When the German army attacked Poland in 1939, the world faced a quick and mobile machinery of war. One country after another was overwhelmed and the so called Blitzkrieg was born. These successes confirmed the plans of the military leadership that nothing could ever stop them – and this fact was reflected in the equipment of the troops: almost no weapons and special gear have been developed for defensive purposes since World War 1. Unexpectedly for the Germans, their advance slowed down in the vastness of Russia and finally came to a standstill at the end of 1942. The troops had to hold out in static defence lines for weeks and months. And besides the danger of attacks, another deadly enemy appeared on the front: snipers.

Every look over the trenches could be the last one. In this precarious situation the Germans remembered an item that was developed for the battlefields of World War 1 – indirect firing devices that allowed soldiers to shoot at the enemy without exposing themselves. The so called “Spiegelkolben” (mirror stock) was industrially made as well as improvised variants by troops at the front. An old manual Gebrauchs-Anweisung zum Spiegelkolben B.A.F. mit Ladehebel für das Gewehr 98 (manual for indirect firing device B.A.F. with cocking handle for rifle 98) shows how it functions. The rifle’s stock was put into the upper part of the housing and secured with clamps. The lower part holds a second buttstock with trigger. Both triggers were connected by a chain; so the soldier could aim the target through the periscope and if he pulled the trigger, the rifle’s trigger was also pulled by the chain. The most complicated part of the device was the cocking mechanism. An expensive construction of rods and joints was necessary to allow the soldier to cock the rifle from cover. Similar devices were also used by other nations during World War 1.

After the war-related events went badly in 1942, the Germans again began to develop an indirect firing device now called “Deckungszielgerät” (DZG). In the meantime, the army had introduced the semi-automatic Gewehr 41 from Walther so there was no need for a complicated cocking mechanism and the device could be made simpler. Not until 10 rounds were fired, the soldier had to pull the whole device back to his trench to reload the weapon. Unfortunately, the Gewehr 41 (and later the G/K 43) never reached the front line in great numbers. As a replacement, the device was modified with a second adjustment possibility to accept the stock of captured Russian semiautomatic SVT rifles. These weapons got the German designation Selbstladegewehr 259(r) and were well liked by the troops. If no self-loading rifle was available, the device could also be used with the standard K.98k rifle. The official manual D.1852 Deckungszielgerät was published on 8 January, 1943. No production figures are known and the very few surviving examples do not carry a makers name or code.

Shots could not have been especially accurate, but the device probably had some merit when harassing the enemy or forcing attackers to stop and take cover.

The new indirect firing device was made of a simple housing of pressed steel and a wooden buttstock with periscope. Again, a chain connected both triggers. The stock of the rifle rested on two cross bolts that could be repluged for compensating different stock types. The plug-slot for the SVT was marked with a big “R” (for Russian). Two adjustable pressure pieces were fixed in the top cover to press the stock down against the cross bolts.

The position of the periscope could be varied, depending on the height of the sight line of the rifle. The holes in its top cover were designed for fixing camouflage material. For easier transportation, the buttstock could be swung in the housing or taken off after loosening two screws.

In folded position the length of the indirect firing device is 18.9 inches (480 mm), the height 11.42 inches (290 mm) and the width 5.12 inches (130 mm). The total weight is 7.94 pounds (3.6 kg).

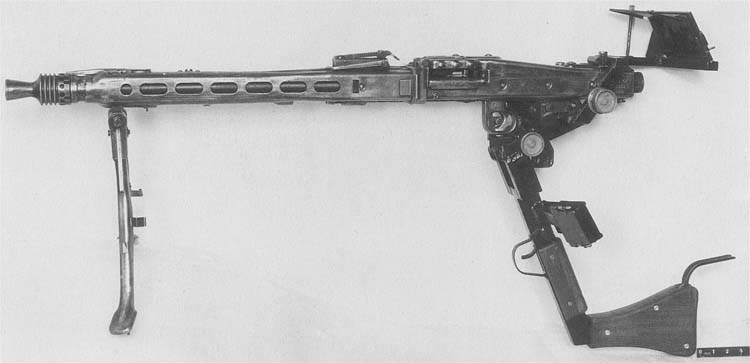

Since the indirect firing device worked well with semiautomatic rifles, the German army thought about using a similar one for their machine guns. But the recoil power of full automatic machine guns was too heavy for a filigree device. Trials showed that it was very difficult to hold the weapon on the target even with short burst. Devices for machine guns stayed in development until the end of the war, but they were never introduced.

Even though a Sturmgewehr 44 could also be used with this indirect firing device, a more simplified one was developed near the end of the war. No exact dimensions or weights are known, but the weight should have been much less than the old device. There was no longer a metal housing for the device and the wooden buttstock was replaced by a metal folding stock like the MP 40 and only two little mirrors were used instead of the periscope. A few pieces went to the front line in March 1945 for trials. The supplied questionnaires should have been given back until 1. May 1945, but this never happened.

Inspired by the indirect firing devices for rifles, a German soldier constructed a self-made device for the Raketen-Panzerbüchse 54, better known as the Panzerschreck. In 1943 this weapon came to the front in large numbers to replace the Panzerfaust. The rocket-propelled grenade could penetrate 160 mm of armor, but the target had to be closer than 250 meters.

Without a doubt, it was very dangerous for the soldiers and so an indirect firing device would have helped a lot. The idea of a clever soldier was printed in the magazine Von der Front für die Front (From the Front for the Front) in October 1944. This magazine was sporadically published and contained a mishmash of suggestions for improvements concerning weapons and all kinds of military equipment. The device was made of two additional handles and a periscope. It could be easily made by armorers, but in February 1945 an industrial production came into planning. The first order amounted to 100,000 pieces, but it’s unlikely that any of them were delivered.

| This article first appeared in Small Arms Review V14N6 (March 2011) |