By Dan Shea

SAR takes a look at one of the common problems in this popular rifle

To begin with, Bill Ruger’s popular .223 caliber (5.56x 45mm NATO) Mini-14 has a true select-fire version. The selector has semi-automatic, three shot burst, and full automatic positions. Sturm, Ruger & Co. manufactured these rifles starting in the 1970’s, and still makes them today.

There are a few Mini-14’s that were converted to full auto only by Class II manufacturers using an M14 style selector, but these are few and far between. The vast majority of Ruger machine guns are firearms that were factory made by Sturm Ruger, and transferred either to police departments or law enforcement Class 3 dealers.

Problems with the AC-556 are not all that prevalent. In the course of buying and selling many of these rifles, one common problem stood out from the rest. It is a byproduct of re-assembling the rifle. We thought that the readers of SAR should be aware of this, and a pictorial would be the best way to explain how to avoid this problem.

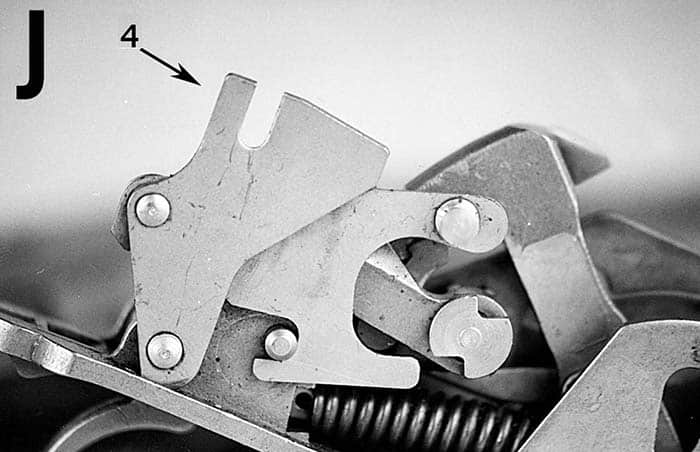

When re-assembling the rifle, the link positioner assembly has a flat sheet metal “Notch” that can easily have its ears broken off. This occurs more often than you might think, and it is an avoidable problem. What makes it worse, is that Ruger will not sell the spare parts to repair this, so the firearm that this happens to must be returned to the factory for repair. Since these are NFA registered firearms, you could be without your AC-556 for upwards of six months due to transfer times!

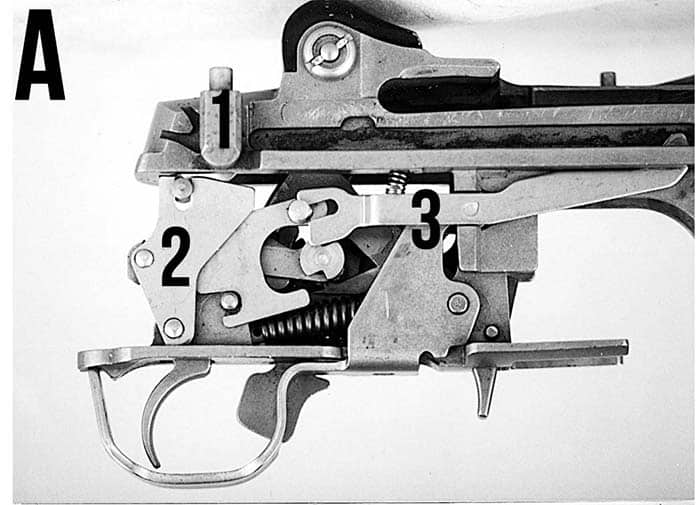

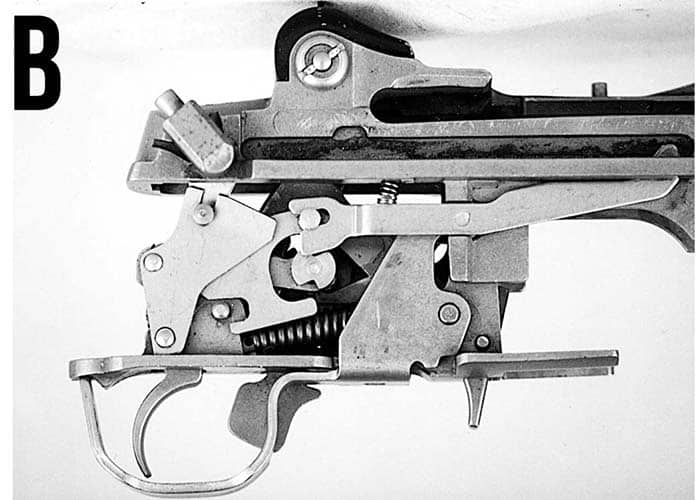

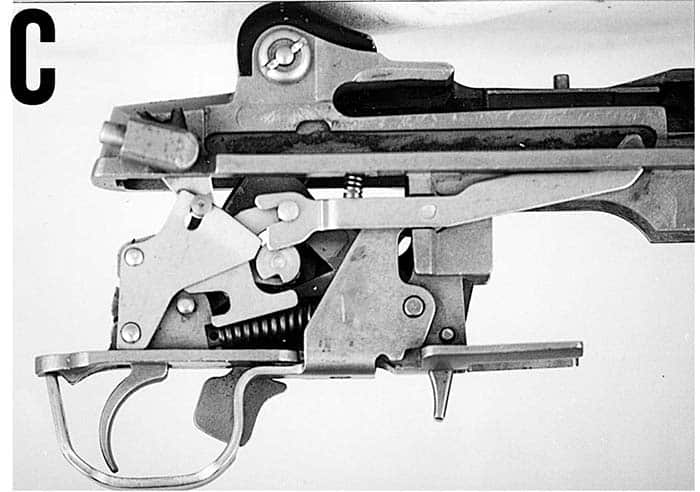

The photos show the linkage positions in the various select fire positions.

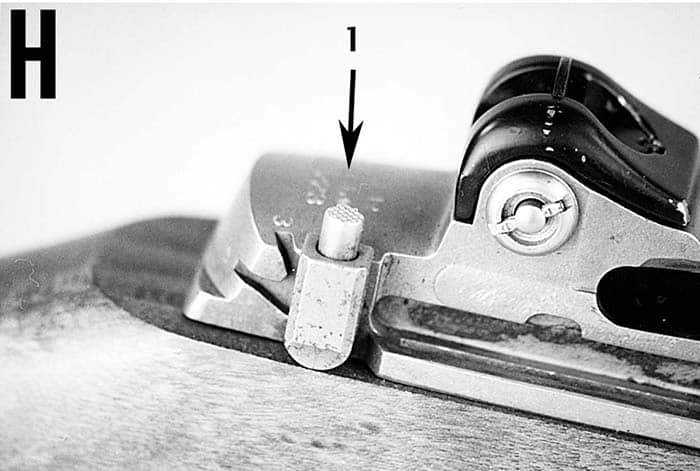

1) Selector Assembly

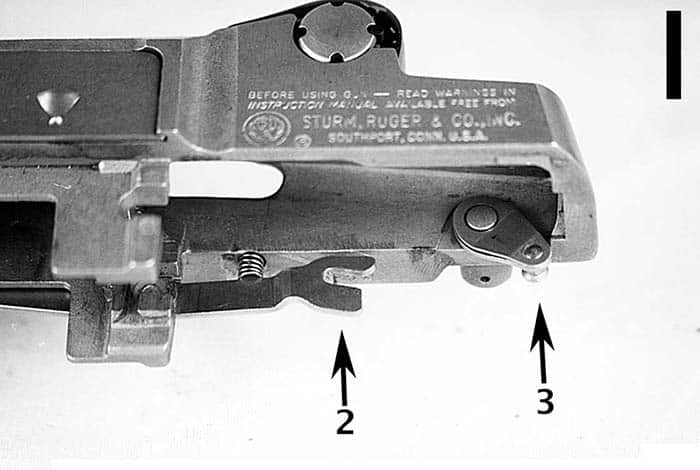

2) Link Positioner Assembly

3) Rocker Arm Assembly

AC556 Disassembly hints:

1- Point the rifle in a safe direction.

2- Remove the magazine.

3- Pull charging handle to the rear and inspect chamber to ensure it is clear.

4- Make sure the hammer is cocked, and the safety is on “Safe” (Refer to figures on page 31)

5- Place selector on semi-automatic (Figure A page 31)

6- Utilizing a punch, or the tip of a cartridge, pry the trigger guard to the rear and lift out as in (Figure D).

7- The trigger group can now be removed to the bottom of the rifle (Figure E).

8- The barrel assembly/ receiver assembly can now be lifted from the buttstock.

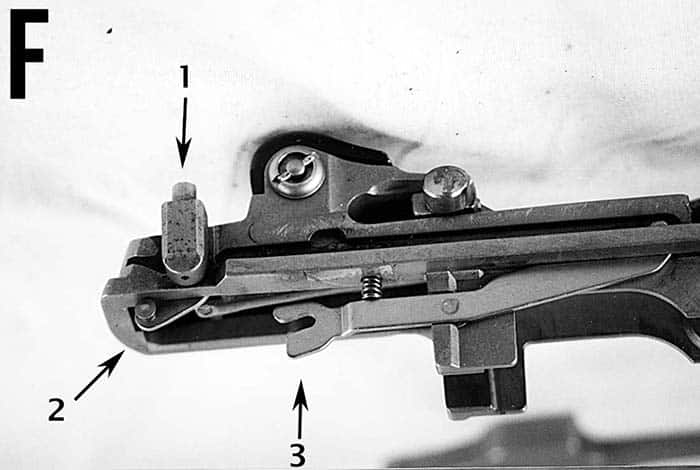

9- (Figure F) The rear of the receiver assembly shows the positions that you should have for the selector, selector arm assembly, and rocker arm assembly.

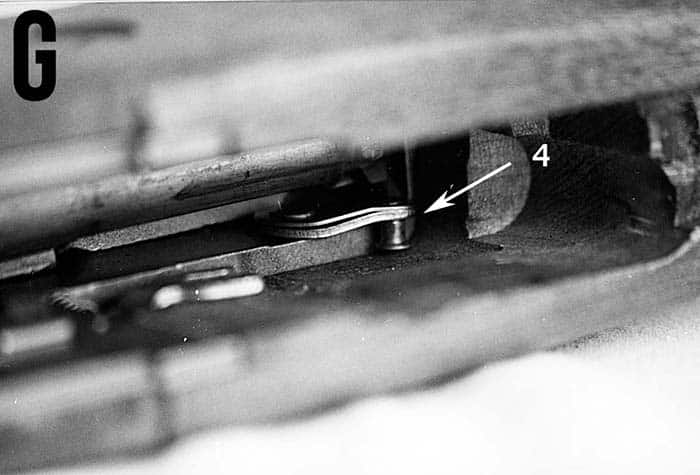

10- A split flat spring is what keeps the selector arm assembly from coming off of the selector post. Figure G-4 shows it’s correct position in the stock for re-assembly.

11- Remove the recoil spring guide and recoil spring (Not shown). The recoil spring is heavily compressed, so take precautions to contain this, or suffer the consequences of lost parts or damaged soft body parts.

12- Pull the slide handle to the rear- align the locking projections on the slide with the disassembly notch on the receiver and remove the slide (Not shown). 13- Pull the bolt forward until it can be pivoted out of the receiver. Align the firing pin projection with slot in lower receiver bridge and remove bolt from receiver.

After you are done with cleaning the AC-556, it’s time to begin the reassembly. This is the reverse of the above steps.

When you reach the point where you have the barreled receiver replaced into the buttstock, it is time to start checking linkage positions. This is the point where the problems generally occur, and the damage gets done. If you look in figures G, H, and I, you will see the positions of the various parts. The selector should be on semi auto. This will make the other parts be in the proper positions for re-assembly.

Slide the trigger group up into the front of the magazine well position then make sure that group inserts straight up into the stock. Return the trigger guard to it’s locking position. Gently cycle the action and try the different selector positions.

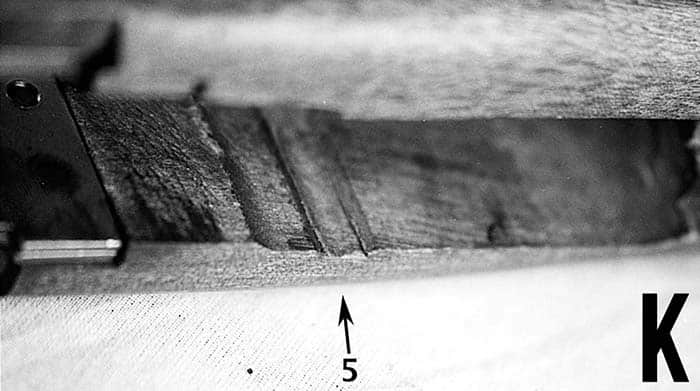

Figure J-4 shows the part of the link positioner assembly that is generally broken off in re-assembly.

Figure K-5 shows the channel in an AC556 stock for the link positioner to move up into position.

| This article first appeared in Small Arms Review V1N8 (May 1998) |