By Charles Brown

Some wag once described a camel as a horse designed by a committee. If that’s true the M1919A6 is the camel of the light machine gun world. It looks like the small arms equivalent of a couple of kids building a dog house from scrap lumber. The combination of events that preceded the A6’s deployment in the fall of 1943 reads like a laundry list of what not to do in a weapons development program.

The U.S. Army concept of a rifle caliber, easily transportable automatic weapon for close support of high mobility troops originated with the Cavalry as far back as 1919. The Chief of Cavalry and his staff, drawing on WWI experiences, realized that in order to remain relevant in modern warfare the Cavalry would have to increase the combat power of mounted troops and proceeded to lobby the Ordnance Department for a suitable weapon. The Ordnance Department, up to its eyeballs with surplus everything, provided a weapon, the M1922 Browning Machine Rifle, which was a modified M1918 Browning Machine Rifle, later known as the Browning Automatic Rifle, with a barrel featuring a series of large diameter annular flutes or fins near the chamber end of the barrel in an attempt to improve cooling and increase sustained fire capabilities. The M1922 was also equipped with a bipod mounted on the gas cylinder tube and butt rest. The M1922 was accurate and reliable; however it had a couple of drawbacks. Even with the finned barrel it was unable to provide sustained covering fire because of overheating and the limited magazine capacity of 20 rounds.

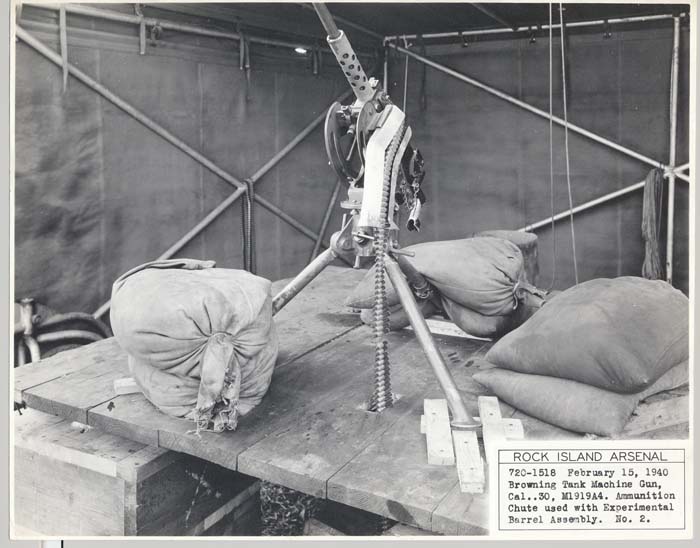

In April of 1929 the Ordnance Committee acting on Item # 7613 responded to a request from the Chief of Cavalry and furnished two air cooled M1919 Tank Machine Guns with shoulder stocks and the emergency tripod, dismounted, and one tank gun with a “modified” barrel to Ft Riley KS for testing. While there is little detail as to the nature of the modification it appears from the test results that the “modified” barrel was some sort of lightweight barrel that was thought to be able to function without the use of the gas assist booster present on the M1919 Tank Machine Gun.

In the February 6, 1930 meeting of the Ordnance Committee, the test report was read into the record as Item #8086. In short, the Cavalry found that that the tank gun with the modified barrel was wholly unsuitable due to overheating, which caused loss of accuracy and got the weapon so hot that it was nearly impossible to handle or pack. They were not very enthusiastic about the unmodified M1919’s either, actually requesting that ground type Lewis machine guns be furnished from stores for further field testing. The Chief of Cavalry also requested the Ordnance Department to develop a weapon capable of sustained fire while maintaining accuracy, being hand carried, able to be readily transported on a pack horse, and equipped with a shoulder stock, carrying handle and a light weight tripod. The Ordnance Committee obliged and recommended shipment of 25 Lewis guns and 250 47-round magazines for further evaluation. It not presently known if these Lewis guns were ever shipped or not.

What was going on here was the Calvary was pressuring Ordnance for a newly designed weapon by finding fault with whatever was furnished. Given budget restraints due to the Great Depression, a parsimonious Congress, ever paranoid of a large standing army and with the huge store of weapons left over from WWI, chances of a new weapons development program were somewhere around zero.

When the harsh realities of the situation dawned on the Chief of Cavalry he changed his tune and on August 22, 1930 he requested that the M1922 Browning Machine Rifle be replaced by the M1919 Tank Machine Gun modified by removing the telescopic sight and brackets, front sight and the auxiliary trigger and grip along with a laundry list of other changes involving front and rear sights and the emergency tripod but retaining the M1919 shoulder rest. On August 26 the Ordnance Department forwarded this request to the Adjutant General adding the proviso that the request be held in abeyance until the Cavalry actually had time to test out this theory.

While all this was going on some enterprising Ordnance officers of the 1st Cavalry Division at Ft. Bliss TX had started tinkering with the 4 M1919 tank guns furnished for pack mounting tests by jury-rigging front and rear sights, removing the auxiliary trigger and grip and changing the clamp style barrel jacket mounting of the emergency tripod to a clevis style that attached the tripod by the front mount adaptor holes in the casing. When the Chief of Cavalry arrived for a visit he was suitably impressed and fired off a letter to the Ordnance Technical Committee attached to drawings prepared by the folks at FT. Bliss showing the necessary modifications that the Cavalry considered essential. One of the essentials was an adjustable shoulder stock “firmly and permanently attached.” The eight drawings dated 8-26-30 and one sheet of revisions dated October 14, 1930 was forwarded to the Ordnance Committee, where on October 30, 1930 all of this was read into the record as Item 8523.

In 1931 the Infantry got involved and what would lead to the M1919A2, M1919A4 and the M1919A6 began to gain traction. Somewhere along the line the shoulder rest got the heave-ho. The basic design for the M1919 Tank Machine Gun was the M1917 water cooled. Converting the water cooled design to air cooling opened several cans of worms. The closed-bolt firing system and field stripping for barrel changing in the water cooled M1917 were not a big deal, providing that one kept the barrel jacket filled with coolant. Loss of the water cooling efficiency of the original design required that the barrel mass be increased to help with the heat dissipation problem. This increased the weight of the recoiling parts, which required greater energy to function the weapon, leading to the development of the gas assist “booster” design. There was only so much to be gained solving the heat dissipation problem by increasing barrel mass before the Law of Diminishing Returns took effect. No matter what you did, the air cooled Browning weapon would run hotter leading to the danger of cook-offs and rapid wear of barrels. The cook-off problem in the M1919 Tank guns and its follow-on designs was mitigated somewhat by the installation of the bolt latch which when applied held the bolt to the rear preventing chambering a round in a hot barrel and provided more air circulation for quicker cooling.

The cold hard fact was that barrels on the air cooled ground guns were going to have to be changed much more frequently, which required the weapon to be field stripped and head-spaced for the new barrel. Something designed as an air-cooled infantry weapon from the ground up like the German MG 34 and its follow-on, the MG 42, would or should take changing barrels, shoulder stocks, carrying handles and mounts into account in the original design.

The Cavalry and Infantry apparently decided that something, the M1919A2 and the M2 tripod and the follow-on M1919A4, was better than nothing, but that didn’t keep them from grousing about barrel changing and other shortcomings of the air cooled .30 Caliber ground Brownings. All this grousing about barrel changing led to some experimentation at RIA.

Ordnance was not opposed in principal to acquiring a new light machine gun and even held field trials for the foreign manufactured Hotchkiss and Solothurn weapons. The Ordnance Committee meeting on March 29, 1934 discussed the results of the trial as Item # 11357 noting that the quick change feature of barrels was looked on favorably by the Infantry. The Infantry wanted a relatively light weight weapon that was rifle caliber and belt fed capable of some level of sustained fire and able to be deployed by one man. The M1919A4 needed two men to deploy, the Gunner carrying the tripod and the Assistant Gunner carrying the A4. The M2 tripod/A4 combination weighed in at 48 lbs and usually had to be separated into two pieces to change the weapon’s position. The Infantry was aware of the German MG 34, which featured a butt stock and a bipod mounted on the weapon along with a very effective quick change barrel feature. The weapon could also be mounted on a ground mount if the need arose. This appeared to be the style of weapon best suited to the perceived task. Ordnance wanted to purpose-build a weapon to serve the Infantry’s needs. However the system in use at the time to solicit designs, develop new weapons, and test, field trial, and mass produce took years. The Infantry, well aware of the time required to approve new weapons, needed something to satisfy their needs yesterday, not years down the road.

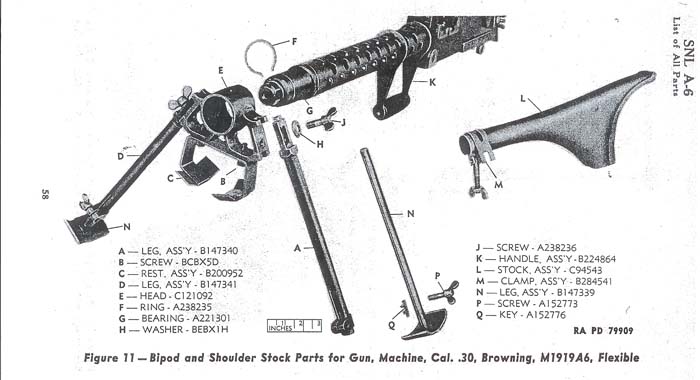

Much wrangling back and forth ensued with the Infantry suggesting that the M1919A4 currently in production could be modified at little cost using non critical materials to satisfy their immediate needs and some new weapon could be developed at a later date. By early 1943, Ordnance agreed to develop a kit of accessories to be furnished to adopt the M1919A4 to the configuration that the Infantry desired. During development and testing of the new accessory kit, Ordnance discovered that this was not going to be a stroll in the park due to design and parts logistics issues and decided to purpose-build and name the modified weapon M1919A6 Major Item 51-125 and declare it a substitute standard. The business of the quick(er) change barrel resurfaced and got incorporated in the design concept.

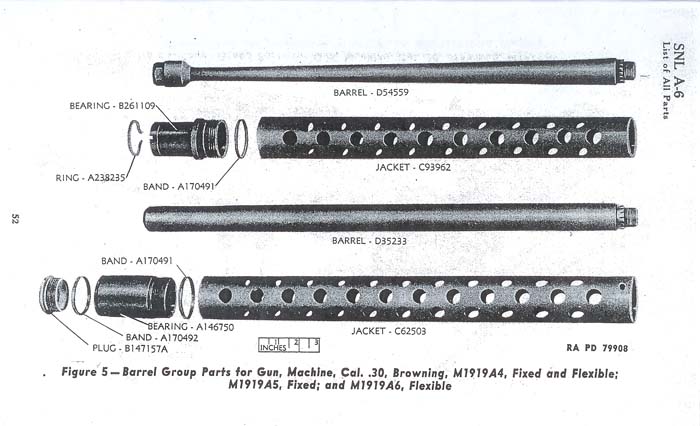

The whole business of changing the A6 barrel profile, which made it lighter, is usually wholly misunderstood. It was never about making the weight of the weapon lighter, which it did; it was about making the barrel and hence the recoiling parts lighter and solving one of the M1919A4’s design deficiencies. All of the air-cooled Cal. .30 Browning ground guns were makeovers from the M1917 water cooled design which was a pure recoil operated weapon. The M1917 design used a 3 lb. barrel that was changed by field stripping the weapon. When the air-cooled Tank gun was designed it was necessary to increase the mass of the barrel to aid in heat dissipation. Since the barrel needed support at the muzzle, a ventilated jacket with elongated slots was designed. This heavier barrel increased the weight of the recoiling parts and since the energy from the firing of the cartridge needed to operate the weapon remained the same, Browning had to come up with additional energy from somewhere. Browning developed the “muzzle attachment” later known as the front barrel bearing which besides supporting the end of the 18-inch long 5.6 lb. barrel provided a chamber closed off with a removable “muzzle attachment plug” having a hole that aligned with end of the muzzle. During the very short time the projectile was in this chamber expanding gas from the burning propellant applied rearward force to the end of the barrel adding additional recoil energy and making these weapons recoil operated gas assist.

Coming up with this solution, Browning reached back to his roots and his original “device” which used the combustion gasses exiting the muzzle to move a plate with a hole that the projectile passed through which was attached to a rod to cycle the action of a rifle. When the designers of the A6 lightened the barrel they were doing so to eliminate the need for the gas assist function. By shortening the barrel jacket and adding wrench flats to the muzzle which protruded far enough to allow the barrel to be unscrewed from the barrel extension from the muzzle end and withdrawn from the front and a new barrel to be installed in the reverse manner.

The decision to reduce the barrel mass attempting to get a front change barrel was probably not a good one. The M1919A4 with its 7.5 lb. barrel was already marginal on overheating during sustained fire and reducing the mass did not make a tenuous situation any better. The Saginaw Steering Gear Division of General Motors, the premier quality, low cost and high production manufacturer and, after July, 1943 the only maker in regular production of the M1919A4, was selected to be the producer/developer of the new weapon. Saginaw got busy and fabricated new parts that were cast using an alloy developed by Saginaw Malleable Iron, one of their subsidiary companies. This alloy, a perlitic malleable iron, called ArmaSteel, had been developed pre-war to cast certain automotive parts that were difficult to machine.

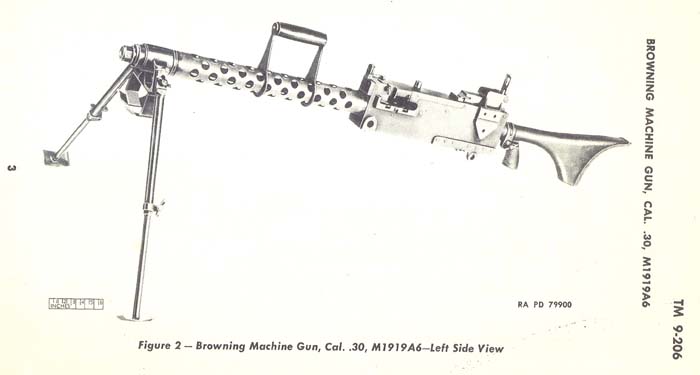

A review of the Ordnance Department drawings of A6 specific parts shows a common original date on the majority of the drawings of 7-23-43 and this author takes this to be a convenient date to cite for beginning of production. Other than the added parts, the weapon remains an M1919A4. And just like the A4 with the addition of a pintle, the A6 could be mounted on any tripod that would accept the A4. Like all the other M1919’s, the A6 could use either ammunition supplied in fabric belts or metallic link belts.

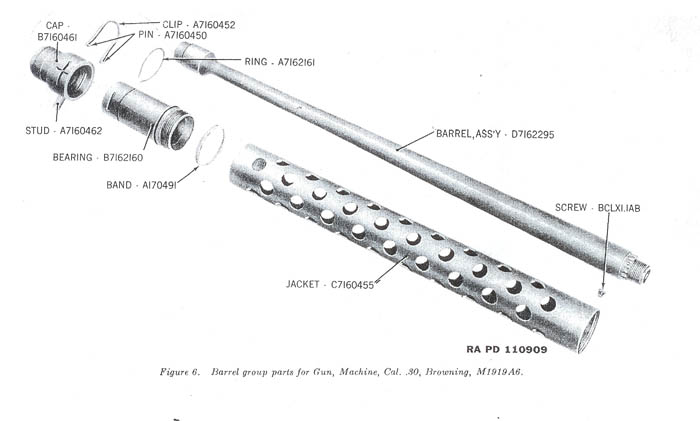

The first combat application of the 1919A6 occurred in the Salerno area of the Italian Campaign in the late fall of 1943 and later in the Anzio area in January of 1944. Things did not go well. While engineering assessments showed that the weapon as fielded lacking any booster would function, it failed its combat test. The principal shortcoming was a reliability issue, a lack of reserve power to function the weapon when dirty or firing with the muzzle depressed below horizontal. The lightweight barrel also made overheating even more severe. Ordnance engineers reviewed the problem and decided that even with the lightened barrel maybe John Browning with his idea of the gas assist booster was on to something. Back to the drawing board, literally. Not wanting to forgo the front change barrel concept the designers came up with a cap style booster removable without the need for a tool. This design required a different front barrel bearing and an even shorter barrel jacket.

The cap style booster solved the reserve recoil energy problem but as with all things one problem begets another. The clip that held the cap to the front barrel bearing was easily dislodged allowing the cap to fall off the bearing, and to make things worse, the retaining clip that held the bipod head on the bearing was prone to slipping off allowing the entire bipod to slide off the bearing.

In time all these problems and a few others were solved. A different style booster cap retaining clip with a locking feature replaced the earlier design along with a thicker retaining ring for the bipod head. Development of .30 caliber Stellite barrel assemblies and later chrome lined bores and front barrel bearing surfaces for the A6 improved the wear characteristics of the barrel. Another feature developed late WWII was the design of the flash hider/booster for both the M1919A4 and the A6. However this accessory was not in regular production until 1950.

Post-Korea the M1919A6 got a new look with the new carry handles, originally designed in 1944, which was clamped to the barrel jacket and the M7 booster/flash hider with the locking style clip. This style of wood carry handle was adapted to the M1919A2 BAR and the M1917A1 water cooled Browning.

The M1919A6 soldiered on past the introduction of the M60GP machine gun in 1957 and into the very early stages of the Viet Nam war and with Army Reserve and National Guard units until nearly 1970. The M1919A4 and A6 in stores became fodder for various military assistance programs, especially to Israel.

The Israeli Defense Force proceeded to convert these weapons to 7.62×51 NATO and decided to use the original concept of furnishing a kit of accessories so that any M1919A4 could be become more or less instantly an A6 wannabe. This allowed the use of the standard A4 profile barrel simplifying supply issues and helped with overheating. They re-designed and fabricated a new bipod with fixed length legs and a spring loaded plunger that engaged the holes in the bottom of the barrel jacket allowing the bi-pod to be positioned anywhere on the jacket. The IDF version of the carry handle has a solid plastic handle and the champing bolt is equipped with a wing nut for easier adjustment. The IDF butt stock is a near exact copy of the USGI stock except for Hebrew script on the upper right rear surface.

Total WWII production includes about 44,000 purpose built weapons produced by Saginaw Steering Gear along with an unknown number of conversions from M1919A4s and A5s. Post war and through the Korean War, RIA both rebuilt M1919A4s and A5s into M1919A6s and produced about 8400 new purpose built 1919A6 models. According to the RIA Historical Summary for the period 1 July 1955 to 31 December 1955 the last 3 new built M1919A6s rolled off the RIA production line. The last mention of RIA’s connection with the M1919A6 was the rebuilding of 432 M1919A4 to M1919A6 configuration between 1 July 1957 and 31 December 1957. Following the transfer of engineering and support activities for these weapons back to the Springfield Armory on 12 July 1957 Saco-Lowell Shops produced a small number of purpose built M1919A6’s along with maintenance parts.

| This article first appeared in Small Arms Review V16N2 (June 2012) |