken.

During the rebuilding process, the ejector plates had been changed on all the guns and replaced with new made ejector plates that had the point of impact moved 6 mm forward to compensate for the shorter cartridge. This is not a good solution, as the ejector will hit the ejector plate earlier and both parts will wear more than necessary. The lighter barrels also add to this problem, as the MG34F2 will unlock its action faster than what is intended and the parts will go rearward with more force than the system is designed for.

In the mid 1980s it was decided that an AA tripod was necessary for firing against helicopters and other flying vessels, so a number of these were ordered from DISA in Denmark. Later, new cradles were ordered so that the AA mounts could be used with the MG3. A small number of MG34s that were earmarked for the AA tripods were fitted with MG3 AA sights on a locally made base.

The last accessory to be developed for the MG34 in Norway was a plastic mechanism cover. This model was identical to the older canvas type except for the material used. As they were made shortly before the guns were to be scrapped it is doubtful that they were ever issued. The only place I saw any sign of them was at a scrap pond awaiting destruction.

Throughout the 1980s the MG34 became more of an accessory and a necessary evil to the soldiers of the Home Guard and less of a vital part of the small arms inventory. Very few soldiers could use it effectively. Some units had good instructors and armorers that kept their MG34F2s running and maintained them properly, while others might as well have carried railroad ties around with them. The HK21 was strongly considered as its replacement around 1989, but was dropped due to its low tolerance in high stress situations. A small number was bought and tested with specialized units of the Home Guard.

Booster cones

The original German MG34 used a booster cone opening of 11 mm when normal ammunition was to be fired. There was also a booster cone with a 9.5mm opening to be used with the lighter aluminium-cored practice ammunition. After converting the guns to caliber .30-06 it was found that a booster cone opening of 10.5 mm would be ideal to ensure proper reliability. During the last conversion process it was decided to manufacture booster cones of 9.5 mm, 10 mm and 10.5 mm and change these around until the gun worked during test firing. The original intention was to mark the correct booster cone opening under the lid of the transport crate, but this was seldom done. In other words it was just sheer luck if the gun kept its correct booster cone through some years of maneuvers.

When the MG34 was scrapped in the 1990s after almost 50 years of service in Norway, especially in the Home Guard, it was not without a bit of sadness. During our yearly exercises it was a common sight. Most of the machine guns were scrapped for metal, but a small number were deactivated and sold to members of the arms collecting society.

Manuals

Several manuals were issued on the MG34 during its service life in Norway. These were issued in 1949, 1956 and 1988. Training charts and even the old German instruction film “MG34” are noted in older publications. The instruction film seems to be mostly lost today, except for a few rolls that have been transferred to DVD recently.

HK21E

In the late 1980s the HK21E was a strong contender to be the replacement of the MG34 in the Home Guard and it was tested on many occasions. A small number was purchased for the Home Guards 016 Special service units. The original HK21 was tested in Norway for the first time as early as the 1960s. The testing was done in both caliber 7.62×51 and 5.56×45 and the guns were literally shot to pieces. The Armed Forces Museum has a crate with the remains of these weapons.

1919A4

In the early 1990s, a 1919A4 Browning machine gun was converted to 7.62×51 caliber by local enthusiasts in the Oslo area. The conversion was quite successful and the Browning worked flawlessly. Nothing came out of this, but at the time there were still a lot of 1919A4 Brownings in storage in Norway.

MG3

In 1967, the Norwegian Armed Forces adopted the G3 rifle for all its branches and started manufacturing it at Kongsberg. More than 200,000 G3s were made in the years to follow. The G3, known as the AG3 in Norway, replaced the M1 rifle and M1 carbine in the Norwegian Army as well as the K98k in the Home Guard. It would later replace both the submachine guns and the pistols for most of the Norwegian units and was for a while the universal small arm of the Norwegian Armed Forces. The armed forces adopted the MG3 at the same time as the light and medium MG, but kept the MG34F1 for the Home Guard.

The MG3 was a well proven machine gun at the time and is still state of the art in its class along with the MAG58. When the German Leopard tanks were purchased for the Norwegian Cavalry, the tanker version of the MG3, the MG3A1 was adopted with it. The Rheinmetall manufactured MG3s that were initially purchased did not present any problems at all, except for the normal wear and tear on any machine guns. For the medium machine gun role, the MG3 was mounted on rebuilt 1919A4 tripods with newly made cradles made by DISA in Denmark.

Around 1970 the Norwegian Air Force rebuilt a number of MG Lafette 34s to take the MG3 and used them for perimeter defence of the air bases. Technically these mounts are similar to the MG Lafette 42, but are easily separated from these by the crude front mounting bracket.

When it was finally decided to replace the Home Guards MG34F2 with the MG3 in the early 1990s, the guns were to be supplied from Turkey, not a country known for its high standard in arms-making. When the Turkish MG3s were first issued there were quite a few problems with them. Cocking handles breaking off were only minor problems. Many Home Guard soldiers, enthusiasts and officers felt that they might as well have kept their old MG34F2s. Quite a few of the Turkish MG3s turned out to have severe headspace problems and literally blew up during firing. After this had been investigated it was found out that the chambers of the barrels had been made incorrectly, and new bolts and barrels were purchased from Heckler & Koch in Germany to solve this problem once and for all. The barrels have chrome lined bore and the same Cr marking as the WW2 MG42 chrome lined barrels.

The status of today is that Norway is still equipped with the MG3 and there seems to be no other machine gun on the horizon. A few Leopard II tanks were bought from Belgium, equipped with MAG58 machine guns, presenting a supply and logistics situation. Amusingly enough, the Swedish Army, who has the MAG58 as their standard LMG, recently bought Leopard tanks with MG3s and had to deal with the same problem. If the two countries would have traded the machine guns and mounts with each other a lot of logistics could have been made easier.

Apart from the MG3, Norway uses the M2 HB .50 cal. in the Vinghøg soft mount with the Raufoss Multi Purpose ammunition and FN Quick Change Barrel set-ups. The issue pistol is the Glock 17, known as the P 80, the MP5 and the G3 rifle are also in use. Snipers use a locally manufactured bolt action rifle built on the 98k mechanism. Our new combat rifle is the HK416, which is presently being introduced to all branches of the military along with a number of HK MP7 PDWs.

| Barrel | Bolt | Number of rounds |

| I | I | 3 single, 20 round burst |

| II | I | 3 single, 15 round burst |

| III | II | 3 single, 15 round burst |

| This article first appeared in Small Arms Review V16N4 (December 2012) |