By Christopher R. Bartocci

With the current controversy surrounding the U.S. M4 carbine, many manufacturers have jumped in with solutions to address the current deficiencies of the M4. Many offered haphazard improvements that were less than military grade to say the least. The initial challenger to the M4 was the German firm Heckler & Koch. They took the basic AR-18 short stroke tappet system that was refined by H&K engineers for use in the HKG36 and fitted it into an M4 platform: hence the commencement of the HKM4 program. The modifications did not just stop there; they reconfigured the lower receiver and used some much more durable components with the most important being a stronger bolt. They also used their highly regarded chrome lined hammer forged barrels. After a lawsuit settlement with Colt Defense, the name was changed to the HK416 due to Colt?s trademark on the term “M4.” That trademark would soon be lost when Bushmaster challenged Colt and got it revoked. The HK416 went on to be tested and used by the U.S. Special Operations Forces as well as other military and police throughout the world. Unofficial word has said that Osama Bin Laden was dispatched by a SEAL with an HK416. Although unofficial, the people who make this claim are extremely credible.

The war in Afghanistan was quite different from the streets of Iraq. Iraq turned to be more of an urban battlefield where combat was up close and personal. Many troops were mounted in vehicles and most engagements were less than 100 meters. The 14.5 and 10.3 inch M4/HK416 did quite well in this environment. The shorter ranges were where the weapons shined the most. Afghanistan on the other hand brought back the half kilometer shot. Troops from the U.S., as well as allies, found themselves being outgunned by peasant Taliban soldiers shooting a thousand yards with old Mosin-Nagant bolt action 7.62x54R rifles. Of course there is a mixture of Mausers, Enfields as well as Springfields to name a few of these long range battle rifles. The enemy was out of the range of the 5.56mm M4 and SA80 rifles – to just name a couple 5.56mm rifles in service in that theater of operations. The problem was so serious the British MoD put out an immediate requirement for a 7.62×51 sharpshooter rifle. That contract was taken by Karl Lewis with his new LM308MWS, which is now type classified by the Brits as the L129A1 rifle. However, another 7.62x51mm rifle found its way into the mountains and caves of Afghanistan, the Heckler & Koch 417.

The HK417 was first introduced to the military community in 2006. Some of the first to test the rifles were the U.S. military. When looking at the HK417, it looks like an HK416 on steroids – everything looks the same but bigger. To fill the demands in the market the HK417 is selective fire. This can make a designated marksman rifle into a CQB weapon with the flick of a switch. Barrel lengths are offered in 12, 16 and 20 inches.

The lower receiver has lineage of the AR-10-type rifle but the similarities end there. Starting from the rear, the receiver extension is larger in diameter when compared to the standard M16/M4/AR-10 rifles. The HK is approximately .210 inches larger in diameter making it proprietary. The end of the receiver extension has three drain holes that apparently assist to egress water in over-the-beach conditions. The stock is also proprietary HK. There are 5 positions of adjustment. By rotating the buttplate 1/4 turn the buttplate is removed and there you have two battery storage components. There are three mounting apparatuses for a sling.

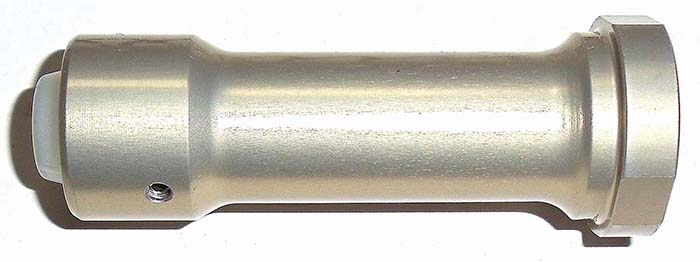

The lower receiver is manufactured from aircraft grade aluminum. The buffer and action spring are large in diameter compared to the rest of the industry. The buffer is unique in that it has a flare to the rear by the bumper. This too, may have to do with removing water. The receiver extension is pinned in place to prevent it from ever coming loose in the field. HK offers four different pistol grips but the receiver will accept most any of the aftermarket grips. The lower has an ambidextrous selector lever. The bolt catch is similar to that of any AR-10 type rifle in both location and function. The magazine catch button is larger and round making it a little easier to access than the traditional button. The trigger guard can fold down in the same manner as any other M16/AR-15 type rifle. The HK417 is offered in selective fire as well as semiautomatic only configurations.

The magazine used in the HK417 is a proprietary translucent polymer magazine: you are able to see how many cartridges are in the magazine. The polymer is quite thick and very sturdy. They come in both 10- and 20-round capacity. The early prototype HK417 rifle utilized the steel G3 magazines and a few can be seen. Very few of these remain.

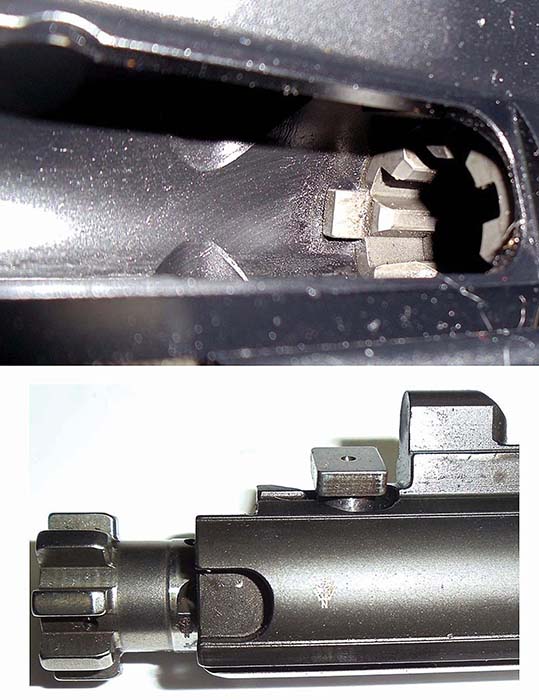

The bolt carrier group looks identical to the HK416 but larger. The carrier is one piece with the hump machined where the carrier key would normally go on a direct gas rifle where the operating rod strikes. The most unique aspect of the bolt carrier is the firing pin lock system. A spring loaded arm attached to the carrier locks the firing pin to the rear with the assistance of a firing pin spring that insures the firing pin is always to the rear. When the trigger is pulled and the hammer released, as the hammer gets ready to strike the firing pin, the top of the hammer lifts up on the firing pin catch to release the firing pin so when the hammer strikes, the pin is free to connect with the primer. Once the bolt carrier cocks the hammer during cycling, the firing pin spring pushes the firing pin to the rear were the lock engaged and keeps the firing pin from moving. What does this do say you? A couple things, such as prevent accidental discharge by slam fire. Some primers are very sensitive and the inertia of the firing pin moving back and forth when the bolt carrier closes on a live round. This also can be the solution to prevent slam fie conditions with an extremely high cyclic rate. The carrier also has a captive firing pin retainer pin. Some early models may have one you can remove but as of this writing all carriers have the captive pin. The bolt is quite hefty and has a proprietary nickel-type finish on it. There bolt has a multi-lugged locking system like the standard AR-10. The extractor is heavy duty and not removable for cleaning. It is held in place by a roll pin. Additionally, the bolt has dual ejectors. This increases significantly the ejection force that is needed with short barreled rifles where the bolt carrier group may move faster than a single ejector can egress the cartridge case from the receiver. With the exception of the extractor not coming out for routine cleaning, the carrier group comes apart like any other AR-type carrier with the addition of the firing pin spring. The charging handle is unique in that the latch can be moved to the opposite side to accommodate a left or right handed shooter. An armorer is required to do the swap due to the small roll pins involved.

The upper receiver is also manufactured from aircraft grade aluminum. It incorporates a forward assist and a fired cartridge case deflector. The ejection port dust cover is manufactured of high impact polymer. The barrel is the same high grade ordnance steel that HK is famous for the world over. The barrel is hammer forged and chrome plated with a 1 turn in 11 inch twist to stabilize 147- through 175-grain projectiles. The chamber on the HK417 chamber is fluted in the same way as the original G3 and MP5 family of weapons. Barrel life has many factors but HK tests the barrels out to 10,000 rounds. The barrel of course will last longer if taken care of and a lot of full auto fire is not done. The barrel has a standard flash suppressor with notches on the end to cut barb wire with a bullet. The gas block is pinned to the barrel with extremely strong roll pins. There is a gas valve with two positions. There is one setting for suppressed and one for normal/non suppressed. The proprietary 1-piece handguard is designed and patented by HK. There are quad Mil-Std 1913 rails. The handguard is held on by two large locking screws. Normally, these screws are tightened to a recommended HK torque specification. In an emergency “field expedient” situation, these screws can be tightened and removed by using one of the locking lugs on the bolt.

The rifle comes with HK proprietary back-up iron sights. The most common rear sight is the diopter rear sight that HK is famous for, which is adjustable for windage and elevation. Also offered is a low profile flat aperture that is needed so some optics can fit over it. There are two front sights as well. The standard is the nonadjustable standard configuration, another HK trademark. There is also a folding front sight that attaches to the top of the gas block. However, any aftermarket back up sight may be used.

The heart of the HK417 is the gas system – the same as the HK416 but with a larger gas block you would expect for a .30 caliber barrel. The system is a short stroke tappet system via push rod. The piston, which has three gas rings attached, is inserted into the rear of the gas block. The operating rod assembly consists of the pusher rod, return spring and guide. The rear of the pusher rod is inserted in the upper receiver, pulled in, and the front of the operating rod is inserted into the back of the piston. The cycle of operation begins by the hammer striking the firing pin; the hammer disengages the firing pin lock on its forward motion. The primer sets a spark igniting the propellant. As the powder burns high pressure gas rapidly builds forcing the projectile down the bore. Once to projectile passes the gas port under the front sight base, some gas is tapped into the gas block where a piston chamber is created between the front of the piston and the back of the front sight base. As the gas expands the pusher rod is forced to the rear where it strikes the top of the bolt carrier sending it rearward. Excess gas from the front sight base is pushed out the front of the gas block via an exhaust port. As the bolt carrier moves rearward the cam unlocks the bolt and the bolt extracts and ejects the fired cartridge case. The pusher rod is now pushed back into the gas block via the return spring. The bolt carrier cocks the hammer and moves to its rearmost position where the action spring and buffer push the bolt carrier forward. At this point the firing pin lock is engaged. The forward movement of the carrier strips a cartridge off the magazine and feeds it into the barrel extension and then into the chamber. The cam notch rotates the cam locking the bolt. The buffer absorbs the shock and the rearward motion of the bolt carrier when it slams into the barrel extension preventing bolt carrier bounce. This is only an issue with the rifle in the fully automatic mode. The benefits of the push rod piston system are touted as being cleaner than the direct gas system by the fouling not being introduced into the bolt carrier and heat not being transferred to the bolt and carrier increasing part life. The advantage of these benefits over the direct gas system has been, and will be, debated for quite some time.

The MR762A1

With many of the high speed rifles these days, a commercial customer can read all about them but they are unobtainable. The weapons are available to military and law enforcement customers only. Due to importation bans, it is that much harder for commercial customers to obtain many of these weapons even though they are manufactured in semi-auto only configurations. For many years there was a high demand in the commercial market for a civilian version of the famous HK416. Few weapons have been so highly publicized in the last 20 years. Not until January of 2011 did HK officially announce the MR556A1 commercial rifle to the industry. Now in January of 2012, HK announced the release of their MR762A1, the commercial equivalent of the HK417 with a suggested retail price of $3,995. As expensive as the rifle is, there are for sure going to be collectors who will want this high quality rifle in their collection.

What made it possible for the American consumer to have these fine HK rifles was the opening of HK’s facilities in Columbus, Georgia and Newington, New Hampshire. To comply with importation laws, several parts are either made or finished in the U.S.

The lower receiver is very similar to that of the HK417 with two major changes. First, the takedown and front pivot pin have spring loaded locks in them. To push the pins out a pin punch or the modified Allen wrench are used to push in the plunger to install and remove the pins. These special pins remove the play between the upper and lower receiver and therefore help to increase the accuracy of the MR762A1. That tool is held in a compartment inside of the stock. The automatic sear hole is not there and the trigger group is a proprietary semiautomatic only group. What is so special about this feature is that the safety selector lever can be engaged with the hammer in the forward position.

The upper receiver is very similar with the most notable change being the barrel extension. On the left side there is a tab sticking out and on the left side of the bolt carrier is a notch that that tab slides next to. A selective fire carrier does not have that notch cut, so the selective fire carrier will not close in the receiver making it unusable. This is obviously an anti-conversion provision in the rifle’s design. The semi-auto bolt carriers are marked with a “MR” on the right side of the bolt carrier. The handguard is slightly modified as well. First, there is no gas valve regulator – there is only one setting. The locking bolts on the MR762A1 are tightened with an Allen wrench instead of a large Philips screwdriver used on the HK417. The 16-inch barrel is manufactured from the same steel and manufactured with HK’s famous cold hammer forging process. The only real difference is the barrel on the MR762A1 is not chrome plated. HK engineers believed that the chrome plating could have an adverse effect on the precision accuracy of this carbine so they omitted this step. Minus these few changes, the MR762A1 is identical to its military big brother.

The test and evaluation rifle was sent with back up iron sights, one 10-round magazine and a custom HK black soft tactical carrying case. An additional 10- and 20-round magazine was requested for testing the rifle. For reliability testing, the rifle was equipped with the AimPoint Comp4s reflex red dot sight. This is the same sight known as the M67 sight issued to U.S. troops. During testing 300 rounds of Silver State Armory 147gr FMJ and 200 rounds of Pierce Ammunition 147gr FMJ were used with no malfunctions of any sort. To add, the rifle was dry, no lubricant was applied at all. Accuracy testing was done at 100 yards with a Leupold Mark 4, 3.5 to 10x scope with an illuminated reticle. This scope has a 40mm objective and is equipped with bullet drop compensator for the 7.62x51mm round with a 168gr projectile. The illuminated reticle is turned on or off by the user and has 11 increments of brightness. Three different types of match ammunition were used for testing for accuracy. These types of ammunition were Silver State Armory 175gr OTM, Hornady SUPERFORMANCE 178gr Match OTM and a custom Pierce Ammunition 150 grain Hornady SST projectile. Both Silver State Armory and the custom Pierce ammunition shot sub-MOA but the tightest group of .540 inches was shot with the Pierce Custom ammunition.

The rifle was what you would expect from H&K: a fine example of German engineering with attention to detail, proprietary and reliable. With the $3,995 MSRP, the rifle will be purchased by the serious collector. The MR762A1 is also a suitable choice for American police and other law enforcement agencies looking for a precision 7.62mm/.308 Win semiautomatic rifle. Over the last couple years H&K has heard the voice of their customers and answered giving them what they wanted: a commercial version of the HK416 and HK417.

| This article first appeared in Small Arms Review V17N1 (March 2013) |