By William R. Bishop

As readers of SAR may know, I recently completed a military tour in Bosnia and was able to observe and handle many foreign weapons. One which caught my eye was that carried by the Belgium contingent – the Fabrique Nationale Carabine. Upon returning to America I kept on thinking about that FNC. I discovered they were available and decided (actually, my wife Linda gave me permission) to get one. A phone call to Gene Guilaroff, who has supplied me “black rifles” in the past, had an FNC Paratrooper with 18” barrel on the way to me.

After becoming quite familiar with my FNC, I wanted to learn more about it but quickly discovered there was little information available. Well, that situation has now ended with the publication of this two-part series on the FNC. This first article will provide a detailed overview of the rifle, including its background, technical details and operating characteristics. The second article, to be published shortly, will cover in detail its conversion to a factory-correct select fire weapon. Hint for all Class III enthusiasts: registered sears are plentiful and relatively inexpensive!

Installment 1 of the FN FNC in America.

Background

The birth of the FNC begins with its grandfather, the world famous FN FAL 7.62mm battle rifle. In the period 1963-66 as the arms market showed interest in smaller calibers, particularly the 5.56mm round, FN responded by designing the 5.56mm CAL rifle. Essentially the CAL was a smaller version of the FAL and continued to use the unique adjustable gas system. Unfortunately, the CAL was costly to manufacture/unreliable and therefore discontinued in 1975. It should be noted that 15-20 semiauto CAL’s were imported into America and sell (if available) for around $7500.

During 1974-76 FN redesigned the CAL into what we now know as the FNC. This was done for two reasons: 1) to compete in the 1976 Swedish arms tests and 1977-80 NATO cartridge evaluation trials; and, 2) to market a reliable 5.56mm rifle which could oppose the M16. Ultimately, in addition to Belgium, Sweden and Indonesia became licensed manufacturers of the FNC. At last count the FNC remains used by these three countries’ military forces and also is exported to parts of Asia and Africa.

Three importers are known to have brought semiauto FNC’s into the United States. Steyr of Secaucus, NJ and Howco of Laurel, MD brought in a total of about 1000 into the US during 1982-early ’83 timeframe. Gun South Inc. of Birmingham (later Trussville), AL imported approximately 5000 from mid 1983-88. When first imported in 1982 the price for an FNC was between $1000-1100. In 1985 this dropped to around $750 for either version to stimulate sales. In 1989 the importation of FNC’s, along with SIG, etc. was halted upon order of President Bush.

There were three imported versions of the FNC:

*Standard Model – Fixed stock with 18” barrel

*Paratroop Version 1 – Folding stock with 18” barrel

*Paratroop Version 2 – Folding stock with 16” barrel

Interestingly enough, while the folding/collapsing stock versions of military style weapons tend to be more rare, this is not the case with the FNC. Almost 90% of all imported FNC’s were the folding stock variation while the fixed stock comprised just 10% of the total. Also, the short 16” barrel is relatively uncommon and quite desirable.

Technical Details

Layout

The FNC is constructed of steel and aluminum alloys that are designed for reliability of operation and straightforward construction. Most of the parts are finished with a rugged satin black enamel which is baked on. The aluminum parts are black anodized while several steel items are dark gray parkerized.

With an overall length of 39.25” and unloaded weight of 8.3 lbs. (Para Version 1) it is of similar dimensions when compared to other 5.56mm rifles. The relationship of stock, trigger and handguard is excellent and readily lends itself to ease of handling and shooting. The handfilling front handguard is particularly well designed and remains cool to the touch even after periods of extended firing.

The trigger is designed by FN as a single-stage model and is fairly stiff. Trigger slack takeup requires 2.5 lbs. of pressure while sear disengagement needs an additional 8 lbs. to achieve release. Creep is typically .04-.05” which is well within specifications for a rifle designed for hard battlefield use.

The FNC is designed to use the NATO STANAG 4179 (Colt AR15-type) magazine. While a blued all-steel 30-round mag was originally available, it is generally hard to find and expensive. This is not a problem as the Colt 20 and 30-round versions work perfectly well and are found everywhere. For you serious collectors, the Beta-C mag should work properly in the FNC.

Receiver

The upper receiver is composed of stamped sheet steel with all welding performed robotically. The barrel extension, which includes the cartridge feed ramp, is spot welded into the front of the receiver. The rear of the receiver is given structural integrity by having the rear take down support also spot welded in. The rear sight assembly, too, is welded onto the receiver. To carry the bolt assembly, two U-shaped guide rails are spot welded inside the receiver. Next to the right guide rail is the ejector, which is riveted in place. Finally, to keep debris from getting inside the receiver there is a cocking slot cover which is spring loaded to ride over the cocking handle when the bolt assembly reciprocates.

The lower receiver is milled from aluminum alloy stock which is black anodized to reduce visibility. The magazine release is very similar to the Colt AR15 and is well positioned for one finger use. The trigger mechanism replicates the FALs’ and is easily accessible for maintenance. By rotating the safety switch vertically upwards it can be slid out to permit greater internal access for mechanism adjusting and/or replacement.

Barrel

The FNC’s imported into the US had two different length barrels. One was 18” and the other was 16”. Paratroop FNC’s came with both lengths while the standard fixed stock model came with the 18” version. Unlike the AR15, there has never been a heavyweight or “target” FNC barrel.

The barrel is hammer forged with a 6-groove RH twist which, is then hard chrome plated. Twist is 1/12” and designed to stabilize the US M193 55gr. bullet. It may not fully stabilize the newer US M855 62gr green tip slug. Interestingly enough, the Swedish Bofors-manufactured FNC (entered service in 1987 as the AK5) initially used a slow twist barrel due to humanitarian concerns about excessive wound trauma. They have since adopted the 1/7” twist as used on the M16A2 rifle.

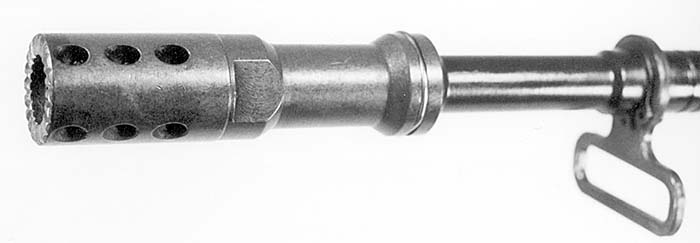

The FNC barrel has a parkerized NATO-standard 22mm flash suppressor (LH thread!) which is very similar to the FAL “shorty” factory model. Flash suppression is adequate, but the main purpose of this device is to allow the mounting/launching of rifle grenades. Finally, the barrel is ribbed to support a clip-on bipod and front sling swivel.

Operating System

The gas-operated recoil system is a combination of the AK and FAL systems. A takeoff port in the barrel directs expanding gases through the gas block and into the gas tube. This tube carries the gas piston, which is part of the bolt carrier assembly. The gas slams into the head of the gas piston and forces the entire bolt carrier assembly to move backwards. As it begins moving to the rear, a camming action causes the bolt to unlock from the barrel extension and extract the spent cartridge case. Further bolt assembly movement causes the case to hit the ejector, recock the hammer and compress the recoil spring. The spring then drives back into battery the bolt carrier assembly, which strips off a fresh cartridge from the magazine and cams the bolt back into engagement with the barrel extension locking lugs. It is now ready for another round to be fired.

The FNC bolt is similar in size to an AR15 bolt and has two large dual-opposed locking lugs. The firing pin rides within the bolt, but is unusual in that it is retained by the bolt carrier and floats for 7mm. A firing pin spring is used so that an accidental inertia impact with the cartridge primer (which AR15’s are known to do) is eliminated. This firing pin is very thin and perhaps the weakest point in the FNC system.

Finally, the FNC gas system is adjustable in two separate ways. Should crud build up and more gas pressure is needed to cycle the action, an extension on the gas piston tube is rotated 90 degrees clockwise. This will cause the gas piston tube to close over an exhaust port located on the gas block and result in increased pressure being diverted against the gas piston head. The second adjustment is in regard to the firing of rifle grenades. By flipping up the grenade sight the gas is then cut off from flowing through the gas block and the FNC will not cycle. This permits the full force of the gas to be directed against the base of the grenade. Of course, a special ballistite (blank) cartridge is required to generate the high pressures required for launching.

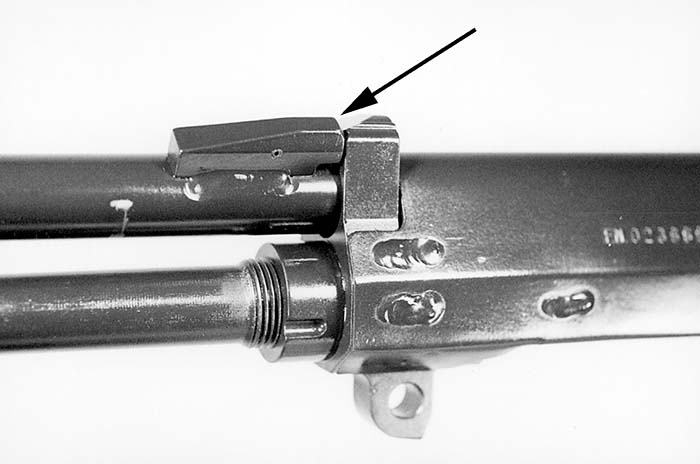

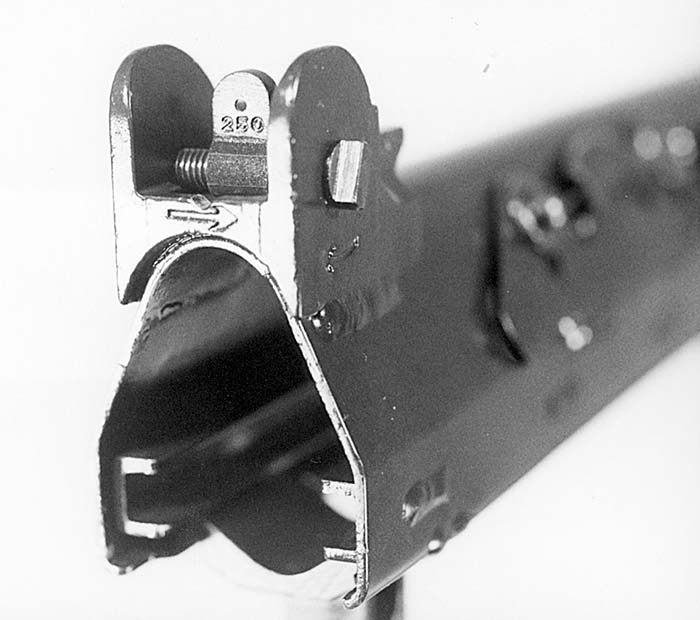

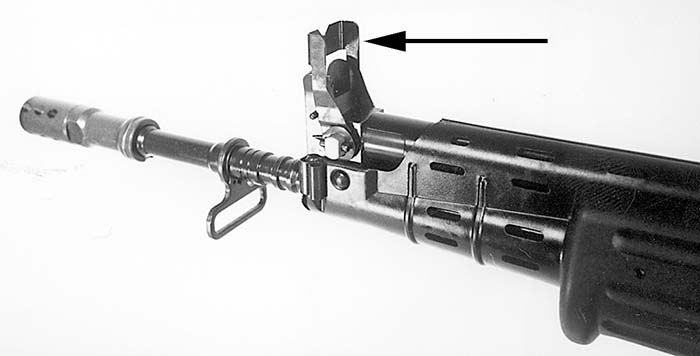

Sights

Sights on the FNC are clearly in line with those of the FAL. The rear is an aperture type that flips into two positions: one for 250m and the other for 400m. It is protected from accidental knocks by two ears, which extend up from the base. Each adjusting click of the detent will traverse the bullet point-of-impact 1cm at 100m. The front sight is a spring-loaded post, which is also protected by two ears. Although there is no detent, each 1/4 turn of the post will elevate the bullet 1cm at 100m. While the sight adjusting function is performed with the combination tool, the Uzi SMG tool is also perfect for the job. Sight radius for the FNC is 20”.

Furniture

All the furniture on the FNC is rugged black plastic. The handguards are compression molded and riveted with brass nibs to steel liners. These liners give excellent structural integrity while being vented to dissipate the heat both forward and through the top. The pistolgrip is a direct takeoff from the FAL and is wedge shaped with a fairly steep rake to increase control while in rapid fire. The pistolgrip also contains the oiler/cleaning kit.

The sturdy folding stock is also a copy of the FAL paratroop unit. The two legs and buttpiece comprising the stock are made of aluminum, which has been finished in a baked-on satin black enamel. Also, the top leg of the buttstock is encased in plastic to reduce the effect of temperature extremes on the shooter’s face. The stock is fixed to the lower receiver via an aluminum mounting block which has been black anodized. To fold the stock, simply thumb aside the lock button, disengage the stock from the mounting block and fold against the right side of the rifle.

The fixed stock is also made of hard black plastic with a steel buttplate. It is mounted directly to the lower receiver via one screw. Swapping folding and fixed buttstocks is quite simple and requires no modifications to the bolt carrier, recoil mechanism, etc. Simply remove the screw, replace the stock, and reinstall the screw.

Spare Parts

Just recently the import of Indonesian-manufactured spare parts has taken place. Spare barrels, firing pins, magazines, tools, etc. are all available from Tampa Bay Military & Police Supply Inc. These items are officially licensed from FN and built to military specifications by the quasi-governmental firm of Bandung. Since Indonesia has been fighting terrorists and internal unrest for many years it is safe to say these parts have stood the test of time and will work quite well in the FNC. Two particularly interesting items are the 16” and 18” barrel assemblies with the 1/7” twist which will permit stabilization of the heavier M855 62gr. bullet.

Accessories

The FNC factory manual dated March, 1982, shows the following accessories to be available:

M16 Bayonet Adapter – This is attached to the barrel and permits the US M7 bayonet to be used. Otherwise, the FN “tubular” bayonet is used by sliding it over the NATO-standard 22mm flash suppressor.

Telescopic Sight – This is a superb 4×28 milspec scope manufactured by Hensoldt. It has the typical picket-post crosshair and sports an olive green finish. It is attached to the scope mount via two STANAG screws and is adjustable for windage and elevation.

Telescopic Sight Mount – This is a quick disconnect mount very similar to the SIG AMT design. The forward end of the mount is inserted into a cutout that is machined into a protrusion coming up from the barrel extension. The rear is then lowered until it lays against a dovetail which is part of the rear sight base. A lever on the mount is then pushed which cams into the dovetail. Neat, simple and very quick.

Bipod – This is a sturdy cast aluminum “claw clamp” design similar to the model used on the AR15. It functions by squeezing the spring-loaded legs together and placing the open mouth against the barrel. Releasing it will cause the mouth to close around the barrel and remain in place. With a working height of 11” it gives excellent support to the FNC.

Combination Tool – This tool is very handy for cleaning the gas piston, gas block port and adjusting the sights. Normally quite difficult to find, it is now being imported by Tampa Bay Military & Police Supply Inc. and an excellent addition to the tool box.

Operating Characteristics

The FNC is a fun firearm to shoot. Its simple, yet solid, construction gives it a balance and heft which yields confidence. Whether in the paratroop or fixed stock versions, it remains an excellent firearm to employ.

To load the FNC simply insert the magazine into the feed well and push until it locks into place. Grasping the cocking handle on the right side of the receiver, pull it to the rear and release smartly. A round will be chambered. Take it off safe, aim through the sights and press the trigger. Recoil is well dampened and presses directly back into the shoulder. Recovery onto the target is rapid for followup shots.

Accuracy testing with 210 rounds of first quality (not surplus) IMI M193 ball ammo provided by Cole Distributing revealed my particular FNC fired a consistent 10-round group of 2 1/2 MOA. This was with iron sights and stiff trigger, while the average velocity clocked at 3281 fps. The accuracy with this particular FNC/cartridge combination was outstanding and exceeds any military requirement I am aware of. One comment: many shooters avoid “surplus fodder” due to concerns about overpressure, corrosion, etc. This is clearly not true with Cole’s .223 IMI cartridge. It is very accurate/clean burning and is highly recommended!

For reloading purposes the FNC is not as friendly as the AR15. Most cases being ejected from the FNC are dented due to impacting the cocking slot cover. Unlike the H&K series of rifles, there is no optional ejection port buffer to snap on and reduce case damage.

Breaking down and cleaning the FNC is similar to the AR15. First, take out the magazine and make sure the chamber is empty. Cock the weapon and place it on safe. Push out the two captive takedown pins that connect the upper and lower receivers together. Grasp the cocking handle and retract the entire bolt carrier assembly towards the rear. As the handle reaches the cutout at the rear of the cocking slot pull it (the handle) out from the bolt carrier assembly. Use your finger to slide out the bolt carrier assembly from the upper receiver rails.

Next, press on the recoil spring retainer plate and rotate it 1/4 turn in either direction. This will disconnect the recoil spring/guide from its attachment point inside the gas piston. Slowly withdraw it towards the rear as spring tension is released. Finally, separate the bolt from the bolt carrier by rotating it 1/4 turn counterclockwise and remove it from the bolt carrier. Be careful the firing pin spring does not accidentally fall off the pin and get lost! Remove the handguards by snapping off their spring retainer clip located in front of the gas block.

Cleaning the FNC is very simple. Standard solvents and oils are used, but make sure all ammonia-based products do not come into contact with the aluminum lower receiver. It will attack non-ferrous metal! Cleaning the barrel from the breech end is simple and the only proper way to do so. Make especially sure you address the receiver extension where the bolt locks up as it will harbor a good amount of crud. Other places to make sure are clean include the hard chromed gas piston area, the gas tube it travels in and the gas block with its porting hole. For really stubborn carbon deposits in these areas I use a wooden popsicle stick or the combination tool to scrap them away.

Reassembly is the reverse of disassembly. Items to watch for include making sure the cocking handle is placed back into the bolt carrier assembly (it’s easy to forget) and the gas selector lever is placed into the “normal” and not full power position.

Conclusion

The FN FNC is one of the “best kept secrets” in military-style rifles to be imported into America. It is clearly one of the best. When comparing its cost to similar imports the true value of the FNC will become even more apparent. In fact, I consider it one of the few remaining “bargains” to be found. Where else can you get a firearm of this type from an internationally respected manufacturer for the price of a green label AR15?

Firing the low recoil and commonly available 5.56mm cartridge makes it a pleasure to shoot and even easier on the pocketbook. Further, its supply of high capacity magazines is assured for years to come. As an additional incentive, the import of licensed spare parts has begun and will keep the FNC running long into the future.

Fabrique Nationale’s FNC until now has been little known in America and deserves much greater respect than has been accorded. Belgium, Indonesia, Sweden and a host of other armed forces cannot be wrong. Now, with your knowledge of the FNC, you will not be either.

Stay tuned for a future article on how to convert the FNC to select fire – with registered transferable factory parts!

Arclight

Attn: Gene Guilaroff

PO Box 173

Alvaton, KY 42122

(502) 622-7309

Tampa Bay Military &

Police Supply, Inc.

Attn: Dana Reed

501 S. Falkenburg Rd.

Tampa, FL 33619

(813) 662-9433

fullauto@gte.net

Cole Distributing, Inc.

Attn: Gary Cole

PO Box 50271

Bowling Green, KY 42102-2871

(502) 843-6844

www.cole-distributing.com

| This article first appeared in Small Arms Review V2N3 (December 1998) |