By Christopher R. Bartocci

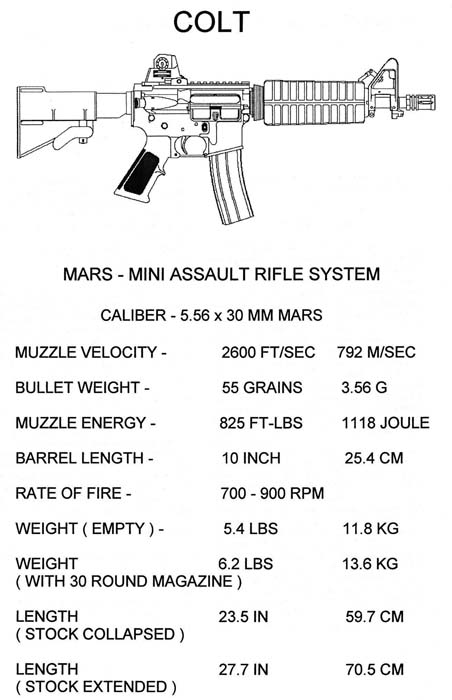

The concept of a PDW (Personal Defense Weapon) is to provide personal firepower in between that of a pistol and a carbine. Several attempts have been made: the 5.7x28mm caliber by FN, the 4.6x30mm by Heckler & Koch as well as the 6x35mm by Knight’s Armament Company. The U.S. military has asked from time to time for lighter and more compact versions of the M4/M16. Colt was involved with one in particular, showed up with it and then told it was nice but they really do not have a requirement for it.

Around 1997, Colt’s Manufacturing Company, Inc. went to work on a new project. Colt was approached by Michael Harris of Special Analytical Services (SAS) with a concept of a mini-assault rifle that would have the purpose of being a personal defense weapon as well as have law enforcement and military applications. By design, the intent of the MARS was to replace the 9mm pistol as well as numerous variations of submachine guns. A Colt development team, headed by Engineer James Taylor, set out to bring Harris’ concept to life. The MARS was designed with the concept of having a smaller and lighter weapon that could win a fight against an AK47. The MARS was, and still is, different from the FN and the H&K cartridges. The 5.7×28 and 4.6x30mm cartridges primary purpose was to defeat body armor. Unfortunately after they defeat the armor, they have very poor terminal performance. They are ballistically very similar to the .22 Winchester Magnum cartridges. Harris believed the MARS could replace 80% of all pistols and submachine guns as well as up to 20% of rifles and carbines.

The 5.56x30mm Cartridge

The MARS fired a newly developed 5.56x30mm cartridge. Ballistically, the 5.56x30mm MARS cartridge is very similar to the .221 Fireball. The new cartridge was developed to enhance accuracy and range over current cartridges such as the 9mm NATO and 5.7x28mm. The MARS cartridge exploits the high energy densities of modern ball powders. The 5.56x30mm cartridge would be effective out to 300+ meters. Another goal was to enhance lethality over existing small submachine guns. The 5.56x30mm cartridge would have the penetration capabilities of the 5.7x28mm cartridge but have increased lethality over that as well as 9mm NATO ammunition. The MARS cartridge was a wildcat cartridge that was never made in quantity. All 5.56x30mm ammunition was hand loaded by Michael Harris. The cartridge began with the standard 5.56x45mm cartridge case. It was trimmed down and formed in a custom die to the proper dimensions of the 5.56x30mm cartridge. It was loaded with a 55gr full metal jacket boat tail (M193 Ball bullet), 62gr full metal jacket boat tail with penetrator core (M855/SS109 bullet) as well as a tracer bullet. Using the 55-grain bullet, the MARS rifle would fire it at a muzzle velocity of 2,620 fps out of its 10-inch barrel with muzzle energy of 838 ft/lbs. There was a problem found with the pressure levels within the 5.56x30mm MARS cartridge as the case was prone to bulge or rupture.

The MARS cartridge can be loaded to any mission specific configuration which could include hollow and soft point bullets as well as ball and armor-piercing. It is loaded up with magnum pistol-type ball propellant, which is burned at rifle pressures to achieve higher velocity in its short 10.5 inch barrel. The MARS is battlesight zeroed in at 200 meters and the path of the bullet stays within approximately 3 inches of the line of sight. The 5.56x30mm bullet will penetrate a Kevlar helmet and vest at 300 meters. The MARS was also chambered for the 9x30mm MARS cartridge which was a necked down 10mm magnum cartridge case.

There were three prototypes made during the course of development. The upper and lower receiver, bolt and stock assembly were all shortened. According to Colt’s MARS Project Manager Jim Taylor, every component was basically walked through the manufacturing process. The components nearly all started out life as standard M4 components and were modified to MARS specifications. Due to the shorter 5.56x30mm cartridge, a new magazine was created. This enabled the magazine well to be shorter contributing to the shorter upper and lower receiver. The magazine was made from a standard GI 30-round magazine. Material was removed from the middle and welded together. The follower was cut down as well. The magazine was merely a prototype and very clumsy but worked well for the testing and proof of concept.

The overall length of the collapsible stock was shorter than the standard carbine. The front portion of the stock just ahead of the locking latch was removed of an inch. Due to the shorter buffer tube a modified buffer was designed. It was similar in design to the standard buffer, just shorter. Due to the decrease in length, two tungsten weights were used and with the use of tungsten, the smaller buffer was nearly identical in weight to the standard H buffer.

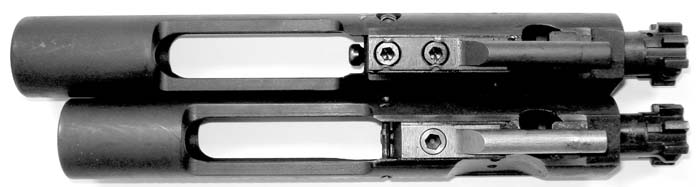

The bolt carrier was shortened overall, particularly the rear behind the bolt carrier key and used a modified firing pin. The carrier key was shortened and only has one carrier key screw. The firing pin was shortened and the rear head was removed. The rear of the firing pin is visible from the top of the bolt carrier. The bolt is the standard rifle bolt assembly.

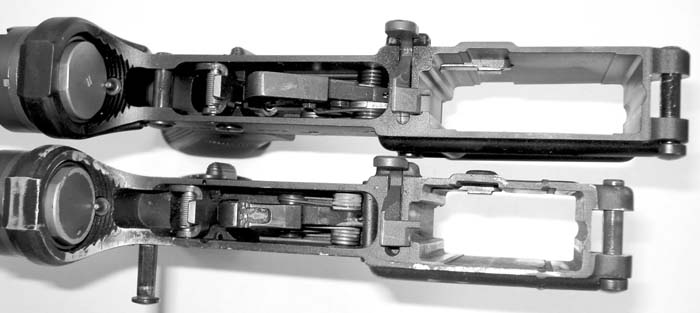

The lower receiver was modified to make it more compact and to accept the shorter magazine. The magazine well was cut in the middle, material removed and electron beam welded back together to accept the shorter magazine. This is easily seen in the prototype due to the bottom of the magazine well not being straight. The new process of electron beam welding allowed the fabrication of prototypes for a relatively modest cost. According to Colt project leader Jim Taylor, the MARS rifle may have been the first extensive use of electron beam welding for firearms prototyping. Due to the desire to maintain the bolt design and existing cam path in the bolt carrier, the MARS rifle had to modify the location of the hammer/trigger pins, selector lever and the automatic sear had to be moved slightly rearward. On the prototype MARS lower receivers, the fire control holes were drilled as per mil-spec for the M4 carbine. The original holes had to be plugged and new ones drilled in the proper location. Due to the hammer being moved rearward, a large steel roll pin was installed to prevent damage to the lower receiver if the trigger was pulled without the upper receiver installed. If the hammer was to fall on the aluminum receiver it would damage the receiver because it would hit the inside of the receiver on an angle rather than square. Due to the firing pin head being shortened, a pocket was cut into the hammer where it will strike the firing pin. This pocket allows the hammer to strike the firing pin square rather than on an angle. Also, if the disconnector was to fail, the firing pin could not protrude through the breech face to detonate the primer unless the bolt was locked. Additionally, if the hammer was to ride the bolt, there would not be sufficient energy to fire the cartridge. The MARS was designed to make use of as many existing machines and fixtures as possible to minimize the potential cost of going into production.

The upper receiver was made shorter as well. The upper receiver was cut right in front of the fired cartridge case deflector, material removed and electron beam welded back together. Additionally the ejection port dust cover was shortened. Standard handguards were used as well as the gas tube. The bayonet lug was removed from the front sight assembly. The 10-inch barrel uses the standard 1/7 inch twist and has the standard A2 compensator. The top of the barrel is stamped “MARS” to denote the caliber.

Preliminary Colt testing of the MARS indicated some highly desirable characteristics. Although relatively small, the weapon pointed like a rifle. The MARS equipped with a 1.5x optical sight firing low impulse 5.56x30mm cartridges at a relatively low cyclic rate appeared to many who fired it to be one of the easiest weapons to learn how to shoot. In hindsight, it appeared the use of the proprietary 5.56x30mm cartridge was an impediment to selling the weapon. Colt wanted to have a proprietary cartridge. Perhaps a more suitable solution would have been to go with the already currently available .221 Remington cartridge. With modern propellants, the .221 Remington cartridge may have been loaded to achieve the goals set out by Harris and Taylor for this proof of concept, and to do it without chamber pressure problems.

MARS was patented on October 27, 1998 (U.S. Patent Number 5,827,992) by Colt engineer James Taylor and Michael Harris (founder of Specialized Analytical Services). Unfortunately the MARS never found acceptance and never entered production. The main interest in the MARS was by the Israelis as a possible replacement for their police Uzi SMG. This was exactly the type of market the MARS was designed for. The production numbers that were discussed would have been 2,000 guns per year for a term of 10 years. Due to this low number of units versus the cost to tool up for the MARS, Colt decided against going into production. Colt had also felt that introducing a new compact firearm would hinder sales of their M16A2/M4 carbine variations.

I would like to thank Project Leader Mr. Jim Taylor for his assistance with this article by providing first hand knowledge of this program. I would also like to thank Colt Defense for providing access to photograph this interesting prototype weapon.

(Small Arms Review contributing editor Christopher Bartocci works as a Technical Specialist for Colt Defense LLC. The articles written by this author are of his own research and evaluation and in no way represent those of Colt Defense LLC.)

| This article first appeared in Small Arms Review V12N4 (January 2009) |