By Jean Huon

At the end of the World War II the French Army was equipped with a variety of material of a range of qualities. The Allies had provided Stens, Thompsons and M3 submachine guns, and many others were used by the Army at the beginning of the campaign to recover French power in Indochina that included the Gnome & Rhone R5 (a French Sten copy), MAS 38, F.N.A.B. 43 and German MP40. In addition to the problems presented by the maintenance of these diversified materials, their use involved the provisioning of three different types of ammunition.

History

Faced with this indisputable fact, Headquarters reacted quickly and charged the Section Technique de l’Armée to draw up a new table schedule to develop a new submachine gun. The program was established on May 11, 1945. The ammunition retained was the 9mm Luger, which offered an excellent weight and power/recoil and was now largely available in the world. The other characteristics related to a simple design and economic production. During tests, other characteristics were added to include a cover on the ejection port, a folding (or telescopic stock) and a folding magazine housing.

In 1947, the three national small arms factories presented several prototypes: MAC with sheet metal tubular frames, folding metallic stocks and magazine housing, MAS with cast steel frames, delayed opening bolts as used on light assault rifles, with wooden or metal folding or non-folding stocks, and MAT with a weapon having a rectangular frame, folding magazine housing and wooden stock. In 1948, these guns were perfected and some of them used in Indochina as well as some other prototypes, such as the M.G.D. from Merlin-Gerin, the AME and the Hotchkiss prototypes. After having tested these many models, the Army fixed its choice in June 1949, with the MAT 49.

Production

The MAT 49 was developed by Chief Engineer Monteil and the director of MAT, Mr. Delamaire. Manufacturing was focused on sheet steel stamping as the development of these new techniques for the time had been made with the collaboration of German engineers working in Saint-Louis and the Dallet Company in Brives. Serial production began in January 1950, slowly at first, then at a more constant rate with 4,600 weapons per month in 1952 and up to 10,000 units later.

Improvements were made during its manufacture. In May 1950, the length of the frame became slightly longer and then over time a succession of minor modifications generally not affecting the interchangeability of the parts, but making it possible to reduce production costs. Thus, manufacturing time that was originally 6 hours was brought back to two hours in a ten year period. The use of crucible cast steel or sintered iron elements also considerably reduced the number of machine tools necessary for machining, as well as the raw materials.

The MAT 49 SMG was manufactured by Tulle Small Arm Factory, from January 1950 to the mid 1960s, with more than 700,000 weapons produced, and the Châtellerault Small Arm Factory, from May 1950 to November 4, 1954, with 125,143 gun being produced.

Description

Manufacture of the MAT 49 primarily consists of stamped and welded plates with just a few parts requiring machining. The receiver frame is rectangular. On the right is the ejection port with a cover actuated by a spring to be automatically opened when the bolt goes forward or rearward. The cocking lever is on the left with a cover. The external profile of the barrel is slightly tapered, is bored 9mm and has four grooves with 250 mm (9.84 inch) left turn. There are side vents at the chamber that allows the evacuation of gases in the event of firing out of battery. A perforated jacket surrounds part of the barrel length.

The bolt is a parallelepidic block with a cylindrical section before the head and has a fixed firing pin. The extractor is placed on the right and there are grooves for the ejector on the left. The lower face is machined in order to provide passage of the magazine feed lips on both sides. The bolt is longitudinally bored to let the recoil spring rod to pass through.

The pistol grip unit consists of two symmetrical parts assemblies welded according to the vertical median plane. It joins together the grip, the housing for the firing mechanism and the flanks supporting the magazine housing. The grip is made up of two plastic plates, secured by a through screw. The left plate is provided with a thumb rest. The trigger mechanism includes the trigger, sear and a safety part associated with the grip safety. The magazine housing is also a folding front grip.

Two models of magazines exist: the standard 32 shot model and the desert 20- or 25-round type with single column.

The stock is steel wire and affects the shape of a trombone. It slides in side tubes laid out on both sides of the receiver. A transverse push-button and notches in the arm of the stock makes it possible to adjust the stock in three positions for transport or parachute jumping with the stock entirely pushed back forwards, the intermediate position for the guard or ceremonies, and in the full extension for shooting.

The rear sight is a folding L with two eye pieces (100 or 200 m) and the front sight is protected by a hood.

This description relates to the most current model of the weapon produced between May 1950 and 1962. Later, one of the most outstanding modifications concerns the grip safety, which immobilises both the sear and the bolt until the trigger is squeezed. All the weapons that were provided with this device carry a five pointed star on the left face of the trigger.

From 1962, manufacture is further simplified in the Series K: the grip is entirely made out of stamped sheet metal with removal of the plastic elements and becomes ambidextrous, the barrel sleeve is fixed to the frame by arc welding, instead of electric points welding as used before, and the cocking lever is in the shape of a hook in place of the knurled cylinder.

Accessories

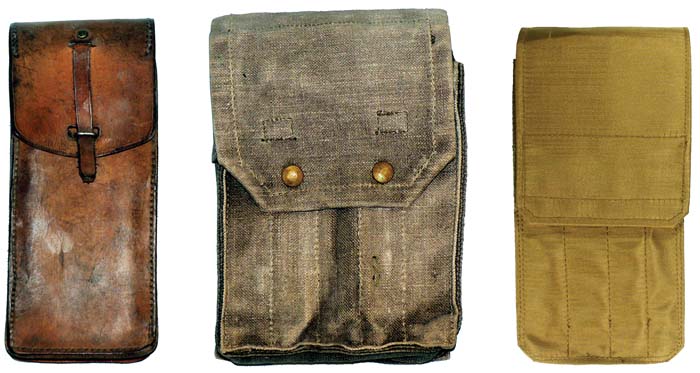

- Leather cartridge pouches are of natural color for the Army and Navy, black for the gendarmerie and Air Force, red for Saharan troops or white for ceremonial purposes. They measure 27 x 11 x 4 cm (10.6 x 4.3 x 1.5 inches) and can contain four magazines. These cartridge pouches are carried very high on the level of the abdomen are particularly uncomfortable.

- Cartridges pouches similar as above, but made of khaki nylon and closed by Velcro.

- Haversack in khaki fabric that contains five magazines. The use of belt loops makes it possible to carry them at a low level on the hips in a much more comfortable fashion. They were used by paratroops and commando units.

- Blank shooting plug.

- Cleaning kit in a leather pouch containing a loading tool, oil can and a cleaning rod in two parts.

- Leather sling of the same color as the cartridge pouches.

Use

Before the arrival of the FAMAS rifle, the MAT 49 submachine gun was issued to corporals, NCOs of the Army and the Navy, as well as the major part of the Air force. The gendarmerie replaced it with the HK MP 5 A3, Browning riot guns and also by the UMP SMG. The police now use the Beretta M12 S SMG.

A number of countries also used the MAT 49 including Algeria, Barbade, Benin, Bolivia, Burkina Faso, Burundi, Cambodia, Cameroun, Centrafrican Republic, Chad, Comores, Congo, Djibouti, Gabon, Guinea, Israel, Ivory Coast, Laos, Liban, Madagascar, Mali, Mauritania, Morocco, Niger, Rwanda, Senegal, Togo and Viet Nam.

Variations

The MAT 54 (also called MAT 49-54) was a specific model developed at the request of the Police of Paris. It is characterized by a fixed wooden stock, a long barrel with a perforated cooling jacket, front sight protected by ears and two triggers allowing single shoot. There is also a devise that prohibits the use of the full auto trigger.

The MAT 54 S.B. is the standard length model with a wooden stock and a trigger mechanism allowing only single shot. This model was used by armoured car companies and prison guards.

The MAT 49 was rebarrelled in 7.62 mm Tokarev and used in North Vietnam. The barrel is slightly longer: 270 mm (10.6 inches).

Disassembly-Reassembly

Remove the magazine and clear the weapon. Put the magazine housing at 45 ° angle. Remove the stock. Press on the front lock to separate the frame and the pistol grip unit. Extract the bolt, recoil spring and cocking lever. Reassembly is in the reverse order.

Evaluation

The MAT 49 is an excellent weapon. It is manufactured with robust and quality materials. The design makes it very compact whether the stock is extended or not. The presence of a grip safety and the folding magazine housing are major safety assets. Control during firing is very manageable and precise shooting up to 50 meters is capable with two-shot bursts.

MAT 49

Caliber: 9mm

Ammunition: 9mm Luger

Overall length: 0.720 m (28.34 inches)

Length with stock retracted: 0.460 m (18.11 inches)

Barrel length: 0.230 m (9.05 inches)

Weight: 3.5 kg (7.72 lbs)

Magazine capacity: 20-32 shots

Cyclic rate: 600 rpm

MAT 49/54

Caliber: 9mm

Ammunition: 9mm Luger

Overall length: 0.900 m (34.43 inches)

Barrel length: 0.365 m (14.37 inches)

Weight: 3.950 kg (8.72 lbs)

Magazine capacity: 32 rounds

MAT 54 S.B.

Caliber: 9mm

Ammunition: 9mm Luger

Overall length: 0.750 m (29.52 inches)

Barrel length: 0.230 m (9.05 inches)

Weight: 3.4 kg (7.5 lbs)

Magazine capacity: 32 rounds

| This article first appeared in Small Arms Review V13N11 (August 2010) |