By Robert G. Segel

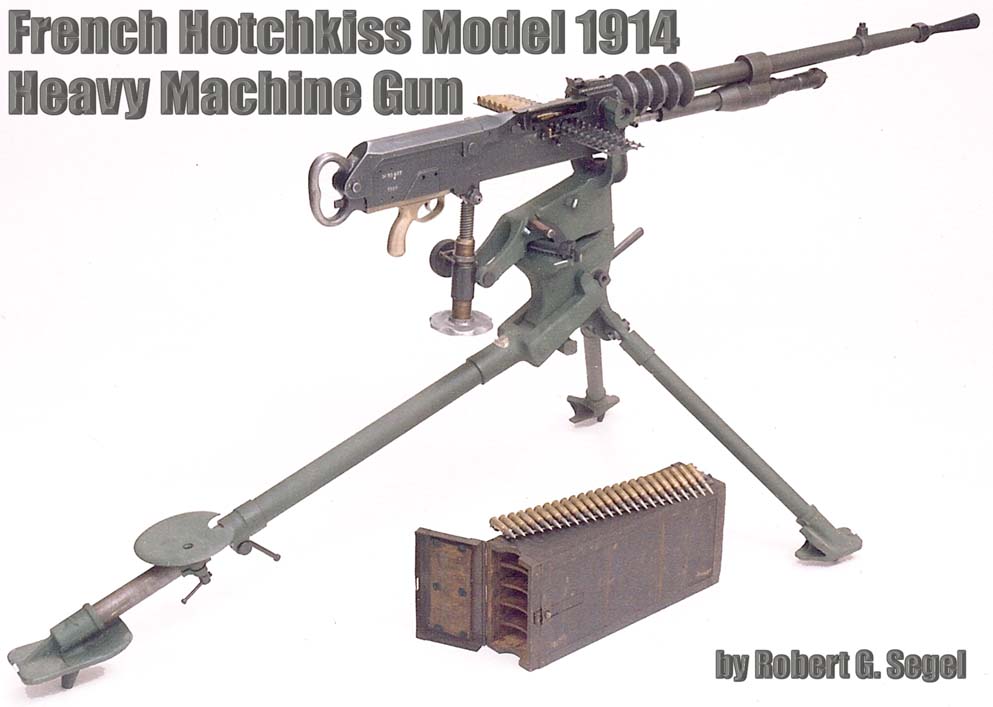

The Hotchkiss Model 1914 was the standard French Army heavy machine gun during World War I. It was also the primary heavy machine gun of the United States A.E.F. (American Expeditionary Force). Heavy but rugged and dependable, the Hotchkiss Model 1914 saw continuous service along the entire line of the Western Front for the full duration of the war (1914-1918). It continued in French service after the war in France’s Colonial endeavors and as a secondary armament role within Europe up to and including the Second World War.

History

Upon Hiram Maxim’s success in harnessing the energy of the recoiling forces in producing the world’s first truly automatic machine gun, inventors everywhere attempted to design firing mechanisms that replicated the full automatic function without infringing on Maxim’s patents.

One such inventor was a young Viennese nobleman and officer in the Austrian Army. Captain Baron Adolph von Odkolek had successfully designed and constructed a prototype gas-operated machine gun and sought to market his invention. In 1893, he traveled to the world famous Hotchkiss manufacturing facility in St. Denis, France, just outside the city limits of Paris, to see if they would be interested in building his gun.

Laurence Benét, head engineer and promotion manager, and his assistant Henri Mercié, were actively trying to come up with a new machine gun when Odkolek came to them in 1893. They tested Odkolek’s prototype and were generally unimpressed with it due to overheating problems. They did, however, recognize that there were certain mechanical features; particularly the simple operation of a gas piston housed underneath the barrel that they saw as extremely promising. Benét refused to manufacture Odkolek’s gun on a royalty basis, but instead offered to buy the patent rights outright so as to pursue and refine the development of the operating system. Odkolek agreed and a lump sum payment was negotiated in return for assigning all manufacturing rights to Hotchkiss.

Benét then started work on designing a new gun using Odkolek’s operating principles. His new gun was chambered in 8mm Lebel and was gas-operated employing a simple reciprocating piston that did not infringe upon John Browning’s patent on a gas-operated gun that used a swinging lever as used on the Colt Automatic Gun.

The first model of the new gun was tested at the St. Denis factory by Laurence Benét in 1895. In honor of Benjamin Hotchkiss, the founder of the company, the gun was named “the Hotchkiss.” Instead of feeding ammunition from fabric belts, the new gun used metal strips, each containing 30 rounds. Shunning the use of a water jacket for cooling, the new gun was air cooled. A brass shoulder piece, or stock, was permanently attached to the frame. While mechanically the new gun performed better than they had hoped, they found that the heavy barrel they used overheated too quickly destroying the rifling after a relatively small number of rounds had been fired.

Hotchkiss Model 1897

The solution to overheating that Benét came up with is a design feature that to this day defines the Hotchkiss machine gun – the large doughnut rings around the breech area. Benét knew that more metal mass was needed around the breech area to absorb the heat generated at this point, but just adding solid metal would add tremendous weight to the gun. Instead, he introduced brass circular doughnut-shaped fins at the critical area around the breech. This provided ten times the surface area around the breech area and added little weight. This was incorporated into a new model: the Hotchkiss Model 1897. The French Army adopted this weapon and purchased a limited number of the Model 1897 as they were particularly keen on it being air-cooled and lighter in weight than the water-cooled Maxim. Water source was a problem in the desert environment of the French colonies in Africa and the Hotchkiss solved a logistics problem. The gun proved to be fairly reliable, but was still prone to overheating even with the massive brass cooling fins. Though there were minor improvements in the next two models, the basic gun remained the same as a gas-operated, air-cooled, strip-fed machine gun.

Hotchkiss Model 1900

The refinements that occurred in 1900 mostly centered on making adjustments to the original mount. Since overheating was still a problem, the brass doughnut cooling rings were replaced with steel ones and the barrel was redesigned with a lower carbon content to help extend barrel life in a sustained fire mode.

The Hotchkiss Model 1900 achieved a great amount of success and was sold world wide with many going to Mexico and Japan. The first conflict between major powers in which machine guns were employed by each participant was the Russo-Japanese War of 1904 and ’05. The Russians were equipped with Maxims and Madsens, while the Japanese had the Hotchkiss. The Japanese were very impressed with the Hotchkiss design and after the war obtained a license to produce them in Japan – ultimately adding some design features of their own resulting in the Type 3 and Type 92 heavy machine guns.

During the Russo-Japanese War new and old tactics were tried in the use and deployment of machine guns and thus began the learning curve of the capabilities of machine guns in actual warfare. The French, British and Germans had observers taking notes during the war noting the use, deployment and tactics for use in their own applications. The Germans learned quickly. The British and French did not.

While the French Army had a few of the Hotchkiss Model 1900s, they embarked on a program to develop their own machine gun produced in their own government arsenals. They felt they could do it better and did not like paying royalties to a commercial firm such as Hotchkiss for the use of a gun. The result of their effort was the ignominious Puteaux Model 1905 and the St. Etienne Model 1907. (See SAR Vol. 6, No. 11, August 2003 Mitrailleuse Saint Etienne Mle 1907.)

When World War I broke out across Europe in 1914, France found itself at a serious disadvantage due to a small stock of automatic arms consisting of the already outdated and complicated St. Etienne Model of 1907 and some Hotchkiss Model 1900s. But France was fortunate in the sense that it had a domestic company with a proven machine gun that could tool up for large mass scale production in a very short period of time. With a few more minor tweaks in production methods and materials, and the removal of the shoulder stock and replacing with a simple D-grip, the new weapon of war was the Hotchkiss Model 1914. The reliable qualities of the Hotchkiss were quickly recognized by the entire army, and were issued as front-line equipment with a large number of brigade companies having been formed and equipped with this weapon.

The best instance, among many, demonstrating the efficiency of the Hotchkiss was in the spring of 1916, during the heroic defense of Verdun, when a section armed with two Hotchkiss machine guns held its position near Hill 304 for ten consecutive days and nights. Entrenched 150 yards behind the crest, which the Germans were endeavoring to seize, this unit repulsed unaided all assaults, mowing down the succeeding waves of attack as they reached the summit. During these ten days, the section, cut off from all supplies and communication expended over 150,000 rounds of ammunition. The original and normal supply of a section was 5,000 rounds. Fortunately, a dump of infantry cartridges was near at hand and all hands, including officers, set about reloading the feed strips, thus enabling the section to carry on to the end. When it was realized that each gun fired upwards of 75,000 rounds and still were serviceable, one must admire the robust nature of the Hotchkiss and its reliability.

The U.S Army Arrives

When the American Expeditionary Force arrived in France in 1917 with no machine guns, the French provided enough Hotchkiss Model 1914s to equip the first 12 Divisions. Ultimately, 5,255 Model 1914s were delivered to the U.S. troops with 224 per Infantry Division, with 16 per Infantry Regiment and 16 per Machine Gun Company. Later Divisions were additionally equipped with Colt Vickers Model 1915 and lastly the Browning Model 1917, which saw only limited service.

The Hotchkiss proved as reliable and robust in the hands of the Americans as it was with the French; filling the role as an offensive, defensive and anti-aircraft weapon. The hard learned lessons of use and tactics by the French were taught to the newly arrived US forces during 1917 and 1918. When US troops finally entered combat in 1918, their use was employed with efficiency.

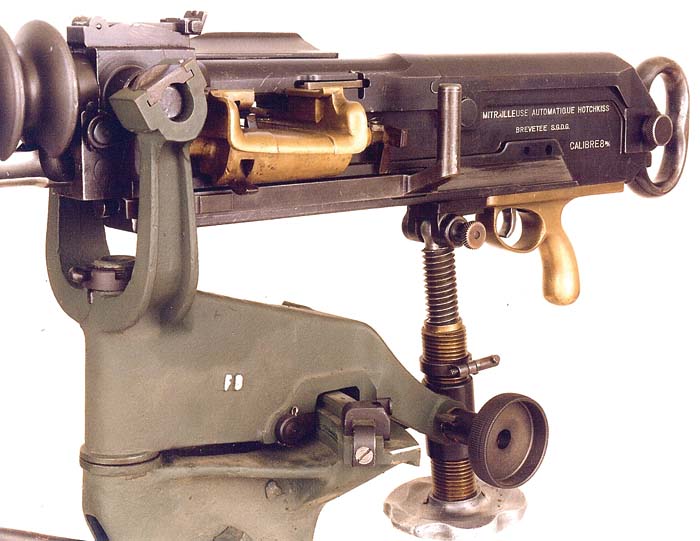

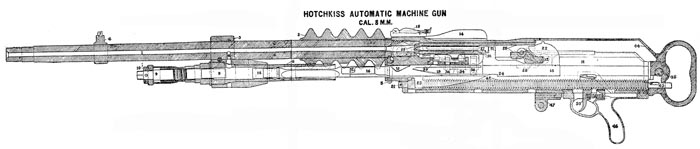

Description of the Hotchkiss M1914

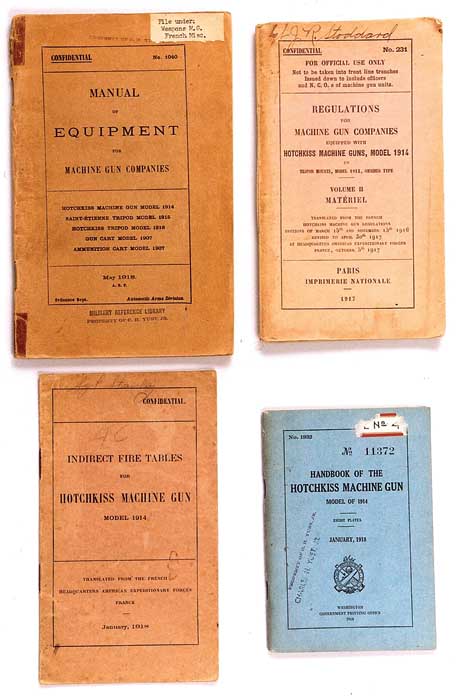

The description of the Hotchkiss M1914 is best related in the Handbook of the Hotchkiss Machine Gun Model of 1914, No. 1932, as printed in the Ordnance Manual of January, 1918. “The Hotchkiss machine gun, Model of 1914 (Mitrailleuse Automatique Hotchkiss), caliber 8mm, is chambered for the standard French rifle ammunition. The gun is classified as heavy, air-cooled, gas operated, and fed from metallic strips or linked bands.

“In order to eliminate artificial cooling devices, air is utilized as a cooling agent. The barrel is heavily made, which tends to retard overheating. To assist in the natural cooling of the gun, a radiator having five large annular ribs is shrunk over the rear end of the barrel.

“Expanding gases furnish the energy for the operation of the gun. After the gun is fired and the bullet has passed the gas port in the barrel, the live powder gases expand through the gas port into the cylinder and impinge against the head of the piston. This throws the piston to the rear, compressing the recoil spring which furnishes energy for the counter-recoil. The various lugs and cams of the piston actuate the feeding, firing, extracting and ejecting, and control the operation of the gun.

“The feed strips or bands are metallic stampings on which are formed three parallel rows of teeth for holding the cartridges in place. The feed strips are flat and hold 24 cartridges in a single row.

“The feed is entirely mechanical, and is independent of the inclination of the gun. The feed strip is ejected automatically. By the employment of strips the consumption of ammunition is easily controlled, and a much better economy is feasible than with a long band.

“The gun is composed of only 30 pieces that are easily dismounted. There are very few springs and screws, and only a few of the main parts are indispensable for the proper functioning of the gun.

“All parts of the gun are constructed in such a manner that it is impossible to assemble them improperly. The ordinary dismounting and assembling of the gun can be accomplished without the aid of a single tool. The dismounting of the barrel or gas cylinder necessitates a wrench which forms a part of the accessories of the arm.

“On account of its weight the Hotchkiss is fired from a tripod or other suitable mount. The arm is especially adapted to defense work and to barrage fire or indirect fire. When used for night firing it is fitted with a flash screen.”

Operation

A loaded feed strip with the cartridges facing up is inserted into the feed block until its movement is stopped. Pull the cocking handle to the rear locking the moving parts in the rear cocked position, and then push the cocking handle forward. The cocking handle does not reciprocate during firing. Again, the 1918 edition of the Handbook of the Hotchkiss Machine Gun Model of 1914 best relates the operation of the gun. “Pulling the trigger releases the trigger from the sear notch on the underside of the piston allowing the recoil spring to drive the piston forward. The lug of the firing pin resting between the firing pin tang and the breech block tang of the piston carries the firing pin forward. The nose of the locking cam of the piston, bearing against the breech block lock, carries the breech block forward.

“The breech block forces the front end of the ejector out of the path of the breech block. The lower part of the breech block face strikes the base of the cartridge, stripping it from the feed strip and driving it forward into the chamber. The feed wheel is now advanced over the first half of the feeding movement by the action of the large feed cam of the piston against the operating lug on the operating wheel of the feed wheel. The feed wheel pawl engages the feed wheel ratchet and prevents rebound. As the breech block closes against the cartridge in the chamber, the extractor springs over and engages the rim of the cartridge. The breech block has now reached the end of its forward movement and the breech block lock is in position above the recoil blocks in the receiver and is free to lock. This movement is accomplished by the locking cam of the piston working against the cam surface of the breech block lock, causing the rear end of the latter to tilt down in front of the recoil blocks.

“The piston continues forward, carrying the firing pin and primes the cartridge. The recoil spring abutment of the piston, striking against the counter-recoil buffer in the front end of the receiver limits the forward motion.

“After the explosion has taken place and the bullet has passed the gas port in the barrel, the live powder gases expand through the gas orifice into the gas chamber and impinge against the head of the piston, forcing it to the rear. This action compresses the recoil spring and stores up energy for the counter-recoil.

“The piston withdraws the firing pin from the primer. The lower cam of the breech block lock riding on the upper cam surface of the piston raises the breech block lock clear of the recoil blocks.

“The breech block tang on the piston striking the rear shoulder of the breech block carries the breech block to the rear. The extractor withdraws the empty shell from the chamber. The rear end of the ejector rides out of its groove in the breech block, which pivots the front end of the ejector into the path of the cartridge. The cartridge base strikes the ejector, which throws the shell out to the right. The small feed cam on the piston now completes the rotation of the feed wheel and places the next cartridge in position above the stripping finger. The feed wheel pawl engages the feed wheel ratchet and prevents rebound.

“The backward motion is limited by the rear end of the piston striking the breech cover. If the trigger is held back by the finger, the mechanism starts immediately on its forward motion. If the trigger has been released, it springs up and engages the sear notch of the piston holding the gun in the cocked position.

“When the feed strip has been fired through, it allows the upper lug of the arrestor to spring up and the arrestor catch engages the arrestor lug on the piston. This holds the piston back so as to allow the loading of the next strip.”

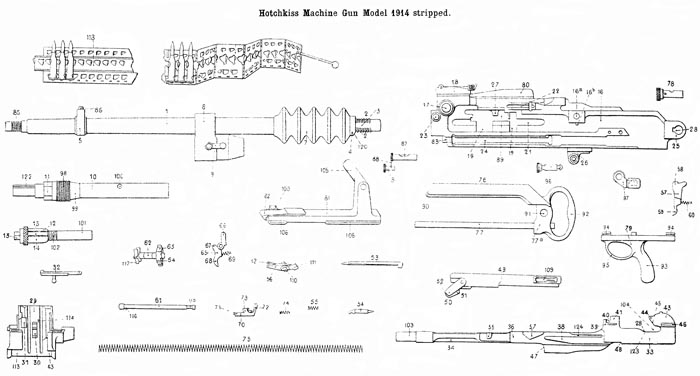

Basic Field Stripping

To field strip the gun, make certain that there is no feed strip in the feed tray and pull the cocking handle back far enough to visually inspect the chamber to make sure it is clear.

Pull out the feed block key and remove the feed block. Press in the recoil spring guide located within the D grip and pull out the breech cover pin located on the left side of the receiver just in front of the D grip. Remove the breech cover and recoil spring to the rear. Slide the trigger guard to the rear and remove. This can be accomplished by tilting the trigger a little toward the rear and removing it downward.

Draw the cocking handle to the rear until it comes out of the guides on the receiver. Then pull the piston and breech block the remainder of the way out of the receiver. Rotate the front end of the ejector out until it is at right angles to the receiver, and then remove the ejector. To rotate the ejector, grip the top lug with the finger nails or place a finger over the axis of the ejector along the side of the receiver and give it a quick draw to the rear.

To remove the barrel, move the barrel lock completely to the rear and place the barrel wrench over the gas cylinder support with the handle to the right horizontal to the ground. Push down on the barrel wrench until the barrel stop pin strikes the top of the receiver. Pull the barrel out toward the front. Unscrew the gas regulator, which can easily be turned by hand if it has been kept clean and well oiled.

This completes the basic field stripping of the weapon. Reassembly is in the reverse order.

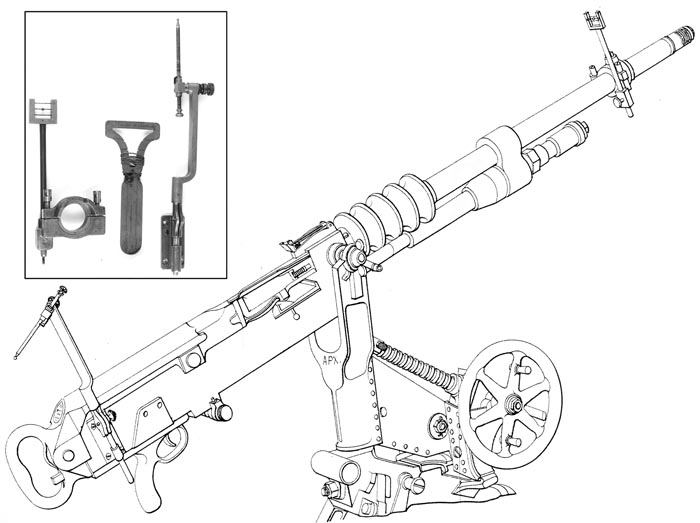

Mounts

The Hotchkiss Model 1914 used two primary mounts. The first was the Omnibus Model 1915 mount produced at Puteaux that was originally intended for use with the St. Etienne Model 1907. The Omnibus Model 1915 tripod was the last iteration of tripods designed for the St. Etienne Model 1907 and could be, and was, used to a great extent with the Hotchkiss M1914. It consists of two essential parts: the traversing group and the tripod. The upper part of the traversing head is fork-shaped and has two recesses on which the trunnions on the machine gun are locked in place. The traversing head also carries the telescoping elevating mechanism and the traversing clamp. The distinguishing feature of the Omnibus Model 1915 tripod that makes it instantly recognizable is the large elevating wheel located on the left side of the traversing head. The tripod consists of three groupings: the pivot body, the trail, and the legs. The pivot body serves as a bearing for the traversing head. The trail consists of an arm and an inner tube. The arm is joined to the pivot body and the inner tube within the arm may be extended to lengthen the trailing leg. The trail terminates in a shoe provided with a trail spike. The trail also carries the gunner’s seat which can be fixed at any convenient position by means of a hand bolt. The two front legs are jointed at their upper ends to the same trunnion at the body of the pivot. They are joined together by a separator which keeps them apart when the tripod is set up. The right leg is provided with a leveling screw to vary the length of this leg for uneven terrain. Additionally, each front leg has a knee joint making it possible to bring the mount to a kneeling position by folding the lower part of both legs under the trail. An anti-aircraft extension that attached to the pivot head was also available.

The second type of tripod used was the Hotchkiss Tripod Model 1916. Manufactured by Hotchkiss for the M1914, it was similar to, but simpler and slightly lighter than, the Omnibus Model 1915 tripod with some obvious differences. It, too, consisted of two essential parts: the traversing group and the tripod. It also had a forked-shaped traversing head with two recesses on which the trunnions on the machine gun are locked in place. But instead of the large elevating wheel, elevation was controlled by a simple wheel located directly beneath the telescoping elevating mechanism. The tripod also consisted of three groups: the pivot body, trail and legs. As with the Omnibus 1915 tripod, the pivot body accepted the traversing head, and the trail consisted of an inner tube that could be extended out and the gunner’s seat could be adjusted. The two front legs, however, did away with the separator cross bar and the knee joints and the right leg leveling mechanism.

There was actually a third tripod that saw very limited use with the Hotchkiss M1914, also named the Hotchkiss Tripod Model 1916, which was made in the United States. Commonly called the “Cleveland Mount,” it was manufactured by the Standard Parts Company of Cleveland, Ohio. In October, 1918, 2,500 were reported as completed. This was the only work performed in connection with this gun in the United States. For all intent, it was a copy of the French manufactured Hotchkiss Tripod Model 1916 except that it had a distinguishing feature that consisted of a large 360 degree traversing head above the pivot head that allowed a full 360 degree traversing movement for anti-aircraft fire.

Anti-Aircraft Sights

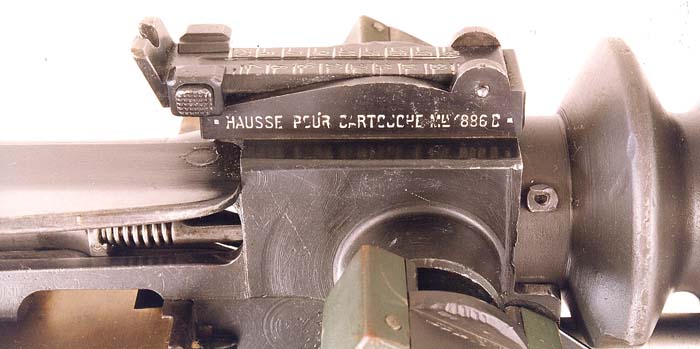

The auxiliary sight for anti-aircraft firing comprises four essential parts: the mire, the guidon, the support bracket for the mire, and the support clamp for the guidon.

The mire (rear anti-aircraft sight) is made with a moveable scale ended by a bead. It is mounted in a trunnion case supported by a shank inserted into the mire support that is then fitted into the mire support bracket. The mire support bracket is affixed by four screws to the right side of the receiver between the pistol grip and the D grip.

The guidon (front anti-aircraft sight) is made of a laying frame supported by a shank inserted in the hole of the guidon support clamp. The frame is made of two fork-shaped branches connected by three horizontal parallel threads. The center thread is provided with a bead. An illuminating disk set on each branch level with the central thread facilitates night firing. The guidon clamp is made of two semicollars with a bored block to receive the guidon. It is set on the front end of the barrel against the front sight band. Essential with the anti-aircraft sights is the hand-held stadia for range finding.

Accessories

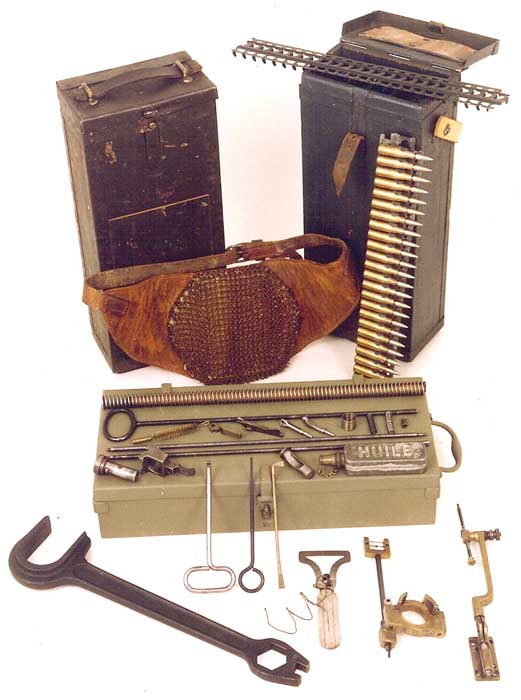

As the premier front line heavy machine gun for two armies, there were a number of accessories associated with the Hotchkiss Model 1914 that included: strip loaders, strip resizing tool, clinometer, anti-aircraft sights and stadia, barrel and gas regulator wrench, hand extractor hook, defective cartridge extractor, flash hider, leather mittens with chain mail and asbestos pads for handling hot barrels during barrel changes, a leather with chain mail and asbestos pad shoulder epaulette to carry a hot barrel on one’s shoulder when advancing, canvass gun case and a metal armorer’s box containing cleaning rod, jags and brushes, oil bottle, spare recoil spring, screwdriver, hammer, pins and punches, chamber gauge, gas cylinder scraper, spare firing pins, extractors, ejectors, small springs and pins, etc.

Conclusion

The Hotchkiss Model 1914 was the right gun at the right time serving the French Army admirably as well as the US Army. It was reliable and robust and could be counted on regardless of the situation, climate or terrain. The only complaint, and generally considered the weak point of the weapon, was its feed strip design that was clumsy to handle requiring constant feeding of the gun and strips easily deformed or bent. The other chief drawbacks consisted in its excessive weight in comparison to the Vickers and Browning, and the length of time required for cooling – four minutes and six seconds of time and a sponging with water being required between each burst of 1,000 rounds. However, the simplicity and ruggedness of the gun enabled it to be dismounted and reassembled in less than a minute without the aid of a single tool. Nevertheless, the Hotchkiss remained in service with the French both at home and in their colonies up to World War II. The United States did not keep the Hotchkiss in their inventory after the war and discarded them in favor of the superior Browning guns. But their contribution to the allied war effort was immense being the most widely used heavy machine gun of the allied forces and they played a pivotal role in the ultimate victory in World War I.

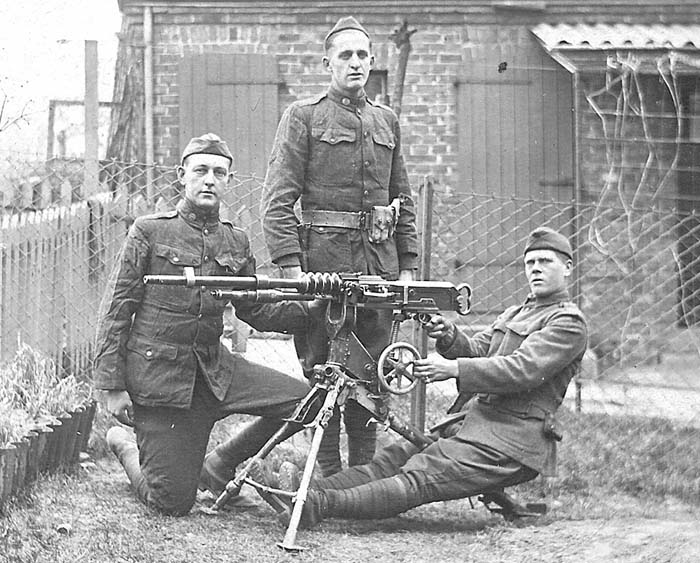

French Poilus man their Hotchkiss Model 1914 mounted on an Omnibus 1915 tripod in the combat zone.

Segregated US “Buffalo Soldiers” of the 366th Machine Gun Company of the 92nd Division fire their Hotchkiss M1914 on German soldiers across No-Man’s Land, July, 1918.

Company of French machine gunners with their Hotchkiss Model 1914s mounted on Hotchkiss Model 1916 tripods. Note the Barr & Stroud type range finder at the rear.

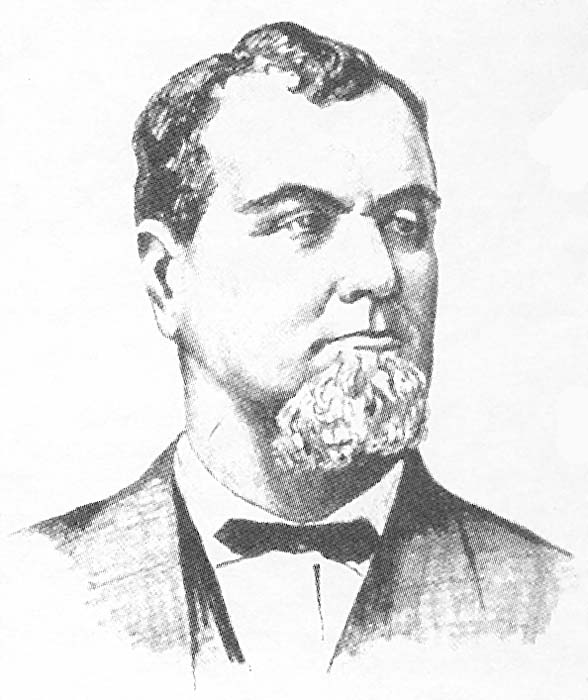

Benjamin Berkeley Hotchkiss, 1826 – 1885

Born in Watertown, Connecticut in 1826 and then moving to Sharon, Connecticut in his early youth, Benjamin Hotchkiss began his mechanical experiments in his father’s hardware factory. In the 1850s, he served as an apprentice at Colt’s Patent Firearms Company in Hartford, Connecticut. Becoming a master mechanic, he is credited with designing and perfecting various models of the Colt revolver and Winchester rifles. In 1860, he developed an improved system of rifling and a new kind of percussion fuze for projectiles. As with so many American firearms inventers of the time, Hotchkiss moved to France in 1867 where his firearms inventiveness was given better consideration. In France, he demonstrated an improved metallic cartridge case that was immediately ordered for manufacture in St. Etienne and the French placed an advance order for a machine gun Hotchkiss had in mind by using the destructive forces of an explosive shell in a rapidly firing gun. With this backing from the French government, Hotchkiss remained in France and four years later in 1871 established his own company, Société Anonyme des Anciens Établissements Hotchkiss et Cie (Hotchkiss and Company) in Saint Denis, just outside Paris.

There, with a background in designing artillery projectiles and systems of firing, Hotchkiss formulated what he considered to be the best caliber to produce the most destructive force capable from a rapid firing weapon. The result of his calculations was a bursting charge cavity of correct dimensions and a balanced fuzed nose with a 37mm projectile. The gun he built around the 37mm round was intended for flank defense and he introduced a new and unique feature: each of the five barrels was rifled with a different pitch ensuring a sweep of the target area with shrapnel.

While the Hotchkiss Revolving Cannon, on first impression, resembles a Gatling gun, it is operationally markedly different. The five barrels are mounted parallel to each other around a central shaft and are rotated and controlled by means of a hand crank that also controls the loading, firing and extracting operation. Unique to the Hotchkiss internally is that the barrels are rotated intermittently without turning the breech mechanism. Thus, the barrels are stationary at the moment of firing negating any centrifugal force normally imparted to projectiles at the start of their flight when fired from a continuously rotating barrel. Additionally, there was just one firing pin and spring instead of five and a single loading piston.

The impressive 37mm round contained 3-1/2 ounces of powder. The cartridge case measured 3.66 inches without projectile, 6.68 inches long with projectile, and a complete round weighed 2.42 pounds.

There were six models of the manually operated Hotchkiss Revolving Cannon depending on their specialized purpose: the light 37mm for field use; a high velocity 37mm for flank defense and fortifications; the 37mm designed for shipboard use only; a 40mm for fortifications; a 47mm gun for naval use; and a 57mm gun, also for naval use.

At one time or another, the Hotchkiss Revolving Cannon was used by just about every navy in the world including Germany, England, Holland, Italy Austria, Turkey, Denmark, Russia and the United States. The French Navy alone used over 10,000 revolving cannon and four million rounds of ammunition.

It was the Hotchkiss Revolving Cannon and his fuzed rounds that earned Hotchkiss his fame and fortune and his name known around the world.

Laurence Vincent Benét, 1863 – 1948

Born at West Point, New York in 1863, Laurence Benét was the son of General Stephen Benét who was at one time the Chief of Ordnance of the Untied States Army. During his father’s tour of duty at the War Department, Laurence prepared for college at Emerson Institute and was graduated in mechanical engineering from Yale in 1884. The following year in 1885, he went to France to work for Benjamin Hotchkiss at the Hotchkiss Company where he began a fifty year career with that famous firm.

Showing great mechanical skill and managerial talent, he rose through the ranks while at Hotchkiss. Upon the death of Benjamin Hotchkiss in 1885, Benét was well situated within the company and was appointed in 1887 by the Hotchkiss stockholders to be the head engineer and promotions manager whereupon he made as his assistant the very talented Henri Mercié. It was this dynamic team of Benét and Mercié that then orchestrated the next successful phase of the Hotchkiss Company. With the company well established in the arms field by the success of Benjamin Hotchkiss’ revolving cannons, Benét and Mercié were at the right place at the right time for the new invention of the age: the machine gun.

Benét took two brief leave of absences during his tenure at Hotchkiss. During the Spanish-American War he served as an Ensign in the United States Navy, and during World War I, he served with the American Ambulance and Hospital Corps in France and for the last two years of the war was a member of the advisory staff of the American Expeditionary Force Purchasing Board.

For these and other services he was honored by various Governments; his decorations included the Grand Officer of the French Legion of Honor, French Medal of Honor, Commander of the Military Order of Christ (Portugal), Commander of the Order of the Crown (Romania) and Officer of Osmania (Turkey).

After his retirement as Vice President and Director of the Hotchkiss Company, Mr. Benét was made honorary President of the Company. He returned to the United States in 1937 living in Washington D.C. until his death in 1948. He is buried in Arlington National Cemetery.

In an interview after his retirement, Benét said, “I believe I have been called a ‘merchant of death.’ Do I look it?” “I’m sorry,” he added, “that my fingers are not dripping blood this morning.” His profession, he said, did not fill him with horror. “One of the great satisfactions of my life is that the Hotchkiss machine guns saved Paris from the Germans. Most of the liberties we enjoy were won by the sword. If people have nothing else to fight with they will fight with their hands.”

| This article first appeared in Small Arms Review V12N4 (January 2009) |