By Michael Heidler

In the sixth year of the War, the resources of the German Reich had become scarce. How practical would it be to fire two bullets with one cartridge? This idea woke the interest of the Waffen-SS.

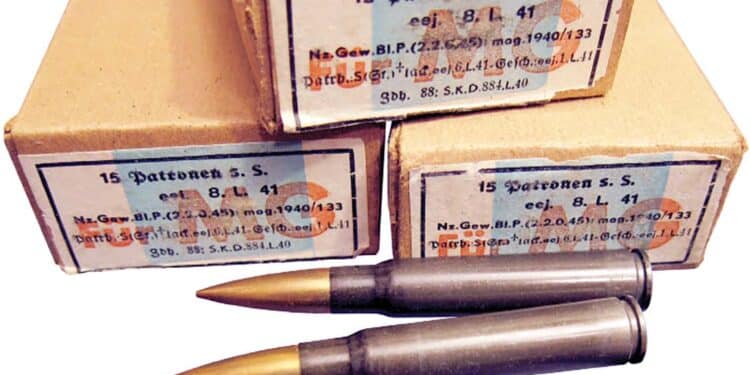

By the end of 1944, the German Armed Forces (apart from the numerous captured weapons) mainly used two types of rifle cartridges:

- 7.92x57mm with s.S. (heavy spitzer) bullet for rifles and machine guns

- 7.92x33mm kurz with the short Mkb bullet for machine gun carbines/ assault rifles

In order to make the cartridges more effective, a large number of other bullets, such as tracer, hard core or even explosive projectiles, were put in the cases.

Another way to increase cartridge performance was chosen in autumn 1944: If two bullets could be put in a single cartridge case, the double effect on the target could be achieved simultaneously with savings on raw material, weight and transport space without additional training for the soldiers. On the weapons themselves, nothing would have to be changed. With the loss of territory in the east, the ongoing supply of the necessary raw materials for the armaments industry partially dried up, and the air raids on the Reich further reduced the already scarce transport space.

Experimentation

The idea of putting two bullets in one case sounded simple. But the devil was in the details. The experiments with different bullets and powder types dragged on for a long time. In addition to the Heereswaffenamt (Army Ordnance Office), the SS ordnance office department “Research, Development Patents” (FEP for short), headed by SS-Gruppenführer Dr.-Ing. Otto Schwab, was involved in it. Some of the test firing attempts took place at the Gottow shooting range, which was part of the Kummersdorf Army testing institute and was officially named “Wa Prüf 11—Special Equipment Department.”

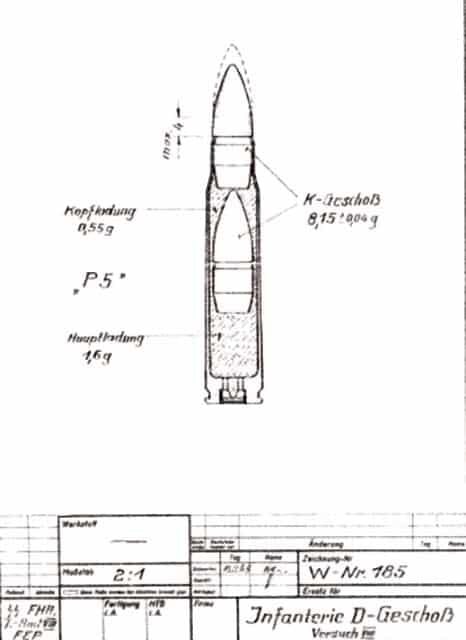

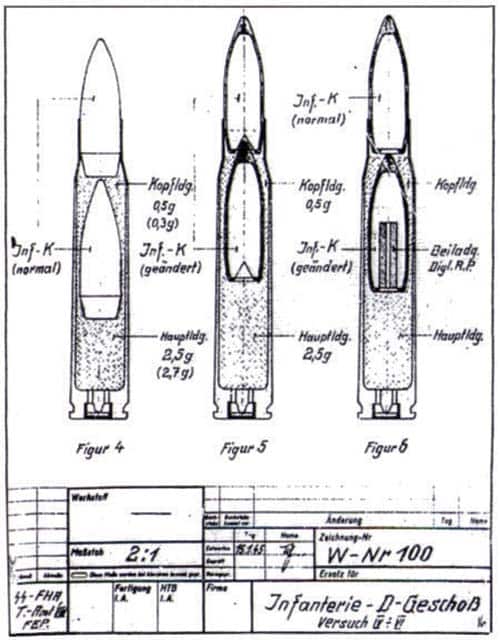

The experiments started with two bullets, 123.5 grains each (8g each), of the standard rifle cartridge in a case with a 24.7-grain (1.6g) powder charge. During a test with three rounds, under the direction of SS-Untersturmführer Winzer, a very large dispersion was noticed at a distance of 30m. The last shot got stuck in the barrel. Increasing the load to 37 grains (2g) brought little improvement. Also, in this case, bullets got stuck in the barrel. Two Mkb bullets were then put in the case, and the charge was increased to 37.037 grains (2.4g). With 16 rounds fired, the result was satisfactory. There were no outliers, and no bullets got stuck in the barrel.

Now it was time to increase the distance. For the next attempts, the target was hung at 100m. The case with the two Mkb bullets was filled with a main charge of 24.7 grains (1.6g) and an additional front charge of 1.23 grains (0.8g). The accuracy was again satisfactory with an average of nine rings per round. So far, so good, but the trajectory no longer matched the sights of the weapons. Calculations showed that the speed of the shorter Mkb bullets had to be increased from 665m/sec to 750m/sec.

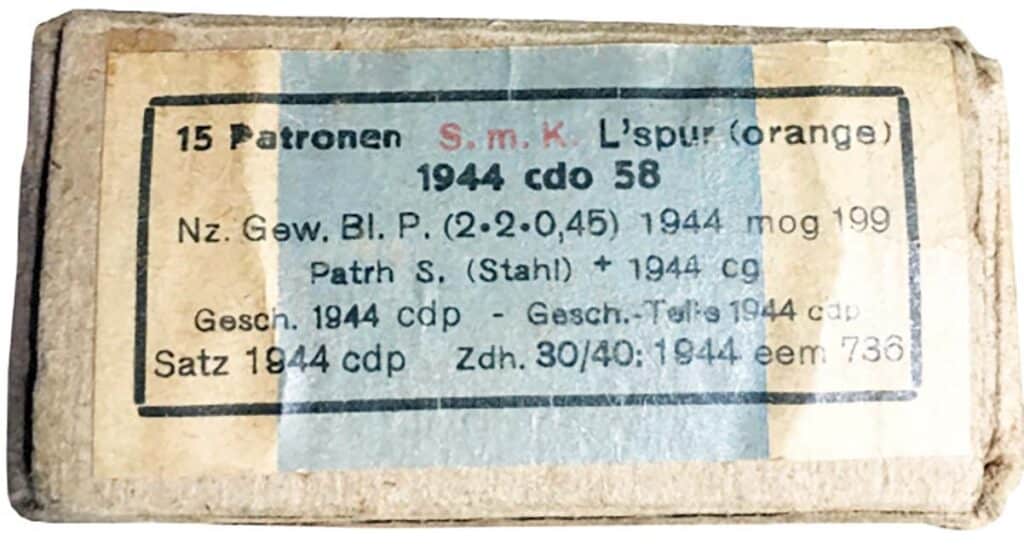

Detailed investigations also showed that the second bullet flew in the slipstream of the first bullet and thus in a zone of reduced pressure. This resulted in a fairly constant deviation from the trajectory of the first bullet. In the meantime, it was January 1945, and the SS put the team under pressure. The SS ordnance office therefore contacted the Finower Industrie GmbH, which, as an experienced manufacturer of infantry ammunition, was to make the double-bullet cartridges ready for series production. Two SS technicians from FEP were assigned to Finower for this purpose. The best results were achieved with a cartridge containing one heavy bullet 193.7 grains (12.55g) and behind it a shorter and lighter Mkb bullet. At the beginning of February, it was clear that “the characteristics of this new type of infantry ammunition have been clearly recognized by extensive tests and that special manufacturing difficulties are not to be expected.” The Heereswaffenamt successfully carried out a mass firing test with these cartridges.

Before the new ammunition could go into series production, there was a meeting in Friedenthal near Oranienburg on March 17, 1945. The illustrious group counted many well-known names, such as SS-Standartenführer Dr. Heeß (Institute for Criminal Technology RSHA) and SS-Obersturmbannführer Otto Skorzeny (Unit I B Friedenthal). Plant manager Eibl explained that the double-bullet cartridge weighed 445.2 grains (28.85g), in contrast to the normal s.S. cartridge weighing 419.8 grains (27.20g). A cartridge with two bullets saves 158.2 grains (10.25g) on the case and 53.24 grains (3.45g) on the powder compared to two normal cartridges, without reducing the combat effect on the target and without putting more strain on weapon mechanics. Test firing with the machine gun MG42 was successful.

SS-Untersturmführer Schürmann of the SS-paratroopers praised the development and agreed to order 15,000 cartridges for the special infantry battalion Friedenthal (named after the castle Friedenthal). However, the delivery was initially to be seen as an “emergency solution” without special requirements at any point in the manufacturing process, and any problems that might occur were accepted. The main thing was that the cartridges could be delivered as quickly as possible. It is unclear whether and where production actually started. Reports or other evidence of use in action are not known. In any case, all cartridge production in Finower ended due to a lack of raw materials in March 1945.

On April 25, 1945, the SS-FHA T-Office (SS-Führungshauptamt Technical-Office, SS-FHA’s main operational department), which had meanwhile relocated from the encircled capital Berlin to Dachau in Bavaria, discussed the future manufacturing options. Since there were no suitable factories in the still unoccupied part of Bavaria, production would begin in Italy, the Protectorate or Tyrol. The Austrian inspector for armament and equipment in Salzburg would explore new companies and workshops. But ultimately, nothing came of it. In May, the War was finally over in Europe.

| This article first appeared in Small Arms Review V24N5 (May 2020) |