This build is based on the AXTS A-DAC lower receiver. Notice the Hera Arms magazine, Tangodown vertical pistol grip with Manta grip sleeve and rail covers, VLTOR MUR-1 upper receiver and Aimpoint Comp4s and 3x magnifier on A.R.M.S. mounts.

By Christopher R. Bartocci

In Part 1, we examined two custom built AR-type rifles that were built from hand selected parts to build rifles that would exceed Mil-Specs and make a truly more reliable and durable rifle. The first was built off of a Mega Arms lower receiver and the second one was built on a new San Tan Tactical lower receiver. The third rifle is built on one of the finest lower receivers in the industry, the AXTS A-DAC fully ambidextrous lower receiver manufactured from an aluminum billet. The fourth rifle is built on the Aero Precision ambidextrous lower receiver with also Aero Precision upper and scope mount. Like the first two, all of the components are hand selected to build the ideal rifle for reliability and longevity plus ease of operation. The parts chosen were based on this author’s opinion of what are the better component and by no means is to be taken as these are the best and all others not. Any AR aficionado will have their own opinion on what feels best and looks best.

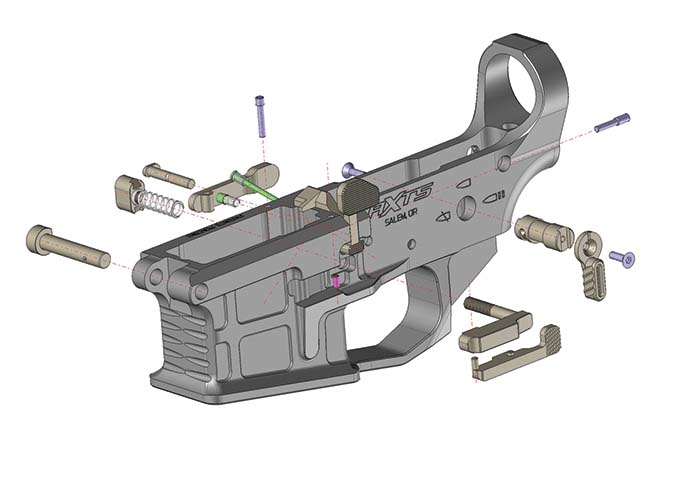

The third rifle is built on the AXTS lower receiver. This is a fully ambidextrous lower receiver that has an additional capability not found in any other. The receiver was designed to be as fully ambidextrous as possible. There is a good size bolt release on the right side of the rifle above the magazine release button. On the left side, the ambidextrous magazine release is right below the bolt catch and easily manipulated with the trigger finger of a left handed shooter. The bolt catch on the left side has a large oversized lever making for easy manipulation even with heavy gloves. The unique feature in this rifle is if it were to malfunction, the shooter would drop the magazine via depressing the magazine release button but hold the magazine catch button inward and pull back the charging handle to retract the bolt while never altering your grip. The bolt will lock open to the rear. This saves valuable time clearing a malfunction when you normally would have to switch hands to push in the lower portion of the bolt catch inward with your left thumb, and pull the charging handle to the rear with your right hand. Your firing hand never leaves the pistol grip. As received, this lower receiver came with the Battle Arms Development Ambidextrous Safety System safety lever. The receiver has a very distinctive look to it and is brilliantly machined. The magazine well has a larger bevel to it making insertion of the magazine faster, especially in low level to no light conditions. The front of the magazine well has grooves cut for better grip.

Starting at the stock, the VLTOR Modstock was again selected for its durability and comfort. The receiver extension with its 6-stock positions has numbering of all 5 positions visible through the hole in the top of the stock. The receiver extension end plate is also manufactured by VLTOR. This has a reversible design (SASE-2) that will accept a single point sling. The standard “H” buffer is used. The standard rear takedown pin was used and the front is a proprietary one to this lower receiver, slightly longer. The Magpul MIAD pistol grip was again used due to its comfort. The removable back straps make the grip custom fit to the size of the shooter’s hand. This author has very large hands so the largest insert was used making the grip as comfortable as can be for the grip as well. They have ones that hold batteries, oil bottle and a spare bolt.

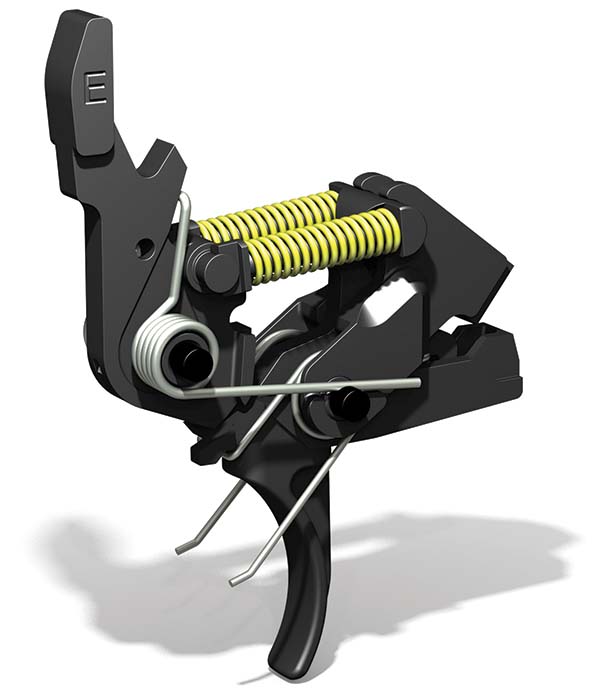

The trigger chosen for this build is the High Performance Firearms HPERFIRE. The “service” trigger model 24E offers several improvements over many of the current designs. These include faster restroke, fast and steady reset, very clean hammer release, pretravel is flat and smooth, user-adjustable low trigger weights without screws and a much faster than stock lock up and heavier hammer fall. This was accomplished in two ways. The trigger weight depends on sear friction; HPERFIRE changed the mechanical advantage to reduce the trigger weight. He changed the shape and location of the hammer and trigger sears. They added two over center toggle springs that further reduce friction while slightly increasing the hammer fall energy with the two toggle spring set up, but increasing hammer fall energy over the Mil-Spec hammer/spring. One of the major issues with reduction of trigger weight by reducing the power of the hammer spring is the possibility of misfires due to a light hammer strike on hard primers. The toggle system can prevent this ensuring reliable ignition. All in all, faster, higher hammer energy, faster lock up and a smooth light weight trigger is now possible. This gives the shooter several advantages, which include: an anti-flinch action, constant weight stroke, and single stage trigger that allows the shooter to shoot slow or fast. This trigger with the yellow springs (medium) the trigger broke at the advertised 3 1/2 pounds. This has to be one of the finest trigger groups this author has ever tested.

The upper receiver chosen is the VLTOR MUR-1. The receiver is one of the finest in the industry and quite popular with many high end original equipment manufacturers (OEM). The forward assist chosen is again the extremely high quality Iron Viper steel teardrop forward assist with a checkered pattern on the pad of it. The larger surface area of the forward assist makes it easier to use and the checkering makes for a no slip grip. The forward assist/fired cartridge case deflector is removable. You can have a forward assist/fired cartridge case deflector combination or just a fired cartridge case deflector.

The barrel chosen for this rifle is a 16-inch cold hammer forged barrel manufactured by FN USA and finished off at Spikes Tactical. Hammer forged barrels are known to last longer for accuracy and heavy use. The U.S. military has refused hammer forged barrels for the M16/M4 family of weapons because Rock Island said that hammer forging cannot duplicate the sharp leading edge of the button cut rifling which means decreased accuracy. Where the hammer forged barrels shine is the less sharp edges; without them the barrel lasts longer. The barrel has a chrome plated bore and chamber which is another additional characteristic of a longer lasting and more reliable chamber. The other feature of this barrel chosen as a reliability enhancement was a midlength gas system. The 7-inch carbine gas system has always been known to be less reliable than the 12-inch full rifle gas system. This is primarily due to the closer gas port to the chamber. This virtually doubles the port pressure on the carbine causing higher cycle rate and more importantly speeds up the extraction process. The residual pressures have not fully dropped during extraction, so the extractor has to work that much harder to pull that cartridge case out of the chamber and sometimes will result in a failure to extract. The midlength gas system finds that sweet spot in-between the 12 inch rifle and the 7 inch carbine allowing further dwell time, which allows the cartridge case to be extracted much easier creating a more reliable system. For the front sight, the A.R.M.S. #41-B silhouette sight was used. For an AR-15 aficionado, the classic look of the triangular front sight is desirable. The A.R.M.S. sight folds down out of the way and when needed, with only the lift of a finger, engages the front sight. It has the same appearance as the standard front sight post. It also has a bayonet lug. This particular one was installed by Spikes tactical and it was pinned in place. A.R.M.S. does make bolt-on versions of this front sight. This author does not care for bolt on front sights. After several experiences test firing rifles particularly hard and on automatic fire, it was found that bolted-on front sight bases will migrate forward first causing short stroke and then completely not cycle due to the gas being completely cut off. This does not happen with the pinned on front sight base; it is secure and reliable in all conditions. The VLTOR compensator was used for the muzzle device. This is a very high quality and effective muzzle brake/flash hider.

The trigger chosen for this rifle is the HPERFIRE 24E single stage trigger. The two toggle springs increase hammer spring force. The author found this to be one of the finest triggers he has ever used.

The rail system chosen for this rifle is manufactured by Centurion Arms. Centurion Arms President LaMonte LeClair is an active duty SEAL out of Crane, Indiana so this is a veteran owned business. This company is a good example of someone who designs the kind of gear he, as a Navy SEAL, wants to carry. His experiences throughout his career are benefitting his customers by producing military grade systems. The C4 Midlength (9-inch) (P/N 06099) is an incredible rail that is designed specifically for a midlength barrel. The machining is first rate. What is really nice about this is that it does not require a special barrel nut or tools to install – just a couple Allen keys. This rifle was built with just a barrel nut so the rail was placed around the barrel nut and tightened and then the front two screws were installed and that was it. If you were to have a rifle with the Delta/Slipring on it, you would need to remove that assembly. With this rail system, the barrel is fully free floated increasing accuracy and cooling. It takes all the weight of accessories off of the barrel, which is a big advantage. The vertical pistol grip is from Tangodown. Their heavy duty polymer pistol grip is a fine quality grip that is strong and robust. Lastly, Manta Rail Protectors were put on the exposed 3, 6 and 12 o’clock rails. These are the best rail covers in the industry. They are built out of a proprietary material that withstands incredible temperatures. We had gotten the rail up to 500°F and the grip panels were around 60°F. Also, they were heated with a lighter and did not burn.

The charging handle chosen is the AXTS Raptor charging handle. This new charging handle is ambidextrous and allows the shooter to disengage the charging handle latch from either side of the charging handle. The handles are large enough to actuate even with heavy gloves on.

The bolt carrier group chosen is a completely chrome plated group manufactured by Ron Smith and Smith Enterprises. They have made these carriers for many years. Chrome plated carriers go back to the initial design of the AR-10 by Gene Stoner. Chrome is an extremely durable finish, easy to clean, self lubricious and corrosion resistant. The basic reason for it being replaced with manganese phosphate is cost. Sometimes old is new. Many manufacturers have gone back to chrome carriers including Knights Armament and Lewis Machine and Tool. Smith does not believe in staking the carrier key screws. He believes that if they are properly torqued to 58 inch pounds plus some blue Loctite is plenty to do the job. Staking offers little benefit unless it is going out to the masses whom there may be a concern with taking off the carrier key and not knowing how to put a new one on properly. This particular Smith Enterprises carrier has already had over 1,000 rounds through it without a hitch. Smith claims the key to preventing hydrogen embrittlement is heat treating after the carrier is chrome plated.

The fourth rifle built for this series was build off of an Aero Precision Gen II lower receiver. This is an ambidextrous lower receiver. The right side bolt catch utilizes the PDG ambidextrous bolt release, which the receiver is cut to accept this feature. This lever sits above the magazine catch and is pushed downward to disengage the bolt release and push upward to engage. The receiver came with the Norgon ambidextrous magazine release lever. Moreover, this new generation lower came with the markings for the 45° Battle Arms Development Ambidextrous Safety System lever.

Starting at the stock, the Magpul ACS-L stock was chosen. This triangular shaped stock has two battery compartments and a lock for the latch. There is also another compartment in the rear of the right side of the stock for storage. For the receiver extension, the VLTOR A5 assembly was used. This 7 position receiver extension is longer than a standard carbine designed to convert 20 inch M16A2 and M16A4 rifles with fixed stocks into telescopic stocks. This uses a longer buffer as well. When used on a shorter barrel, this system will slightly decrease cycle rate. This is a good enhancement for any carbine. The receiver extension end plate is also manufactured by VLTOR. This has a reversible design (SASE-2) that will accept a single point sling. The rear takedown pin and the front pivot pin are the Battle Arms Development Enhanced Pin Set. This improved the gripping surface and pull strength without using oversized heads, lower profile and will not obstruct an ambidextrous safety, slightly extended (+0.030 in) over mil-spec pins and has a bullet tip guide to prevent damage to the receiver from a tool slipping off the pin and damaging the receivers. The Magpul MIAD pistol grip was again used due to its comfort. There removable backstraps making the grip custom fit to the size of the shooter’s hand. This author has very large hands so the largest insert was used making the grip as comfortable as can be. They have grip cores that hold batteries, oil bottle and a spare bolt. The Magpul Enhanced trigger guard was used as well.

The trigger chosen for this rifle is the JP Enterprises (JPFCP-1EZ) trigger set. This is a single stage match trigger that comes with two hammer springs. The yellow is for competition and the red for mil-spec harder primers. Also in the kit are oversized anti-walk pins and an adjustable/convertible selector/safety lever. The trigger breaks at 4 3/4 pounds. The trigger is fully adjustable with two screws.

The bolt carrier group chosen for this rifle is the JP Enterprises Full Mass Operating System selective fire bolt carrier. This bolt carrier is manufactured from 416 Stainless Steel and has a roller burnished finish for frictionless operation. When properly lubricated, the bolt carrier group is extremely smooth. The carrier has 100% increased bearing surface for smoother operation and improved alignment and lower wear in the upper receiver. The JP Enhanced Bolt has much greater life expectancy over the standard GI Mil-Spec bolt. The Mil-Spec standards manufactured from Carpenter 158 steel. This material is considered not the best by 2014 standards. JP makes their bolt out of SAE9310 steel, which is an extremely high grade steel and makes for an extremely hard surface with a tough, ductile core resistant to structural failure and life expectance far exceeding Carpenter-158.

The barrel on this rifle is a 16 inch cold hammer forged chrome lined barrel manufactured by Daniel Defense. Daniel Defense manufactures their own hammer forged barrels in-house. These are barrels that are military grade and manufactured to the highest standards. The barrel has been proof tested and then magnetic particle inspected to ensure against stress fractures. The rifling is the NATO 1 turn in 7 inches, which means this barrel will stabilize projectiles from 55 up to 80 grains. This barrel uses the midlength gas system which has been previously explained in detail. The gas block is a Daniel Defense low profile gas block that is pinned in place. This is far more durable than the bolt on front sight bases. Pinned on front sight bases will not migrate forward with heavy use. The flash suppressor chosen for this rifle is the Yankee Hill Machine Phantom Compensator with aggressive end cuts (YHM-28-5C2). This is a very effective and popular compensator whether sold individually or put on by an OEM.

The handguard used on this rifle is the Daniel Defense Omega X 9-inch quad Mil-Std 1913 rail mid-length free floating rail. The Omega X is really a hybrid version of the standard Omega rail. The largest difference is the way it mounts to the rifle. The X version has a smooth transition from the upper receiver to the rail. There are no external bolts. This is a 2 piece rail system that offers a continuous top rail along with 2 quick detachment ports for a sling. The barrel nut is proprietary to the Omega X and is assembled with a provided wrench. The rail stops right behind the front sight base or gas block on the barrel. This particular mid-length model can be used with a low profile gas bock on a 7 inch carbine gas system and will cover the gas block giving a longer handguard for the carbine length gas system operator. The barrel is fully free floated increasing accuracy, better dissipation of heat, as well as protects the barrel from having the weight of the accessories and force of a vertical pistol grip right on it. The rail is manufactured from 6061 T-6 aluminum and finished to Military Specification Type III hard coat anodized. The handguard weighs just 11.7 ounces with a width of 1.90 inches. Attached to the handguard is the Yankee Hill Machine folding vertical pistol grip (YHM-9640), which is covered with a Manta grip sleeve. The rails at 9, 3 and 6 o’clock are protected by Manta rail protectors, which have been previously discussed with the third rifle.

The iron sights on this rifle are a little out of the ordinary but very well thought out and very practical. Most combat rifles today have some sort of an optic on them. Some are unmagnified red dot and holographic sights. Others are 4x combat sights that are adjustable or fixed power and others use more of a long range sniper-type scope. Any magnified optic can cause some degree of difficulty with quick target acquisition at low power at best (under 4x) but when higher power scopes are involved, without proper cheek weld, acquisition is very difficult and the target may be very blurry. The Dueck Defense Rapid Transition Sight or RTS are front and rear sights (A-2 style) that mount to the front and rear of the top rail of the rifle. They sit at a 45-degree angle so when a close up target appears, with a slight 45 degree angle tilt, the shooter has iron sights to engage. The rear sight has both standard A2 long and short range apertures as well as elevation. With these being angled they do not interfere with the primary optic on the rifle. These were found to be extremely convenient and easy to use.

The optic tested on this rifle is the Bushnell AR Optics Rifle Scope 30mm tube 1-4x 24mm Drop Zone-223 BDC Reticle. Bushnell has brought to market an entire line of optics dedicated to the AR platform of rifles, everything from: precision optics, midrange optics, red dot optics and more, and all brought out at very reasonable prices. This particular optic was chosen because the role of this rifle is to be a basic combat rifle intended for close range (under 300 meters) but may be called upon for close quarters as well. For close quarter battle the scope can but put down to 1x and used effectively, but if a target appears at 50 to 300 yards the scope can be adjusted to make it effective out to those distances. The optic does have a drop zone reticle as well for adjustment at known distances. This is a lot of scope for an MSRP of $253.99 and will do all the necessary tasks asked of it. The optic was mounted to an Aero Precision lightweight 30mm scope mount. This mount cantilevers slightly making it the perfect dimensions to mount this optic putting the rear of the scope flush with the rear of the upper receiver. There is no interference with the charging handle.

Through part 1 and part 2, four “Boutique Black Rifles” have been built using numerous manufacturers’ parts throughout the industry. This is a tiny drop in the bucket as to what is all out there. The author’s prejudices did come out with a few products. Everyone has specific products they are die-hard on and I am no exception. However there are many manufacturers that specialize in specific components that will really increase the reliability and longevity of your weapon system. Many of them will make you more comfortable and much faster at manipulation of the rifle. Major reliability enhancements such as hammer forged barrels and midlength gas systems will greatly increase your reliability and longevity. But if precision accuracy is what you want, putting all your bullets through the same hole, a button cut match barrel is what you want. By knowing exactly what you want to do with your rifle, you will be able to pick out the parts that will get you to where you want to be. SAR would like to thank the multitude of manufacturers who supplied the parts to make this two part series possible. As journalists, we cannot properly do our job without all of their support.

| This article first appeared in Small Arms Review V19N3 (April 2015) |