By Paul Evancoe –

What is a thread-locking compound, and what is its purpose? Thread-locking compounds are designed to prevent threaded fasteners from becoming loose when exposed to vibration and other counter-torquing forces that cause the screw or nut to back away from its tightened seat. Ultimately, this circumstance results in mechanical failure if thread-locking measures are not taken. This is a common phenomenon seen in all engines/motors, mechanical devices of all purposes and—yes, that’s right—firearms. While thread-locking compounds are employed in firearms for many purposes, the most common is to lock the screws used in rail and scope mounts.

Numerous thread-locking compounds are available online and from gun, automotive and hardware stores. In general, thread-locking compounds are adhesive-based, cure anaerobically and only work on metal threaded surfaces. The majority are formulated for specific ranges of temperature and pressure.

Most thread-locking compounds require the application surfaces to be near perfectly clean in order to achieve adequate surface bonding for proper thread-locking performance. They are additionally formulated for permanent performance where a screw, bolt or nut will likely never need loosening, and for semi-permanent performance where a screw, bolt or nut will probably need to be unfastened for maintenance or loosened for readjustment. In either case, when disassembled, residual thread-locking compound must be entirely removed from the metal surfaces where it was previously applied, prior to any reapplication in the reassembly process. Those of us who have experienced this disassembly, cleaning and reapplication process can affirm that the process is somewhat meticulous and absolutely time-consuming.

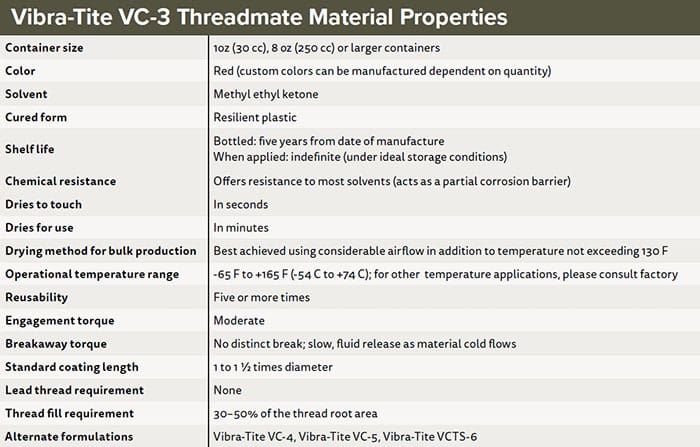

Vibra-Tite VC-3 Threadmate, manufactured in the USA by ND Industries, with headquarters in Clawson, MI, entirely resolves the above issues. VC-3 utilizes a special blend of acrylic resins to prevent fasteners from loosening—even under extreme vibration. VC-3 is a powerful locking and sealing coating for threaded fasteners that works on the principle of “friction through viscosity.” Working much like a nylon insert self-locking aircraft nut, VC-3 holds parts in place even during extreme vibration, and it also resists gas and liquid leakage by acting as a seal between mated threads.

Designed for use on any external and internal threads of virtually any material or finish, VC-3 is not an adhesive or an anaerobic. Unlike traditional liquid lockers that cure to form a hard bond, VC-3 is a blend of resins designed to remain flexible and absorb vibration. This unique difference makes fasteners coated with VC-3 truly adjustable, removable and reusable.

Pre-cleaning of parts is not required except for wiping off any visible oil, grease or dirt for optimal performance. VC-3 dries to the touch within seconds of application and coated parts are ready for assembly in just a few minutes. Additionally, parts coated in VC-3 require no cleaning or removal of previous VC-3 material. VC-3 can be reapplied directly over the previously coated surfaces, and the new will bond to the old.

The features of Vibra-Tite VC-3 Threadmate are numerous. For example, parts coated with VC-3 have an indefinite shelf life and can be stored indefinitely before use. This means you can prepare fasteners in advance so they are ready to use any time. VC-3 works on both ferrous and non-ferrous metals, most platings, wood and plastic screws, creating a reliable, powerful thread lock and seal. It won’t harden like traditional threadlockers.

Additionally, VC-3 uniquely offers multiple reuses because it remains a thick, resilient, taffy-like “viscous resin.” Its cold flow properties actually minimize galling or stripping of soft threads during reuse. Using steady pressure and standard hand tools, parts coated with VC-3 can easily be adjusted, removed and reused.

Compared to anaerobic adhesive threadlockers, VC-3 is a low-cost highly versatile alternative. It works on fasteners of any shape or size, from tiny eyeglass screws to large construction bolts. It works with all internal or external threads under virtually all environmental extremes. Unlike anaerobic threadlockers, VC-3 threaded parts can be air dried and then installed into an underwater mating part in both fresh and salt water. VC-3 won’t deteriorate or change in viscosity with prolonged submergence. This unique attribute alone puts VC-3 head and shoulders above other thread-locking compounds.

| This article first appeared in Small Arms Review V22N5 (May 2018) |