By Christopher R. Bartocci

The SOPMOD (Special Operations Peculiar MODification) program was initiated by USSOCOM (United States Special Operation Command) and implemented by Naval Special Warfare Center, Crane Division, Crane Indiana, in the mid-1990s. SOPMOD set forth the requirements for a new family of weapons for SOCOM use that would be standard for all branches. This would include enhancements of the M4A1 carbines, rail adaptation systems, enhanced versions of the M16 series rifle, optics that include thermal, night vision, video module, range finder and integrated pointer-illuminator. In addition to optics would be silencer/ suppressors, muzzle brakes, bayonet and shot counter.

Part of the SOPMOD requirement was for a CQBR or Close Quarters Combat Receiver. It was to be between 10 to 12 inches and fit on the standard M4A1 lower receiver.

The CQBR

(Close Quarter Battle Receiver)

NSN 1005-01-498-1913

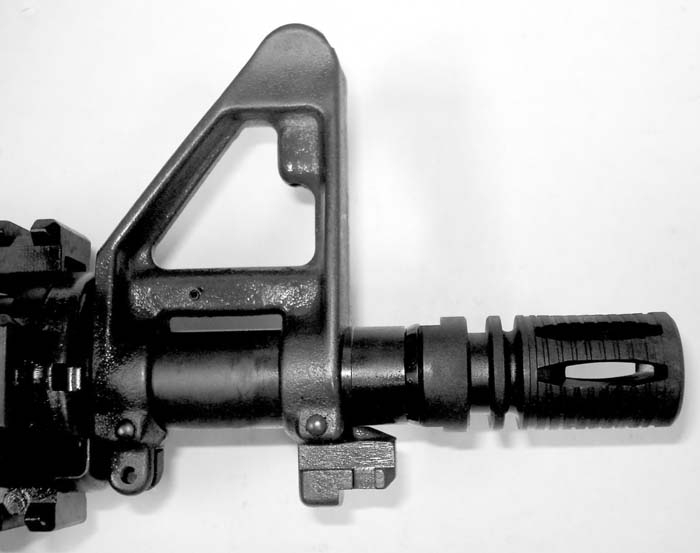

The CQBR receiver was first produced at Crane. The barrel started out life as a standard Colt M4 14.5 inch barrel. The gunsmiths at Crane would cut the barrel down to 10.5 inches, re-thread the muzzle and modify the gas port. Development of the CQBR barrel was assisted greatly by Karl Lewis, President of Lewis Machine and Tool (LMT). Then, a Knight Armament Company (KAC) RIS (Rail Interface System) and a flash suppressor/ quick detachment for the KAC silencer were added. The back-up rear sight chosen was one manufactured by Lewis Machine and Tool.

Due to the short 10.5 inch barrel, the CQBR receiver remains relatively cool even when firing at a faster rate of fire. The complete Colt manufactured Mk18 Mod O carbine. A standard government issue “Property of U.S. Govt M4A1” lower receiver with the six position LMT stock assembly mounted with the CQBR (Close Quarter Battle Receiver) consisting of the Lewis Machine and Tool back-up sight and SOPMOD stock with. Knight’s Armament RAS with rail protectors, vertical pistol grip and compensator (for use with KAC quick detach suppressor). Owing to the short barrel, a significant amount of powder burns after it leaves the barrel and with this decrease in temperature, and additional modifications, the CQBR carbine will have an extended barrel life over the standard M4A1 carbine 14.5 inch barrel.

As previously stated, the original 10.5 inch barrel was modified by the gunsmiths at Crane. Lewis Machine and Tool had also produced some 10.5 inch barrels. Colt got together with Crane and told them that rather than Crane go through the efforts of modifying the barrels of M4 carbines, Colt could just make the barrels to Crane’s specifications: which they eventually did. This made it simpler for Crane to have Colt barrels due to the fact Colt is the sole manufacturer of the M4 carbine and government inspectors were already present in their facility. The barrels would be made to the same manufacturing specifications as their standard GI M4 barrel. At around this time, the specification was changed for the barrel length. The new specification called for a 10.3 inch barrel instead of 10.5 inches. It was found that 10.3 inches was the shortest the barrel could be for installing the KAC sound suppressor. This is the configuration Colt is producing today.

Currently, Colt Defense manufactures the complete CQBR upper receivers and barrels. They are 10.3 inch light contoured barrels with a chrome lined bore and chamber with the standard 1 turn in 7 inch twist. The M4/M16A4 “F” front sight base is used to properly align the front sight with the rear. They come from Colt as per specification with the Knight Armament Company RIS as well as RAS (Rail Adapter System) as well as the KAC flash suppressors which are for use with their QD sound suppressor. The bolts provided by Colt have the black extractor buffer, heavy gold extractor spring and the rubber O-ring to enhance extraction force. As per military specification, the bolts are proof tested with a 70,000 psi proof cartridge and then Magnafluxed to check for stress fractures in the metal. According to Colt, there are several Bills of Materials for the Mk18 Mod 0. The back-up rear sights are provided by SOCOM to Colt. Normally, the provided sights are the Lewis Machine and Tool back-up sights, however; others may be supplied as well.

The Mk18 Mod 0

NSN 1005-01-527-2288

With the acceptance of the CQBR receiver, the complete weapon was type classified as the Mk18 Mod 0. The U.S. Navy/SOCOM has large stocks of obsolete M16A1 rifles that were in the navy arsenals. The M16A1 rifles were used as the host weapons for the CQBR upper receiver. The standard M16A1 rifle upperreceiver was replaced with the CQBR upper receiver. The original bolt carrier group from the M16A1 was used. Some of the original bolts were upgraded with the SOPMOD Reliability Kit including a new ejector spring that is much stronger and speeds up the ejection of the fired cartridge case. The three gas rings were replaced with a single McFarland gas ring and there was a rubber O-ring placed around the extractor spring increasing the extraction force by a factor of 4.

The lower receivers from the M16A1 rifles were modified for use with the CQBR upper receiver. The complete fixed stock/buffer assembly was removed and replaced with a telescopic stock assembly. The receiver extension plate was replaced with a 1-point sling adapter. The stock chosen was the SOPMOD stock assembly manufactured by Lewis Machine and Tool. This stock has a dual battery compartment for storage of batteries for optics. The profile of the LMT stock is triangular and is very similar to the Colt Advanced Combat Rifle stock. The receiver extension has six positions rather than the standard four of the typical GI Colt M4. Many weapons had disconnector springs replaced with the stronger carbine spring as well. However, many different stock assemblies may be seen on MK18s, although many are not “officially” authorized.

Colt provides both CQBR upper receivers as well as complete firearms. The complete firearms have CQBR upper placed on new Colt “Property of U.S. Government” marked M4A1 lower receivers. The SOPMOD stock is provided.

There is no standard MK18 configuration and the configurations mentioned in this article are the most common found. The Mk18 can be found with just about any accessory out there in use (mostly not authorized by Crane). The most common rail systems are the Knight’s Armament Company RIS and RAS. However, the NAVY EOD (Explosive Ordnance Disposal) has procured CASV-EL rail systems from VLTOR that are tan color. These weapons were equipped with A.R.M.S. #40 back-up sights. Most EOD MK18s will be equipped with M68 reflex sights on LaRue mounts, but EOTech holographic sights are showing up as well. Another interesting accessory EOD purchased was the Arrandondo magazine well adapter, which is an extended magazine well that makes speed reloading faster and easier to accomplish at night. EOD procured 1,100 tan color GripPods and A.R.M.S. #40 back-up iron sights. The GripPod (NSN 1005-01-541-1772) is a fairly new accessory introduced in 2003 that has seen major use with the Special Operations Forces as well as the military at large. The GripPod won the CQB and Midrange Bipod contract by U.S Army at Picatinny Arsenal for nearly 100,000 units. GripPod is currently shipping 200,000 GripPods to the U.S. Marine Corps to field one for every infantry marine. This vertical pistol grip doubles as a grip and a bipod. By pressing a button, a bipod springs out from the base of the grip at the speed of 1/90th of a second. The length of the unit is long enough to allow the shooter to freely maneuver with a 30-round magazine in the weapon. The unit folds by grasping both legs together and pushing them back up into the pistol grip. This enabled the troop to drop to the ground with his Mk18 and go prone, but supported.

Back-up sights are also not standard. The most common is the Lewis Machine & Tool sight. This is a fixed position rear sight identical to the standard A2 fully adjustable rear sight. If this sight is used, the optics will have to be risen to the point of aim with the sights. Also common are the Knight back-up sights – both fixed and adjustable elevation models that is part of the SOPMOD kit. Also common are the A.R.M.S. #40 and #40L back-up sights. Also used is the Matech sight. As with the M4 and M16A4 weapons, a plethora of aftermarket sights can be seen on government weapons in Iraq and Afghanistan as Uncle Sam has not had enough to go around.

Optics is not standard for the Mk18 Mod 0. Depending on what unit they are going to will determine their optics as well as availability. The most common optics would be the SOPMOD Trijicon ACOG reflex and day optical scope, and the AimPoint M68 red dot sight. Also, the EOTech holographic sight has been seen in use. The MK18 is best used with reflex sights and not magnified scopes. The purpose of the MK18 is close quarter battle and reflex sights are perfect for this task.

The Mk18 Mod O has proven itself in many different arenas of combat. The Navy uses them for boat security, boarding teams in their fleets, EOD, SEALS and Search and Rescue units. SOCOM has issued them as well. They may be seen n the hands of Rangers, Airborne troops, Green Berets as well as Operational Detachment Delta. The modularity of the M16/M4 systems is what has kept it the U.S. military’s weapon of choice for more than 40 years. Short barreled versions have served well in the caves of Afghanistan. The M4 carbine and Mk18 carbines has been the weapon of choice in Iraq for many reasons. These include increased mounted units as well as urban combat where targets are at close range. Colt Defense had designed a CQBR version of their OICW candidate with this barrel length as well. However, the OICW was a piston operated system with Colt’ proprietary monolithic upper receiver.

Another secret to the Mk18 Mod 0 carbines success is the adoption of the Mk262 Mod 1 ammunition. As a rule, the shorter commando barrels decrease the velocity of the projectile so much that a tremendous amount of energy is lost so the main advantage of the 5.56mm cartridge, hydrostatic shock, is minimized. The projectile will just go through the target or splinter and come apart. The M855 ammunition exacerbates this problem even more. As with the M4 and M16A2/A4, the inconsistency of terminal performance of the issued duty cartridge has caused problems in the Global War on Terrorism. When these thin, malnourished “evil doers” are struck with the M855 projectile, they go right through. The yaw rate is very inconsistent and varies from lot to lot. Due to the penetrator core, the accuracy potential of the weapon is not realized. The M855 is ideal for asquad automatic weapon, but not a rifle where accuracy of the single shot is more critical then laying down a heavy volume of fire on buildings, vehicles or other barriers. SOCOM saw this problem and turned to the USAMU (United States Army Marksmanship Unit). SOCOM at the time was working on the SPR, destined to be the Mk11 Mod 0 and 1 rifles. They were looking for a long range match-grade combat 5.56mm cartridge. The USAMU had already developed an incredibly accurate long range cartridge that would deal with SOCOMS issues. The 77-grain Sierra Open Tip Match projectile showed excellent sub-minute of angle accuracy. However, SOCOM needed to militarize it and turned to Jeff Hoffman at Black Hills Ammunition. They told him what they wanted, and he provided the most accurate combat 5.56mm ammunition in the world. Some of the things Hoffman did was use a stronger military brass, crimped and sealed primer, flash inhibitor and worked with Sierra to produce a 77-grain OTM with a cannulure. Not only was this ammunition incredibly accurate, but extremely and consistently lethal. Due to the long profile of the projectile, when the bullet strikes a target it quickly begins to yaw and splinter in the same manner as the M855 projectile. It would perform consistently regardless if the round came from a 20, 18, 14.5 or 10.3 inch barrel. Now SOCOM’s ammunition of choice, the Mk262 Mod 1 ammunition has proven itself in the caves of Afghanistan and Iraq. The M855 ammunition has much responsibility in the terminal performance of the M16/M4 families of weapons. The early M193 ammunition inflicted more destructive wounds than the M855. The Mk262 picks up where the M193 let off, but with the benefit of long range precision accuracy.

Research for this topic was quite difficult due to there being no standard weapon. The variations are numerous depending on where they were procured, equipment available at the time of procurement, unit purchased and individual purchased equipment used on the Mk18 Mod O. Shown in this article are the most common variations found. I would like to acknowledge the assistance of Karl Lewis, President of Lewis Machine and Tool, David Lutz of Knight’s Armament Company, William Keys of Colt Defense, Joe Moody of GripPod and Eric Kincel of Vltor for all of their technical assistance and providing the equipment to show in this detailed study.

| This article first appeared in Small Arms Review V11N7 (April 2008) |