By Michael Heidler

Once the creator of one of the first mass-produced light machine guns, Denmark had slept through the dawn of the submachine gun era.

While Denmark’s neighbours busily experimented with the new type of weapon in the 1930s, at first nothing happened in the country of the machine gun. The Dansk Rekyl Riffel Syndikat (DRS), which was founded in Copenhagen before World War I, continued with machine gun production. The Model 1903 and its successors sold well, and the brand name “Madsen” had already established itself into far countries. The officer, inventor and Minister of War Vilhelm Her-man Oluf Madsen had been the driving force behind the development, and in his honor the weapons bore his name.

When the Wehrmacht invaded Denmark in April 1940, there were only a few foreign submachine guns in use by the Danish Army. Negotiations with the Finnish arms factory, Oy Tikkakoski Ab, on a licensed production of the Konepistooli M31 (Suomi) were in progress but could not be finished before the German occupation. At the end of 1940, the company, now renamed Dansk Industri Syndikat A/S (DISA), began production of the Finnish submachine gun with a slightly modified stock and protected front sight as the M/41 under German control. The approximately 1,400 weapons produced were first used in Danish units and taken over by the Germans after the disarmament in October 1943. At DISA, each weapon model and each variant received its own P (project) number, even if only some mark-ings were different. For example, the P.5 was the version for Portugal, to which the weapon was offered in 1943.

Otherwise, not much happened in the course of the war. The development of their own submachine gun was going on slow. By the time P.13 was finally finished as the “Model 1945,” the war was over, and the design was already obsolete. An interesting feature: the bolt was attached to a slide which extended over the barrel and also covered the recoil spring. For cocking, the slide was pulled back until the bolt was locked by the sear—just like a conventional blowback pistol. This slide moves back and forth with each shot. This circumstance, and the elaborate milled parts, a solid wooden stock and a complicated interior were no longer up-to-date. The installation of a folding stock did not help either. Only Mexico and El Salvador bought a few pieces.

At the same time, however, a further development had been worked on, and it was to become a major commercial success for DISA: an uncomplicated, modern submachine gun with a sheet metal receiver, folding stock and a simple but effective safety.

The work on project P.16 would be completed by the end of 1946. The production-ready weapon was called “Model 1946” (M-46) and was sold under the brand name “Madsen.” The first weapons were sold to the Danish police. Thanks to a cost-effective production, inquiries soon came from South America and Asia. El Salvador, Paraguay and Thailand were among the first foreign customers.

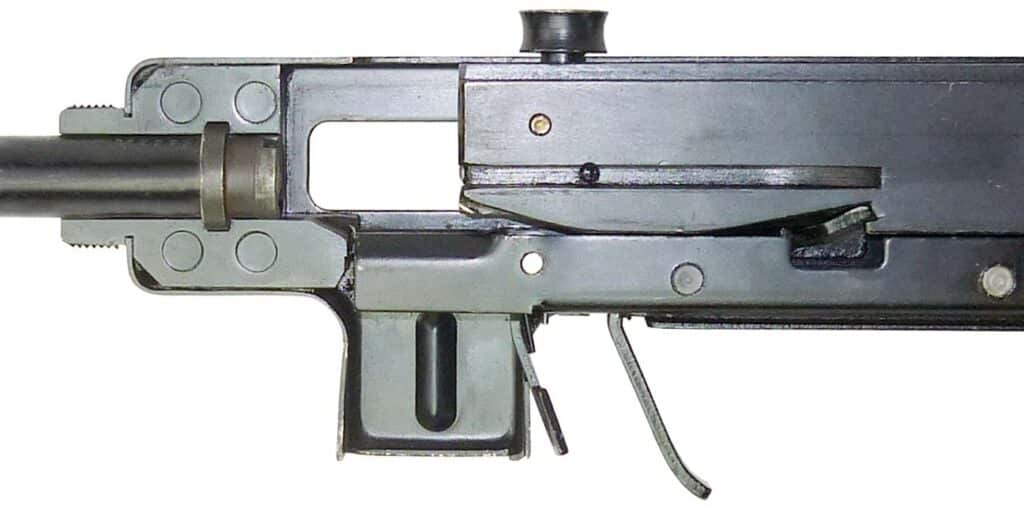

The weapon is an unusual design, consisting of two receiver halves, each of them pressed from one piece of sheet metal including the grip piece and magazine well. They are held together at the back by the hinges of the side-folding wire stock and at the front by the barrel nut. The cocking handle is a bracket-shaped slider that rides along on top of the receiver. Disassembly of the M-46 is very easy: one must unscrew the barrel nut, pull out the barrel, remove the cocking slider and then open the left side of the receiver, almost like a book. All internal parts such as bolt, recoil spring and buffer will remain in the right receiver half and can be easily removed. No tools are needed, and there are no connecting pins that can get lost. Weapon cleaning has never been easier, as there are no inaccessible places.

On the other hand, the operating principle is not very innovative. The Model 1946 is a conventional blowback design firing from the open bolt. The cocking slider can be operated from both sides due to its position on top of the receiver. It moves forth and back with every round fired. The weapon is fed by a stick magazine with 32 rounds (9x19mm). The small magazine loader is practically stored inside the hollow grip together with a spare extractor and a second firing pin.

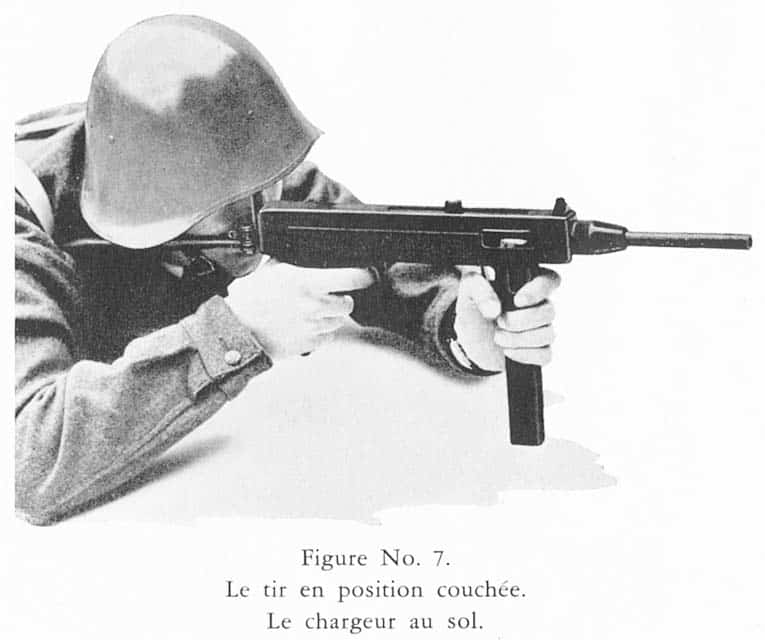

The safety mechanism is extraordinary: the bolt can be locked in the open or closed position by means of a manual safety switch located on the left side of the receiver right above the trigger. And then there is an additional automatic safety in form of a lever just behind the magazine well. To fire the weapon, one must grasp the magazine and this lever securely with the non-firing hand to release the bolt. Otherwise, the lever protrudes into the receiver and blocks the way of the bolt. This kind of safety is highly unusual in submachine guns. Only a few weapons, such as the Italian TZ-45 from World War II, have almost identical safeties. Most commonly the designers rely on a grip-safety located in the grip piece. The lever behind the magazine well has one big disadvantage: the weapon cannot be fired with one hand. In case of injury or if only one hand is free, the shooter has an unsolvable problem.

In the following years, DISA did a slight revision of its submachine gun, resulting in the P.56. The main improvement was the new cocking handle. It got the shape of a button, was firmly attached to the bolt, and there was no need to remove it before disassembling the weapon.

On November 7, 1950, the submachine gun was presented as “Model 1950” on the shooting range at the old Mosede Fort near Copenhagen. Military representatives from Great Britain, India, the United States and several other countries were allowed to attend the successful demonstration of firing 20,000 rounds with a weapon from the current serial production. After 2 hours and 17 minutes the test was over—and the gun still alright. Not a single malfunction occurred during firing. In the days before the demonstration a barrel was already stressed with 42,970 rounds and then measured. The muzzle velocity decreased by less than 10 percent and the bore widened by 0.04mm (0.0015 inch). The military, in any case, seemed to have been convinced by the Mad-sen M-50, because it soon became an export hit. Orders followed (again) from El Salvador, Guatemala, Venezuela, Colombia, Indonesia and many other countries.

To be even more successful in the international market, there were a few minor improvements to the weapon, as well as a few variants to choose from. From the Model 1953 (P.74), the thread for the barrel nut was relocated from the receiver to the barrel. A curved magazine was supposed to improve the cartridge feed (although the straight stick magazines were working properly). In addition, an alternative barrel nut could be used in connection with a perforated bar-rel jacket with integrated bayonet lug. The last DISA submachine gun was the Madsen Model 1953 Mark II (P.127). It too was optionally available with barrel jacket and bayonet. On request, wooden grip plates could be attached so that the grip piece did not heat up in the sun as much as the standard grip piece made of pure metal.

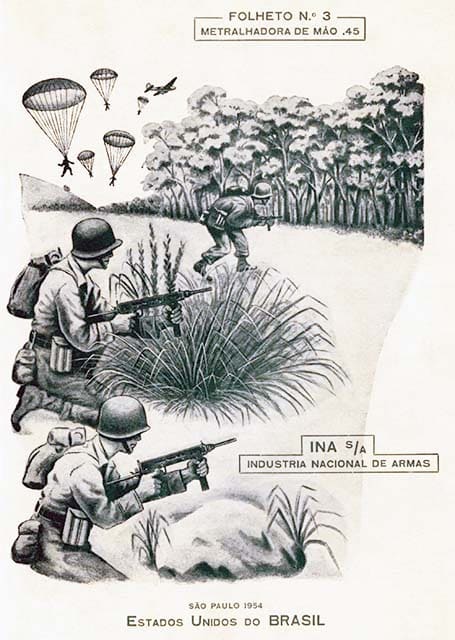

In Brazil, the Indústria Nacional de Armas S/A manufactured the submachine gun under license in São Paulo. Contact with the Danes was made in 1949, and DISA assem-bled some prototypes in the desired .45 ACP caliber. Already in the middle of 1950, serial production began in the factory in Brazil. The weapon was given the model designation INA M950. The most noticeable difference to the Danish model was the cocking handle relocated to the right side of the receiver. Three years later, a slightly improved version followed—the INA M953. Among other things, the magazine well was extended. The submachine guns were used in large numbers by army, navy, civilian police and other armed units. When the military forces switched to 9mm ammunition in the early 1970s, the INAs were gradually sent back to the depots for storage. The number of weapons is not known, but it was enough to let the military think about a conversion to 9mm caliber. Originally, the state-owned armaments company Indústria de Material Bélico do Brasil (IMBEL) was to produce a conversion kit consisting of barrel, bolt and magazine so that the replacement work could be carried out directly in the respective depots. But the conditions of the weapons varied a lot, and many had to be repaired first. Ultimately, therefore, the weapons were sent to the IMBEL factory in Itajubá for rework and conversion. In addition, the submachine guns received a fire selector switch because most of them went to the police, and they wanted a semiautomatic function.

As great as the success of the Madsen sub-machine guns was in the world, it remained modest in its homeland of Denmark. Only the Danish police bought weapons from DISA. The army, however, preferred the M/49 “Hovea,” which was adopted in 1949. It was nothing more than a copy of the Swedish Carl Gustaf m/45. The state-owned weapons factory (Haerens Vabenarsenalet) in Copenhagen was chosen for its production.

| TECHNICAL DATA M-50 | ||

|---|---|---|

| Caliber | 9 x 19mm | |

| Length (stock retracted) | 530mm | 20.86in |

| Length (stock extended) | 795mm | 31.30in |

| Length of barrel | 200mm | 7.87in |

| Weight (empty) | 3.15kg | 6.94lb |

| Magazine capacity | 32 rounds | |

| Rate of fire | 550 rounds/min | |

| Sight | Fixed peephole 100 meter |

| This article first appeared in Small Arms Review V23N7 (AUG/SEPT 2019) |