By Dickson Ly

Chiappa is an interesting firearms manufacturer. They are located in Brescia, Italy, which is typically associated with manufacturing of over/under and side-by-side shotguns with manufacturing dating back 500 years. They have a wide portfolio of products catering to a wide array of clientele. From reproduction muzzle loaders to classic as well as modern lever action rifles to the famous Rhino revolver. They even produce 1911s as well as M4/ AR-15s chambered in .22LR rimfire cartridge.

The company was originally founded in 1958 by Ezechiele (Oscar) Chiappa under the name Armi Sport. With limited budget, he first started working from the basement of his house producing firearms. The company continued to grow, and the Chiappa Group was created. They moved to the current facility in 2002, but they are constantly expanding.

Oscar’s son, Rino, is now the CEO and president of the company. Rino’s wife, Suzanna, is the head of the export department and handles all of the export paperwork. Their daughter, Giada, is the CFO of Chiappa Firearms and the vice president of Chiappa USA.

Giada grew up with the company, and she knows the complete production process inside and out. She took time out to act as my tour guide. Being the third generation of a family business, every employee including her must have passion to work. In fact, she started working for the family business when she was 12 years old (those were the days before labor laws were in place). She remembered riding her bicycle through the basement between the workshop machines and recalled the struggles of a small family business.

With only 85 employees in the company, they have no union. As Giada explained, they treat every employee of the company with great respect. Every person has to do his part in order to succeed long term for the company. They are willing to hire new employees with little to no firearms background as long as they have a strong work ethic and are willing to learn.

Compared to traditional gun makers located in the valley of Gardone Val Trompia in the North, Chiappa is located south of the city of Brescia in an industrial area along with manufacturers producing various automotive parts.

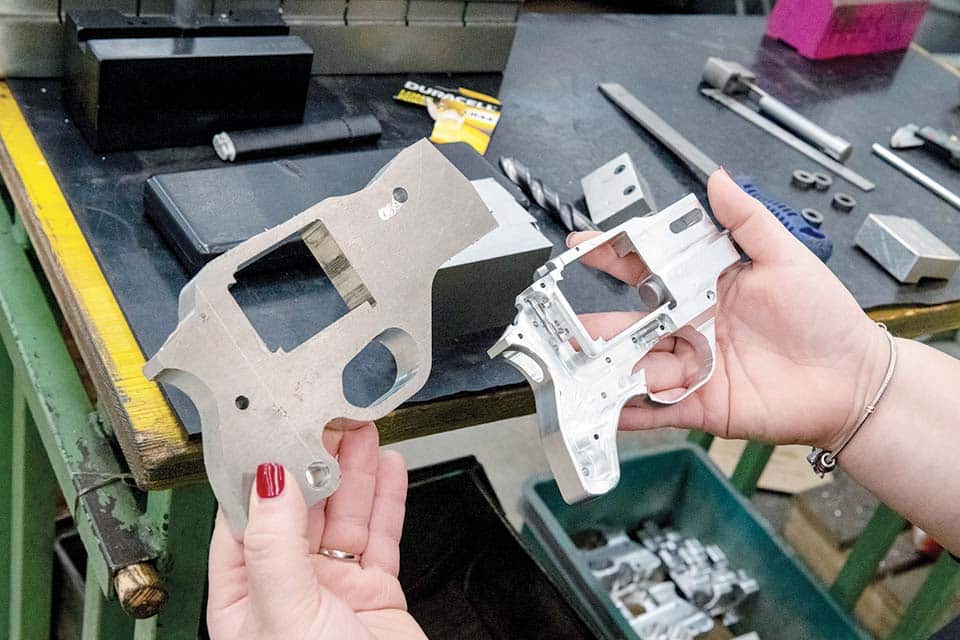

Boxes of rimfire revolver frames fresh from casting.

Production

We started the tour in the barrel production section. All the barrels are made in-house at the factory, and currently they are in the process of preparing to receive a new barrel drill and dimple machine from the U.S. in a few weeks. This is surprising as most small manufacturers simply outsource their barrels, but it is usually more difficult to control quality when it is not done in-house.

They also have a metal injection molding (MIM) machine, making parts designed for rimfire pistols and rifles where the durability and strength from forged steel or aluminum is not required or too costly. Similar to plastic molding, the raw metal, such as stainless steel, is heated to 1400° Celsius (2552° F) then it is channeled into the mold cavities. Once cooled, the formed parts will be pushed out. Although the molds can be costly, it is offset by high-production volume. MIM is also a much quicker production method than CNC machining.

On another section of the production area, it housed a very wide and tall machine designed to cut the beech wood furniture. Pieces of rectangular wood blocks are fed into it, and it does the majority of the cutting, including its almost final shape and cutting the areas for trigger housing and cavity for securing the stock to the receiver. This machine is not used by wood stock manufacturers, because it originally was designed for the furniture making industry. In fact, it is used by the famous Swedish furniture maker IKEA.

The final sanding down of the stocks is still done manually with a drum sander. The stocks are transferred to a small room and have oil applied to them to reveal their true colors. They are polished at the end to get a great shine.

One rather interesting point: They sell a lot of DIY assembly kits with unfinished wood stock to the U.S. market for the people who want to build their own gun, much like a hobbyist kit.

For semiautomatic pistol slides, they have an automated robotic arm where the bar stocks are fed to the CNC machines and then get picked up by the arm to get polished. The whole process from raw material to finished slide is done with no human intervention.

While the assembly of firearms is done mostly by men, each firearm is packed neatly into its packaging, then into cardboard boxes by mostly female workers. It’s apparent that every firearm is handled with love and care, even if the packing process is repetitive in nature.

Throughout the production area, the workers employ a barcode system on each firearm that relates to its specification as well as production progress. Each employee also scans his or her employee card when beginning work at his or her station; management can track time spent per manufacturing step per firearm. This is beneficial as the company can identify if there are inefficient production processes and/ or employees, and once they are identified, they can then find a solution to the problem.

Right next to the door that took me back to the office, there was a tall, large steel green door with a label “Shooting Range” in English which took us to the basement of the factory. Chiappa has a small 25m shooting range for test firing. Each firearm gets test-fired five rounds, and when the process is complete the computer automatically prints out the results. The shooting range computer also links up to the company server along with the barcode system so the company can pinpoint where the firearm is during assembly as well as during testing.

All Chiappa shotguns, such as the three-barrel Triple Crown and Triple Threat 12-gauge break-action shotguns, are produced by Akkar in Turkey.

Rhino

The Rhino is one of the most recent and unique revolver designs of this past decade. The designer, Antonio Cudazzo, is an architect by profession, but he is passionate about firearms. He wanted a carry gun that has the reliability of a revolver yet be light, compact and have low recoil. He was close friends with Emilio Ghisoni, the designer of the infamous semiautomatic Mateba Autorevolver.

Bin full of freshly deburred and polished M9-22 slides.

Chambered in .357 Magnum as well as the more common 9mm cartridge, the Rhino features a short grip compared to traditional revolvers. It looks strange at first, but in reality, it provides good purchase to the shooter’s hand.

Due to the purpose being concealed carry, the original Rhino features a 2-inch barrel. The Rhino’s unique design featuring the barrel at the bottom of the cylinder provides extremely low bore axis, reducing flip and recoil as the pistol goes straight back close to the middle of the hand instead of top of the hand. This was realized to be an advantage in competition shooting, and subsequent models feature 5-inch long barrels. The latest version, the Charging Rhino, features a 6-inch barrel with a black anodized finish in contrast to the nickel-plated trigger and cylinder along with a grey laminated grip. Due to its longer length, there are Picatinny rails at 12 o’clock and 6 o’clock that can accommodate red dots, lights and lasers.

Chiappa had been playing with various types of PVD colors and finishes. Their latest idea is to create a Rhino in a chameleon, multi-color PVD finish called the Rhino Nebula.

Due to its complex manufacturing, the factory currently produces 600 to 800 units a month, and there are 1,000 to 1,500 units on back order.

CHIAPPA

“Hooray for Hollywood”

This revolver is also getting popular on the silver screen. It is used in the latest “Fast & Furious” film, being carried and used by The Rock. It will also be in the upcoming “Terminator: Dark Fate” movie with Linda Hamilton reprising her role of Sarah Connor and Arnold coming back as the Terminator. Previously, it was in “Suicide Squad,” “Total Recall” (the 2012 remake) as well as in video games such as “Battlefield 4” and “Rainbow Six.”

Chiappa has received numerous requests to produce an identical version of the Rhino as seen in comic book movie “Suicide Squad,” used by the iconic Harley Quinn character. Chiappa reached out to Warner Brothers for its permission and possible licensing agreement; however, the movie studio refused to have any collaboration with any firearms manufacturer. The movie armorer company that did the modification to the revolver had also signed an agreement with the studio not to reproduce these revolvers as they were strictly made for the film.

CBR-9 Black Rhino

I was fortunate enough to be one of the few lucky people to handle the prototype CBR-9 Black Rhino, which was recently unveiled at the 2019 IWA Outdoor Classics trade show in Nuremberg, Germany. The Black Rhino is a PDW (personal defense weapon) similar to the likes of the Heckler & Koch MP7 and FN P90. The Black Rhino is chambered in 9mm and feeds from a patent-pending, proprietary double-stack magazine that funnels the rounds to become a single stack for enhanced reliability instead of alternating the rounds left and right. It is extremely compact and is designed to be fired one-handed if the situation requires it.

Rhino Nebula .357 Magnum Special Edition revolver with PVD finish and blue laminate grip.

Like the Rhino revolver, it is a continuation of the same concept that offers extremely low bore axis in order to reduce felt recoil. This means the barrel is as close to the index finger as possible, and the action is situated above the barrel with the hammer flipped upside down. Giada tells me the prototype has been fired one-handed in full-auto with great accuracy, producing minimal recoil with little to no training.

It’s designed by Antonio Cudazzo in collaboration with Tanfoglio, and the final design is completed by Chiappa engineers. As a joint project, the commercial semiautomatic version will be sold by Chiappa, and the military select-fire version will be marketed and sold by Tanfoglio. Both versions will be made by Chiappa due to its expertise in rifle production.

It has a wide aluminum upper receiver with a polymer lower. It has a retractable stock that can be removed. For the American commercial market, it may come with a pistol brace instead, which is still being developed at the time of writing. It has a Picatinny rail on top, ready for optics, but it also comes with bright fiber optic iron sights that are flush-fit and integrated inside the top rail. Right at the shooter’s index finger is the ambidextrous bolt hold-open and release. The magazine release is positioned at the shooter’s thumb just like a semiautomatic pistol. The ambidextrous safety is high up near the top of the upper receiver and requires the shooter to push forward to disengage. The charging handle is at the foregrip and can be switched from the left to right hand with minimal tools. It also has a small, integrated vertical grip up front that can be folded down with a push of the button to unlock it, similar to the HK MP7.

The gun is held together by push pins that come apart quite easily. It features a compensator as a muzzle device which can be unscrewed by pushing back a locking tab.

Many would question the effectiveness of the 9mm round. In spite of that, the U.S. Army recently selected Brugger & Thomet’s APC9K 9mm submachine gun for their Personal Security Details. The CZ Scorpion Evo 3 is another SMG that was recently adopted by the Hungarian Defense Forces and Hungarian police, the Finland police and Czech Republic Armed Forces and police, amongst other military and police services in many countries. With budget constraints in many militaries as well as in police departments, the 9mm round may not be such a poor choice as it simplifies logistics instead of procuring a special round like the MP7’s 4.6mm or FN’s 5.7mm cartridges.

Conclusion

I have visited a good share of factories across the world, but Chiappa is certainly the most dynamic and adaptable company that sets itself apart and caters to several different clientele with rimfire pistols, revolvers, reenactment rifles to tactical rifles and shotguns. Chiappa continues to innovate with unique firearm designs and finds demand on the products that it produces. As a gun enthusiast, this author appreciates companies that think outside the box to create unique looking firearms that also have performance benefits.

There will certainly be more Chiappa product placements on the silver screen near you.

| This article first appeared in Small Arms Review V23N10 (Dec 2019) |