By Michael Heidler

During World War II, the Japanese military forces only used a few different flare pistol models. The Imperial Army used almost exclusively the single-barreled Type 10 in caliber 35mm; however, flare pistols with several barrels came into service with the Imperial Navy with the Type 90.

The designation Type 90 comes from the year of introduction, calculated according to the then valid Kōki calendar, in which the era begins 660 BC. The Type 90 was therefore introduced in the year 2590, according to the year 1930 in our calendar. The weapons themselves are not marked with a model designation. It is only found in documents.

The flare pistols Type 90 were developed by the weapon factory Nambu and were produced in two different configurations: Kayaba Seisakusho made them with two barrels and Kayaba Kōgyō with three barrels. The Imperial Japanese Navy used both of them throughout the end of the War. On the two-barreled model, both barrels are positioned parallel to another. On the three-barreled model, the third barrel is placed along the top center of the two parallel barrels. The functioning remained the same. In contrast to the Army, the Navy chose a slightly smaller caliber of 28mm. This means that the ammunition was not interchangeable.

A spring-loaded, non-breeching lever is placed below the bottom barrels, which when pulled, allows the breech to be opened for loading. Empty casings are extracted by a central extractor placed in the middle of the three barrels. Rectangular, colored markings on each barrel indicate which type of cartridge is to be loaded in which barrel. On the triple barrel Type 90 these are:

- Right barrel: two green stripes with a black stripe in between;

- Left barrel: two red stripes with a yellow stripe in between;

- Upper barrel: a wide white stripe.

The empty casings are pulled out by a centrally placed extractor.

All three barrels are color-coded, depending on the type of flare rounds to be loaded.

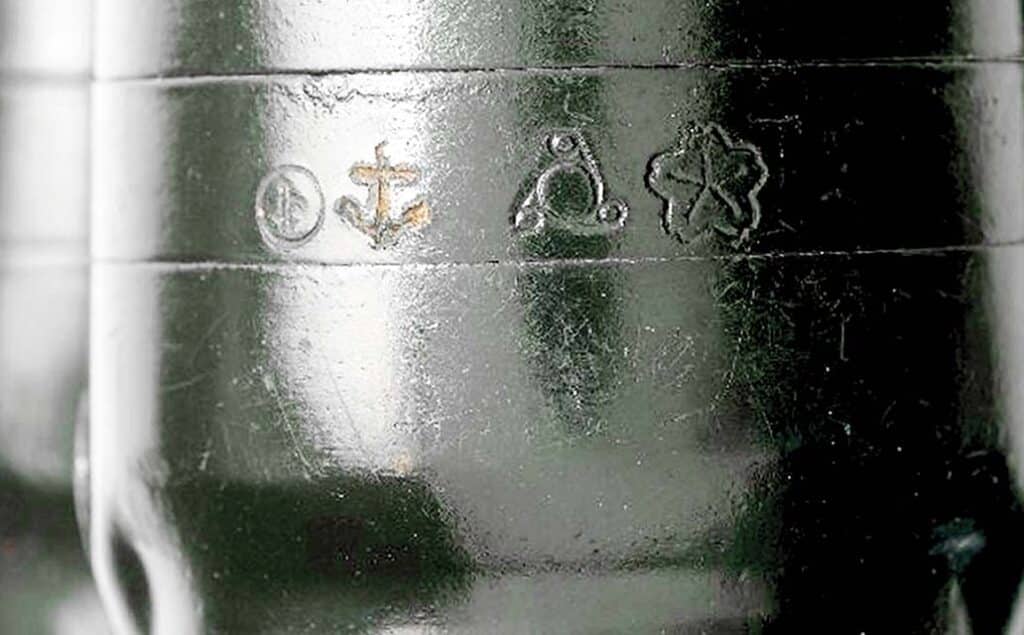

The white stripe represents standard flare rounds for illumination in the dark. The barrel with the green stripes was loaded with a black smoke round for obscurement to disturb the enemy’s view. And the barrel with the red and yellow stripes was used for all sorts of color-coded signal rounds. The markings are mostly decals, but on some weapons they were completely painted or restored with paint. The entire weapon is otherwise covered with a black lacquer to protect it from the salty sea air and splash water. On some weapons, the barrels were blued instead of lacquered.

A rotating lever on the back of the upper receiver is used for cocking all three barrels. The operator turns it about 150 degrees counterclockwise before letting it snap back to its vertical resting position. Now all three firing pins are cocked. There is a small control hole behind every barrel, and in the cocked position the rear end of the striker for each barrel protrudes through its hole as a cocking indicator. The barrel is selected by a smaller lever located below the cocking lever: right for the right barrel, left for the left barrel and center for the center barrel. It is not possible to fire two or three barrels simultaneously.

When the weapon is fired, the upper assembly moves backwards on the grip frame. Here it is in the rear end position.

Both Type 90 models incorporate a recoil buffering system to absorb, at least partly, the heavy recoil. When the weapon is fired, the upper assembly moves backwards on the grip frame against spring pressure. It is only a short distance of movement of about 1/8 inch. A manual safety switch is located on the left-hand side of the weapon above the pistol grip. The lower position is “safe” (white letter) and locks the trigger. When set on “fire” (red letter), the trigger is allowed to be pulled for firing. On the double-barrel model the center position acts as an additional safety.

When the safety switch is pushed down, it blocks the movement of the trigger.

Markings on the housing, such as the Navy acceptance mark (anchor) and the maker’s mark of Kayaba.

Modifications

Over time, the design of the three-barreled Type 90 has undergone some modifications. Some were production-related, others offered small improvements. The early variation had wooden grip plates and a vertical break-open lever with finger recess. This recess soon disappeared, and later, grip plates were made from Bakelite. In the last variation, the redesigned break-open lever was curved, and the barrel selector lever engaged in detents for positive identification of the selected position. The most striking design change, however, affected the receiver. It was for many years made of two parts, connected together between the barrel assembly and the action housing. On later variations it was only made of one piece.

A carrying bag with shoulder strap was issued with each weapon. Most of them were made of leather, but there are also a few known made from canvas. Instead of a printed manual on paper, the bag contained an aluminum plate with printed instructions. These plates made more sense than paper, considering the tropical climate on the Asian islands and the humidity at the high seas.

Leather pouch for the triple-barreled Type 90.

Rarity

In the entire production period from 1930 to 1945, only about 6,000 pieces of the triple-barrel model have been produced according to Japanese sources. The number of the two-barreled model varies around 10,000 pieces, depending on the source. But according to American foreign weapons research reports, the total number of flare pistols manufactured in Japan for military purposes in World War II was only about 30,000.

Naval weapons are very rare today. When Japan surrendered in September 1945, there was not much left of the once proud Imperial Navy. Most flare pistols had gone down with the ships. And what survived received little attention, because the American soldiers preferred to collect “real” pistols, rifles and edged weapons as souvenirs.

| This article first appeared in Small Arms Review V24N4 (April 2020) |