By Frank Iannamico

On a recent assignment for SAR magazine, I had the opportunity to spend a few days at Gemtech’s Research and Development Center located near Boise, Idaho, as a guest of co-founder Dr. Phil Dater.

During my visit, I had to chance to observe and shoot quite a few suppressor equipped firearms. The suppressors demonstrated were both production and prototype models; all regardless of caliber, were hearing safe. One experimental model that impressed everyone in attendance was Gemtech’s .22 LR caliber integral Mist-22 suppressor, adapted to a Czech CZ 415 bolt action rifle. All that could be heard was the firing pin striking the cartridge, and the bullet hitting the target down range.

The Gemtech Mist suppressor was originally designed for one of the most popular .22 rimfire rifles in the country, the semiautomatic Ruger 10/22. The 10/22 has been in continuous production since 1964. Few rifles on the market today can boast of being in production for 52 years, with a reported 6-million sold. Since its introduction, the 10/22 has been offered in many different configurations and models. It was only natural to design and produce an integral suppressor for the Ruger. The Mist 22 was designed by Gemtech exclusively for a Lipsey’s, a large firearm wholesale firearms distributor in Louisiana.

The Gemtech Mist 22 is a complete barrel and suppressor assembly. The barrel portion of the Mist just under 9-inches in length, with a match grade 22 LR chamber and a 1 in 16 inches, right-hand twist. The suppressor core is permanently attached to the barrel, giving it a legal overall length of 16.25 inches. In place of conventional baffles, is Gemtech’s one-piece G-Core Monolithic Baffle.

As soon as I returned from my Gemtech trip, I ordered a Mist for my 1976 vintage Ruger 10/22, and I am very pleased with its quiet performance. However, as on any suppressed full-automatic or semiautomatic firearm, most of the noise heard is generated by the action cycling. On the 10/22 some of the noise can be reduced by replacing the steel bolt stop pin with a nylon Volquartsen Recoil Buffer.

Mist to Savage Conversion

Note: altering the Mist suppressor as described below will void any factory warranty.

To satisfy my desire for a suppressed bolt-action .22 rifle, I purchased a Savage Mark II FV-SR rifle. The Savage is an economically priced bolt-action rifle that comes with a suppressor ready ½-28 threaded 16.5-inch heavy, fluted barrel, a user adjustable AccuTrigger™, and black synthetic stock. The Mark II weighs 5.5 pounds with an overall length of 35.25-inches. A 5-round detachable metal box magazine is standard, but 10-round capacity mags are available.

In place of conventional iron sights, the Savage Mark II comes equipped with a 14-position Picatinny rail mounted on top of the receiver, for use with a multitude of optics from red-dot sights to variable-power scopes. This allows the rifle the to be used at both close and long ranges.

As mentioned earlier, the Mark II is equipped with Savage’s AccuTrigger™, which is user adjustable from approximately a 2.5-pound pull to a 6-pound pull. The rifle’s standard oversized bolt handle is another desirable feature. Operation is smooth, and the extra size and weight of the bolt handle allows for positive movement into each position, and be manipulated with minimal shift to the shooter’s point of aim. The clean, crisp action and smooth operating bolt are two more features that make the Savage Mark II an attractive package, and a perfect candidate in which to adapt a Mist suppressor.

One of the primary features that attracted me to the Savage MK II FV-SR was its standard ½-28 threaded barrel, which would allow me to mount my Gemtech Outback suppressor. My Outback has been upgraded with the G-core option, which makes cleaning less of a chore. My Outback can is shared with a stable of .22 caliber pistols, which involves a lot of switching back and forth.

I was pleased with the performance of my Savage Mark II fitted with the Outback. However, I could not get the idea of the Mist adapted to a bolt action rifle out of my head. I like the idea and look of an integral suppressor; the overall length would be shorter, and I would not have to keep switching the suppressor from the rifle to the pistols. Fully convinced, I ordered another Mist suppressor.

For the adaptation of the Mist to the Savage I needed the help of a skilled gunsmith, so I contacted Tony Veronesi at Veronesi Gunworks. Tony is a Class II manufacturer with a modern, well-equipped shop, and he has assisted me with a number of projects in the past.

After the Mist suppressor was transferred to me, I took it and the Savage rifle to Tony’s shop. After removing the trigger group and bolt, the next step was to remove the original barrel. The barrel is secured with two pins and lightly pressed into the Mark II’s steel receiver. After taking some measurements, Tony announced that the Mist could be easily adapted to the receiver by a few machining operations, and the Savage’s fluted barrel could remain intact. This was good news, although I was willing to sacrifice the original barrel for the conversion, I was pleased that it was not necessary.

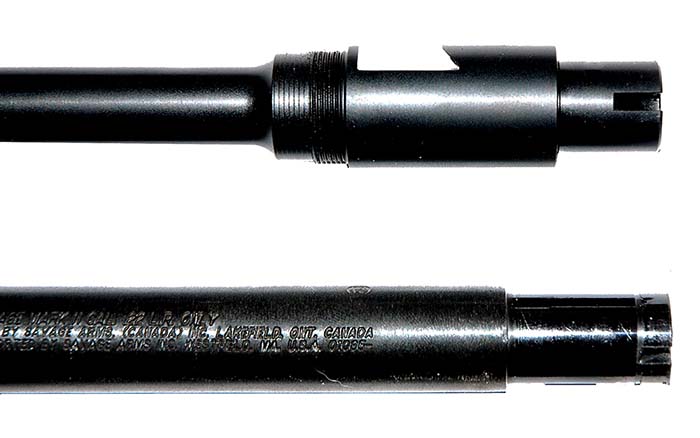

One of the first operations involved the machining away a portion of the Mist’s barrel tenon to allow it to fit far enough into the receiver as the original barrel. Fortunately, the breech end of the Mist’s barrel is only .0005” (half of a thousandth) of an inch smaller in diameter than the Savage barrel and matched up perfectly with the receiver.

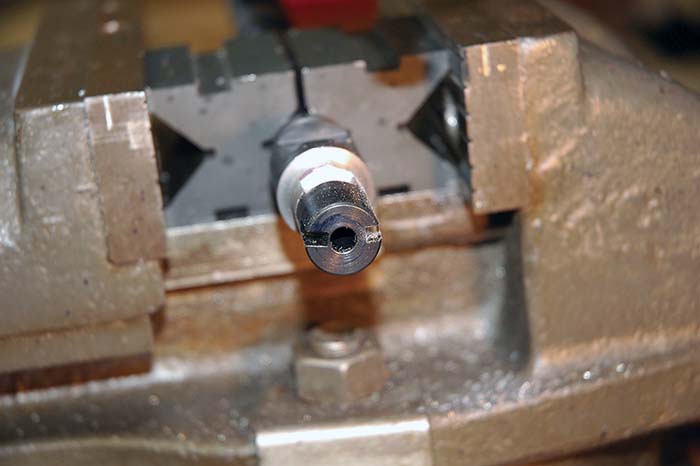

The Ruger 10/22 has a single extractor, while the Savage Mark II has two, a primary and secondary extractor, necessitating a second extractor slot to be milled in the breech end of the barrel.

Next, a flat was milled on the bottom of the Mist’s barrel to assist in adjusting the proper headspace. The barrel end inside of the Savage’s receiver is beveled so that the barrel can be moved slightly forward or back until the correct dimension is achieved. A set screw is then tightened onto the milled flat, to hold the barrel in place so that the holes for the cross-pins used to secure the barrel can be accurately drilled.

Since the outside diameter of the Mist’s suppressor tube requires a stock channel .920-inches in diameter, slightly larger in its outside diameter than the Savage’s barrel, the stock needed to be milled open slightly to fit the suppressor.After approximately 50-rounds were fired, a few failures to extract the spent case from the chamber occurred. The chamber was polished with a bronze bore brush attached to a drill. After the polishing, no more problems were encountered. The suppressed Savage turned in a very impressive sub-one-inch, five-shot group at a range of 75 yards off of a rest.

The outer tube of the suppressor is easily removed for cleaning. I have found an easy way to clean the Mist’s monocore baffle is to use a piece of 1.5-inch PCV pipe approximately 17-inches in length. Attach threaded end caps to the pipe, and fill it with your favorite solvent. Remove the stock and outer tube; there is no need to remove the receiver or trigger group. Insert the suppressor end into the PCV tube and soak it for a few days. It is recommended that the suppressor be cleaned every 500 rounds. If not cleaned periodically, the outer tube can be difficult to remove.

| This article first appeared in Small Arms Review V21N1 (January 2017) |