By David Lake

As the name implies, Battle Arms Development, Inc. (herein, Battle Arms, or BAD) is a product development firm. They specialize in creating new products and solutions to satisfy the needs of the hobby and professional shooter; and even solve the problems these shooters don’t yet know they have. Preemption is the Battle Arms’ strategy to successful problem solving. BAD was founded by an engineer and architect with an impressive resume in the themed entertainment industry, George Huang. He has worked for Walt Disney Imagineering, Universal Studios, and many major casino hotel resort venues around the world. His work mainly involved creating lighting and special effects displays to attract and impress the crowd. George’s superpower is that he knows what people want.

In 2009, Battle Arms Development was launched and began by offering a few armorers tools and AR-15 accessories. Today, BAD is an OEM supplier to dozens of other small arms manufacturers. There’s a good chance that your favorite boutique AR brand features the BAD selector lever as standard equipment. And BAD offers its services as a consulting firm and project development partner to a handful of new, small startups in the arms industry. Battle Arms’ latest claim to fame is that they’re an engineering and manufacturing partner to Bentwood Gunsmithing, the creators and purveyors of the world’s lightest AR-15 rifle, known as the OIP.

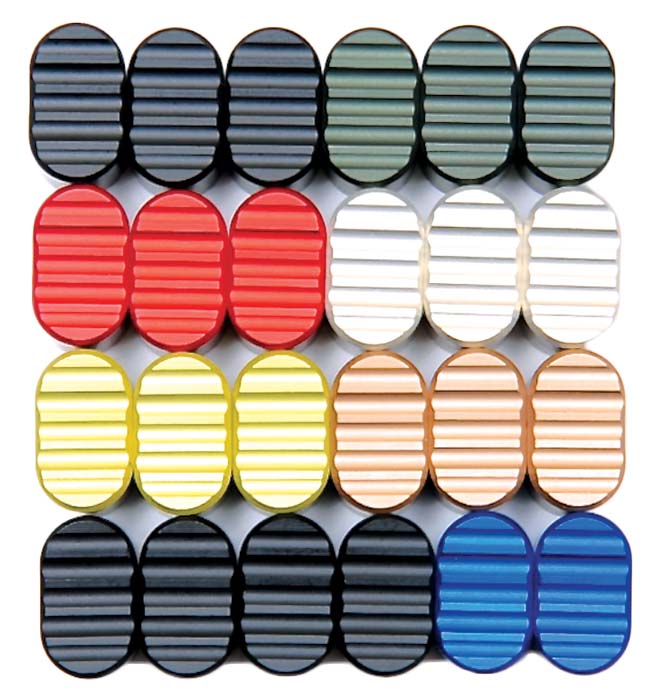

The mainstay of the BAD product line is the modular ambidextrous safety selector for the AR-15. The safety can be regarded as an innocuous and relatively simple part of the AR-15 mechanism. And that is not untrue. But George Huang is not one to accept that simple conclusion. He saw that the selector is one of the most important parts of a rifle. The rifles used in service by law enforcement and security companies may never fire, and if so, rarely. But, those same rifles may be deployed and carried and handled and loaded and unloaded on a daily basis throughout their service life. The selector lever can see more use than the trigger in some cases. And this begs the question, why then do we spend up to $400 on a trigger for our AR-15, and just accept the solid, cast safety that came in a little bag with our rifle’s small parts kit? Well, we shouldn’t. That’s the straight answer. The safety selector on a rifle is as important as the brakes on a car. The selector made by BAD has been optimized to enhance its role and utility. The selector levers are modular, that is, they can be interchanged as required to fit a shooter. The internal barrel of the BAD safety is made of hardened steel. The detent pin supplied with the safety selector kit is also harden stainless steel and features an improved geometry – this coupled with similarly refined geometry of the track in the selector barrel, where the detent rides, results in the most positive feeling safety on the market. The BAD safety delivers audible and tactile feedback to the shooter. The modular levers that are available in different lengths and profiles can also be had in many colors. There’s a BAD safety selector lever to match your new camouflage dip or Cerakote treatment. Or your selector can be red, pink, Tiffany Blue, zombie green or even raw stainless steel, just to upset the monotony of the “black rifle.” The BAD selector lever is available in two basic operating designs featuring the typical 90 degree swing and the 50 degree short throw lever. Among those two options, there are two basic constructions as well: the standard, BAD-ASS (Ambi Safety Selector) and the BAD-CASS (Combat Ambi Safety Selector), which has been “up-armored” for professional use. The CASS unit is mechanically locked together by a robust dovetail and a locking torx screw. The CASS lever is available in a select fire version also, to suit the needs of government agencies and the lucky owners of legal M16s. Battle Arms also makes a selector for the S&W MP15-22 to replace the plastic OEM part. And as a teaser Battle Arms would not confirm, but won’t deny, plans on an upcoming short throw safe/full-auto only selector with no semi-auto setting.

Another growing sector of our shooting community is long range precision shooting, also known as “tactical rifle.” This shooting discipline employs what some may call a “sniper rifle” to engage practical targets at distance, in less than ideal conditions. A shooter may be required to shoot without a bipod, or from a rooftop, or while lying in weeds or gravel. The targets may present at unknown distances, or with limited time exposures. This type of shooting has become very equipment oriented. More and more, shooters of “tactical rifle” can simply buy superiority over the other competitors. Enter Battle Arms Development. BAD did not invent the detachable box magazine (DBM) kit for the bolt action rifle, but they did indeed make it better. Most DBM devices place the magazine release button outside or far enough from the trigger guard that the shooter’s support hand is required to eject the spent magazine, and replace it with a new magazine. The BAD-DBM incorporates the magazine release paddles into the contour of the trigger guard. This allows the trigger finger to extend forward and easily reach and operate the mag release. This frees up the support hand to simultaneously go off in search of a full magazine, which cuts down reload time by half.

It should be agreed upon that Battle Arms is not really in the accessory market. It is more correct to say that BAD is in the problem solving business. One of the biggest persistent problems affecting shooters today is control and handling of their weapon. If parts and accessories don’t claim to make your gun more reliable, they probably claim to enhance its feel, handling, and control. This may allude to the shooter interface – the ergonomics of the gun, specifically, the stock and grip and forearm. It is not misleading to suggest that a rifle’s attitude and performance under fire can be tamed by a proper fit to the shooter and balance in his hands. Also, control and handling can be enhanced further by enforcing proper “hold” by the user. Technique can usually make up for technology to some degree, and vise-versa. Remember that next time someone is selling you something. Knowing this, BAD conspired in the development and refinement of a next generation stock assembly for the AR-15. Battle Arms calls their optimized lightweight butt stock the BAD-LBS. The LBS and its accompanying SABERTUBE receiver extension represent some “next gen” thinking. The length of the tube, and angle and draft of the butt plate are based on research into firearm behavior, the structure of the average human body, and the abilities and ideals of today’s shooting community. This may sound like snake oil at first consideration, but it has merit. Less experienced shooters tend to “blade” their body toward a target, or turn sideways while presenting the rifle. This position further encourages bad form by suggesting that a shooter place the rifle’s butt plate very high on the shoulder. The shooter must then bring the stock comb up to the head, which is setting atop a relaxed and vertical neck. This technique is ideal for slow fire, off-hand target shooting. This is not the way to present a semiautomatic combat rifle to a would-be assailant on the battlefield. This is not the way to carry your AR-15 onto the high-stakes game of multi-gun competition. This sideways and “open” hold of a rifle leaves the gun largely unsupported against any force besides gravity. Recoil and carryover forces from the cycling mass in the rifle will push and pull the shooter around, and recoil will push the gun back into the shoulder, then up and over and away from the shooter; off to the high one o’clock direction. By positioning oneself correctly behind and “on top of” a rifle, that rifle’s inherent control and accuracy can be improved. Proper form and hold on a rifle will reduce muzzle climb and overall recoil. Proper form will facilitate faster target transitions and make “walking fire” possible, and ultimately effective. The stock assembly offered by Battle Arms is not for decoration. It is a bolt-on performance enhancing upgrade for the AR-15. The BAD-LBS and SABERTUBE work by simply encouraging correct form and magnifying the performance enhancement afforded by the employment of proper technique. It will help you shoot better. The SABERTUBE and LBS componentry is all made from 7075 aluminum and type 3 hard-coat anodized. The SABERTUBE is honed and polished inside for smooth motion of the rifle’s recoiling mass. The unique dimpled structure of the tube promises great strength at an overall weight savings and, though the SABERTUBE’s length falls somewhere between that of rifle and carbine, it uses a standard carbine buffer and spring assembly.

Most of the ideas and innovations from Battle Arms began as inert boring parts that we see on “old fashioned” AR-15 rifles. Most hobby shooters and professionals alike are generally content with what they’ve got. Most just want “more,” not necessarily “better” when it comes to guns. But not George Huang. He has the habit of scrutinizing everything and looking for possibilities and greatness in the most mundane and inanimate things. The takedown and pivot pins on the AR have been brought into the 21st century with the BAD-EPS (Enhanced Pin Set) kit. These pins include a neodymium-iron-boron rare earth magnet that secures the detent pin in a small dimple at the bottom of the pivot pin, to assist with holding the pin while it is inserted into its pocket, atop the spring. The EPS pivot pin incorporates a shallow guide channel to maintain control of the detent pin until it snaps into the main groove on the pivot pin, thereafter remaining captive. This method facilitates a tool-free installation, and makes losing the elusive little detent impossible. One step further is the BAD-EPS-Ti. This pin kit comes crafted in 6AL-4V titanium for ultimate in corrosion resistance, strength, and weight savings. They’re also beautiful to look at. Both EPS pin kits feature improved head geometry, and increased length, both to make tool-free operation fast, easy, and painless. The EPS kits include selected premium springs and detents to ensure correct, positive function. Since Battle Arms’ involvement in the OIP ultra-light rifle project, titanium has become more common in Battle Arms’ lineup. Soon to go up for sale is an ultra-lean titanium gas block by BAD said to weigh less than the gas tube. Some firms in the gun industry shy away from the use of Titanium for its added expense and the extra care that must be taken during the manufacture of parts, but George Huang is not scared of Titanium. Keep an eye on Battle Arms for more upcoming Titanium accessories.

The magazine button is another boring item that is overlooked by everyone. Not at BAD. The Battle Arms magazine button, the BAD-EMR, has seen that the magazine release button rise to new levels of distinction. It’s made from 7075 aluminum, because it’s harder and stronger and costs more and is more difficult to machine. But it’s better, therefore it is the material chosen by George Huang to craft a simple button. They come in 8 different anodized finishes, some will match your camouflage pattern, others, like red, gold, or blue will boldly stand out against your black rifles. The EMR is slightly taller than other buttons. The screw does not protrude through the V-shaped face, and the smooth horizontal serrations allow the finger to “swipe” the button to initiate lightning fast mag changes. The extra height makes for ideal application to competitive shooting. For more serious endeavors, the magazine latch post can be cut short in order to mount the EMR lower, and below the “fence” on the receiver, to avoid inadvertently dropping a mag.

Whenever Battle Arms cannot improve on an item (where perhaps someone already has), BAD stocks and sells those optimized premium parts on his web store. Battle Arms Development stocks the ambidextrous magazine release from Norgon, anti-rotation pins, and takedown and selector detents from KNS Precision, the Fortis SWITCH rail and the SHIFT short angle grip. Also, BAD carries the modular Tactical Link sling mount, the MFT Battlelink collapsible stock and triggers from Geisele, ALG and CMC. Rainier and Battle Comp muzzle brakes as well. The consumer can buy with confidence if George is selling it. The reason Battle Arms carries these fine products from these respectable companies is that the Battle Arms brand of complete rifles (soon to be unveiled) are all built using these premium parts.

The beating heart of the AR-15 is the receiver and Battle Arms has not forgotten this. BAD offers two trim levels to their receivers. The entry model, coined the BAD-15, is a premium forged lower that features a precision wire EDM cut magazine well. The working surfaces are all CNC machined and holes are all precision reamed to size. All markings are laser engraved into the aluminum in fine detail. The Battle Arms “SPARTAN” logo shows itself in bold 3D relief. Prior to final finish, the BAD-15 is tumbled in fine abrasive media to even out the texture and marks from tooling or fixtures to produce a smooth satin surface. The receiver is finished in a Mil-Spec Type III Class 2 hardcoat anodizing.

The next step up in receivers is the BAD556-LW; available as a matched set upper and lower. It’s a departure from the norm even among the “billet” receivers of today and is a radical departure in that it weighs less than a basic forged receiver. The design takes cues from architecture. The “web and strut” can be found in skyscrapers and aircraft. It’s a beautiful and efficient way to incorporate strength and rigidity without adding more material. The overall aesthetic of the BAD556-LW finds its roots in Battle Arms’ collaboration on the OIP ultra-light rifle project. When compared to the exclusive and elusive OIP receiver (the OIP receivers are also made by Battle Arms), The BAD556-LW features a full length Picatinny rail to give the shooter a multitude of sighting options. This receiver lacks the see-through windows of the OIP allows for the use of a dust cover door. So it offers all the versatility and capability of any receiver, but weighs less and looks amazing while doing it.

The other major component of the AR-15 is the barrel. The barrel is the last influence a shooter has on a bullet before it is sent out, alone, into the world to find its target; the singular task for which all bullets are made. The barrel of a gun cannot be taken lightly and is, in fact, an iconic image today (recall a James Bond intro montage). The barrel requires supreme quality and precision and must be built to a specific purpose; the length, weight, taper, twist rate, contour and construction material all determine the role for which any barrel is ideally suited. The “one size fits all approach” is a losing strategy when it comes to the barrel on your AR-15. Late in 2014, Battle Arms released the LIGHTRIGID barrel. The thinking behind it was that if little material was used, little material would be required to support it. This is true in architecture and engineering alike as the heavier a structure becomes, the heavier it must then become to maintain strength in its operating threshold. As a barrel gets longer, it must become fatter to maintain rigidity. As a barrel becomes heavier, its spine is taxed by its own weight, and a stressed barrel will exhibit increased harmonic frequency, which leads to poor accuracy. At an extreme degree, a barrel can be made so thick and heavy, that it will not exhibit any harmonic activity, but nobody wants to carry that barrel around. The length and weight of a barrel do not directly determine inherent accuracy. Rigidity and internal finish and tolerance determine accuracy. Battle Arms set out to make the best light barrel; not the lightest good barrel. Double heat treated and cryogenic stress relieved 416 R stainless is used in the LIGHTRIGID barrel. This stainless alloy can be machined and tooled while maintaining a superb surface finish. The twist rate is 1-8 inches. This is actually the ideal twist for 55 and 62 grain .223 projectiles. 1-7 inches has found some popularity, and thus, demand in the current market. There is little demonstrable reason for a 1-7 inch barrel on a compact rifle wearing a 14.5 or 16-inch barrel. 1-7 is better suited for the DCM course, in slow fire high power competition. In fact, some high power shooters at Camp Perry still use 1-8 inch twist with bullets up to 80 grains. The LIGHTRIGID barrel has been kept to a minimum safe contour. It’s also worth mention that these barrels have extra material around the chamber and are thicker over the length behind the gas block than the standard M4 barrel profile. This is done for added safety, better accuracy and a longer service life. The gas block journal is only 5/8 inch diameter (this was the original design of the first AR rifles). The barrel is fluted across the entire length as a measure to save weight. The rifling is formed by a precision button process. The LIGHTRIGID barrel only comes with a mid-length gas system; it is preferred over the standard carbine as it runs with slightly reduced pressure and particulate in the gas charge. These barrels are chambered in .223 Wylde, an improved 5.56 NATO chamber that allows for the reliable use of all NATO spec ammo, and yet returns supreme levels of accuracy with match grade .223 ammunition. All LIGHTRIGID barrels come threaded with the standard 1/2 x 28 at the muzzle. As an option, the LIGTRIGID can be had in a 2-tone finish.

Yet to come from Battle Arms: There are rumors of their own ambidextrous charging handle, lightweight (and maybe modular) bolt stop, lightweight magazine latch, and an array of caliber choices in the new LIGHTRIGID barrel. Be on the lookout for .300 AAC blackout (subsonic and supersonic variants), 6.8 SPC, and even 7.62 NATO and 6.5 Creedmoor, whenever the BAD556-LW grows into the large pattern. There are two exciting (and unofficial) projects that are being kept in a vault, in the sub-basement of the Battle Arms’ research laboratory – a 6.8 SPC specific receiver set, to accommodate the new optimized pattern magazines, which allow the 6.8 to stagger correctly and utilize some extra room in the mag for new and better bullet profiles. This receiver pattern is very specialized; to both the bolt group and magazine, but it does let the 6.8 come into its own realm and stretch it legs rather than share space with the underachieving 5.56. Also we found an impossibly cool new take on the AR receiver. It’s a PDW monolithic receiver/stock combo. It’s a joint endeavor between Battle Arms and Cross Machine Tool. It features a sliding wire frame stock that lives in and on the receiver. The receiver is the stock and the stock is the receiver. To reiterate, the ultra-short PDW style collapsible buttstock mechanism does not attach to the receiver – it is born there. This new design cuts inches and ounces off the assembled configuration of many other offerings to this market. It comes with its own special space-saving buffer and spring system and even a beard-friendly carbon fiber cheek rest. The entire surprise will not be spoiled here, now. Suffice to say that it is an over-achieving piece of engineering and is peerless in execution. SAR will have images of this exciting receiver in an upcoming issue.

Battle Arms Development is rapidly becoming a front-runner in the race to reform and re-brand the AR-15. But BAD is not a giant disconnected company. One can actually call the office and speak to George Huang. Or you can speak to his wife (who is really the boss). Battle Arms has always held the ideals of “progress and innovation” higher than “production and margins.” Respect and reputation are also on the list of what’s important at Battle Arms. BAD seeks out and welcomes contact with and feedback from the end user of the product. Battle Arms can offer tremendous input and insight in projects or ideas to established companies or new startups. They should not be seen as a competitor, but a partner. The goal and purpose of Battle Arms Development is to make what you the shooter; weekend player or workweek professional, want and need from your rifle.

Battle Arms Development, Inc.

180 Cassia Way, Suite 510

Henderson, NV 89014.

Phone: (702) 802-3588

www.battlearmsdevelopment.com

https://www.facebook.com/BattleArms

Instagram: Battlearms

| This article first appeared in Small Arms Review V19N7 (September 2015) |