By Jean Huon

Just as repeating rifles had been brought into service in the armies of the foremost countries, semiautomatic rifles quickly appeared.

During 1883, Hiram Maxim transformed a Winchester carbine into a semiautomatic weapon. In France, the Clair brothers had produced a pistol functioning by the use of gases since 1888 and they applied the same mechanisms to shoulder weapons such as shotguns, .44-40 carbines and 7×57 military rifles (tested by the French Army in 1898). Additionally in France, a score of prototypes were developed since 1894 by several military factories. Other countries also produced semiautomatic rifles:

- Austria (Mannlicher),

- Belgium (Braüning-F.N.),

- Denmark (Madsen-Rasmussen, Bang),

- United States (Browning, Springfield),

- Great Britain (Farquar-Hill, Griffith & Woodgate),

- Italy (CEI-Rigotti, Revelli),

- Japan (Nambu),

- Norway (Quist),

- Sweden (Bang, Kjellman-Frieberg),

- Switzerland (Mondragon)

In 1898 in Germany, Mauser produced a rifle functioning by short recoil, followed by sixteen other prototypes until 1908. In about 1900, DWM developed a semiautomatic rifle having a mobile knuckle breech similar to that of the Lüger pistol. However, just before the First World War, no country seemed ready to decide to adopt a semiautomatic weapon for their troops except perhaps France, which considered the startup of the Meunier 7×59 rifle. But the imminence of the coming conflict made the project fall through.

At the beginning of WWI, some rifles were used by the crews of aircraft and balloons. France was interested in Winchester 1907, 1910 and Remington Model 9 rifles and a purchasing commission went to the United States to acquire such carbines. Germany used the Mexican Mondragon rifle and brought into service some Mauser 1916 rifles.

Very quickly, machine guns replaced rifles to arm aircraft. In 1916 the French manufactured one thousand Meunier rifles for ground use and sent them to the battle. It wasn’t until 1917 that another semiautomatic rifle was developed by MAS andemployed in substantial quantities with 85,333 specimens being made.

After the war, most countries embarked on programs to develop new automatic weapons. Germany, for a time, was prevented from this and at the time of the rearmament of the Wehrmacht, a repeatingcarbine was retained to equip the troops: the famous K 98k.

In 1935, Mauser developed the G 35 that functioned by short recoil. It was followed by another model in 1937 that functioned with the use of gases with a piston below the barrel. At the same time, Walther developed the A 115 whose piston is presented as a sleeve which moves around the barrel.

But it wasn’t until 1940 that a true program is defined by the authorities. Heereswaffenamt (HWaA), which controlled all of German weapons production, drew up the schedule of conditions of a new semiautomatic rifle that included:

- length of barrel similar to that of K 98k,

- use 7.92mm Mauser ammunition,

- barrel should not comprise vent of uptake,

- no external part located on the top of the weapon must be moving at the time of the cycle of operation,

- if the driving system has suddenly weakened, the weapon must be able to be used like a manual repeating rifle.

The companies of Mauser, Walther, Krieghoff and Rheinmetall all were interested in producing a prototype, but only Mauser and Walther succeeded in actually progressing to the prototype stage.

It is quite obvious that with such a schedule of conditions, the choices were limited. The systems functioning by short recoil or long recoil of the gun were not retained because of their weight and their complexity. HWaA wanted a system that was invented in Sweden by Bang. What resulted were two weapons that were very closely related and known as the G 41 (M) for the Mauser rifle and the G 41 (W) for the Walther rifle.

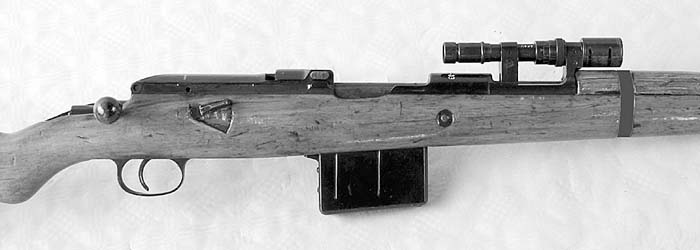

G 41(M)

Gewehr 41 Mauser (G 41(M)) is a development from prototype S/42 (D) constructed before the war. It uses a straight line bolt with a rotating breech block. Difficulties of development delayed its mass production, which started only at the end of May 1941. In spite of a plan to produce 70,000 rifles in April 1943, it was not certain that Mauser could carry out the 15,000 rifles which had been ordered.

Description

The G 41(M) has a one piece stock similar to that of K 98k. It functions by relaxation with the mouth, with a cone to capture gases. The actuating rod is located under the barrel, which is partially covered by a handguard fixed to the stock with two bands. The frame is capped by a cover, receiving the bolt carrier and the bolt that holds two lugs in front. The lever action is on the rear and is similar to that of a manual repeating rifle. The recoil spring is located inside the bolt. The lever does not move in action, but in the event of failure of the driving system, it allows the use of the weapon like a manual repeating rifle. Ammunition is located in a ten shot magazine that is located in front of the trigger guard. It is fed by two clips of five cartridges or with cartridges in bulk. The safety is a rocking lever on top of the cover. Pushed to the right (S), it locks the trigger mechanism and the bolt in open or closed position and prohibits firing. Pushed to the left (F), it allows firing. A hold open device used for disassembly is placed on the cover at right, or on the right side of the stock. The rear sight is graduated in hectometers from 100 to 1,200 meters, while the front sight is a blade protected by a hood. A portion of cleaning rod is under the gun and the weapon can receive the standard German bayonet. A sniper variation does exist using the ZF 40 scope.

Disassembly/Reassembly

Open the bolt and clear the weapon. Place the safety on the shooting position. Push the two latches on the cover front and open. Push down the hold open device and extract the bolt carrier and bolt. Remove the actuating lever. Push the mouth cone retainer and dismount it. Remove the sleeve and actuating ring. Retract the stops that maintain the bands. Take off the handguard. To remove the rod, it is necessary to unscrew the trigger guard/magazine and dismount the group frame and barrel from the stock. Reassembly is carried out in the reverse order taking care to properly position the bolt carrier lug in the corresponding hole of the actuating lever.

G 41(W)

Walther also produced a semiautomatic rifle that functioned by capturing gas at the muzzle but used the Swedish Friberg andKjellman system for locking the breech. This rifle appears more accurate than G 41(M) and was manufactured in much greater numbers. The first deliveries took place at the end of 1941 and SS units seem to have been the first to be equipped with it. This weapon was manufactured by two firms: Carl Walther, Zella Mehlis (code ac), with 20,996 rifles being built and Berliner- Lübecker Maschinenfabriken, Lübeck (code duv), with 96,477 rifles being produced.

Description

The G 41(W) has a one-piece stock made in beech or laminated wood. A wooden or plastic handguard covers the barrel and is secured by two bands. The barrel ends with a cone gas take, with a flat rod over the barrel. It pushes a bolt carrier with an actuating lever located on the top at the right side. A bolt open device is located near the actuating lever. The actuating rod has its own recoil spring located under the barrel in the forearm. The rod pushes a piston located under the bar-rel and actuates the bolt carrier. The bolt has two lugs at the head on both sides. Two recoil springs are located inside the bolt cover. Ammunition is located in a ten shot magazine that is located in front of the trigger guard. The safety is at rear of the bolt cover. Pushed on the right (S), it locks the trigger guard and the bolt in the open or closed position. Pushed on the left (F) it allows shooting. The rear sight is graduated in hectometers from 100 to 1,200 meters and the front sight is a blade protected by a hood. A portion of cleaning rod is under the gun and the weapon can receive the standard German bayonet. A sniper variation does exist using the ZF 40 scope.

Disassemby/Reassembly

Open the bolt and clear the weapon. Open the bolt and lock it in the rear position. Push the safety on the right. Push the lug of the recoil plate springs to the front and remove the bolt unit. Unlock the bolt open device and retain the bolt carrier pushed by the springs. Dismount the bolt carrier, bolt and springs. Take off the locking lugs, firing pin carrier, firing pin and its push rod. Push the mouth cone retainer and dismount it. Remove the sleeve and actuating ring. Retract the stops that maintain the bands. Take off the handguard. To remove the rod, it is necessary to unscrew the trigger guard magazine and dismount the group frame and barrel from the stock. Reassembly is carried out in the reverse order, but it remains delicate. There exists a preferential position for each locking lug but a locating pin makes it possible to find this one easily. One will also take care to properly place the push rod of the striker with the thinned part backwards.

EPILOG: G 43

The gas action from the mouth imposed on the G 41 rifle program showed that it was complex, too heavy, prone to fouling, difficult to remove and lacked reliability. However, the G 41(W) did reveal some excellent qualities. At this point in time, Waffenamt realized that it was possible to improve the system.

It is undoubtedly a result of contact with Russian semiautomatic rifles Tokarev SVT 38 and SVT 40, that the Germans report themselves that the gas action from the mouth was not the best. Walther altered its G 41 by preserving the locking device but applying the gas port with actuating rod as used on the Tokarev. The new weapon, designated the G 43, was built by three factories with labor provided by the concentration camps of Neuengamme and Buchenwald.. They were: Carl Walther, Zella Mehlis (codes ac or qve), Berliner-Lübecker Maschinenfabriken, Lübeck (code duv), Gustloff Werke, Sühl (code bcd). A great number of subcontractors furnished several parts. At the end of the war the G 43 was re-designed K 43.

Characteristics: G 41(M)

Caliber: 7.92mm

Ammunition: 7.92mm Mauser (8x57JS)

Overall length: 1.175 m (46.26 inches)

Barrel length: 0.552 m (21.73 inches)

Weight: 5.100 kg (11.25 lbs)

Capacity: 10 rounds

Characteristics: G 41(W)

Caliber: 7.92mm

Ammunition: 7.92mm Mauser (8x57JS)

Overall length: 1.123 m (44.21 inches)

Barrel length: 0.545 m (21.45 inches)

Weight: 5.050 kg (11.14 lbs)

Capacity: 10 rounds

| This article first appeared in Small Arms Review V11N6 (March 2008) |