By Jim Schatz

“A successful demonstration is a day where no one at the demo gets hurt, all the guns work as designed, you hit all your targets and, if you are a salesman the customer leaves with the intention to buy your product, in that order. Strive for perfection!”

Safety is the first concern but preparation is the key to a successful demonstration!

(We now continue the helpful hints that the author started in SAR Volume 3 Number 12)

Quality ammo is the fuel that reliably runs quality firearms. Use only sound ammunition that you know from experience will perform properly during your demo. Don’t cut corners on demonstration ammunition.

Ammunition Guidelines and Special Considerations

1. Avoid using corrosive ammunition. It can permanently harm or damage weapons, suppressors and magazines and makes cleaning more time consuming and urgent.

2. Avoid the use of foreign military surplus, reloaded or remanufactured ammunition in your demonstrations unless you are 100% confident in its quality. The function and performance of the weapons is only as good as the quality of the ammunition fed into them. Use new ammunition from the major ammunition manufacturers for the best and most consistent results. If you are forced to buy ammo locally before the demo or borrow strange, untested ammo, try it before the demo and attendees arrive. Don’t be upended on your big day by strange, unfamiliar ammo!

3. DO NOT use ammunition loaded with lead bullets (unjacketed) in demonstrations. They can cause feeding problems in auto-loading weapons and foul bores adversely effecting accuracy. Small shavings of the lead projectile can peel off during feeding, melt and find their way into unimaginable places (gas systems, sound suppressor baffles and vent holes, even firing pin cavities.)

4. Try and select ammunition that is accurate, reliable and clean burning. It should also have the lowest possible recoil to make it easier for the shooter to fire and control the weapon. Stick with the major manufacturers and in particular their “premium lines” (i.e. Federal’s “Hydra Shok”). At least attempt to utilize this ammunition in your portion of the demo to insure top performance.

5. Keep separate the 9mm weapons from those chambered in calibers 10mm Auto and .40 S&W. Keep 10mm and .40 S&W away from .45 ACP. Separate these ammo types and weapons on the firing line to prevent the smaller rounds from being loaded into the larger bore causing potentially dangerous bore obstructions.

6. Avoid using 12 gauge 1 1/8 ounce, 2 3/4 dram equiv., # 9 or 7 1/2 “Light” shells or lighter in the auto-loading shotguns. While in many cases they will function the weapon reliably, some brands do not provide sufficient impulse to reliably operate the mechanism of the weapon in the hands of all shooters. Stick with at least the # 9 “Heavy” loads or defense ammunition (OO Buck, 1-ounce slugs, etc.) for your demo purposes.

7. DO NOT use ammunition in caliber 9mm with a bullet weight of less than 100 grains. Many caliber 9mm weapons, especially those originating from Europe, are designed to function reliably with ammunition loaded to 9mm Parabellum, 9mm Luger or 9X19mm NATO specifications with projectiles weighing @ 124 grains. 9mm demo ammunition should always be loaded with projectiles with weights in excess of 100 grains, preferably in the range from 115 to 158 grains, unless it is tried and proven specialty ammunition (i.e. frangible, blank, etc.) designed specifically to function in the weapon(s) you are demonstrating.

8. Good old “brass” material is still considered by most experts as the best material for cartridge cases. It has a proven record of reliability and strength. Beware of ammunition loaded in steel or aluminum cases. If you must or chose to use non-brass cased ammo, test this ammunition extensively first in your demo guns before your scheduled demo. The relatively soft or brittle non-brass case material and/or the high internal pressures can cause the cases to expand excessively in the chamber (especially into fluted chambers) or actually rupture resulting in poor extraction and ejection and even damage to the weapon or injury to the shooter or bystanders. Beware of the really good (cheap) deals. They are often not always the best choice for an important demo. Remember that many stoppages and malfunctions in otherwise reliable weapons occur as a result of operator misuse, poor maintenance, bad feed devices (magazines, drums and belts) and faulty ammunition.

Common rounds today that are often mixed together in weapons with potentially damaging or even dangerous results to the weapon, shooter and bystanders. 9X19mm Luger rounds must be kept well away from .40 S&W and 10mm Auto ammunition or live round bore obstructions will sooner than later occur.

Avoid using these types of non-brass cased ammunition in your demos unless it is an expressed requirement of the customer. If this is the case, test fire the weapons (two magazines at least) with this ammunition prior to your demo to insure reliable function and use ammunition from the same lot in your demo.

Example 18:

As a result of a successful demo, a local P.D. purchases a brand new sound suppressed 9mm submachine gun with all of the whistles and bells, an investment for a small agency of almost $1,800. On their very first trip to the range with the new expensive weapon they loaded cheap, locally reloaded ammunition into the “silenced” weapon. With each pull of the trigger the shooter and bystanders were absolutely amazed at just how quiet the weapon was, just like in the movies, and almost no felt recoil to speak of. This gun was definitely worth the money! But the ammunition sure wasn’t. After firing 9 or ten rounds in semi-auto the weapon stopped firing. At the same moment an onlooker noted that the target had not been hit once even though it was only 15 yards away. Upon inspection of the weapon it was found that the 10th round did not fully feed or lock into the chamber of the buzz gun. An obstruction caused by 9 projectiles lined up in the bore of the brand new $1,800 weapon kept the 10th round from chambering. For the cost savings of a box of ball ammunition the P.D. bought a new barrel for the new weapon and a great deal of embarrassment.

Lesson: Don’t cut corners on ammo quality.

9. Magazines of assorted ammunition, loaded prior to the actual firing by one of the attendees, illustrates quite well the reliable function of the products with all types of ammunition. Depending on your product this is very effective, as many competing guns are not totally reliable with all ammo types, especially the large cavity hollow points. However, make certain that you trust each type of ammunition that you mix in the magazine and try this as part of your test fire procedure. You can mark the magazine to denote it as a magazine containing assorted ammunition. Better yet, have it in a clear plastic page and ask an attendee to note the mixed ammo types inside and load it at random in the magazine for you. You should shoot this magazine, as the assorted recoil characteristics of varying ammo types may feel strange to the novice who may attribute it to the weapon.

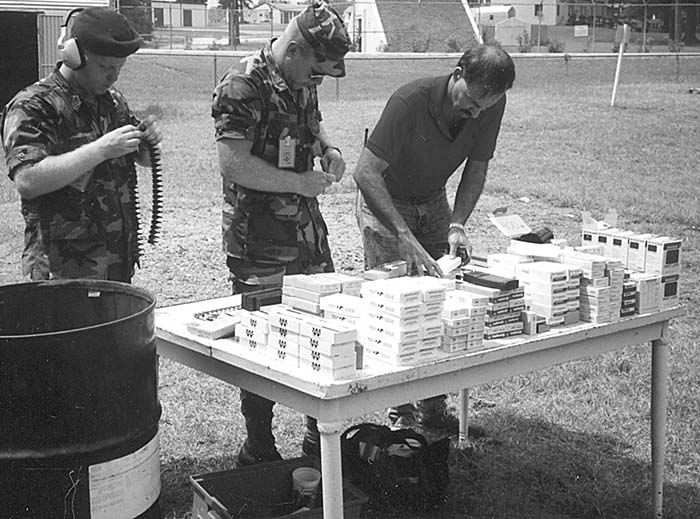

An ammo supply point like this looks nice and pretty and seems safe enough. However, if there are non-compatible rounds on the table they will find their way into the wrong magazine or weapon, guaranteed. Don’t risk it. Position the ammunition directly behind the weapon on the firing line along with the applicable magazines for it. Position non-compatible ammo types and weapons on opposite ends of the firing line.

10. Use tracer ammo (or Hornady’s “Vector” ammo) whenever possible in your demo as the visual effect and results of your proficiency downrange are immediately apparent to the attendees, especially when shooting firing briefcases or at non-reactive or long-range targets. However, just keep in mind that tracer ammo is generally somewhat less accurate for precision long-range fire and it is immediately apparent when using tracer ammo when you don’t hit your targets! As tracer is relatively expensive and often hard to get, use it primarily for your shooting and not that of the attendees. Remember to ask permission first before shooting tracer as many ranges prohibit its use or there may be restrictions due to weather conditions. Always have a fire extinguisher handy during the demo and clean the weapons thoroughly as soon after firing to negate the adverse corrosive effects of some types of tracer ammo.

This demonstrator is decked out for a crowd of photographers. Generally, wearing uniform items like your customers is frowned upon. Always keep in mind that you are the sales rep and they are the user. It’s best not to cross that line. Note: Know the weapons you demonstrate. Use the 80 degree locking piece in the HK MP5K-PDW when firing the weapon with sound suppressor and folding buttstock, especially if shooting heavy (147 grain) subsonic ammunition to insure reliable operation.

11. Blank ammo – Rarely will you demo guns with blank ammo. But when it might help sell the product keep in mind that generally speaking blank firing is actually harder on most guns than is normal “ball” ammunition. The reason is that a blank round normally does not contain a projectile that gets launched from the bore. This means there is no bullet to act as a gas seal in the bore so additional gas pressure is required to cycle the blank firing gun. This additional gas pressure can cause overfunction stoppages, higher cyclic rates and felt recoil, increased fouling and premature breakage of internal parts.

The roller-locked HK’s (MP5’s, HK33, G3, HK21, etc.) only function reliably with the black tip Dynamit Nobel Plastic Maneuver blank ammunition. This special type of ammunition was more or less created for the roller-locked guns that require additional recoil impulse to reliably work the bolt. The roller-locked HK’s will not function with U.S. M14 or M16 blank ammo (too under powered). The newer gas-operated HK’s (G36, SL8-1) will function with M16-style blank ammo. All require the applicable HK BFA when firing blanks.

If you shoot blanks make absolutely sure you personally control the ammo and blank firing gun. At all costs do not allow the weapon with the BFA attached near live ball ammunition. Mr. Murphy likes this trick where live rounds are inadvertently loaded in with blank ammo. Firing a live ball round into a blank firing adapter can be quite a shock and potential serious hazard (meaning injury or death!) to the weapon, shooter and bystanders. Though there are new “safety” blank firing adapters (for the HK G36) designed that can “catch” at least one live projectile accidentally fired with the BFA in place this scenario should be avoided at all costs for obvious reasons!

Weapon Specific Guidelines and Special Considerations

1 HK MP5 Family

a. Clean the HK MP5SD barrel and barrel ports using the special barrel cleaning device (ID# 225376) every 200 – 300 rounds during the course of your demonstration. This will help prevent blockage of the gas vents and the annoying difficulty of trying to remove the sound suppressor over an extremely fouled barrel due to lack of regular cleaning.

b. Make certain sound suppressors stay tight and properly indexed for accuracy on all suppressed MP5’s during demo’s to include the MP5SD (this also includes the sound suppressed pistols like the MK23/Mark 23’s and USP45 Tacticals). Poor accuracy, change in the point of impact and even damage to the “can” can result if the suppressor comes loose during your demo. This is where the pot holder or heat resistant glove comes in very handy.

c. Make certain the muzzle and sound suppressor threads are clean and lubed on any “Navy” model MP5’s, to include the MP5/10 and MP5/40, before installing the sound suppressor. Dirty threads may make it difficult to install or remove the suppressor.

d. Use the protective cap for the muzzle threads (where applicable) any time and immediately after the sound suppressor is detached from the weapon. When the sound suppressor is attached to the weapon, the HK MP5 for example, store the protective cap on the thread cap holder (ID# 205483) that fits in the pistol grip of the weapon. This will prevent the threads from being damaged which will prohibit the attachment of the suppressor.

e. To show the consistent tolerances that the MP5 parts are produced to and to demo the ease of repair (simple parts replacement, no fitting required) interchange assembly groups between like weapons. For instance, disassemble various models of MP5’s and interchange their assemblies to create various MP5’s.

Beware however, that not all of the assembly groups are interchangeable. Trigger groups and bolt groups between MP5K’s and those of full size 9mm MP5’s, the MP5/40 & MP5/10 and rifle caliber HK’s many times may fit but in fact are not interchangeable. Bolt locking pieces in K’s, SD’s and A2/A3’s are different, so the bolt groups are not interchangeable though they will fit. Once interchanged, shoot the weapons in the demo with the interchanged parts and change each weapon around again.

f. Use the stronger gray G3/HK91/HK33/HK93 assault rifle extractor springs (ID# 200445) in all of your 9mm MP5’s for increased reliability and durability. Use the unique bent gray-color MP5/10 and MP5/40 extractor spring only in the MP5/10 and MP5/40. The gray assault rifle extractor spring is produced from thicker, stronger wire than that normally used in the 9mm MP5. Install the new spring and try the gun before your demo. (Note: The reason HK still assembles 9mm MP5’s with the copper-colored spring is for some types of ammo that are under powered. With this ammo the stronger gray spring may not allow the extractor to snap over the rim of the case during feeding and locking. The author has never experienced this. In fact the German HK demonstrators use only the gray extractor springs and without problems of any sort.)

A tough act to follow. If you’re slotted behind one of these in a large demo pack up your stuff and leave. No one will remember you. A U.S. Navy Fast Attack Vehicle armed with twin M240’s (MAG58’s), MK-19 automatic grenade launcher and 7.62X51mm Mini Gun. Though things are a lot more intense when demoing an animal like this one, the same basic range safety rules and demonstration guideline discussed within the article still apply.

g. If the extractor of the roller-locked HK rifles and smgs that use the flat style gray or copper-colored extractor springs (G3, MP5, HK33, etc.) can be easily moved in the bolt head using just one finger, replace the extractor spring! Most often this spring is damaged because people remove it to clean under the extractor. This is not necessary. It can also be damaged and thus needs replacement if there is a feeding or failure to eject stoppage where the round or case pushes out on the extractor as the bolt slams shut bending the spring and making it unserviceable. If the extractor is loose in the bolt head because the spring is damaged the empty case may slip off of the bolt head during the ejection stage and not clear the ejection port. When in doubt, change the spring and don’t leave home without them! This rule of thumb applies to all HK weapons that utilize this style of extractor spring.

Beware if you have a failure-to-feed or eject as the resulting obstruction (live round or empty case) may push outward on the extractor destroying the function of the extractor spring resulting in numerous failure-to-eject stoppages until a new extractor spring is installed. Check the spring and extractor with the finger.

h. If the lips of your 9mm MP5 magazines are bent or the seam in the front of the magazine housing above the oval plate is split and pushed outward at the very top from long term use or abuse, replace that magazine housing or the complete magazine. This split can result in feeding and ejection stoppages.

i. To demo the effectiveness of the sound suppressors on the MP5, shoot the weapons side by side, one suppressed and one unsuppressed and don’t shoot on steel targets or into an indoor range backstop to avoid the excessive noise of projectile impact.

Demo the difference between subsonic and supersonic ammunition in a “Navy” model MP5 by firing a mixed magazine (every three or five rounds) of both through one weapon with suppressor attached.

Don’t forget to add 5 cc’s of water to the wet technology sound suppressors (MP5, USP45T, UMP and MK/Mark 23) for maximum sound reduction. It lasts about 20 rounds or 24 hours without use.

j. Don’t shoot HI impulse ammo in the MP5/10 or MP5/40 fitted with a LO impulse locking piece or damage will occur to the buttstock buffer and or receiver. Generally, you can shoot LO impulse ammo in the weapon fitted with a HI impulse locking piece, and thus shoot mixed or alternating mags of HI and LO impulse ammo, without stoppages. As a rule, LO impulse 10mm Auto or .40 S&W ammunition is most loads under 1,100-fps muzzle velocity. HI impulse ammunition being in excess of 1,100 fps.

However, try this trick with your particular demo gun before attempting it in your demo, as some guns are more sensitive with certain ammo than others. For maximum reliability when using just one type of ammo stick with the correct locking piece for the ammunition that you are using!

Recent developments in .40 S&W ammo (hotter) fired in broken-in (more than 1,500 rounds fired to date) MP5/40’s may require the use of the “HI 25” impulse locking piece to prevent overfunction. Watch for the signs of overfunction (buffer damage, bolt carrier strike on buttstock backplate, roller bulges in the receiver buttstock grooves, etc.) and correct it as necessary.

Underfunction (too little function/bolt velocity) is usually seen as anemic recoil or ejection of the spent cases. In worse case scenarios underfunction may cause failures-to-eject or even feed stoppages as the bolt is not moving far or fast enough in the receiver. In this case try the LO impulse locking piece for that specific ammunition.

k. Use the special 80 degree locking piece (ID# 214292) in the MP5K-PDW when shooting it with a folding stock and sound suppressor attached, especially when shooting the heavy (with a bullet weight greater than 140 grains) subsonic ammo. Like the issues with the powerful 10mm Auto and .40 S&W cartridges the MP5K outfitted as described above can overfunction and run too fast causing failures to feed or eject. Using the 80-degree locking piece will reduce the function of the gun (bolt travel and velocity) and improve its reliability. You can shoot the weapon without the sound suppressor or with lighter 115-grain ammo with the 80 degree locking piece installed without the reliability of the weapon suffering. However, if you’re not shooting with a sound suppressor, the standard “16” MP5K or unmarked MP5A2/A3/N/SF locking piece is best.

l. If you are shooting the MP5K in the HK discreet firing briefcase you must use a standard MP5K with 4.5-inch barrel and “SEF” trigger group. The design of the briefcase prohibits using the longer barreled (5.5-inch) MP5K-N or any MP5K fitted with any of the ambidextrous trigger groups.

m. Review the “MP5 Submachine Gun Family Operators Manual”, available from HK Inc., to supplement your knowledge of the MP5 variants before conducting your demo.

n. Review Part III of this four part series entitled “Specific Safety Guidelines and Precautions” for additional safety related issues that apply to the MP5 that are not listed in duplicate within this section.

o. Don’t mix 9mm and 10mm/.40 S&W flash hiders on 9mm MP5’s and 10mm/.40 S&W MP5’s and make certain that the locking lever on the flash hider (and MP5 BFA) is properly engaged and locked closed before firing the weapon or you risk launching it down range. At a minimum your accuracy will suffer if projectiles strike the improperly attached flash hider.

2. USP Pistols

a. Use the correct magazine in the right USP! The 9mm and .40 S&W magazines look almost identical to one another, except for the markings on the magazine body. The mags are interchangeable but 9mm rounds do not feed reliably from the .40 S&W magazines and stoppages may occur. Mark or constantly check these magazines during demos.

b. As with all self-loading pistol designs, maintain a firm grip on the USP to insure reliable function. Don’t “limp wrist” the USP, especially the .45 caliber models.

c. Keep the sound suppressors tight on those USP’s (and MK23/Mark23’s) that provide a means to mount such devices. Such suppressors from Knight’s Armament Company use internal rubber O-rings to hold the suppressor tight and secure on the barrel during transport and firing. Make certain these O-rings are present (they blow off easily when using compressed air during cleaning) before your demo and carry a spare or two in your parts kit.

3. MK/Mark23’s and USP45 Tacticals

a. While they look alike, the magazines for the MK/Mark 23 and USP45 are not the same. The MK/Mark 23 magazine floor plate is contoured with the opening to the magazine well. The floor plate of the USP45 is not. They should not be mixed as reliability can be adversely affected.

b. MK/Mark 23’s are most impressive when shot at ranges of 50 to 100 meters and are very capable in proficient hands at longer distances to show their superior accuracy, with and without the sound suppressor attached.

c. Use only HK-approved sound suppressors on these pistols. It takes a great deal more than threading the barrel of a short recoil-operated handgun to insure proper function and system reliability. If the sound suppressor is not properly designed for and timed for use on a specific model pistol the weapon can be permanently damaged in as few as 20 rounds fired. When properly tuned for the pistol the sound suppressor will have little or no ill effect on the function or durability of the host handgun. At the time of writing, the Knight’s Armament Company and Bruegger & Thomet sound suppressors are approved for use on the HK pistols after extensive testing by HK.

d. If using wet technology sound suppressors such as the fine KAC version for the MK/Mark23 and USP45 Tactical, do not miss the opportunity during your demo to fire the combo “wet” by adding the prerequisite 5 cc’s of water. The difference to the human ear is dramatic.

2. Roller-Locked HK Rifles (G3, HK33, HK53, HK91, HK93, PSG1, etc.)

a. If shooting blank ammunition, insure the blanks are the black serrated tip “Plastic Maneuver” blanks available from Dynamit Nobel in Cloister, NJ. Only these special blanks designed specifically to operate the roller-locked actions of the HK rifles (and MP5’s) will reliably function the weapon with the HK blank firing adapter. Conventional US blanks designed for gas-operated weapons do not provide the required recoil energy to properly actuate the roller-locked breech of the G3 rifle and its many descendents.

b. Beware of after market scope mounts that clamp to the receiver of the rifle using screws or rotary locking knobs. The degree of torque and the extent that these mounts can be tightened is generally not limited by design. It is thus possible with such mounts to over tighten the mount to a point where the free movement of the bolt group is impaired during firing leading to improper function.

c. Trigger groups and internal trigger mechanisms for 5.56mm, 7.62mm and even pistol caliber HK roller-locked weapons look very similar and can be accidentally and unknowingly interchanged. Generally the ejectors for different caliber HK roller-locked guns are different and thus these parts should not be swapped between weapons. It is very easy to install an MP5 trigger group in an HK53. The ejectors are different so the function of the weapon will be adversely affected. If you are unsure, consider marking or color-coding the trigger groups and mechanisms to prevent this simple mistake.

d. Buffers. There have been many changes in the 5.56mm HK rifle buffers over the past 30+ years. The general rule of thumb is the 5.56mm HK roller-locked rifle should have at least one buffer, two is generally not a bad thing but should also be avoided. Early HK33’s, HK33K’s, HK53’s and HK93’s and their variants had a strong spring buffer incorporated into the back end of the bolt carrier. At some point during the production of the weapon the buffer was moved from the bolt carrier into the back plate of the buttstock. Ensure your rifle has a spring bolt buffer in either location and do not use MP5 buttstocks (fixed or retractable) in the 5.56mm HK rifle for any reason. The buffer prevents what can become extensive damage to the tail end of the rifle’s receiver if the bolt begins to strike the backplate of the buttstock. (When functioning in its optimum range the bolt should stop just short of hitting the buffer or buttstock, though this can easily change depending on the ammo used, the age of the weapon or the bolt gap in the bolt group).

e. Do not exchange bolt heads or bolt groups in HK-roller-locked rifles, especially those that are well used without first checking the bolt gap. The gap between the rear side of the bolt head and front side of the bolt carrier when measured up through the magazine well, with the weapon assembled, the bolt forward and the hammer down should be .1 – .5 mm. The rifles prefer a slightly larger bolt gap, say .3 – .5 mm as bolt gap normally decreases (tightens) with use. Too much or too little bolt gap can effect the weapon much in the same way as improper headspace and can cause failures-to-extract, eject, feed and lock. Bolt gap should be checked every 5,000 to 10,000 rounds and adjusted using pairs of larger or smaller rollers as necessary.

5. G36’s

a. Cool early non-heatshield equipped forearms with water, or exchange them during shooting to reduce or eliminate overheating that can make the weapon hard to handle during extensive firing sessions, such as long demos. New forearms for the G36 created for the Spanish Army in 1999 include internal heat shields to reduce the transfer of radiant heat through the forearm to the shooters hand.

b. Check or reconfirm zeros anytime the carrying handle assembly is removed or reinstalled. Tighten the mounting screws using the torque screwdriver available from HK to 250 Ncm to insure consistent return to zero after remounting.

c. For the correct G36 250 meter battlesight zero at 25 meters the POI for all rounds should be 1.75 inches below the POA with red dot and optical sights.

6. HK21E and HK23E Machine Guns

a. Use only pre-linked U.S. M13 link ammo belts (M27 in the HK23E) or new links with good quality ball ammo in the HK21E. HK21E’s imported into the U.S. after 1998 are designed to use only U.S. M13 (German DM6) disintegrating link belts. These newer guns should not be used with German DM1 non-disintegrating link belts. NEVER USE used links if at all possible as damaged links can change the feed pitch of the belt through the ratchet feed system reducing reliability.

b. Use the # 9 locking piece (ID# 222102) in the HK21E and HK11E? fitted with either 17.7 inch or 22.0 inch barrels for optimum belt pull and function.

c. Use a lot of oil, preferably Breakfree CLP on the bolt group (on the locking rollers and the gap between the locking piece and bolt head from below) before and periodically during firing (@ every 1,000 rounds) to insure positive functioning when the bolt gets hot, dry and excessively ladened with carbon fouling. Failures to lock will occur if lube is needed.

d. HK21E buffers take a beating as a result of prolonged hard use. Watch the inside of the stock backplate around the buffer bolt for signs of bolt carrier impact, a sure sign of the need for a new buffer spring or buffer assembly.

e. 1,000 round continuous cyclic bursts in demos are impressive but risky due to the lack of lube and build-up of carbon. 500 round bursts are safer to conduct (less chance of stoppages) and cheaper. Properly maintained HK21E’s will drag a full 1,000 round belt along the ground without assistance during firing, a show of immense belt pull and strong function.

f. Check for the correct position of each round within the link before your demo, especially after the belted ammo is handled or transported. As in most belt-fed machine guns, stoppages will occur if the round is severely out of position within the link. When feeding or dragging a 500 round belt on the ground give it something smooth to slide on (pavement, cardboard, hard ground, etc.) not grass, stones, sand or mud.

f. The HK21E is most impressive when fired for accuracy, though this trait is generally not considered important in a crew-served weapon. The guns are capable of sub-MOA accuracy with and without telescopic sight, a belt-fed sniper rifle if need be. For special operations or special law enforcement applications this trait is very useful for precision engagements, to avoid stray rounds and to insure greater hit percentages on target.

g. The HK21E or HK23E provides the best (tightest) 3-round burst and full auto cone of fire (group size downrange) when held and fired from rigid positions. When firing with the bipod use the old-style bipod with non-adjustable length legs for maximum rigidity. Dig the feet of the bipod into the ground and slide your body up against the dug-in bipod legs for a very stable position. Use the non-firing hand to hold the buttstock up into the shoulder.

In the assault firing (standing) position ALWAYS use the assault grip mounted at 45 degrees to the left for the non-firing hand. Adjusting the sling so that the non-firing arm can just barely be locked out with the sling held rigid over the non-firing shoulder and under the firing arm. This firing position provides stability close to that of the bipod firing position above when an aggressive stance is utilized.

7. Benelli Shotguns

a. Inertia-operated Benellis, such as the M1 and M3 models, work best if not held extremely tight against the shoulder, primarily when shooting light # 9 or 7 1/2 shot ammunition. Give them room to recoil rearward initially so the inertia spring can be compressed by initial recoil. Adding too much weight to the inertia-operated Benelli, such as ammo carriers or heavy sights and mounts, can also adversely affect reliability. These Benelli models definitely have a break-in period of @ 250 rounds before the customary Benelli reliability can be expected from all sample guns.

b. Shooting the pistol grip equipped Benelli one-handed makes quite an impression on attendees and it can be done fairly easily and comfortably to demonstrate the weapon’s reliability even when held in a non-conventional shooting position. Use defense ammo (OO buck) to insure reliable functioning.

c. Make certain the magazine extension and ghost ring sight components stay tight on the weapon during prolonged shooting sessions. A drop or two of blue Loctite thread fastener on the threads will secure these components yet allow them to be easily loosened or removed when necessary.

Closing Comments

There you have it. Suggestions made from experience for those of you who must conduct demonstrations as part of your profession or business. Always keep the KISS principle in mind as Mr. Murphy loves to come to demos if invited. Keep him away through thorough preparation and attention to detail. When in doubt, leave it out (of the demo).

| This article first appeared in Small Arms Review V4N2 (November 2000) |