The expansive exhibit floor at the annual AUSA

By Jim Schatz

Each year, as the air turns cool in the Washington, DC metro area and the trees that line the banks of the Potomac River begin to turn to color, the Army rallies for the Association of the United States Army (AUSA) Annual Meeting and Exposition held in 2007 from October 8-10 at the Washington Convention Center. This year’s event was larger than any before it and is, as always, an excellent opportunity to see the latest military equipment on display from around the world; not to mention the small arms – the real focus of this report

Protestors

As one arrived at the site of the show, the AUSA banners flew high and proudly from the tall buildings in downtown DC. The day was clear and sunny, a perfect day for such an event and folks were in high spirits as they made their way to the convention center by taxi, the Metro and on foot. However, this feeling of slight elation was dampened by the chanting and insulting signs of anti-war/anti-America protestors roaming outside of the center and harassing the visitors and denigrating the soldiers and contractors entering the facility. Waving their “blood” stained hands in the faces of the attendees and harassing our brave men and women warriors making their way inside, one could not help but wonder if they realize that their very right to protest, to spout their anti-freedom rantings, has and was paid for with the blood of so many courageous military men and women who have sacrificed so unselfishly and so dearly for our freedoms. To their great credit, the proud and disciplined soldiers in uniform were seemingly not enraged by the actions and mindless rantings of the protestors.

Quietly and Professionally

The mood inside the building was positive, electric in a way and yet reserved. The “surge” in Iraq is clearly working. Civilian and U.S. military deaths are down and insurgent deaths are up. The Army has once again, as it has always done quietly and professionally, performed at its very best for America and for the Iraqi citizens who maybe do not yet realize fully what freedom, independence and a true self governing country is.

The Army gathers each year at the annual AUSA Meeting to celebrate its successes, recognize its heroes and in many quiet ways morn its irreplaceable loses. In 2007, there was much work to be done in all these areas.

The big news on the show floor, besides the hum about troop withdrawals and the success of the surge and the meeting and greeting of old friends and comrades in arms, was the then very recent announcement of the sizable contract awards for new armored vehicles called MRAP. The MRAP (Mine Resistant Ambush Protection) translates to highly mobile but equally protected wheeled vehicles to provide improved protection against IEDs and RPGs. More than 6,400 RG31 MK5 MRAPs have been ordered thus far for the Army alone from just one of numerous vendor teams, BAE Systems through its partnership with General Dynamics Land Systems, while another 600 MK5Es, an extended version of the RG31, have been ordered on a separate $135 million dollar contract for the U.S. Marine Corps. These are huge contracts with the biggest defense contractors in the world. The show floor was awash with armored vehicles of all shapes, sizes and even colors (yes, there was one in British SAS desert “pink” as well). The MRAPs have proven highly effective in countering modern ballistics threats with U.S. and coalition forces. They have and will continue to save lives on the battlefields wherever they are deployed. Most countries involved in OEF/OIF are buying into them at the moment.

AAI

(www.aaicorp.com)

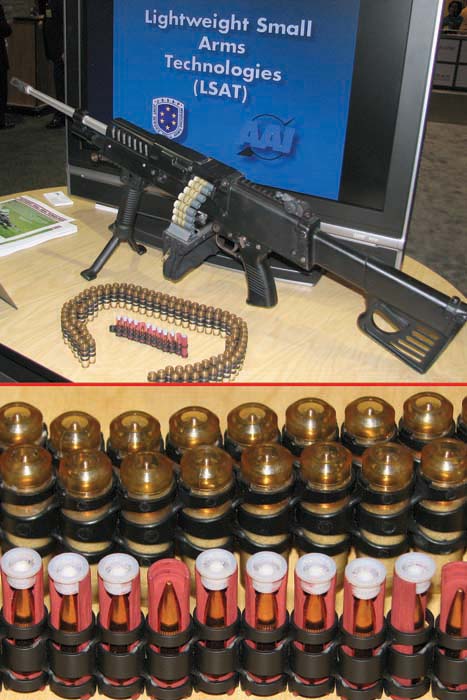

The U.S. Army’s LSAT (Lightweight Small Arms Technology) demonstrator program continues with further success with both its Cased Telescoped (CT) and Caseless Telescoped (CL) ammunition types. AAI reps reported that to date 6,000 rounds of CT ammunition have been fired in the LSAT LMG prototype 001 with prototype 002 testing to begin shortly. Various successful live-fire demonstrations had been conducted for U.S. Army officials at Fort Benning and elsewhere. The caseless ammunition firing weapon is further behind and is challenging the designers to solve the tough-nut chamber sealing issue that haunts all auto-loading caseless ammunition firing small arms. Reportedly, the firing mechanism is in final development with a two-part expanding chamber design similar to that of the ill-fated H&K G11 Rifle.

Thus far, 100 rounds of the rectangular DNAG G11-style ammunition, the basis for the LSAT caseless ammunition, have been fired on test fixtures only. The first cylindrical LSAT caseless ammunition was expected to be completed by end of CY07.

While still clearly in the early R&D stages of development, the LSAT program offers scalable technology that can be applied to other types of small arms such as 7.62mm rifles and machine guns. LSAT offers 35-50% system (weapon, links, ammo) weight savings, but only if system durability and soldier ruggedness can be assured. Watch this program carefully. Put your money on the CT ammo.

Barrett Firearms Manufacturing, Inc.

(www.barrettrifles.com)

The big news at the Barrett booth this year was their 240LW, an in-house development to reduce the overall weight of the U.S. M240 GPMG. The Barrett 240LW (LW for Light Weight) employs a fluted barrel and one-piece CNC machined steel receiver. Offering a weight reduction of 5.5 pounds, this brings the outstanding reliability of the otherwise heavy M240 machine gun into a more portable, maneuverable weight range of 21.5 pounds, and along the lines of lighter GPMGs like the M60 and HK21E, without the need to employ more exotic materials with questionable durability. While there is no official program for this Barrett-funded creation, one can only wonder, “Why not?” Barrett also announced at AUSA that the “BORS” (Barrett Optical Ranging System) is now available for commercial sale at $1,500 each with mount; $2,700 with the L&S MKIV telescopic sight.

Beretta Law Enforcement and Defense Group

(www.BerettaLE.com)

Beretta Firearms Company may be the longest running small arms exhibitor at the AUSA event, continuously supporting the U.S. Army Annual Meeting for more than 23 years. The newest product on display at the Beretta booth this year was the new Px4 Storm Subcompact Pistol. Available in calibers 9x19mm Luger and .40 S&W, the Px4 Subcompact, with 3-inch barrel, weighs only 26 ounces and holds an impressive number of cartridges (thirteen 9mm rounds or ten .40 S&W rounds) for such adiminutive pistol.

Colt Defense, LLC

(www.colt.com)

This year Colt came to the AUSA Show to impress the attendees with new and long awaited developments in the M4 family of weapons. This includes the open public display (and even disassembly) of thehighly secretive M5 Advanced Military Carbine with piston operated gas system, Colt’s new patented aluminum rail system offering 100% return to zero capability and redesigned front sight assembly. Other unique features include barrel heat sink and airflow grooves to help cool a hot barrel and reduce the occurrence of cook off. Colt claims the new op rod M4 has fired over 12,000 rounds without cleaning or stoppages. It is even fitted with proprietary drain system to allow for over-thebeach use wherein the operator can safely fire the weapon without the need to first fully drain water from the interior of the weapon.

In addition to the Colt LE1020 Law Enforcement Carbine with piston operated gas system, Colt representatives were also showing SLA models of various prototype folding stocks for use with the M4 and M5 Carbines to reduce the overall length of the weapon to compact PDW size. The Colt 5.56mm PDW, as it was being referred to, sports a 10.3-inch barrel, new buffer and spring built into the back of the bolt carrier, 3-position QD sling attachment points and LaserMax vertical foregrip with green aiming laser. Firing at 700-900 rounds per minute, the Colt 5.56mm PDW stands ready for the release of the long rumored requirement from the U.S. Army for a rifle-caliber Personal Defense Weapon. At the time of writing, little additional information was available on any such release by the U.S. Army for such a weapon. However, according to sources within PEO Soldier, this requirement is still being written by the user proponent.

FNH U.S.A, LLC

(www.fnhusa.com)

The big news at the FN booth was, of course, SCAR. If reports from both company representatives and from U.S. officials are correct, the SCAR Light and Heavy models and the 40mm EGLM grenade launcher could enter series production as early as March 2008. Reportedly production, fielding and logistical funds have been programmed for full SCAR (12-16 thousand units) and EGLM fielding within USSOCOM once the full production Milestone C decision is made. This is expected to come after the final Operational Test (OT) report is completed and reviewed. At the time of writing, the USSOCOM was finishing up the last of the OT phases with U.S. Army Rangers and Special Forces, U.S. Navy SEALs and U.S. Marine Corps MARSOC personnel. One interesting note was that the BOI (Basis of Issue), which was originally heavy on the SCAR-L (5.56x45mm NATO) side, has now been revamped and it shifted to the SCAR-H (7.62x51mm NATO) variants at the request of the user community. Maybe someone in the SOF world knows something we don’t? An 85% commonality of parts between the SCAR-L and SCAR-H certainly will help to reduce the logistical burden on the organization, especially when one considers just how many different weapons the SCAR family will eventually replace.

The SCAR-L was also involved in the congressionally mandated Extreme Sand/Dust Tests at Aberdeen in 2007 wherein it competed against its potential rivals in the U.S. DoD rifle market. This included the XM8, HK416 and Colt M4. Reportedly, the SCAR-L completed the test with good results but not before a change in the lubrication cycle was required to insure reliable function and test completion. The op rod SCAR-L did reportedly finish ahead of the direct gas operated M4 along with the other two operating rod carbines tested.

General Dynamics Armament and Technical Products

(www.gdatp.com)

(GD) announced that the .50 caliber XM312 is now a separate effort split from the Army’s Future Combat System program and has received some close attention from the U.S. Army and USSOCOM recently for potential replacement of the venerable M2HB heavy machine gun. The XM312 has been modified to accept the standard U.S. M9 disintegrating metal link belt common to the U.S. M2HB. Due to the light weight and reduced recoil of the XM312, it can be mounted and employed anywhere a 7.62x51mm M240 GPMG can be used. Under the current schedule, Low Rate Initial Production (LRIP) of the XM312 is anticipated to begin in 2010 with full production to begin in 2011.

GD representatives also stated that M2HB and MK19 production is “maxed out” at the moment with series production ramped up to meet U.S. and foreign friendly requirements. Approximately 1,800 to over 2,000 of each will have been procured during CY07.

NAMMO

(www.nammo.com)

If you want to witness ammunition and ordnance perfection and innovation, the NAMMO booth at AUSA is the one to visit. Makers of some of the finest high performance small arms ammunition in the world, to include the armor piercing M995 (5.56x45mm NATO) and M993 (7.62x51mm NATO) rounds, they also have an IR Tracer round now in final U.S. Navy qualification testing for use with passive night vision devices. Most notably the progress of the preprogrammed air bursting 40x53mm HV ammunition for the U.S. MK47 Striker ALGL (Advanced Lightweight Grenade Launder) is now in final type classification in the U.S. 90,000 rounds will have been delivered to the USSOCOM by December 2007 for combat evaluations by USSOCOM and other U.S. Army units.

Night Vision Systems

(www.nightvisionsystems.com)

NVS had on display the clip-on Knight’s Armament Company Universal Night Scope Thermal (UNST), or model M890. The maker claims this small 23-ounce device, mounted forward of a variety of optical and reflex sights, can provide human target detection up to 1,000 meters. The UNST can be quickly detached via the throw lever mount, fits on most any rifle or scope and can even be used in a hand held mode when detached.

ST Kinetics

(www.stengg.com)

Singapore based ST Kinetics had on display in their booth a series production sample of their new Air Bursting Modular System (ABMS) for any 40x53mm grenade machine guns. This bolt-on system can be added to the weapon in minutes by the operator and allows for the use of preprogrammed air bursting ammunition to attack targets hidden behind cover, in the defilade, using their quick attach Fire Control System. Using time-of-flight technology, the ABMS ammunition contains 300 tungsten balls within its warhead and costs approximately $350-400 each. Each round has a self-destruct feature and when programmed for air burst will detonate 2 meters above the target and at any location before or after a barrier as determined by the gunner. The ammunition programming “coil” attaches to the muzzle of the grenade launcher and therefore requires no permanent modification to the host weapon. The entire system costs $50,000 at this time. ST Kinetics is also currently working on a 40x46mm LV air burst system as well.

Part 2 of the 2007 AU.S.A Show Report appears in the next issue of SAR and covers current U.S. Army small arms programs and the results of the recent U.S. Army Extreme Carbine Sand/Dust Tests.

| This article first appeared in Small Arms Review V11N7 (April 2008) |