Original MAC box for their .22 M16/AR15 with conversion kit and magazine. (Courtesy of Wayne Daniel)

By Frank Iannamico

When first adopted 1964, the early M16 rifle was not an especially popular weapon. Its small cartridge, unusual appearance and unconventional construction made it difficult for military purists to accept. The M16 also encountered a number of reliability problems early in its service life, but by 1967 most of the issues encountered with the weapon were addressed with the introduction of the M16A1 model. In reality, the M16 proved to be accurate, controllable in automatic fire, and had less component failures than previous service weapons. In 1982, the M16A1 was replaced by the product improved M16A2. The U.S. Army adopted the M4 carbine in 1994, while the current Marine Corps general issue is the M16A4 rifle.

With the latest M4 and M4A1 carbines, the U.S. Army seems to finally have the weapon it had sought since 1939. A compact, powerful, accurate and lightweight rifle that is controllable in the full-automatic or burst mode of fire. The M4 features a 14.5-inch 1:7 twist hard-chrome lined barrel that can mount the M203A1 grenade launcher. The U.S. M4 has an adjustable telescoping buttstock to accommodate the size and physical characteristics of just about any soldier. The overall length of the M4 is 33.88 inches with the buttstock fully extended and 30.69 inches in the retracted position. Weight with a loaded thirty-round magazine is only 6.9 pounds. Firing the standard NATO Ball M855 cartridge, the M4 has a muzzle velocity of 2,900 feet per second. The M4 carbine achieves over an 80 percent parts commonality with the M16A2 rifle. The M4A1 features a modular upper receiver, with detachable carrying handle, fitted with the A2 style sights, and STANAG accessory rail on top of the receiver. The rail can mount a variety of hi-tech infrared and night vision optical devices and mounts. The rifle is expected to serve as the main infantry weapon of the U.S. military for the foreseeable future. The M16/M4 series of service rifles are well on their way to surpassing the U.S. service longevity record of the M1903 rifle.

During 1963, Colt decided to offer a semiautomatic version of the M16 rifle called the AR-15, the original name of the weapon before its adoption by the U.S. military. The rifle became popular during the 1980s “assault rifle” boom, especially with military veterans who were issued the M16. However, it would be during the new millennium when the AR-15 would become, arguably, as popular as the legendary 1911 pistol. When the rights for the AR-15 rifle expired, many companies began to make their own copies of the AR-15. Currently, there are approximately 50 companies manufacturing AR-15 type rifles and receivers, and the list is growing. Although the rifle is commonly known as the AR-15, the name AR-15 remains the registered trademark of Colt. In addition to rifles, the accessory aftermarket has boomed. Available are an endless number of upper receivers, handguards, stocks, foregrips, optics, sights and caliber conversions.

One feature of the original design is the rifle’s .223/5.56mm caliber, which lends itself to a relatively easy conversion to the economical .22 rimfire cartridge, while retaining the original barrel. The diameter of the .22LR rimfire bullet is .222-inches, while the M16 5.56 NATO cartridge bullet has a .224-inch diameter. The ability of firing .22 rimfire allows inexpensive target shooting, training and familiarization for young or inexperienced shooters, before transitioning to the standard .223/5.56mm rounds.

In the 1970s, the U.S. Army recognized the value of a .22 caliber conversion. An M16 converted to .22 caliber rimfire would be useful for training, particularly for army reserve units that did not have access to a range capable for live firing of 5.56mm rounds. Several kits available at the time were tested and evaluated; the conversions were designed for semi-automatic operation only.

Early M16/AR-15 .22 Conversions

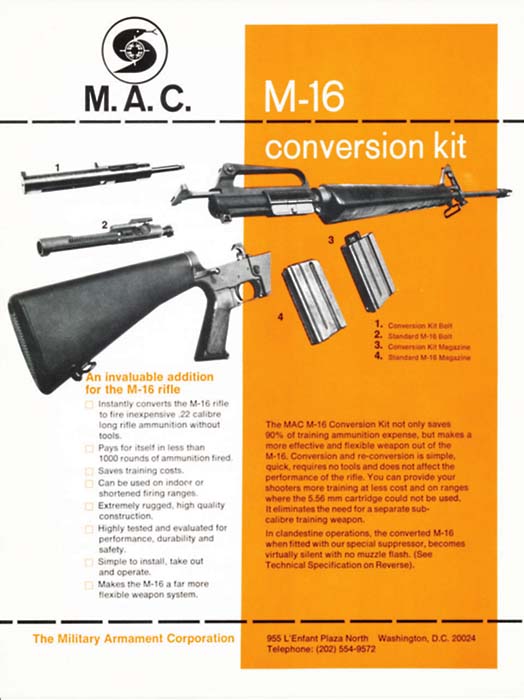

The Military Armament Corporation

In addition to their MAC-10 and MAC-11 submachine guns, a popular product for the Military Armament Corporation was their kit to convert the U.S. M16 Rifle to fire .22 rimfire cartridges. The conversion kit was originally designed by Maxwell G. Atchisson in 1970. Needing a firm to manufacture his new M16 conversion kit, Atchisson contacted the Military Armament Corporation. He was hired by MAC as an engineer in 1971, and negotiated a deal, licensing MAC to produce and market the MAC/Atchisson AR-15, M16 .22 caliber conversion kits. The .22 caliber magazines were fabricated from Colt 20-round M16 magazines. For the next two years, the kits were manufactured and marketed worldwide by MAC.

The British and U.S. Army tested the kits with satisfactory results. MAC advertisements boasted that use of the .22 conversion kit was ideal for training new recruits and offered substantial savings in ammunition costs. The original Atchisson kits were not designed to function in the full-automatic mode of fire. The price of one kit in 1972 was $69.95 with discounts for large orders. The .22 conversion kits were sold to many foreign governments who were issuing the M16 rifles.

An MAC/Atchisson .22 conversion kit was shipped to the Marksmanship Committee at Fort Belvoir, Virginia for testing and evaluation during May 1972. Reportedly, the unit fired 16,000 rounds of .22 caliber ammunition during a twelve-week period without any major functioning or accuracy problems. The conversion unit was evaluated and passed the Military Potential Test at Fort Benning, Georgia. MAC literature printed during 1972, boasted that the M16/.22 conversion kit successfully passed U.S. Military Testing at Aberdeen Proving Ground; however, the only purpose of the test was to determine if the unit was deemed safe enough for further testing.

Atchisson left the Military Armament Corporation in February 1973. After leaving MAC, Atchisson renamed his conversion unit the Atchisson MK I, and began work on an improved version, which became the Atchisson MKII Conversion Device. A final improvement to the device was the addition of a firing pin from the Ruger 10/22 rifle, this variant was designated as the MKIII and was capable of both semiautomatic and full-automatic operation. Atchisson signed an agreement with the Walker Aldridge and Kelly (W.A.K.) Company of Fairborn, Ohio, giving them the rights to manufacture and market his MKII design. Later, a firm called Brocal Inc. acquired the rights to Atchisson’s conversion device. During 1993, Jonathan Arthur Ciener of Titusville, Florida acquired the rights to the MKII and later the MKIII .22 conversion device. Mr. Ciener still manufactures and markets the MKIII device today.

John Foote, another former employee of the Military Armament Corporation, had also designed and built a .22 caliber conversion kit for the AR-15 and M16 rifle. His design competed with Atchisson’s for adoption by the U.S. Army. After the usual extensive testing and government red tape, Mr. Foote’s conversion unit won the competition and was adopted by the Army as the .22 Caliber Adapter, M261. The M261conversion was blow-back operated, with a 10-round magazine designed to fit inside a standard 20-round M16 magazine. The first production run was subcontracted out to Okay Industries, of New Britain, Connecticut. A second contract was awarded to Maremont of Saco, Maine. Mr. Foote later formed his own company, the U.S. Armament Corporation. Mr. Foote eventually sold the company and the rights to the M261 .22 caliber conversion kit.

After Atchisson’s original .22 M16/AR-15 conversion proved successful, other designers, seeing the market potential of conversions, began to design their own similar device. A .22 conversion device developed at the Rock Island Arsenal was the work of Ronald Elbe. Colt, the manufacturer of the AR-15 and M16 rifles, offered their .22 conversion kit designed by Henry Into. There was also a .22 rimfire conversion designed by U.S. Air Force Master Sergeant Julius V. Jurek. The “Air Force” conversion had a rifled chamber insert, and was gas-operated. The 10-round magazines were made of white nylon. It was the only kit that locked the bolt open on the last shot. All of the kits were individually serial numbered.

Modern .22 Conversion Kits

With the current popularity of the AR-15/M16 rifles, there has been a renewed interest for a reliable .22 caliber conversion. Today, there are a substantial number of companies offering drop-in conversion bolts and dedicated barreled upper receivers. Many of the kits available today are based on the original Atchisson design.

All of the early conversion kits consisted of a drop-in bolt assembly and a .22 magazine adapter. The kits used the original barrel.

One of the problems that may be encountered when firing a lot of .22 rimfire cartridges through a M16 or AR-15 in their standard configuration, is the eventual fouling and leading of the weapon’s relatively small gas port and gas tube. Although it will usually have no effect when firing .22 rimfire cartridges in the rifle, the weapon may begin to malfunction when switching back to firing .223/5.56mm rounds. The solution to the problem is using a barreled upper receiver dedicated to .22 rimfire, which does not have a gas port in the barrel. The dedicated .22 uppers are available from a number of manufacturers.

CMMG

The .22 caliber barreled upper receiver evaluated for this article was from CMMG, a well-known source for a growing number of M16/AR-15 rifles, components and accessories. The CMMG upper was designed for the far more prolific semiautomatic AR-15-type platforms. However, for the fortunate owners of select-fire M16/AR-15 rifles, CMMG offers a kit that includes an anti-bounce device and a sear trip for allowing their semiautomatic barreled upper receivers and bolt kits to have full-auto capability. The .22 uppers feature a 16.1-inch premium 4140 Chrome Moly steel barrel with a nitride finish. The upper receiver is a forged 7075-T6 aluminum M4 flat top type with optics rail. Although the CMMG .22 caliber barreled upper has a forward assist, it is pinned in place and non-functional. One of the features is a charging handle designed to prevent the small .22 casings from jamming between the charging handle and the bolt. Although there have been a few reports of some adjusting required to get many AR-15/M16 .22 conversion kits to function, the CMMG unit functioned right out of the box. The upper was tested on a Colt factory M16A1 and an M16/ 9mm Colt SMG (with the factory 9mm magazine adapter blocks removed). The performance of the CMMG conversion barreled upper was 98%, which with any .22 conversion can considered very reliable. CMMG states that their .22 conversions, with the optional sear trip kit, will function with most drop-in auto sears, but will not work with lighting links.

The muzzles of the CMMG .22 caliber barrels are threaded ½-28, a common thread for AR-15 flash hiders and for most .22 caliber suppressors, With a suppressor attached, the 16.1-inch barrel of the test rifle seemed much too long. Since the barreled upper was going to be exclusively used on select-fire M16 rifles, it was decided to shorten it. Prior to shortening the barrel, a call was made to the CMMG tech department to see if the shorter barrel might cause any functioning problems, the answer was no, so the barrel on the test unit was shortened to 10.5-inches and the muzzle re-threaded by Veronesi GunWorks.

The unit was tested with Black Dog standard and drum magazines and CMMG magazines, all fed and functioned equally well. A variety of .22 caliber ammunition was used for the test; the only difference was that high-velocity .22 ammunition noticeably increased the cyclic rate in full-auto, over the subsonic ammo. The shortened barrel and suppressor had no adverse effect on the performance. With the suppressor attached, CCI Standard Velocity, and Gemtech subsonic .22lr ammunition were used, reliability was excellent, and all the rounds remained subsonic when fired.

CMMG’s .22 conversion barreled upper receivers are available in a number of configurations. The uppers are available in the classic AR-15 configuration based on the M16A4, a heavy barrel model with free-float handguards, with an M4 style barrel and hand guards, and an optics-ready model. The barreled upper receivers are easily installed by simply pushing out the two retaining pins, removing the original .223/5.56mm unit, and installing the dedicated .22 upper.

Conversion Bolts

In addition to the barreled upper receivers CMMG offers .22 rimfire drop-in bolt assemblies that use the rifle’s original .223/5.56mm barrel. The bolts are made of stainless steel and are available in both right and left-hand models. The conversion bolts are easily installed by simply removing the original .223/5.56mm bolt carrier assembly and replacing it with the .22 bolt assembly.

Accessories

CMMG offers a number of upgrades and accessories: the auto-sear trip kit for select-fire rifles, a bolt collar assembly for using conversion bolts with CMMG dedicated .22 rimfire barrels, no-jam charging handles, a magazine loader and forward assist adapters for use with original upper receivers. CMMG has recently released their own .22 magazines made of polymer in 10 and 26-round capacities. The magazines will function with most .22lr conversions based on the Atchisson/Ciener system. During the SAR evaluation of the CMMG upper, the magazines were very reliable.

All CMMG products have a lifetime material and workmanship guarantee.

The McFadden Lightnin’ Grip a Revolutionary .22 Rimfire Magazine Loader

In the past, one of the problems with most .22 caliber conversions for both semiautomatic and full-auto guns, has been the tedious, and time-consuming, process of loading the small cartridges into the single-feed magazines. That problem has been solved by a new loader made by the McFadden Machine Company Inc. of Blairsville, Pennsylvania. The loader is called the Lightnin’ Grip.

To use the Lightnin’ Grip, loose .22 cartridges are dumped into a hopper on top on the device. Shaking the loader forces the rounds into a separate compartment and aligns them. After attaching a magazine each squeeze of the handle inserts a round in the magazine. Twenty-five rounds can be loaded in seconds. The loader worked flawlessly loading the AR-15/M16 Black Dog and CMMG .22 magazines and Black Dog’s 50-round drum magazine.

There are a number of adapters available for the Lightnin’ Grip so it can be used to load a number of popular .22 caliber pistol and rifle magazines. The company currently offers several inexpensive adapters for a growing list of popular magazines, including the Black Dog magazines for the Lage’s .22 caliber MAC conversions, SIG Mosquito, aftermarket magazines for the Ruger 10/22 and many others.

Sources

CMMG

M16 and AR-15 conversions

https://www.cmmginc.com/

McFadden Machine

Lightnin’ Grip Loader

http://www.mcfaden.com/

Black Dog Machine Magazines

http://blackdogmachinellc.net/

Gemtech Suppressors and Subsonic .22 rimfire ammunition

www.gem-tech.com/

Trijicon Optics

https://www.trijicon.com

Magpul Back-up Sights

https://www.magpul.com/

| This article first appeared in Small Arms Review V19N9 (November 2015) |