Affable, cheerful and humorous, the doctor appears to be a wonderful real-world example of Marcus Welby – except he carries a gun. His name is Dr. Phil Dater and it might have been his fascination with how things work that led the curious physician to first experiment with sound suppressors in the 1950s, and later in the basement workshop of a hospital where he worked. Given his interest in firearms and his understanding of the scientific method – form a hypothesis, test it through repeatable experimentation and modify accordingly – Dr. Dater naturally took to sound suppressors and has been involved in many of the seminal sound suppressor companies in the modern era. Of all the arcane areas of firearms, suppressors are the most firmly rooted in a “trial and error” design processes because no amount of computers can possibly calculate all the variables at work when a gunshot erupts.

Suppressors have intrigued me too, which is how I’ve come to be sitting in the front row of Dr. Dater’s two-day class on Suppressor History, Technology & Testing conducted at the GSA training contractor, Long Mountain Outfitters in Henderson, Nev. The class is open to anyone, although Dr. Dater insists his students be vetted to assure no one of dubious motivation sneaks in. His information is protected by ITAR regulations, so only DoS qualified foreign nationals can attend and Dr. Dater understandably prefers his competitors to not attend.

Our class consists of firearms engineers, enthusiasts who want to learn what they can, suppressor dealers who want to enhance their sales ability, and several U.S. government employees from various military branches. Unbeknownst to me at the time, a celebrity is sitting in the back of the room, Pulitzer Prize winning author Stephen Hunter.

Dr. Dater displays an assortment of suppressors – “cans” in the vernacular – and immediately makes full disclosure that he’s one of the principals of Gemtech, a suppressor manufacturer. He assures us that his class is non-brand-specific, but that he wants everyone to know he has an interest in Gemtech. “I’ll try not to flog our product as this is not a sales presentation,” he says amiably.

Suppressor Background

Suppressors date to the turn of the century when Hiram Percy Maxim, son of the legendary machine gun inventor of the same name, started the Maxim Silent Firearms Company. Our class later tests one of Hiram’s original cans and surprisingly performs right up with “modern” designs.

Dr. Dater mentions some other famous suppressor inventors such as Mitch Werbell, Mickey Finn, Reed Knight and Doug Olson, pointing out that all of their designs came from trial-and-error experimentation along with scientific and engineering principles. It’s clear he has respect and admiration for these pioneers of silence.

We then jump right into the subject. Dr. Dater explains the basic science of sound. Sound is a form of over-pressure which is measured with a ratio of pressures – reference pressure to measured pressure – expressed in a unit of measure named for another well-known experimenter of sound transmittal: Alexander Graham Bell. The unit is called a decibel.

A gunshot, Dr. Dater tells us, is the sudden release of hot, high pressure propellant gases exiting from the muzzle of a firearm. A second component of a gunshot, the sonic crack, is caused by the bullet travelling faster than the speed of sound, like the sonic boom of a high-speed jet.

Going back to high school physics, Dr. Dater asks the class how to decrease pressure. I brush back the fog of time and remember that pressure is equally affected by temperature and volume. “That’s right,” says Dr. Dater, “If you lower the temperature and increase the volume, pressure decreases. In its simplest form, that’s all a can does to reduce sound – decrease temperature, increase volume.”

Now comes the technical part. Sound is not only a factor of loudness – decibels – but also of duration. Think of tapping your car horn versus an ambulance blaring its siren. The duration of the siren is more damaging than the short toot of a horn, even if they’re the same number of decibels. This leads to a discussion of what constitutes “harmful” levels of sound, which in turn brings us to the U.S. military’s definition of sound measurement as defined in Mil-Std 147 4D.

We will hear a lot more about Mil-Std 147 4D before the class is over. It’s the gold standard of suppressors, the only acceptable measurement of performance. Because the scientific method of trial and error is so important to suppressor testing, having a defined standard like Mil-Std 147 4D is imperative.

Reasons For Suppressors

Thanks to Hollywood, suppressors are widely perceived as only being used by assassins. It may be true that some cans have been used to snipe an enemy (we dropped suppressed .45 ACP rifles to the Resistance during World War II) but in today’s tactical climate, the suppressor has far more benign uses.

With law enforcement switching to patrol rifles such as Colt Commandos, the number one reason for a suppressor is to protect the shooter’s hearing. Additionally, cans serve to enhance command-and-control, confuse or deceive the target, to shoot out street lights or guard dogs on drug raids, to conceal the origin of the shot, muzzle flash minimization and a host of other tactical reasons.

Suppressors are a restricted item in the U.S. because when the National Firearms Act was passed in 1934 in the middle of the Depression, where Fish & Game determined that suppressors were used by poachers trying to feed their families, as well as an unfounded Hollywood stigma that suppressors were for assassinations. The Judge Advocate General of the U.S. Army decreed that suppressors are a part of military equipment. Be that as it may, suppressors can be acquired by paying a $200 federal transfer tax and going through all the Form 4 paperwork associated with NFA weapons.

Or, better yet, make one at home. Dr. Dater told the class about experiments with seized and home-made suppressors that he performed with properly calibrated sound equipment at the California Criminalists Institute. First came the oil filter, nothing more than a common, everyday oil filter fitted to the end of a Ruger 10/22. “That one worked pretty well,” Dr. Dater laughed. “We got a 22 decibel reduction.” He tried a sprinkler head with a wadded up piece of cloth inside, a 2 liter pop bottle, a tennis ball can of three balls and, the best of all, a potato. “The potato worked really well, probably because of the high water content, but the bullet came out with what I’d guess was 30 degrees of yaw. Very unstable,” Dr. Dater said.

How Suppressors Work

The reason why potatoes and tennis ball cans don’t work so well is because they’re not addressing the three ways in which a suppressor works. First, a suppressor decreases pressure by increasing volume so that a bullet driven down the rifling of a barrel exits the muzzle into a tube of (ideally) 20 times the volume of the gun’s bore. Second, the tube serves as a heat sink to lower the temperature of the propellant gases, again serving to lower pressure. Third, the internal system of baffles in a suppressor tube serves to create turbulence to delay the exit of propellant gases, again allowing for more heat transfer and volume expansion.

When the bullet leaves a suppressor, just as it would from an unsuppressed muzzle, an “uncorking event” occurs. An uncorking event is the appropriately named term for what happens when a balloon bursts or a champagne cork pops. It’s the sudden release of pressure, the uncorking of the projectile exiting the muzzle crown, which makes a gunshot as loud as it is.

All suppressors rely on these three factors to work. However, there are two main types of suppressors. We’re most familiar with the muzzle suppressor, a pipe-like device that attaches to the end of a barrel but there is also a category of integral suppressors in which the barrel itself is totally enclosed within a shroud.

With an integral suppressor, the barrel is vented with holes to bleed gases into the shroud, which serves to suck away heat, increase volume and stir up turbulence. A good example of an integral suppressor is HK’s MP5 SD. Several companies make Ruger 10/22s with integral suppressors. The advantage is you’re not adding any length to the barrel; a disadvantage is you’re losing a lot of velocity and thereby giving up considerable terminal ballistic performance, plus you can never remove the suppressor. Integral suppressors are generally quieter than muzzle suppressors.

Additionally, a suppressor can be “wet” or “dry” meaning that an ablative agent, usually water or grease, is used within the can to further decrease sound. Dr. Dater noted that some unscrupulous manufacturers rig their testing by pouring water into a dry can to enhance its performance.

Baffle Stacks

All cans look pretty much alike from the outside: a piece of hollow tube. Granted, there’s a lot of engineering in the tube with calculations based on the pressure of the propellant gases to determine the material (steel, titanium, inconel, aluminum) for the tube and its wall thickness. Factors such as hoop stress and yield stress are figured as well.

But tube construction is really not what separates different designs. The baffle stack – the shape and arrangement of a set of washer-like constrictions within the tube – are what make one design work better than another.

Baffles are certainly not new. Hiram Maxim used them. Your car’s muffler uses them. The K-baffle, so named for its cross-sectional shape, was developed in 1909. It features a large surface area for heat dissipation and achieves increased turbulence for “frequency shifting” by acting like the closed end of a whistle or pipe organ. “Frequency shifting” is a phenomenon whereby a sound wave is reflected back on itself to cancel some of the energy, like swirling your hands in a bathtub in opposite directions.

The M-baffle is another type, also named for its shape in cross-section. There’s a coned baffle and a pinched cone baffle. There are concave and convex baffles. There are slant baffles and mysterious sounding Omega baffles. No one type is inherently superior and, Dr. Dater told the class candidly, of the six different brands of suppressors he routinely uses in testing, any one of them can show the most decibels of sound reduction on any given day. “There’s a lot of atmospheric variation,” he says.

So far Dr. Dater has focused on the technology used to suppress the sound of a gunshot, but what if there is no sound to suppress? The idea of silencing the cartridge, not the gun, has long been a focus of Soviet suppressor technology and is called captive piston technology.

Instead of a propellant igniting to create pressure to push a bullet down a rifled barrel, a captive pistol cartridge retains the propellant in a chamber that pushes a piston into the base of the bullet. The “sound” of the propellant igniting is contained within the combustion chamber of the cartridge so it never escapes into the atmosphere.

In practice, a Soviet SP4 captive piston cartridge generates 124.6 dB, which is about what an integrally suppressed Ruger Mk II .22 LR pistol creates.

At The Range

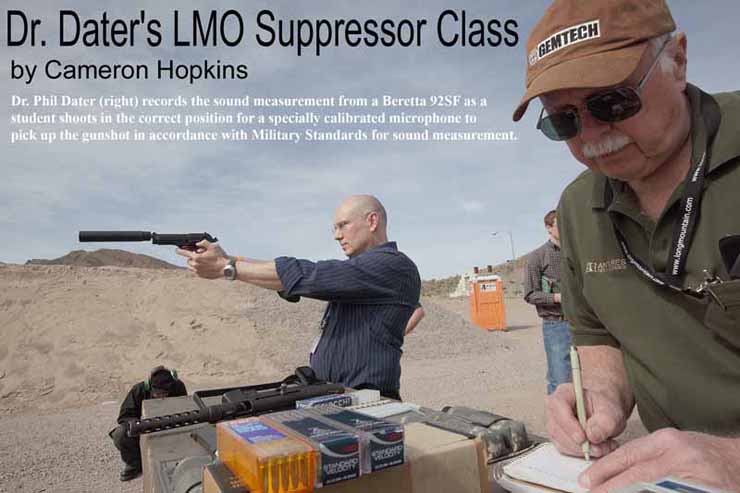

Dr. Dater set up his sound testing equipment at the Desert Hills Shooting Club in nearby Boulder City to demonstrate the theory he’d explained to us with real guns and real suppressors. He started by showing us how Mil-Std 147 4D calls for the microphone to be placed 1 meter to the left of the muzzle, 90 degrees to the bore.

The sound testing equipment itself is highly specialized. The microphone is an LD2530 that’s been certified to a “rise time” of no more than 5 microseconds. The rise time is the time from the start of an event to the beginning of the microphone recording the event – think of it as “response time.”

The microphone is about the size of a pencil eraser and costs $1,000 a copy. It’s connected to a Larson-Davis 800B Type 2 sound pressure meter that in turn is calibrated to a rise time of 20 microseconds. Before any actual sound testing can begin, the unit must be calibrated with another device that produces exactly 400 Hz at 114 dB.

Without this type of precision equipment being properly calibrated and set in accordance with Mil-Std 1474D, any test data is invalid. Some suppressor manufacturers simply concoct “data” from thin air without making any valid tests at all, picking a number that makes their products look good against the competition. Dr. Dater derides such unscrupulous business practices as “specmanship,” the use of fabricated specifications to enhance a flawed product.

As the testing begins, the class experiences firsthand a phenomenon called “first round pop” in which the first round fired registers a higher decibel level than subsequent rounds. This is due to a secondary detonation within the suppressor from superheated, incompletely burned powder entering an oxygen-rich atmosphere. After that “first round pop,” the oxygen is burned off, so subsequent rounds register normally.

The next phenomenon we see in action is how suppressors increase the cyclic rate of full-auto weapons by as much as 200 rounds per minute. This is because the baffle stack in the suppressor delays the gas exit and therefore increases gas pressure back through the gun’s gas port. ARs are known to “run hot” with a suppressor to the degree that gas blow-back through the charging handle can sting the shooter’s eyes, even with eye protection. Accordingly, it’s a good idea to run a PRI “gas buster” charging handle on suppressed ARs.

When the numbers start coming in, we see that sound levels are far more consistent than muzzle velocities. As a longtime handloader, I’m used to chronographing loads that vary as much as 200 feet per second, a significant amount, but the decibel levels from all the guns we’re testing are remarkably consistent. Less than two or three decibels variation isn’t unusual.

The other thing we note is that different brands of 5.56mm suppressors show very little variation. For instance, a Knight’s Armaments M4 QD, SureFire 556K, Gemtech G5 and Advanced Armament M4-2000 were all so close – around 135 dB – that any difference would be statistically irrelevant. We’re talking less than 3 dB difference from the “best” to “worst.”

Which brings us to an important point: suppressor brands shouldn’t be judged solely on their sound reduction. What’s more important are their method of attachment and their point-of-impact shift. Additionally, the dynamics of a weapon are altered substantially with a suppressor making the gun more muzzle heavy, slower to transition between targets and harder to manipulate in close confines. Some brands over-hang the muzzle more than others.

As we shot various weapons – rifles, subguns, pistols, World War II era Welrods, even a pistol used in a murder – several things became clear:

- For pure performance, you can’t beat a .22 LR. The ratio of suppressor volume to bore diameter makes the little rimfire ideal to suppress, along with its low noise signature to start with.

- Suppressors are the world’s best muzzle brakes. Recoil is virtually eliminated.

- Suppressors are great for the guy who hates to clean guns. Dr. Dater says a suppressor should never be cleaned.

- You can minimize the gunshot – the uncorking – but you can’t get rid of the sound from a bolt slamming home or the sonic crack of a bullet. Yes, even suppressed guns make a noise. (The bolt of an M4 slapping home to an empty chamber registers 117 dB.)

- You can’t effectively suppress a shotgun; No Country For Old Men notwithstanding. There’s no safe way to allow the shot column to pass through a baffle stack.

Dr. Dater’s class is a fascinating addition to any tactical shooter’s knowledge base. It’s a classic example of “You don’t know what you don’t know” until you get there and take the highly informative class. For more information, log on to www.longmountain.com.

| This article first appeared in Small Arms Review V14N1 (October 2010) |