By Richard MacLean

A story of business success based on talent, fate, timing, luck and skill in asking the right questions

This interview traces Robbie Barrkman’s progression, first as a competitive shooter and trainer on through his career as a leading figure in small arms innovation and customization. The story is a mini biography as well as a case study in how successful weapons’ businesses are conceived and evolve. Some may think that success depends on an original design and the business skills to commercially develop and market the products. William Ruger is a classic example of both a designer and a person with good business skills.

But the elements of business success are much more complicated than just these two factors. Even with an outstanding design, a business can struggle if the timing is wrong (e.g. Thompsons and Auto Ordnance after World War I). Sometimes it can be fate that links people with complementary skills together (e.g. Horace Smith, Daniel Wesson and investor Oliver Winchester). Or it can be something as mundane as asking the right questions, as will soon be illustrated.

SAR: How did you first become interested in shooting?

Robbie: My dad was a hunter and shooter since childhood. When I was a child, my mother and I would accompany him on Saturday afternoons to the range outside of Johannesburg. My mom was terrified of guns and would come along and read to pass the time. One of the women convinced her to try her luck and her first time up she absolutely drilled the targets. She had a phenomenal, natural ability and within two years was a national champion. Ironically, she never lost her unease over guns.

So basically I was born into a shooting family. My first gun was a lever-action Daisy BB rifle and I was so small my dad had to cock it. When I turned 14 – the legal age for owning a rifle in South Africa – my birthday present was a .22 BSA Henry Martini target rifle. I started shooting competition and did not enjoy it all that much. But at 18, my Dad introduced me to pistol shooting and that really caught my fancy. I started shooting ISU (International Shooting Union) matches.

Right around that time, combat shooting was beginning to generate interest in South Africa. Joe Grant-Greeson went over to the States and trained with the FBI on two-handed shooting similar to the Weaver stance instead of the usual single-handed target shooting. Within a month of his return, I was participating in his classes. We were shooting combat-style from barricades and so on and this really set me on fire.

I got some of my friends involved and we formed our first combat club. We were allowed to use a small range off to one side of my parent’s shooting club. Bill Jordan’s No Second Place Winner was like a bible to us. I had a Smith & Wesson K38 and ammunition was extremely expensive so we all had to reload. My first was one of those Lee Hand Loaders and it took me hours each week to get ready for the upcoming weekend shoots. No one had automated presses such as RCBS or Star – you just could not buy them in a commercial store. The arms embargo had a major effect on our ability to buy guns, ammunition and reloading equipment.

SAR: When did you first meet Jeff Cooper?

Robbie: We had heard about Jeff Cooper in the early 1970s. I talked to the guys and suggested that we try to get him to come out to South Africa to run a class since it would be cheaper than having the 20 of us fly to the States. In 1973, he came out for the first of three visits and stayed at my house.

I hit it off right away with Jeff. I recall first picking him up at the Johannesburg airport and there he was standing at the baggage pickup wearing cowboy boots which was unusual, to say the least, in South Africa. But on top of that, one leg of his trousers was tucked inside one of them. I leaned over and said, “Mr. Cooper, just so you know, your trouser leg is caught in your boot.” Jeff was a big man and he looked down at me and said, “I know. I do that because it makes me look different.” I knew then that this was going to be a really interesting experience. (Laughs)

Jeff was a great motivator. That first class was an eye-opener and got everyone excited. After he left, I called a meeting of the group and we decided to form the South African Practical Shooting Association. It is still in existence today. The problem back then was that without government recognition, the members could not officially represent South Africa in international shooting events.

SAR: How did you go about securing credentials for the new shooting club?

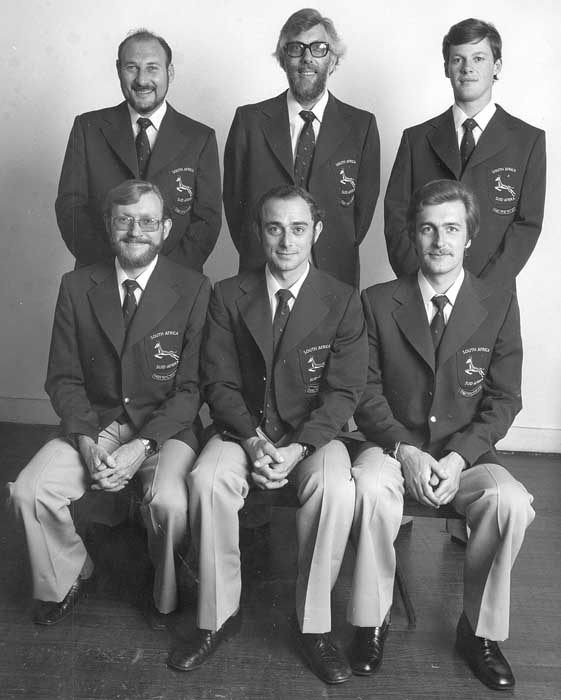

Robbie: With many things in life, it is not what you know, but who you know. (Laughs) My dad was the Chairman of the country’s Shooting Association, which was the controlling body for all shooting in South Africa. The SASA had official government support from the Department of Sports. By coming under the SASA umbrella, we could receive national recognition representing the country in international competition. Only the government could award the green blazer called “Springbok colours” to sports teams, not just shooting teams. It was a really big deal, similar to being named an All-American athlete. It was instantly recognizable within the country and even places like Australia which had a similar system.

At first, SASA really fought us for a long time since it was not traditional shooting. They thought it might be dangerous and had no sporting application. Even my own father was making comments like, “Why don’t you do something else?” Gradually, we grew to the point that they recognized that there would be benefits to coming under their charter. It took several years to convince them, but I learned very valuable negotiation skills in how to create win-win combinations that later proved useful in business.

The first officially sanctioned shoot was with Rhodesia and I went as team captain. By 1976, the group had grown to a couple of hundred and we now had the membership and money to participate in world championships. In 1976, our team participated in the second world International Practical Shooting Confederation (IPSC) in Salzburg, Austria.

SAR: What were you doing to earn a living during this time period?

Robbie: My father was a pathologist and he wanted me to go to medical school. I had no interest in spending eleven years in school so the compromise was to major in dental technology since it was five years. In South Africa, dental technologists are tightly controlled and registered with the same councils as doctors and dentists. You had to be registered to run a lab.

I started a laboratory making crowns, bridges and so on. The timing was perfect because there was a huge demand. It was extremely exacting work since patients and their doctors get very upset if the work is not perfect and even slight imperfections become obvious because of fit issues. This was my first exposure to the importance of quality control and customer service. At the time I came over to the States, the laboratory I sold was one of the biggest in South Africa.

SAR: What about military service?

Robbie: When I left secondary school (high school), I went straight into the army. In South Africa, the military is similar to those in Switzerland and Israel and does not have a standing army. It is an active “Citizen Force” with two years of basic training, then occasional weekend exercises and a dedicated one-month-per-year for three years after that. If you were able to obtain rank, you could stay on. I was in for a total of eleven-and-a-half years ultimately obtaining the rank of sergeant major.

The South African Defence Force was equipped at the time with 7.62mm FAL R1 rifles made in Pretoria under license by Fabrique Nationale. Senior NCOs could use an Uzi instead of the FAL and officers were issued a Spanish Star 9mm sidearm. I was the only NCO in my regiment allowed to carry a sidearm, specifically my Browning Hi-Power, because of my background in shooting and being a Springbok. Plus, I received free 9mm ammunition. (Laughs)

In 1976, I was asked to set up a range and training classes for officers entering the Angolan operational area. I must admit, I got a certain amount of enjoyment ordering around these officers. I had an obstacle course set up and I really put them through some tough training. But again, it was a great learning experience in dealing with sometimes temperamental and self-important people.

SAR: What prompted you to make the transition to the States?

Robbie: At the world championship, Jeff Cooper invited me to visit Gunsite, which he was in the process of building. In April of 1977, my wife and I decided to make the trip since she wanted to visit her parents living in Miami and I wanted to take a look at some dental products for my lab. It was a multifaceted trip.

I visited Gunsite as a student instructor and got a certificate that Jeff told me was the very first he had issued. We were sitting at the lunch table and it is interesting how little remarks can change your whole life. Jeff said, “Too bad you do not live here, I’d really like to bring you on staff.” I talked it over with my wife and she urged me to ask him if he was really serious. He was.

On this trip, I met a guy named Rick Durkee in Phoenix who was interested in opening a dental lab. He had a network of contacts, but no experience in setting up and running such a business. This was exactly my expertise so it had the potential for a perfect partnership. In August of 1977, we came back over to the States after working out a deal with Jeff to teach at Gunsite one week, every two months. We ended up selling the dental lab and our house in South Africa.

SAR: How did you go from part time instructor to full-time staff member?

Robbie: In the early days of Gunsite, the classes were run sporadically according to the demand. For nearly two years, I was so busy with the lab that I did not even teach a class. Then fate intervened again. I was learning how to fly and my instructor and I decided to fly up to Gunsite and use its landing strip. As soon as I arrived, Jeff approached me and asked me to come on staff full time. Right at that time, someone had approached my partner and me to buy the dental lab. It all came together. Initially, I commuted from Phoenix, but by 1981 I was a full-time instructor.

SAR: How did Robar get started?

Robbie: Before I started teaching full time, I had started to gunsmith on the side in my Phoenix house and was also repairing students’ guns in the barn at Gunsite. For liability and other reasons, I decided it was time to incorporate so I went to the Arizona Corporation Commission to fill out the forms in 1981. The woman there asked for the corporate name and I had not even given it a thought until that moment. I picked it there on the spot, “RO – BAR,” from my first and last names. In retrospect it seems odd, but at the time I did not worry about such stuff as corporate names.

Eventually, Jeff wanted me to live up there. He offered to build a home for me to live in along with an attached gunsmith shop that I leased from Jeff. I had been doing some nickel plating back in South Africa and even built my own rectifier from information I got from the book Electro-Plating for the Amateur. I suppose this machine was the very beginning of my company.

My gunsmithing and plating business really started to grow. It was great working at Gunsite because I came in contact with all sorts of agency people – some real shooters – who explained their needs and issues. Some would leave their guns for me to customize to their specifications. That’s how I got into customization.

The timing was perfect since the whole field of custom tactical weapons was in its infancy and I was surrounded by people with cutting-edge knowledge like Clint Smith and Gale McMillan. I asked a million questions and combined this knowledge with my own experience as an IPSC shooter and NCO in the army. For example, I developed some concepts for tactical shotguns and these were commercialized in an agreement with Roger Small of Scattergun Technologies.

The issue that developed was that there were two, separate businesses emerging at Gunsite: my own and Jeff’s. Jeff ran a tight ship and sometimes he could assert his views into how I was running my business. In 1986, we parted ways and I set up shop in a small portion of the commercial building I’m still in today.

With Jeff it was sort of a love-hate relationship, but I always completely respected his knowledge and talent. I last saw him at the 2006 SHOT Show in Las Vegas before he died later that year. It was really heart wrenching to see a man who was once such a big strong guy looking so frail in a wheelchair. We talked for nearly an hour and it was great to re-connect.

SAR: How did you come up with NP3 – the Teflon-based coating Robar is so well-known for?

Robbie: I dreamed that one up on the toilet. (Laughs) No, it’s true, but it obviously requires some explanation.

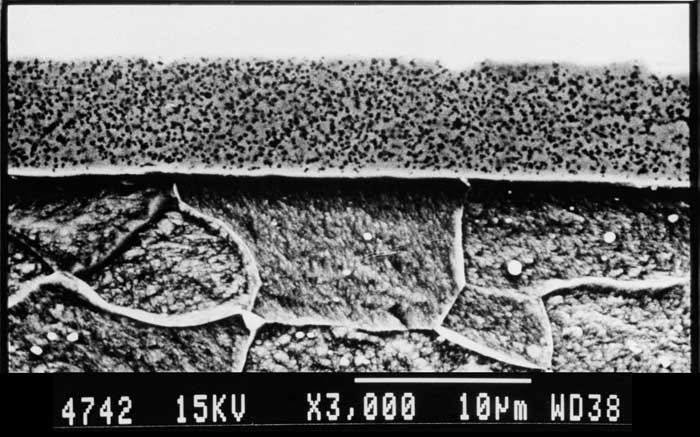

Drilling platforms in the North Atlantic were having problems with the stainless steel unloading couplings galling. The Dutch firm Akso Nobel invented an electroless nickel-Teflon coating to solve the problem, but they needed help getting it out of the laboratory and commercializing it further. The UK company Fothergill Engineered Surfaces joined them in a partnership to commercialize and market the product.

My local supplier of plating chemicals stopped by and as a joke I asked, “What do you have today that I don’t have?” This question turned out to be critical. He left a flyer on nickel-Teflon coatings. I put it aside and one morning on the way to the “reading room” I grabbed the literature and within a matter of minutes, I understood its potential. I immediately got on phone to start the process of obtaining exclusive licensing rights to weapons coating.

Dr. Paul Ebdon approached me to join us in commercializing NP3 and come over to the States. NP3 stands for Nickel – Polytetrafloride and 3 is part of the formula. Robar was predominantly custom gunsmithing in the beginning, but the coating business gradually grew, especially after a cover story article on NP3 appeared in SWAT magazine around 1987. I decided to spin off the coatings business as a separate company called Coatings Technology in 1987. What made the coatings business really take off was our entry into the aerospace business.

SAR: How did you get into the aerospace business?

Robbie: Again, fate intervened. A guy showed up one day with a disassembled Enfield .303 that was his dad’s. He needed help getting it cleaned up and back together. While he was in the shop, he noticed a pistol that had just been NP3’d. Turned out that he was a materials processing engineer working at McDonald Douglas. He was so interested in the coating that he told his manager about it. Within two weeks, she was at our shop and was so impressed that she helped us set up the necessary QC and standards manuals to become an approved vendor for McDonald Douglas. This directly helped us later getting Nadcap certified. You cannot get any business in that industry without this certification.

SAR: What is Nadcap and does this help with the gunsmithing side of the business?

Robbie: The Nadcap Program (National Aerospace and Defense Contractors Accreditation) is similar to ISO 9000 certification only much more rigorous. Mil Spec is another term that many are familiar with, but it is a minimum standard and you are not even audited unless you are doing military contract work. The trend today is to have Nadcap certification to increase the chances of success on a military contract bid. Once we got Nadcap certification, Dr. Ebdon and I went on the road marketing to the aerospace industry to get the word out about NP3.

The NADCAP process has created a quality headset in the business that we otherwise probably would not have had. From the gun coating side of the business, it means that customers get the exact same treatment on their parts as a component that is meant for some exotic aerospace unit, since we use the same coating tanks and quality systems.

Another benefit with this rigorous systems approach is that we have gotten excellent comments and no citations from ATF when they have come out to do audits. We are an 07 manufacturer and at any one time there are, let’s just say, more than a few guns around, so keeping track of these is essential for maintaining our license.

The aerospace business has enabled us to afford the equipment and staff that would be difficult, if not impossible, to justify solely by gunsmithing. It is a win for our customers and a win for us. I think it is indicative of today’s competitive business environment. You need to have some niche or advantage if you are to survive.

SAR: Speaking of business environment, what are your views on how the small arms industry is evolving?

Robbie: The really large companies such as Remington, Heckler and Koch and Winchester have the financial resources to compete in the global marketplace. There is no way that small or mid-size companies such as ours can go head-to-head against these firms in doing things like manufacturing actions for the mass markets.

Twenty years ago, companies like Robar and McMillan had little competition in building tactical rifles and competition pistols. But the technology has changed and the trend now is toward modular systems. It is possible to have companies such as Bushmaster or Less Bare assemble from components and produce an excellent weapon suitable for most needs. The components are so good now that it is even possible for the do-it-yourself gunsmith to build a weapon rivaling those of just a decade ago.

There will, of course, always be niche markets for specialized firms. For example, the small, one- and two-person shops doing custom gunsmithing and gun repair. But for larger firms such as us with 26 employees, you really must have some special advantage that sets you apart. In our case, it is our coatings technologies and our reputation for building superior tactical weapons where lives are on the line.

SAR: Thank you, Robbie, for taking the time to talk about your background and evolution of your business.

| This article first appeared in Small Arms Review V13N3 (December 2009) |