The author quickly disposes of 1,500 rounds of 7.62 NATO ammunition in approximately 30 seconds. Photo by Dillon Aero

By Charles Q. Cutshaw

The 7.62mm GAU-2B/M134 Minigun has been in military use for well over 30 years and although it has long been out of production, the gun is still in widespread use by military forces worldwide. Despite its age, the minigun remains a highly effective weapon for ground forces, special operations use and for enemy suppression as a part of aircrew rescue under hostile conditions. The world’s special operations forces continue to rely on the minigun as an integral component of their weapons inventory. The author can personally attest to the effectiveness of the minigun. In 1969 he witnessed the total annihilation of an attacking North Vietnamese battalion by a minigun equipped AC-47 “Spooky” during a night combat action near Pleiku, Vietnam. The AC-47 decimated the enemy battalion in a matter of minutes, well before it came into range of the defending force’s small arms. The gun has been widely fitted to search and rescue helicopters, including mounting in such aircraft as the UH-1 series, MH-47, CH/HH/SH-53 series and MH-60 Blackhawk helicopters. It is also fitted to attack helicopters such as the AH-1 Hueycobra and MD-500 series. The minigun continues in service in many of the world’s special operations forces and is currently deployed on, among other fixed wing aircraft, the USAF Spectre AC-130 gunships. The versatile and effective gun has also appeared in ground and marine mounted configurations. For example, Saracen Inc. and Dillon Aero currently offer the minigun fitted into former’s Raptor internal security vehicle, which uses the Chevrolet/GMC Suburban as a platform. (See SAR Volume 1 Number 5 on the Raptor vehicle).

Availability of spares and facilities to rebuild worn guns, however, has been problematic for those forces that employ the minigun. General Dynamics, which owns the original tooling for the gun, has not produced spares in many years. The size of a typical spare parts order is small, and the cost of setting up tooling is prohibitive for such a large company. Therefore minigun users have been forced to purchase a hodgepodge of spares produced by small firms, including machine shops whose military contract bids were lowest and who did not have ability to manufacture precision minigun components from blueprints that were questionable at best. Many of the gun’s parts are very difficult to measure even with a the most advanced measuring equipment. Without a gun, or at least the mating parts, it was difficult to know if the new part was any good. The result was components that did not work at all or had to be hand-fitted to the guns due to faulty dimensions. The author personally saw two feeder/delinker housings while at Dillon Aero that were ostensibly made from the same drawing to the same specifications and tolerances, yet both were of visibly different dimensions. Neither would have functioned as intended even if they could have been installed on a gun, which they could not.

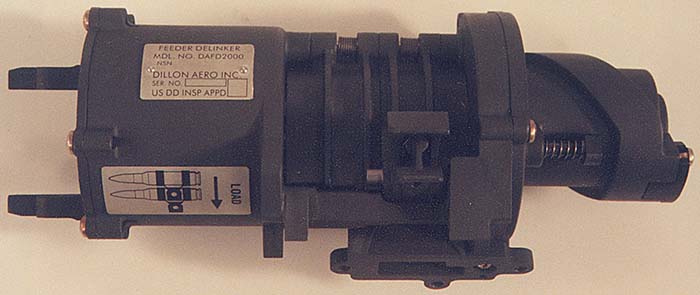

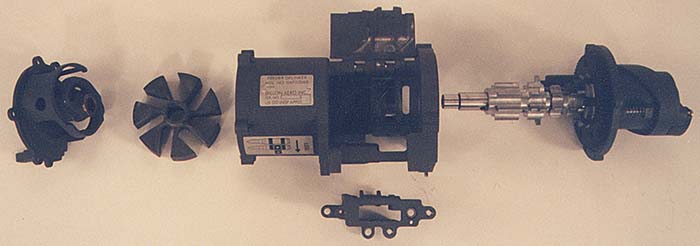

Mike Dillon, president of Dillon Aero, encountered these problems when he attempted to repair his own miniguns several years ago and because of the lack of quality and reliability of available military surplus components, decided to produce his own. At the same time, he recognized several shortcomings in the minigun design and set out to develop product improvements that could be incorporated into new production guns and retrofitted to existing guns as they were repaired. The most significant upgrade to the M134 is the new Dillon Aero feeder/delinker. It is essentially an entirely new design. Mike was annoyed by the need to dismount and completely disassemble the feeder/delinker every time a stoppage occurred in that unit. Checking with other Minigun users, he found this sentiment was universal. Further, it became clear that the feeder/delinker was the weakest part of the M134 system, the cause of almost all stoppages.

Dillon reasoned that if the gunner could open up the feeder/delinker, much like opening the top cover of a conventional machine gun, stoppages could be cleared quickly without removing the feeder/delinker from the gun. He experimented with several hatch designs and finally settled on a split or dual hatch configuration. This dual hatch configuration not only allows rapid clearing of stoppages but also allows the gunner to load the gun without the need to turn the barrels. This latter feature is important for two reasons. First, turning the barrels can cause the gun to fire, which is undesirable and should be avoided. Second, If the gunner is trying to reload the minigun in the window of a moving helicopter, he doesn’t want to lean out into a hundred mile an hour wind and twist barrels, especially if they are hot from having just been fired.

Several other improvements have been incorporated in Dillon’s new feeder/delinker. While the ability to quickly clear a stoppage has merit, preventing a stoppage is even better. Stoppages are usually caused by a restriction of the linked ammunition being drawn into the feeder/delinker. In the original unit a single sprocket forward of the links pulled the linked cartridges into the feeder/delinker unit. If the ammunition belt were restricted, this caused the cartridges to skew nose first into the feeder/delinker, jamming the unit. To lessen this tendency, Dillon added a second, heavier sprocket to the rear of the links to assure that cartridges are pulled with even pressure, both forward and aft of the links, thereby ensuring that the linked cartridge belt enters the feed mechanism with cartridges and links in alignment. Also, combining features of the stripper sleeve (forward sprocket) and the push rod guide (rear sprocket) eliminated several weak features.

The original feeder/delinker utilized the point of the bullet as the forward cartridge stop. The introduction of 7.62 X 51 MM saboted light armor piercing (SLAP) rounds in the late eighties mandated a forward stop that contacted the shoulder of the cartridge rather than the nose of the bullet. General Electric (GE) accomplished this change by adding a bolt-in steel spiral near the front of the feeder/delinker. Although this modification worked, it made servicing the unit even more laborious, as the bolt-in stop is difficult to install and adjust. This same task is accomplished in the Dillon feeder/delinker by casting and machining the stop feature into the forward plate. This permanent feature ensures a more positive “hand off” from the feeder/delinker to the gun’s bolts, thus enhancing reliability and enabling the use of virtually any type of 7.62X51 MM ammunition, including blanks and SLAP cartridges.

Another area of concern to minigun users is how to direct the heavy volume of brass and links away from vital parts of the helicopter like tail rotors. In the past, this was handled by a complex assortment of sheet metal weldments that were fitted over the gun’s existing exhaust port and held in place by screws and brackets. The Dillon Aero feeder/delinker is designed with a three bolt mounting flange on the link exhaust port to facilitate the positive mounting of purpose built link chutes that direct spent links and cartridge cases away from the aircraft. Spent brass and link tubes have traditionally been mounted to the feeder/delinker. The attachment of these two, four-inch hoses made the removal of the feeder/delinker in flight very difficult. To alleviate this situation Dillon Aero has added two bosses to their gun housing casting so that the brass chute can be mounted directly to the gun housing instead of the feeder/delinker. This, in addition to a quick detachable fitting on the gun exhaust port allows the gunner unencumbered access to the feeder/delinker.

The Dillon Aero minigun has been so extensively redesigned that the military would have redesignated it the GAU-2C for aircraft or M134A1 for ground applications, indicating a significant revision to the original design. We believe that this is appropriate, have also designated the new guns in this article and have recommended to Dillon Aero that modified guns be given the new designation so that military can tell at a glance that the gun has been modified to the improved standard.

Another important upgrade to the minigun is the Dillon designed pedestal/pintle mount. The original minigun pedestal/pintle mounts, still in widespread use by many forces, are cumbersome affairs that encase the minigun in a framework that is attached to a pedestal in the aircraft. The gun mount itself is a heavy “U” shaped pintle mount that attaches to both sides of the cumbersome mounting frame. The original mount is not only heavy, but also interferes with gun maintenance and reloading. Even worse, stoppage clearance while in flight is virtually impossible because the complex external frame limits access to the gun.

In the late eighties GE designed a universal mounting for both the GAU 19 (.50 Gatling) and the minigun. This new pintle mount allowed full access to the gun by eliminating the cumbersome external-mounting frame. This mount was a dramatic improvement over previous mounts but unfortunately the bulk necessary to tame the recoil of the .50 cal GAU19 obstructs the feed chute of the minigun. What Dillon has done is simply to retain the lateral geometry of the GE mount while reducing the mass. Also, the support arm of GE’s mounts pitches forward while Dillon’s support arm is either vertical or pitched aft for greater feed chute clearance. Examination of the accompanying photos will reveal that the Dillon Aero mount is elegant in its simplicity . The new mount incorporates single horizontal and vertical pivots. Both the horizontal and vertical pivots are located on the centerline of the firing barrel therefore the gunner experiences no pitching or twisting moment from the gun’s recoil. The stability of this mount enhances accurate shooting. The vertical pivot is mounted to a collar with a thick pivot pin that may be quickly attached or detached via a locking pin with positive detents to retain the gun in place. The new mount, made of 4130 chrome molybdenum steel, is lighter and allows the gunner improved freedom of movement over the universal GE mount. Fields of fire are limited by stops that positively limit the gun’s traverse and elevation, thus preventing the gunner from inadvertently shooting into the tail rotor, landing gear or main rotor of the helicopter on which the gun is mounted.

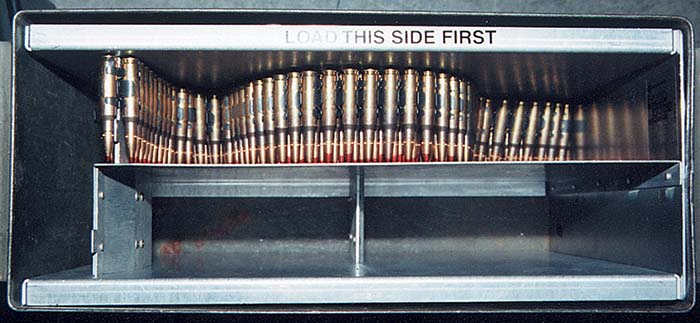

In addition to improving the feeder/delinker for increased reliability, Dillon engineers have modified the internal configuration of the 1,500 round and 4000 round ammunition boxes to further enhance feeding and thus, reliability. By eliminating all of the internal rollers and most of internal baffles that guide the ammunition belts and by modifying the one baffle that remains, Dillon’s engineers have reduced the amount of “pull” required by the feeder/delinker sprockets to draw ammunition from the box through the feed chutes and into the gun. This simplified internal configuration is also much easier and faster to load.

Fire control has also been improved over older guns. Dillon has incorporated the functions of the separate gun control and trigger box into a single, solid state control contained in the trigger box mounted on the gun integrally between the firing handles. The cost of this new system is only about one third of the old separate units and has considerable less external wiring. The control mechanism seen in the photographs is a second prototype, which will be greatly reduced in size in final production guns. The firing rate in Dillon’s modified or, newly manufactured guns, is preset at 3,000 rd/min, rather than the earlier variable rate of 2,000 or 4,000 rd/min. “I took a page out the Navy’s book,” says Dillon. “The guys at the Naval Surface Warfare Center at Crane, Indiana hit on the 3,000 rd/min firing rate as the optimum balance between reliability and terminal effects. Firing rates of higher than 3,000 rd/min can cause link stretch and belt pitch change, resulting in stoppages. Lower rates of fire are not needed as all of the new guns have clutched feeder/delinkers which allow gunners to fire bursts as short as 3 rounds without wasting ammunition.” (Older, unclutched systems, expended 6 to 12 live cartridges overboard each time the gunner let off the trigger)

Dillon Aero now manufactures a complete line of minigun spares and clutches for M134/GAU-2B/A miniguns and will provide them to authorized customers for repair of their guns. All Dillon components, whether manufactured to original specification or to Dillon’s improved standard, meet or exceed US military requirements in terms of both materials and dimensions. Dillon Aero will also rebuild customer guns to GAU-2C/M134A1 specification with all worn components replaced all product improvements incorporated into the rebuilt gun. And finally, Dillon Aero is producing newly manufactured M134A1 miniguns for approved customers. For those customers desiring only the improved Dillon flexible mount, this is available as a separate item, which can be adapted to any helicopter. The Dillon pedestal mount can also be purchased in ground or marine configurations. Dillon Aero can additionally provide information regarding forward firing twin mounts for light helicopters such as the MD500.

Contact:

Michael J. Dillon

Dillon Aero, Inc

8009 E. Dillon’s Way

Scottsdale, AZ 85260

Tel: (480) 948-8009

Fax: (480) 998-2786

Email: Dillon@dillonprecision.com

| This article first appeared in Small Arms Review V3N9 (June 2000) |