By Leszek Erenfeicht & Lt. Col. Dr. Miroslaw Zahor

The late 1980s and early 1990s were a time of change for Poland; shaking off the results of 45 years of Communist rule. Polish small arms development tried to cope with the challenges of modernity, while interacting with profound political and economic changeover of the era. By taking several far-fetched blind bets, the domestic small arms industry was able to cobble up a weapon system more or less capable of satisfying requirements at that memorable time. The problem was that history took such a fast pace that the requirements kept changing faster than the rifle itself.

Warsaw Pact enforced small arms standardization to a degree never dreamed of by the NATO STANAGs. In the ammunition field the Soviet rule was complete and unwavering – Soviet cartridge types were the only ones that Warsaw Pact countries’ martial small arms could fire. There was but one concession in that: the Czech Skorpion SMG chambered for the .32 ACP. This was for a long time a painful thorn in the Pact’s side, and finally in 1982 a “proper” Skorpion vz.82 model in 9mm Makarov was prepared – but then never manufactured because the arm itself was already considered obsolete at the time. More concessions were made in small arms manufacture: Czechoslovaks, Poles and Hungarians were allowed to have their own handguns and SMGs, and the Czechs even had their own rifle and GPMG. All of these were to be on the verge of extinction, however, with the coming standardization of the 5.45mmx39 M1974 ammunition, and matching small-arms system, consisting of AK-74 rifle (with its folding butt versions, the AKS-74 and AKS-74U carbine) and the RPK-74 LMG (with a folder sub-variant RKPS-74). East Germany and Bulgaria dutifully acknowledged Moscow’s dictate and footed a traditionally outrageous bill for the AK-74 license, but Poland, Rumania and Czechoslovakia opted for their own rifles in the new caliber. Of these, Poland chose to go the most ambitious way, claiming her industry capable not only of making its own rifle and carbine (codenamed Tantal and Onyks), but also the ammunition (codenamed Cez). These ambitious goals were set with mostly one purpose in mind: no more Soviets muzzling export sales the way they suppressed the license-built AKM sales, denying export licenses on “recipient’s possible political instability” grounds, only to sell their own rifles at discount prices a month later or so. If the Polish industry would have a rifle of their own design, shooting their own ammo, the license-right holders would have nothing to say about the export – at least on the license rights grounds.

The Tantal project initiated in 1981 led shortly thereafter to a functioning prototype of the wz.81 Tantal rifle – but as it turned out, the privilege of having an indigenous rifle called for many more years of hard work before it was finally fit for service. By 1989, when Tantal was at long last ready for introduction, both People’s Republic of Poland and the whole Warsaw Pact were on the brink of collapse. The General Staff’s ambitious plans to replace the 7.62 x39 weapons with domestic 5.45mm rifles stood no chance of fulfilling at that time. Despite that, both projects pressed on – and even a third one was initiated, when Precision Mechanics Institute with ZM Dezamet of Nowa Deba commenced work on modern bullet trap rifle grenade systems codenamed Fosforyt.

The outcome of the June 4, 1989 election made it clear that Poland wanted neither communism nor the Warsaw Pact any more. At first, the path to NATO seemed a long and arduous one with the Soviet Union still waiting for Yeltsin, and 40,000 Soviet troops still stationed in Poland, it seemed that the best thing possible under these circumstances would be some kind of neutrality, with maybe a distant hope to join NATO sometime in the far future. Plans were afoot to use the defense industry left over from the Communist times to achieve a position similar to pre-war Czechoslovakia: one of an “arms purveyor to the Third World” where Polish small arms enjoyed a reputation for good quality at reasonable prices. The Radom Lucznik factory was at that time still capable of manufacturing 70,000 rifles and 5,000 pistols per year, far more that the Polish Army – even if counting 400,000 soldiers at that time – was able to utilize. Export seemed the only way to save the factory, but for a chance to secure the more lucrative contracts, Polish industry had to go beyond the Soviet-influenced part of the world. The only way to get these was to offer models chambered for Western ammunition. That’s why Radom’s R&D Center (Osrodek Badawczo-Rozwojowy, OBR) started their first serious conversion programs, after the 1970s attempts at re-chambering the PM-63 for 9mm Luger. Now, in 1989, the OBR started to develop the PM-84P (Glauberyt SMG chambered for 9×19) and Tantal/Onyks variants chambered for 5.56×45 SS109. The ‘export Tantal’ was to achieve 90% part interchangeability with basic wz.88 Tantal rifle. Design for the 5.56mm wz.1991 Tantal rifle was ready by 1991, and a year later a 5.56mm wz.1992 variant of the Onyks carbine was also ready. Three prototypes of the former and five of the latter model were manufactured and exhibited during the 1992 MTB Arms Fair in Sopot. Unfortunately, that was all, as later on the program was suspended for three years because of lack of money to buy enough military-grade 5.56mm ammunition for further testing.

Turmoil All Around

All the while, this part of Europe was undergoing an intensive overhaul in both political and economical plane, actuated by both domestic and foreign influenced factors. On February 25, 1991 an agreement was signed in Prague to suspend the military cooperation within the Warsaw Pact as of March 31, 1991. On July 1, 1991 the political structures of the Pact were dissolved, too. During the night of August 18/19, Gennady Yanayev staged a die-hard Communists coup in Moscow. The Yanayev putsch failed because of the overwhelming sentiment of the Muscovites led by the then president of the Russian Federation, Boris Yeltsin. He led to the eventual suppression of the coup and then used it to wrench the remnants of power from the hands of the last President of the whole USSR, Mikhail Gorbachev. The process leading to dissolving of the Soviet empire was crowned by the December 9, 1991 Viskuly agreement abolishing the USSR, and replacing it with a loosely-cut structure called the Commonwealth of Independent States (CIS). The new CIS started the withdrawal of the Soviet forces garrisoned abroad, including the Northern Group stationed in Poland. The last Russian Army soldier left Poland on September 17, 1993, right on the anniversary of the Soviet back-stabbing invasion in 1939.

All through this time the Central European countries repeatedly announced their readiness to join Western military and political structures to shrug off the last ties with the period of the Soviet dominance. The first time NATO responded to that was in March 1992, in Warsaw, when NATO Secretary General, Manfred Wörner declared that, “NATO doors are open for you.” It took almost two more years before in October 1993 the Pact launched the Partnership for Peace program, duly promulgated by the January 1994 NATO summit in Brussels. From that point in time on, the future NATO-partnership for ex-Warsaw Pact countries was granted. With that, the fate of Tantal was finally sealed.

Like Father, Like Son

The 5.56mm wz.91 Tantal rifle and wz.92 Onyks carbine did not differ much from their 5.45mm counterparts, or “parents.” Basically, the most remarkable changes were different magazines and all black furniture, with longitudinal AK-74 style bulges on handguards. Black plastic furniture, including plastic magazines, became a standard at that time, replacing the picturesque medley of tans and oranges of the early Tantal. Similar black all-plastic furniture was also fitted to the last batches of the AKMS made in Radom. The reason for introduction of the plastic magazines in all three calibers (7.62, 5.45 and 5.56) was a prosaic one: Wifama of Lodz, traditional manufacturer of sheet-metal magazines for the Polish small-arms manufacturers have gone bankrupt, and magazine manufacture had to be started somewhere else and possibly use some different, cheaper, technology. A different round brought a slight increase in muzzle velocity (Tantal wz.91: 900 mps vs. 880, Onyks wz.92: 710 mps vs. 700) and energy (wz.91: 1,620 vs. 1,316 J, wz.92: 1,010 vs. 857 Joule) ratings.

Apart from that aesthetical modernization, the only few really new features were brought about in accessories for the Tantal and/or future 5.56mm rifle. The Industrial Optics Center (Przemyslowe Centrum Optyki, PCO) in Warsaw designed prototype optical (LK-4 and LD-6), collimating (CK-1), laser (WL-1) and NV (PCS-5 Gabro) sights for the new rifle family.

The 5.56mm Project is Reborn

Under the PfP, Poland signed an Individual Partnership Program with NATO stipulating that the country would join the Pact by the end of decade. Therefore, the General Staff started several radical reforms in hardware acquisition politics. In small arms ammunition all post-Soviet calibers were replaced with Western equivalents – the new intermediate rifle ammo was to be the 5.56×45, replacing both 7.62×39 and 5.45×39. The former was still used in many units, and there were billions of rounds stored, so the M43 ammo was now considered Limited Standard, while the 5.45mm was rendered obsolete overnight, manufacture closed, and Tantal rifles were to remain in the units only until meager ammunition stocks lasts; and then replaced with either new 5.56mm rifles or the AKMS, whichever was available. At the same time two crash programs were initiated: one codenamed Granulit at the ZA Mesko SA in Skarzysko-Kamienna, to replicate the 5.56mm SS109 round, and the other, codenamed Beryl at ZM Lucznik SA in Radom, to design both an assault rifle and automatic carbine chambered for that ammunition. At the same time, the PCO in Warsaw was ordered to recalibrate their range of optical and optoelectronic sights according to ballistic data of the new round. Finally money was found for ammunition to finish testing of the wz.91/wz.92 system, which was chosen as a base upon which to design the 5.56mm Beryl rifle system. The testing proved that the proposition was viable, but the new rifle needed a stouter butt and stronger receiver to better withstand repeated rifle grenade firing with a more powerful cartridge.

As early as January, 1995, the Tactical and Technical Requirements document was prepared for the new rifle by the ZM Lucznik SA, calling for “assault rifle chambered for the NATO-standard 5.56mm cartridge, effective at ranges up to 600m against troops and lightly armored vehicles” – the latter meaning that the rife grenade capability was again requested – and separate “short automatic carbine of smallest possible size, intermediate between assault rifle and submachine gun, chambered for NATO-standard 5.56mm cartridge, effective at ranges up to 400m against troops and lightly armored vehicles.”

The TTR required that Beryl would:

- fire both 5.56mm SS109 (STANAG 4172) and the older M193 ammunition;

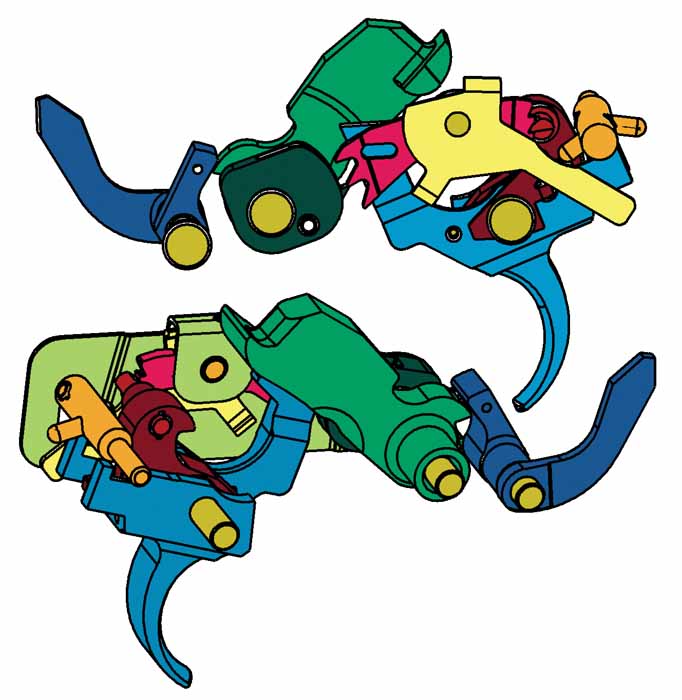

- have a trigger mechanism capable of single, burst (three rounds) and cyclic fire;

- fire both NATO 22mm boom inner diameter and Polish Fosforyt rifle grenades;

- be capable of attaching optic and optoelectronic sights of the 5.56mm modernized PCO family (CK-3 collimating, LKA-4 optical, CWL-1 optics with laser and PCS-6 NV)

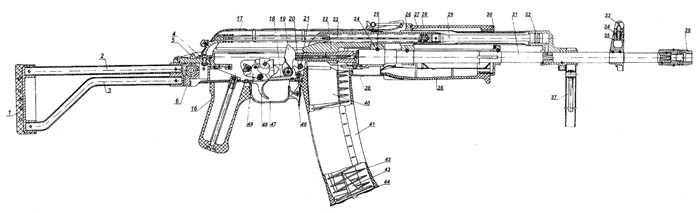

The overall length of the Beryl with butt extended was not to exceed the limit of 944 mm – the AKM heritage still ruling the size of the rifle racks in barracks and vehicles. The latter limit was used to extend the barrel from 423 to 457 mm by replacing the Tantal’s grenade launching muzzle attachment with a much simpler and shorter one screwed and pinned upon extended barrel. Unfortunately for longer-limbed shooters, the stubby butt was left at the same length.

On April 19, 1995 a contract 35/UBR/95 was signed between the Ministry of National Defense and Lucznik in Radom, stipulating that the manufacturer would finish the design, initiate the manufacturing, furnish and test 11 prototypes of the two weapons (rifle and carbine), finish the qualification testing, prepare the blueprints, manual, instructional posters – all within just 9 months. The short term suggests the extent to which the ‘new’ weapon would replicate the Tantal.

The deadline was very short indeed, and each petty problem would endanger it. Indeed, it had to be extended until December 20 because of the problems with a timely delivery of the Israeli TAAS ammunition imported for testing. After the ammo had finally been delivered and cleared customs, initial qualification testing was performed in Radom between December 1 and 15, 1995, after which the initial batch was handed over to the Military Ordnance Technology Institute in Zielonka near Warsaw, where testing was continued. The final minute listed several minor modifications, due to be introduced until January 31, 1996. On May 20, 1996 the Ministry deemed both new rifle and carbine fully compliant with the TTR, following which on August 13, 1996 another contract was signed between the MoND and Lucznik for pilot batches (18 rifles and 6 carbines) to be delivered by January, 1997. After these were delivered on January 20, Lucznik started to manufacture components for the series-production. On March 20, 1997, the Beryl rifle and carbine were introduced into the inventory of the Polish Army as the “5.56mm karabin szturmowy wzór 1996 Beryl” (5.56mm M1996 Beryl Assault Rifle) and “5.56mm karabinek automatyczny wzór 1996 Mini-Beryl” (5.56mm M1996 Mini-Beryl Automatic Carbine), along with Fosforyt rifle grenades and PCO sight family.

Beryl – The First 10 Years

Despite the Zaklady Mechaniczne Lucznik SA going bankrupt and being liquidated in 2002, the 5.56mm wz.1996 Beryl assault rifle was still manufactured for the Polish Army. Out of the ruins of the ZM Lucznik SA a new company emerged, using the pre-war name of Fabryka Broni w Radomiu (Radom Arms Factory) together with the triangular FB logo replacing the Communist era Works 11 logo of ’11 in oval’ cartouche. The demand for its smaller twin brother, the wz.96 Mini-Beryl automatic carbine was initially rather far from overwhelming, to say the least. Frankly speaking, the Tantal and Beryl are distinguished only by an extended barrel in different caliber, a 5.56mm magazine, new buttstock and handguard. For the Beryl, a new optical sight attachment support was devised as an interface between the new rifle and the PCO’s sighting devices family. This sight rail, called Podstawa Optycznych Przyrzadow Celowniczych (Optical Sight Mounting Interface), or POPC for short, was attached over the receiver, instead of the customary Kalashnikov’s side rail.

A cold-forged, hard-chrome lined 457 mm (18 inch) barrel had six grooves, right hand twist, of the universal 228 mm (9 inch) pitch, enabling to use both SS109/M855 NATO standard or older M193 ammunition. Up to this date, the Polish Army didn’t have an opportunity to use that feature, as the Polish 5.56x45mm ammunition (RS steel-cored ball and SM tracer) are fully SS109/L110 compatible. In view of the recent deployment of the Polish troops to Chad, where their logistical support would be provided by the French, it would be an interesting opportunity to test the Beryl’s ‘universal-pitched’ barrels in actual firing the M193 ammunition, as France still has the M193-only FAMAS F1 rifle as their basic infantry weapon. The muzzle device combining flash hider, rifle grenade spigot and muzzle compensator is much shorter than the Tantal’s and it is permanently fastened (pressed onto and secured with pins) to the barrel. The actual muzzle of the muzzle device is threaded to attach a blank firing attachment.

The receivers are differing with small details only. The stock hinge was beefed up and modified to take a new model stock, fitted with the POPC anchor point, and riveted with an additional third rivet to make up for stronger ammunition.

The ash-poker buttstock of the Tantal was dispensed with in the Beryl and replaced by a much more elegant twin tube design resembling the Galil stock. It folds to the right side of the receiver, just like in Tantal. The stock struts were initially (until 1999) covered with shrinking plastic tubes, giving much better thermal insulation, both from cold in the winter and – as painfully realized at the beginning of the Polish troops deployment in Iraq – from the heat as well. The two tubes are connected with a steel buttplate covered with a thick rubber shoe. The stock latch is much improved upon as compared with the Tantal. The new model latch was copied from the Swiss SIG SG-550, which also influenced the G36 stock hinge. The stock is no longer positively latched when folded; in Beryl one does not have to press the button to extend the stock – all one has to do is grab and pull, or give it a slap with left hand.

The POPC sight rail is one of the most extraordinary points of the Beryl rifle, being complicated to the point of denying the very purpose of its existence. It is attached in a very stable way by inserting two front prongs into the grooves milled at the sight base and latching the rear end with an eccentric latch over the special pin provided on the stock hinge. Unfortunately, the POPC was fitted with PCO’s own proprietary rail interface, which precluded mounting any aftermarket sight. As a further point of interest, the PCO sights had no means of moving the aiming mark. To zero the weapon, it was the POPC that got fitted with internal, eccentric controls for windage and elevation, going back to the times of the Civil War-vintage Malcolm Telescopic Sights with its sight base micrometric regulation. These were obviously designed by some dyed-in-the-wool artillerymen, the scales being marked in mils. This was definitively not a user-friendly design, requiring as many as two tools to set (a flat screwdriver and a hexagonal wrench) and requiring fast mathematics from the poor guy trying to zero his rifle. And he had to constantly re-zero it after each field stripping, as one had to remove the whole contraption any time the weapon was cleaned. Additionally, it was only zeroable to one and only distance at a time – there were no stadia signs provided at the sighting mark.

All of these drawbacks were initially hidden, as POPC and optical sights on a mere assault rifle were few and far between in the Polish Army. But after Poland joined NATO and started to implement NATO procedures and take part in overseas missions, this was to change rapidly. Starting with the first Polish contingents to the ISAF in Afghanistan (March, 2002) and Iraq (as of May, 2003), the troops started to flood the General Staff with requirements for optical and red dot sights. Very soon it was obvious that the original POPC is not compatible with the Mil-Std 1913, or Picatinny rail attachments. Ironically, the POPC was early on designed to have one of both interfaces, but as the export plans for Beryl were shelved, so was the Picatinny-compatible POPC.

The handguard was modified to allow attachment of the 40mm wz.74 Pallad grenade launcher on each rifle. In Tantal, a special grenade launcher-handguard was required to attach one. Handguard, gas tube and upper handguard attachments were left as they were in late Tantals. The rifle is fitted for rifle grenade launching and Polish rifle grenades (275 gram ‘GNPO’ HEDP grenade, 320 gram ‘NGOs-93’ parachute flare, 220 gram ‘NGZ-93’ incendiary grenade and ‘NGD-93’ smoke) are all fired with a ball cartridge.

The only big difference in actual individual rifle kit is the cleaning rod is no longer carried under the barrel in the AK-way, but now carried in two sections inside the magazine pouch.

Improving the Beryl

There were some small modifications introduced during the production run of the Beryl rifle. The fire-selector retaining catch was reinforced to eliminate the unnerving tendency of switching the selector from ‘single fire’ to ‘continuous’ under vibration of the firing. Also, the selector switch got a second, perpendicular arm, to reduce the angle required to select the 3-round burst position. The soldiers were complaining that their thumbs were too short to switch the selector position to the 3-round burst without moving the firing hand from the pistol grip. Now it was finally possible to install a sector limiter for the selector lever – this taking the shape of a simple dimple pressed to the edge of the receiver cover, interacting with the new second arm of the switch lever. The receiver cover, previously notorious for separating from the receiver by recoil of the rifle grenade launching, was in 1999 latched down with introduction of the automatic latch, replacing the manually-actuated one, itself a carry-over from the wz.60 rifle-grenade launching rifle. This is the most annoying of the Beryl improvements as the cover still detaches most of the time a grenade is launched, but the automatic latch makes re-assembling a nightmare.

Also fitting the Beryl to modern firing techniques, utilizing the front grip, and ubiquitous red dot sights proved quite a challenge. The first attempt at putting the Picatinny interface on the rifle proved a disaster. The new 2nd Generation POPC was a short one, mounted solely on the sight base by a hand-screw. The sight rail was placed on top of an exceptionally high mounting bracket, enabling to use the mechanical sights at the same time – and in full spectrum, from 100 to 1,000 meters. Theoretically it was a great invention, enabling concurrent use of both sights, but the price for that was paid by the shooter, who had to raise his head very high to use the already very high-placed EOTech 552 sight that was selected by the Polish Army. The shooters quickly got their necks stiff and, as a result, red dot sights were long considered close to useless. Even that 2nd Generation POPC was – at best marginally – suiting only the short collimating sights. To put an optical or NV sight on the Beryl, a longer sight rail placing the sight closer to the shooter’s eye was required.

However, the honors of the first Weaver-compatible Beryl go to the short-lived civilian-legal version of the rifle, called first the Beryl-IPSC, and then Radom-Sport. Two Polish practical rifle shooters from Silesia, Mr. Michal Lubinski (now owner of the Works 11 Ltd. in Katowice) and Mr. Waldemar Lipinski, then on the factory shooting team roster, set forth a list of requirements that were duly incorporated in the rifle. One of these was incorporating a long, trough-shaped sight support bar, replacing the ordinary sight. At the rear end of the trough there was a folding peep hole to use with the folding front sight post as iron sights, and the upper edge of the trough had a Weaver profile, enabling to fix optical and red dot sights on top of the iron sight channel. Later on a similar, but shorter and permanently riveted bar was used in the Mini-Beryl carbine. The civilian rifle also used some of the technologies envisioned for the never-to-be-finished Polish Minimi look-alike, the wz.2003 LMG: a new bird-cage muzzle device, folding front sight base, and the bore of the longer barrel finished with a carbon-nitrogen (Tenifer) coating for better accuracy in lieu of the hard chrome. Radom-Sport was Poland’s first rifle with enlarged controls (safety lever finger shelf, P-shaped magazine release), larger ejection opening, new shorter (5, 10, 15, 20 and 25-round magazines fully compatible with the military 30-rounders). The demand from Polish and foreign shooters was overwhelming, but the Police soon suppressed the sales, by simply denying registration and export licenses. After several years of limbo, the factory finally surrendered and the Radom-Sport rifle is no longer offered.

Beryl wz.04

Cooperation with NATO and other modern armies during foreign deployments of the Polish Army revealed many drawbacks of the Beryl rifle, mostly inherited from the old and user-unfriendly AK-47, incompatible with modern infantry rifle usage doctrine and training regimens. The military establishment traditionally opposed any changes, but then soldiers take to tinkering, forming a large grass-root movement for the modernization of the Beryl rifle. The first Polish contingent in Iraq was totally unprepared for the climate: soldiers had to handle sun-baked rifles with their bare hands, which resulted in the common sight of white rags wrapped around buttstocks and pistol grips. The second contingent already had gloves and the picturesque pirate-gang look of the first contingent was gone – wiped-off with a steel fist by the 2nd Contingent’s CG, Maj. Gen. Mieczyslaw Bieniek. This was required to restore discipline, but as usual, some of his subordinates overdid it a bit and as a result many soldiers were charged with vandalizing military property for applying camouflage, fitting foregrips, Picatinny side rails and other sensible improvements. The spirit survived though, and many photos show the results of soldier’s ingenuity, including fitting a Rumanian AKM handguard with a forward grip, or Picatinny rails bought over the Internet or from US bases’ PX, bolted to the factory hanguards.

After two years of this shadow-boxing, as the 4th Contingent was preparing to go to Iraq in 2004, a new wz.2004 Beryl rifle was on display, fitted with several features taken from the short-lived civilian-legal model, including the bird-cage flash hider, P-handle magazine release, folding front sight base, extended safety lever and a new, translucent magazine. The latter was a disaster as the clear plastic was much more brittle than the black one, shiny, and offered much too much view of the ammunition supply for comfort. Most of these were later-on painted by the soldiers, leaving just a narrow stripe on the side to control the contents. But the most awaited feature of the wz.2004 Beryl was the handguard fitted with a fore grip and side Picatinny rails as well as the new 3rd Generation POPC sight rail. The foregrip used for the wz.2004 was simply another pistol grip, proving that the designer’s knowledge of the modern practical shooting techniques was nil, but even that was still a great improvement over the older model. The side rails were just bolted to the sides of the ordinary handguard with no reinforcements inside, so the rails had no required stiffness to work properly with laser sights. The 3rd Gen sight rail was a most welcome addition, though, being a streamlined version of the 1st Generation POPC, over-the-receiver, long sight rail, with Weaver attachment interface on top. The zeroing eccentrics were gone forever as the new sights had an all-internal regulation of the sighting mark. The new POPC was a cross between the old 1st Gen rail with the civilian-legal Radom-Sport trough-shaped sight bar. It was fitted in the same way as the old one – with prongs inserted into sight base slots and rear end latched on a POPC attachment pin on top of the butt hinge, but was itself a trough-shaped one, with Weaver slots on the upper edges. The new rail was rigid enough, but completely obscured the iron sights, so later on (2007) a new version (4th Gen) was prepared, with higher trough sides, enabling the iron sight to be used for distances of up to 600 meters – and this time finally with Picatinny slots on top. The new POPC is at last a fully usable and sensible design, of length sufficient to fix the EOTech 552 holo sight with the PCO’s MU-3 NV monocular at the same time, or replacing them with a large, 1.6 kg heavy, day-or-night CKW Bazalt thermal-imaging sight unit, also of the PCO pedigree.

In 2005, another version of the modernized Beryl was presented with a side-folding telescoping, 3-position stock of Radom’s own design. The same stock was proposed for the Military Police Mini-Beryl variant, but the MPs opted for a standard stock instead. In 2007, another two variants, presented at the Kielce MSPO fair, had US-made commercial (Leapers UTG) quad rail forends and 6-position folding stocks (one by TDi and one by Leapers).

In early 2008, still another modernized Beryl demonstrator was exhibited, known as wz.2007 – but this one is more of a marketing ploy than anything else. This is just a wz.2004 with a 4th Gen POPC and folding telescoping butt, uniformly sprayed light OG all over. The new magazine was finally opaque, not translucent, and the new flash hider was compatible with the Rotex-III sound suppressor by Brügger + Thomet. The safety lever was fitted with a new device – an extension enabling the safety to be taken on and off with a trigger finger.

The Mini-Beryl carbine

Mini-Beryl is the successor to the wz.89 Onyks automatic carbine in 5.56mm caliber. Compared with the Onyks, the barrel is slightly longer (235 mm), and the muzzle device is of slightly smaller diameter. In Mini-Beryl the handguards attachment has been modified in order not to require tools (screwdriver) to strip the weapon and the furniture is attached with a push pin and not rotated with a screwdriver, like in the Onyks. The sights are taken entirely from Onyks, together with their standard tritium night inserts. The Mini-Beryl has both iron sights and optics rail as standard. This sight bar is riveted to the sight base, extends halfway back over the receiver cover, and has a flip-sight with two U-notches (200-400 m) at the end. The sight bar at first had a PCO proprietary rail to enable the CK-3 collimating (red dot) sight to be mounted directly on the weapon without the need for a POPC rail. Mini-Beryl has a standard Beryl kit, different only by replacing one of the 30-round magazines with a shorter 20-rounder. Despite the short barrel, the Mini-Beryl is still capable of launching rifle grenades, which is easily a world record, as no other compact sub-carbine in the world has this capability – probably because of its redundancy. The idea was original enough to warrant a Polish patent PL 17078 in 1997, but on the battlefield it is totally useless. Carbines are usually issued to personnel whose tasks are more important than shooting a rifle – AFV crews, command staff and so on, with neither a need nor a desire to haul rifle grenades with them. And anyone who ever fired a grenade from the Mini-Beryl would understand why – shorter barrel means more pressure, so the grenade is launched further, but so is the shooter, and woe to anyone who ever dares to shoot that grenade without safety glasses on for the unfired powder particles can be found embedded deep in the skin everywhere on the face of the shooter.

The Mini-Beryl was not officially introduced into the inventory together with the “big” Beryl. It was tested however by various special units, who ordered short batches. The first big order was by the Military Police, and not sooner than 2004 – and then in the wz.2004 version with foregrip-and-side-rails handguard. The front grip of the Mini-Beryl is the same pistol grip as the rear one, which might even work in the Beryl rifle, but here the grip most often interferes with a magazine change, especially using the 30-round magazines. The prototype wz.2004 Mini had the same proprietary folding-telescoping butt as the wz.2004 Beryl, but this was replaced by the old model folder in series-production variant. The wz.2004 Mini has got a full Mil-Std 1913 conforming sight attachment interface on the sight bar sides enabling it to be used with all compliant red dot or other sights. Also, the flip sight was changed. The U-notches were replaced by a peculiar combination of peep hole and a U-notch, both set to 300 m. In 2005, the Military Police introduced the Mini-Beryl as their standard long arm and ordered several thousand. Now, finally with a good buyer in their sights, the FB Radom improved the Mini, replacing the Onyks-inherited gas block with a new one, modifying the gas piston, and introducing a completely new bird cage flash hider. Later on the Mini was introduced in the Army (airmobile and chosen mechanized units) as well, slowly replacing the inefficient and obsolescent 9mm PM-84P Glauberyt submachine guns. Some demonstrators of that model were also fitted with commercial Leapers UTG 6-position telescoping stock.

The newest model, painted light OD overall to match the wz.2007 Beryl has a new bird-cage flash hider for the Rotex-III sound suppressor attachment.

The Midi

In 2006 another variant of the Beryl rifle was tailor-suited to the needs of the 1st Commando Special Regiment of Lubliniec. This was a ‘midi’ version, halfway between the big Beryl and the Mini, with a 375 mm barrel, almost matching the M4 barrel length of 378 mm. The short rifle was called the Beryl-Commando and featured a folding and telescoping butt – not the Radom proprietary 3-position folder-slider, but a commercial Leapers 6-positions M4-style butt installed in a hinged attachment. Later on another demonstrator was unveiled, also along the lines of the Commando – but this time with ambidextrous safety-selector lever and without the 3-round burst capability. Both models were experiments and no series production midi rifles were ever ordered.

Pros and Cons

The Beryl rifle is the last link in the Kalashnikov rifle development in Poland, carrying with it most of the AK-47’s good heritage (simple design, easy operation, reliability and durability) but also the darker side of the Kalashnikov pedigree – bad ergonomics, inability to mount and operate optical sights without having to take them off for each cleaning session, the magazine change is slow and cumbersome because of the fore-and-aft lug arrangement requiring rotating the magazine in place instead of just pushing it up, and no bolt hold-open, slowing the magazine change even more, with cocking handle hard to operate with a supporting hand. With the flat trajectory 5.56mm cartridges enabling the direct shot to 350-400 meters, fitting of the tangent leaf sight scaled 100-1,000 with 100 meters increments is a plain anachronism. More so – fitting it with a U-notch.

The Beryl is a rifle already standing with its back to the wall – there’s no way to revive it again, its modernization potential is already used to the limit. Maybe there would be another handguard model, with or without rails and fore grip, another butt stock – but without major overhaul changing the receiver design to an ‘upper-lower receiver’ standard, nothing really important can be done with it.

Nevertheless, Beryls are here to stay with the Polish Army for a while. It is a testimony to the lost chance in the 1990s, when another, more modern design could have replaced it. Let’s hope the ultra-modern piston-driven MSBS-5.56 project being now developed would succeed and the Polish Army would finally replace Comrade Rifle with something newer and more user-friendly.

| This article first appeared in Small Arms Review V13N7 (April 2010) |