Right hand view of the Schwarzlose Model 07/12 on tripod with shoulder stock, water can and condensing hose. Note how the belt of ammo feeds up into the feed wheel housing from the bottom.

By Robert G. Segel

Andreas Wilhelm Schwarzlose of Charlottenburg, Germany was a well known and respected inventor and arms designer working out of the gun making center of Suhl, Thüringen in the late 1890’s and had many designs to his credit; particularly for self-loading pistols. By 1900, his pistols were sold widely on the European continent and even had modest sales to North and South America. But he is best known, and will always be remembered for, his machine gun which he invented and patented in 1902.

All machine guns at that time operated either by recoil (such as the Maxim) which used the recoil forces to push the barrel rearward which in turn unlocked the bolt for rearward movement, or by gas (such as the Hotchkiss or Colt Automatic Gun) which tapped the expanding gases of the fired cartridge through a small hole inside the barrel near the muzzle which then either drove a piston rearward which unlocked the bolt or impinged upon a hammer and lever which then unlocked and drove the bolt backwards. Both of these types of operating designs were complicated to make and had a large number of small intricate moving parts making them susceptible to a multitude of problems on the battle field. Schwarzlose hit upon the idea in 1902 to design a machine gun that was simple to manufacture and far less complicated mechanically. The design he came up with is known as the delayed blowback method of operation. This method allows the cartridge case to directly blow the bolt to the rear after a brief delay without any locking features of the bolt and no barrel movement. A further simplification of this operation, the direct blowback method, is now common in pistol caliber submachine guns. But for a rifle caliber gun with high chamber pressures this necessitated a unique approach to the mechanical design to prevent damage to the gun and possible serious injury to the operator. The problem was to control the rearward movement of the bolt in the initial stages of firing. With the high pressure in the chamber while the bullet is still traveling down the barrel, any premature rearward movement of the bolt will cause the cartridge case to rupture as it loses its support of the chamber walls and bolt. The design that Schwarzlose invented used an exceptionally strong recoil spring and a very heavy bolt with a series of levers and a toggle joint that operated at a mechanical disadvantage which resulted in a retarding of the rearward movement of the bolt before recoil. The last and most important element of his retarded blowback method of operation was the necessity of having to use a short barrel. The barrel on the Schwarzlose measures just 20.75 inches in length, which ensures that the bullet will exit the barrel before the recoil forces begin the rearward movement of the bolt and the high pressure can be dissipated. Unlike the Maxim, the barrel is stationary and does not move at any point of the firing process and at no point is the breech mechanism ever positively locked. Because there still remained very high chamber pressures when the extraction of the spent cartridge case began, the cartridge case would tend to “stick” in the chamber causing operational failure. This was remedied by having an oil pump located inside the top cover. The pump, with each extraction and loading cycle of the gun, would squirt a shot of oil into the chamber area thus lubricating the cases. The unlocked action designed by Schwarzlose with its lubricated cartridges, large recoil spring, heavy bolt assembly operating at a mechanical disadvantage, short barrel and resulting slow cyclic rate of fire proved itself to be an easily made, robust and simple design that worked very efficiently with overall reliability.

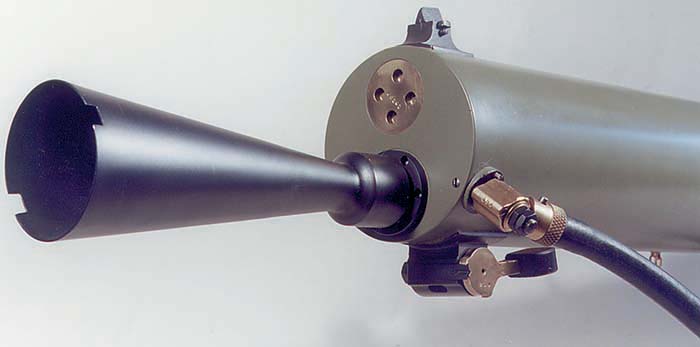

The feed mechanism was designed with heft and simplicity consisting of just two moving parts. Located on the lower right side of the receiver behind a steel or bronze housing door is a star wheel roller. The belt of ammunition is inserted up and over the roller where the cartridge engages with the sprocket. The roller is mechanically linked with the bolt so that when the bolt is in the rearward most position the cartridge that was extracted from the belt is pushed and rolled onto a ramp that is in line with the chamber. The forward movement of the bolt then seats the cartridge in the chamber. When inserting a new belt, the action must be cycled three times before the gun is ready to fire.

The grips and trigger are also of unconventional design. The wood grips fold and lock in either a vertical or horizontal position. The handles would be normally locked in the horizontal position for firing but the trigger can be activated with the handles in either position. The trigger is a wood disk located between the handles and below the gun and is operated by pushing in with the thumbs. There is a metal vertical safety switch set into the center of the trigger. This must be pushed to the side by one of the thumbs to unlock the trigger and allow forward movement. Once the trigger is pushed, the gun will continue to fire until all the ammunition is expended or the trigger is released. The gun fires full auto only with no select fire switch. However, due to the slow cyclic rate of fire of approximately 400 rounds per minute, single shots are possible by a trained and experienced gunner.

The tripod weighs in at 44 pounds and is a very stable platform for the slow and deliberate gun. On the front of the tripod is a metal stud to which an optional armored shield protecting the gunner was attached. The folding legs are locked in place by retaining bars and the legs are extendable. The elevation mechanism consists of a pair of simple toothed arced racks that are adjustable by a reduction gear connected to a turning knob allowing for precise adjustment in elevation and depression. The traversing mechanism is a simple slide that the rear pintle on the gun fits into and travels along a curved horizontal plane. Stop pins can be placed in specific holes to restrict the lateral movement of the gun to the left or right for controlled fields of fire.

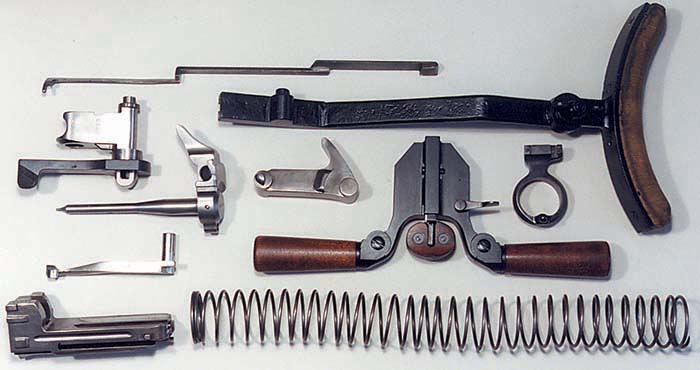

Field stripping the Schwarzlose is an exercise in simplicity since the gun breaks down into just a few parts. To field strip the gun, turn the large lever that is located on top of the rear receiver to the left as far as it will go. This unlocks the top cover which can now be raised and locked in the open position by a cover lock located near the hinge. On the end cap, just to the right and above the trigger is a rotating lock pin. Unscrew the lock pin. This allows the end cap and trigger group to be rotated to the right. Extreme caution must be exercised at this point since the powerful recoil spring will be exerting a lot of pressure on the end cap and trigger group once it is fully unlocked. Ease the butt group off and remove the recoil spring and the recoil spring guide plug from the gun. Now lift out the breech block, firing pin, crank link and crank. The gun is now fully field stripped. To reassemble, merely put the parts back in reverse order

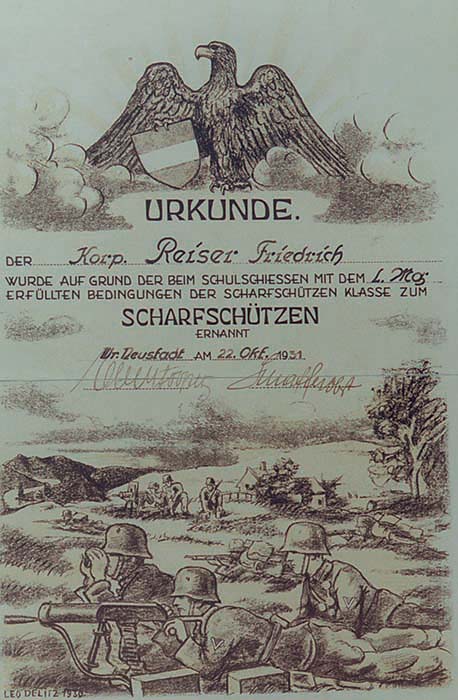

Though designed and patented in 1902, it was not until 1905 that the gun went into production at Österreichische Waffenfabrik Gesellschaft, Steyr, Austria. After a couple of years of testing, the Austrio-Hungary government adopted the gun as the Schwarzlose Maschinengewehr Modell 07. In 1912 the action of the gun was further refined by adding more weight to the bolt, increasing the size of the recoil spring and increasing the angle in the linkage action allowing for an additional fraction of a second increase in the delay of the recoiling parts. This allowed the chamber pressure to drop even more, which meant that the cartridges did not need to be oiled during operation. However, the pump was not eliminated and remained as an optional use operational accessory. The new gun became the Schwarzlose Model 07/12 and all previous models were upgraded to this configuration. Waffenfabrik Steyr manufactured the gun until the end of the war in 1918. There were two additional models of the Schwarzlose. One was the Model 07/12/16 developed for the cavalry. Though still water-cooled, it had a lighter bipod support, a shoulder stock and a shortened 100 round belt. The other was the Model 07/12/R16 for aircraft use. At first the water jacket was louvered and cut away for cooling and then ultimately removed entirely. Extension handles were fitted so the rear seat aerial gunner could aim the gun at obtuse angles. Neither the cavalry nor air versions were widespread. In the inter-war years, the gun was used by the Italians who obtained a great number at the end of the war as reparations. Other countries that used the Schwarzlose as well were the Dutch, Austria, Hungary, Yugoslavia, Czechoslovakia, Sweden and Greece in a variety of calibers. Under a licensing agreement with Steyr, Schwarzlose machine guns were later made at the Janecek Arms Works in Prague and were also produced at the Carl Gustaf State Rifle Factory in Sweden. In all, over 43,000 Schwarzlose machine guns were built.

The Schwarzlose Model 07/12 was a reliable workhorse for a number of countries for many years. Though no longer considered a front line weapon after World War I, the Schwarzlose still saw considerable service through World War II as a secondary weapon. Even as late as 1948, the old Schwarzlose was still in operation serving with the Israelis during their war of independence. The simplicity of design, ease of manufacturing and utter reliability ensured its place in history. There are only a handful of Schwarzlose machine guns in theUnited States, making this a rare and important addition to any collection.

| This article first appeared in Small Arms Review V3N11 (August 2000) |