By Robert G. Segel

The Thompson submachine gun is arguably the most often reproduced miniature machine gun since its graceful lines and well known looks enable it to be instantly recognized and provides a challenge for the machinist to make. Examples encountered run from the truly horrific with poor craftsmanship, sloppy fit and finish, milling marks and poor proportion, to the truly “Cadillac” version that is perfect in almost every detail. Made in a variety of scales, some examples observed are no bigger than your thumb and are sometimes fitted in an obligatory miniature violin case.

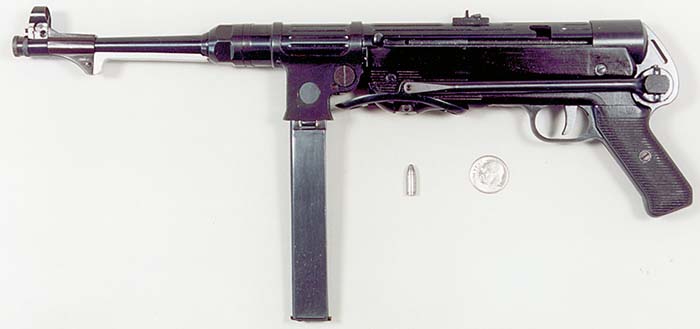

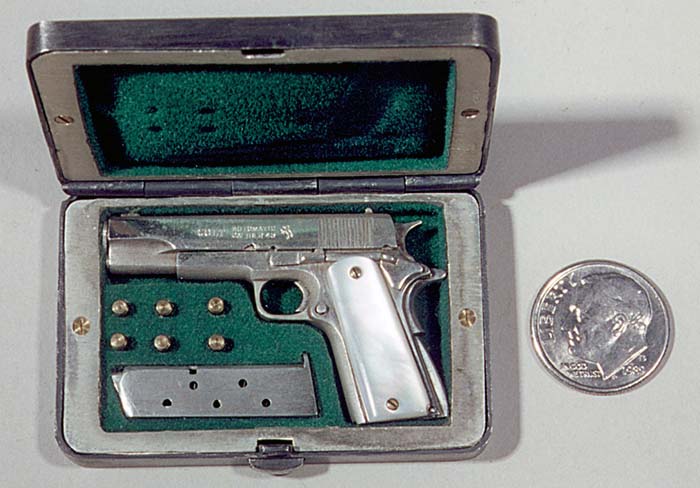

Among the finest miniature Thompsons ever produced were built by Edmund H. de la Garrigue in the mid 1970s. From his little shop in Texas, de la Garrigue offered exacting firing and non-firing one half scale replicas of the Colt Model 1921, Colt ’21/8 ‘Navy’, the Auto Ordnance 1928 commercial or U.S. Model 1928-A1 Military and the later M1 and M1-A1 models. They are exact scale and every part is hand finished to the exact dimensions. From the precise barrel finning on the ’21 and ’28 models, proper slot spacing on the Cutts Compensator and tiny sling swivels on the M1 and M1-A1 models to the proper markings and logos stamped on the gun, these really are accurate miniatures. Considering that there are over 70 separate parts to a Thompson, one can appreciate the amount of time and effort it took to produce these guns. The flat surfaces look flat, the symmetry of the lines are right and it looks like a full sized gun that was just reduced to one half size! To call it a “Teeny-Bopper Chopper”, as one reviewing journalist christened it a number of years ago, just seems a bit condescending and sacrilegious. Each de la Garrigue gun came furnished with a non-functional 20 round “XX” stick magazine. A functional “XX” magazine was available at extra cost. The ATF registered live guns were chambered for a shortened .25-ACP cartridge which is obtained by shortening the .25 auto case by 0.100 of an inch, reducing the powder charge slightly and re-seating the bullet. The firing models will fire in full automatic only because by reducing the height and width of the rocker (selector) by one half, it becomes only one fourth its original surface and it is unable to contain the slam of the .25 caliber in the semi-auto mode. The guns were made to order and customized as to functionality, serial number, configuration, etc. according to the customer’s wishes. Accessories and options included the #2 or #3 Cutts Compensators, 50-round “L” Drum (non-functional), polished walnut display stand and finned barrel where the basic gun is smooth. Records are not available but these guns were marketed for only a very brief period of time and it is generally acknowledged that only about 20 to 30 models were produced in all possible models combined in both firing and non-firing versions. Thus, they are quite rare but are a stunning addition to any collection of full autos. A relative newcomer on the miniature scene are guns made in Russia for the Imperial Miniature Armory. Producing incredibly accurate and detailed Thompsons in the even smaller 1/4 scale that measure just 81/4 inches in length, they are proportioned perfectly right down to the size of the grain in the wood stocks. Some of the parts are so small that they are hard to see without the aid of a magnifying glass and some springs are made from wire that is thinner than a strand of hair. Yet, it can feed, chamber and eject from the drum magazine the tiny dummy cartridges that are provided. They have also produced in extremely limited numbers a fully functional 1/3 scale Russian PPsH 41 complete with working drum magazine and scaled dummy cartridges and a 1/2 scale German MP 38 submachine gun. The quality and workmanship of these Russian built miniatures, particularly in the smaller scales, is truly phenomenal.

Building miniatures is no easy task and some guns would appear to be “easier” to build than others such as the British Sten series of submachine guns. We are all familiar with the history of the Sten gun and the need of the British government to produce a weapon that was not only cheap to produce but the manufacturing process was minimal as well since many parts were farmed out to cottage industries. The manufacturing techniques that applied to the originals work for the miniatures as well. But, appearances can be deceiving because in this milieu, stampings and tack welding can actually be more of a challenge to the miniature maker than machining parts from steel stock. As can be seen by the examples exhibited here made by Gorden Heasman and Jerry Missimer, even these rude and crude firearms have their quintessential character captured in these miniatures. Miniature arms makers are a breed of their own. Their passion for firearms transcends many areas of expertise encompassing history, design, engineering, metallurgy and functionality. The dedication of such notables like Louis Elkas, who worked at Savage Arms Company for 42 years and was their chief gun designer or Michael Barrett, another well known miniature arms maker, manifest itself by going home at night and producing miniature arms of all types. It could very easily take over a year to produce a working miniature that was just right but the time and effort was rewarded with a truly outstanding piece of work.

Next time – Part III: “Manually Operated Guns”

| This article first appeared in Small Arms Review V3N4 (January 2000) |