By Leszek Erenfeicht & Zbigniew Gwózdz

In the early 1970s, most submachine guns still in use with the armies of the world were replaced by assault rifles shooting the intermediate round. The days of the front-line SMG were over. In specialized application the surviving ones were replaced by a new breed of modern low-drag high-speed models, lighter and offering more firepower in an ergonomically superior package. New materials and production methods were applied: sheet stamping, spot welding, powder metallurgy and plastics. Seen against that trend, Polish PM-63 Rak submachine gun, so advanced just a decade earlier, but still machined from solid billet, was rapidly falling into obsolescence.

The rapidly passing Renaissance of the SMG in its new compact guise, created a passing demand for the new firearms of that type. The ComBloc countries, who were at the forefront of the new wave of the PDW-style submachine guns (Soviet Stechkin, Czech Skorpion and Polish PM-63 Rak) were willing to have their share of the cake, but they lacked a modern design chambered for the 9mm Luger – the old German round growing more and more popular all over the world. Attempts at re-chambering existing guns were frustrating, even though a vz.68 Skorpion and PM-70 Rak proved to be viable firearms. Both were however milled of a solid billet, which financially killed them from the start even taking into consideration Communist economics. There were no alternatives: a new, compact, modern and cheap submachine gun was a must.

The hunt for the new compact SMG in Poland was not however only about the elusive export income: human and tactical considerations of the army were taken into consideration as well. As the Rak hit the real military units, problems abounded. The reciprocating slide was hard to master for soldiers with no firearms experiences and seasoned shooters from the elite Special Forces, who tested Rak on its way to inception, had no problems with them at all. Novice shooters were quite the opposite. The reciprocating slide frightened most of them as horror stories of eye glasses or even eye-balls smashed with it began to circulate. Then there was a real problem of shooting with the NBC mask on, where cracks on the glasses really did happen once in a while. In the 1970s, the future war was envisaged as a nuclear conflict, with most of the war fought in NBC protective clothing. In a heavily radioactive fallout-polluted area, a mere cracked glass was a harbinger of a certain death.

The new submachine gun TTR (Technical and Tactical Requirements) set together by the Military Technology Research and Development Main Directorates of the Polish Army’s General Staff included a condition sine qua non for the future firearms: no more experiments with open slides except for the handguns. All future guns were to have a closed receiver with the bolt reciprocating within.

After the TTR of the new project, code-named Glauberyt (glauberite, or sodium calcium sulfate), was sent out to all small arms developing centers, three separate teams at two of these took to designing the new SMG. The code-name was issued according to the new code-naming guideline, allocating the new small arms projects the minerals (glauberite, pyrite etc.) or the Mendeleyev periodic table’s metals (beryllium, vanadium, tantalum, etc.).

The Zielonka Glauberyt

A Glauberyt team of the Military Ordnance Technical Institute consisted of three Lieutenant-Colonels, Henryk Adamczyk, Jerzy Okraszewski and Ryszard Szydlowski. Theirs was a concept of a compact, small SMG of very original – yet overly complicated design. The lower receiver integral with a pistol grip was meant to be eventually made as a single plastic casting, similar in concept to the then rave Austrian Steyr MPi-69.

According to the original concept, the gun was designed for both 9mm Makarov and 9mm Luger chamberings. The caliber change was to be executed by exchanging barrels only: the magazine and bolt were universal. It was a selective-fire blowback automatic firearm, firing from closed bolt. The rate of fire was retarded by a complicated multi-part pneumatic-and-inertia rate of fire retarder.

In 1972, a set of blueprints was fabricated, labeled Pistolet maszynowy wz¢r 1973 (M1973 SMG). Then in late 1974 and early 1975, two testing models were manufactured, s/n G-01 and G-02, sporting an aluminum lower receiver. The costs of manufacturing a die for the plastic receiver at this early stage was deemed far too high to even consider.

The testing proved the design criteria: rate of fire was reduced to about 750 rpm despite a very light weight of the reciprocating parts and the short track bolt. The gun was small, compact, handy, and seemed insensitive to field conditions. The cartridges were fed from 15 and 25-round magazines held in the pistol grip by a catch at the heel of the grip. A plastic cocking handle was placed on top of the receiver, reciprocating between the square front post and flip-over sight with two sighting notches.

Despite the initial plans, both models were chambered for the 9x18mm or 57-M-181S round, better known as the 9mm Makarov. The compact size enabled the SMG to be fired single-handedly or with both hands, using a telescoping shoulder stock and a folding foregrip. In 1976, further development was halted due to technological problems with the plastic lower receiver production. Before the project was closed, a new set of blueprints were produced for an altered, modified model, also with a plastic lower receiver called the Pistolet maszynowy wz.1977 (M1977 SMG). This was, however, never to be put in metal.

Zielonka Glauberyt s/n G-01

Caliber: 9x18mm

Muzzle velocity: 320 mps (1,053 fps)

Barrel lengthv150 mm (5.9 inches)

Sighting radius: 231 mm (9 inches)

Length, stock collapsed: 305 mm (12 inches)

Length, stock extended: 539 mm (21.2 inches)

Magazine capacity: 15 and 25 rounds

R-75: The Radom Glauberyts

At the same time there were two competing Glauberyt (Project R-75) research teams created in the Research & Development Center (OBR) of the General Walter Metal Works in Radom. Ryszard Chelmicki, Janusz Chetkiewicz and Stanislaw Bryx formed the first of these. Their submachine gun was a pure blowback design with the magazine well in the pistol grip and bolt telescoping the barrel for optimal equilibrium. The general layout was to resemble the Uzi, which was at that time deemed to have the optimal disposition for a compact submachine gun. Yet it was not to be another Uzi-clone, as their R-75-I was to fire from closed bolt position with an internal hammer and have a mechanical, inertia rate of fire retarder, oscillating vertically in the pistol grip’s rear channel, perpendicular to the bolt movements – vaguely resembling the one used in a Czechoslovakian Skorpion. The gun was to be manufactured with sheet-metal stamping and spot welding methods, with a bare minimum of machined parts. Even before the model was commissioned, the OBR’s management demanded the team to prepare an alternative model, chambered for the 9×19 Luger. This was a rare display of far-reaching perspective being taken by the industry with a view to possible export, as well as a way to vent-off the recent frustration of the aborted PM-70 Rak modification to take the 9mm Luger round despite its success. The solid front sight post was taken directly from the PM-63. The stock was made of wire, and folding to the top of the receiver, with a spring-assisted opening – again a clear indication, that the designers knew and appreciated the Skorpion. The bolt cocking handles were plastic, but the first ever shooting test left them shattered, and another Skorpion idea was then borrowed: the button-like cocking handles protruding from the receiver sides. Both the R-75-I test model and the prototype series R-81 SMGs retained these.

A peculiarity of the R-75-I was the sight, taking the shape of a triangular plate, rotating on an axis which was set parallel to the bore. This plate had three peep holes for shooting at 100, 150 and 200 meters, with a square notch filed between the 100 and 150 peep holes, used for aiming at 50 m. Right from the start, the R-75-I was planned to be fitted with an external bolt catch lever – which was a novel idea for the SMG at that time on both sides of the Iron Curtain. The characteristic sheet-metal safety-selector lever on the receiver’s left, right behind the pistol grip, survived from the first pre-prototype up until PM-06 model, when it was made ambidextrous. The bolt is oscillating inside a sheet-metal formed, square-sectioned upper receiver. The receiver cover was latched by the side projections of the rubber-bumper mounting-plate to which doubled return spring rods (another Skorpion idea) were fastened.

The other OBR’s team, lead by Wladyslaw Krawczyk and Marian Gryszkiewicz, came up with quite a different proposition. Their R-75-II (or R75-W2 as it was inscribed on the test model) was also a blowback design with sheet-metal stamped receiver, but there the similarities ended. The bolt also telescoped the barrel, but it was a striker-fired weapon with the striker cocked on the rearward stroke of the bolt. There was an investment-cast muzzle brake, bayonet-connected to the muzzle, which at the same time performed the tasks of the gasodynamic rate of fire retarder, bolt cocking device (inspired perhaps by the PM-63 Rak) and forward return spring attachment point. The sight was of a cruciform shape, rotating on an axis set perpendicular to the bore. The four plates of the cruciform were fitted with a notch for 50 meters and three peep holes for aiming at 100, 150 and 200 meters. The front sight was screwed into a drift-adjustable dove-tailed holder. The trigger mechanism used a two-stage trigger – enabling to fire single shots or burst according to the length of the trigger pull (as in PM-63 Rak).

The receiver was constructed from both stamped and machined components, spot-welded or welded together. The test model had a wooden lower receiver with two pistol grips – to be replaced by an integral plastic lower in the series-manufactured ones. The two grips combined with sliding wire stock were to facilitate accurate burst firing.

The design was made fully 9x19mm convertible by using a universal magazine and bolt face, by simple exchange of the barrel. In reality, only the 9×18 Makarov model was ever built and tested.

In 1975, test models of both designs were tested in Radom. The test minutes stressed the high efficiency of the R-75-IIs gas-dynamic retarder, enabling the rate of fire to be reduced to 635 rpm – deemed perfectly effective for such a weapon.

Radom R-75-II

Caliber: 9x18mm Makarov

Muzzle velocity: 313 mps (1,029 fps)

Barrel length: 150 mm (5.9 inches)

Sighting radius: 269 mm (10.6 inches)

Length, stock retracted: 363 mm (14.3 inches)

Length, stock extended: 590 mm (23.2 inches)

Weight, empty: 1880 g (4.14 lbs)

Magazine capacity: 15 and 25 rounds

Rate of fire: 635 rpm

R-81

Despite the encouraging results of the R-75-II trial, it was the other R-75, the R-75-I, that was selected for further development. Some of the rejected prototype’s ideas (namely the dove-tailed front sight, and four-position sight flip) were carried on to the winning proposition, which was deemed better suited for mass-production and adoption. The folding stock was replaced by the sliding butt of the R-75-II, fitted with a folding metal butt-plate in the PM-63 Rak tradition. The stock struts were now made of round bars, sliding through the stock hinge, dropping and getting latched upon extending. The extended and latched stock was oblique to the axis of the bore, enabling the shooter to use the sights placed low on the receiver. The stock latch positioned inside the receiver required extension of the receiver – which was used to provide it with a thicker rubber pad.

As a result of further development, in 1981 a test-series of 10 R-81s (pm wz¢r 1981) chambered for the 9×18 Makarov were ordered for testing. As a result, another batch of 20 was ordered with a different handguard, now sporting a folding fore grip in the PM-63 Rak tradition. At that point a suppressor was also designed for the new SMG and an external thread was added to the muzzle of the barrel extended because of that development from 150 mm to 165 mm.

The R-81 retained the Skorpion-style button cocking handles. These were later replaced by more extending ones due to problems with cocking the weapon in winter gloves. Button cockers were replaced by the ones shaped like the original plastic ones – but machined out of steel for durability.

Vibration during shooting trials caused the one-piece receiver connecting bolt to crawl out, despite the springing tab, cut from the bolt’s side. This was thus replaced by a two-piece one, with two concentric bolts, one within the other, inserted from either side and blocking each other – just like PPSh 41 receiver hinge pin, but of course much smaller in diameter. After the tests, the receiver was ordered to be made of thicker gauge of steel – but excessive flexibility of the receiver remained the number one problem of the Glauberyt ever after, right until the PM-98 radical modification.

After the specified amendments were made, the submachine gun was adopted by the Polish Army and security forces as pistolet maszynowy wz.1984 (PM-84), and ordered into mass-production about 1985 – but tooling and preparation for the initial series (serialed in “PP” – like Prototype Pistol – range) production took several years to complete. At that time a special modification for the internal security anti-terrorism unit was prepared, fitted with a suppressor and a 1st generation laser sight, not much smaller than the gun itself. The first complete guns were manufactured as late as 1990, which sealed their fate effectively. Despite positive test results and favorable reviews, the mass-production of the PM-84 never happened. A feeble attempt at conquering the civilian market was made with the semiautomatic-only version, called the Semi-Automat, but restrictive gun licensing policies killed that initiative and nobody abroad was interested in such a weapon chambered for the 9 mm Makarov.

The overthrowing of Communism gave an additional boost to the already discussed and prepared move of upgrading the personal-defense caliber to 9mm Luger. In 1992, a decision was made to introduce the 9mm Luger as a military caliber and seek a modern, polymer-framed handgun with companion submachine gun in the new caliber. The PM-84 project was shelved for good.

PM-84P

In its original concept, the R-75-I was to be the dual-caliber firearm. This was still a viable option at the time of the R-81, but only one 9×19 barrel for the 30 R-81s was made, as after Martial Law was declared in Poland by the hard-line Communists on December 13, 1981, all export contracts to the countries outside the Soviet zone of interest became a matter of fantasy. Besides, all the 9×19 ammunition at that time had to be imported, as its domestic production at Mesko was only complemented, and early experiments were conducted with it not earlier than 1983, with mass-production starting in 1991. So, when changes were made to the receiver, magazine and magazine well, nobody seemed to care if these modifications prevented shooting 9mm Luger. To make it dual-caliber again meant some degree of re-designing anyway, so a decision was made to abandon it altogether and re-design the PM-84 completely, this time basing it on the larger round.

ZM Lucznik’s management pre-empted the strike, starting the re-design as early as 1991, on its own initiative, and – not at all typically for the Radom factory – with their own money.

In 1992 when a decision was made to adopt 9x19mm and start developing a plastic-framed handgun (which led to adoption of the Wist-94 pistol), Radom was already able to bid a replacement for the PM-84 in the form of the PM-84P, a redesign of the older submachine gun.

Adding the P (for Parabellum, as the 9mm Luger round is called 9mm Parabellum in Poland) in the model name was a very modest token of what the change really meant. The redesign was complete, and thorough. Some changes were made to cater for the more powerful round, some to facilitate manufacturing. Most of the internal parts of the mechanism were left alone and are completely interchangeable between the two guns, but some parts had to be re-dimensioned, then other re-shaped to fit those re-dimensioned. The bolt had to be made larger and heavier, and so also the receiver and pistol grip, housing the larger magazine. Unfortunately, the magazine catch was among the few parts left alone, which was a dire mistake. The magazine catch was a temporary fix made overnight while building the R-81 prototypes, and left untouched later on, because it worked well with the 9×18 Makarov magazine. The design of that catch is truly horrible: it’s safety-pin style spring is impaled on the grip plates screw, which forces the shooter to set it anew with every thorough cleaning of the weapon. The screw in question is totally unsupported by any metallic surface – in the field, this part of the grip was frequently chipped-off, especially in winter, when the plastic parts were frozen. As a result, the magazine catch was lost – and so was the magazine, and the weapon became useless unless the magazine was held in the magazine well by hand.

As the 9mm Luger was a much more powerful round, the older suppressor was too small. A new one was not designed so the external thread was eliminated. Dimensional changes needed in the sights were also used to simplify them and change the layout. In the PM-84 the rear sight was fixed, only the flip-blades were moving, while all zeroing work was done by screwing the front post up and down in a dovetailed front sight base. The new front sight base was fixed, and the front sight post only moved (screwed) up and down. The rear sight riveted axis was replaced by a micrometric threaded bolt – the flips could be rotated about it, and the thread could be rotated to move the sight laterally between the sight protectors. As the 9×19 had a much flatter trajectory, only two settings were needed between 50 and 200 meters, instead of four. The cruciform sight leaf was retained tough – it was patented by the factory and thus a source of royalties. The two redundant arms of the cruciform were used to put sight notches doubling the peep-holes set at 75 and 150 meters.

A sling eyelet was added to the front part of the receiver. This was a result of the creeping change in the tactical role of the PM-84P. The PM-84, as well as the earlier incarnations, the R-75-I and R-81, had only a bottom rear eyelet, behind the pistol grip, where a PM-63 style, single-point sling was fastened. No more points were needed for what was deemed a holster-carried firearm. The PM-84P, though, was not handy and small enough to enable the holster-carry, and so a two-point sling was issued for it, enabling it to be carried across the torso in combat, with holster being only a transport container.

In 1993 after the prototype tests, which indicated among others a higher rate of fire in spite of the heavier bolt (the ROF climbed from 600 to 640 rpm), the PM-84P was ordered and mass-production preparation begun.

Another police laser-sighted version appeared, this time with a much smaller laser, stored in the underbarrel-box, under which the folding fore grip, carried from the PM-84 into PM-84P, was fitted. Several, up to a dozen units of these laser-sighted Glauberyts were made for the Ministry of Internal Affairs.

Before manufacturing began, the old-style small cocking handles were replaced by much larger ones that protruded up. Only then the Army adopted the new SMG as the pistolet maszynowy wz.1984P (PM-84P) and true manufacturing started. Even today, the PM-84P are a vast majority of the around 60,000 Glauberyts manufactured to this date.

PM-98

The experience of use by the late 1990s of the PM-84P by the military and police enabled the realization that the requirements of the two services are different enough to warrant replacing the “universal” PM-84P with a service-specific police model. In the military, the SMG is a PDW, Personal Defense Weapon as a secondary weapon for tank crews, artillery gunners, drivers, clerks and cooks. In police service though, it was a basic source of deadly force, a main armed combat asset in patrol or escort duties and in combat against organized crime. As such, it was not to be carried in the holster, but slinged at port arms, or across the chest, with stock extended. Its predecessor, the PM-63 Rak was also employed for tactical use by the Police – mostly for the lack of the better gun, as it dramatically lacked pinpoint accuracy. Most of the Police special unit Raks had their fore grips folded and duck-taped shut, because they were not durable enough. After the political changes, SMG tactics was based on Israeli practice, which never used the fore grip for the simple lack of it in a Uzi. The Police assault teams needed means to put tactical lights on their SMGs rather than folding foregrips.

The first attempt at making a better suited Police Glauberyt was the so-called Police PM-84P of 1996. The grip was replaced by barrel-shaped handguard, returning to the original 1975 idea. The useless flimsy buttplate (in most cases duck-taped open anyway) was replaced by the fixed, oval, at least three times larger one, fitted with a concave rubber overshoe protecting against slippage of the butt-plate from the shoulder. At the same time the profile of the front sight was changed from rectangular to a conical one.

This were steps in a good direction, but not far enough, and the Police did not order it. Soon, after the military order was completed and not renewed, in 1997, ZM Lucznik SA set about another thorough re-design, this time with Police requirements as a guideline. The result was the ultimate Glauberyt, the PM-98.

The stock was completely changed; even though save for the fixed buttplate it looks identical. The stock struts were replaced with twice the diameter, and more robust rods. The retracting knobs were re-modeled again. First, a left side knob was abolished, along with its corresponding slit in both the receiver and the receiver cover – only the ejecting opening remained on the left. The retracting knob was enlarged again, thinned, looking like a raised canine ear – and so (“Ucho” or The Ear) it was nicknamed by the operators. The fore end was similar to the 1996 proposal, but with a socket in the front of the handguard for the light or laser module. If neither tactical light nor laser sight is used, the socket is filled with a screw-in plug to protect it from debris (or if plug is lost – duck-taped over). The sling eyelets were re-organized again, this time to enable using a three-point sling. The PM-84P had both eyelets placed on the bottom, which caused the slinged weapon to turn upside down. To counter it, the PM-98 had all the sling eyelets welded on the upper part of the receiver.

But the point where police and military models parted forever was in the magazine catch design. The military PM-84P had a magazine catch situated at the heel of the pistol grip, forcing the operator to remove the empty with a supporting hand, and only then allowing to grip a fresh magazine from the pouch. This was perfectly OK for the shooting range but for Police it was far too slow in reloading. The new magazine catch enabled to use the pistol magazine change method, with shooting hand releasing the magazine, allowing it to free fall from the pistol grip, while supporting hand grabs a fresh clip, ready to ram it home and hit the bolt “ear” releasing it from the hold-open device. The inevitable price of all that lightning fast reload was that there are two, almost identical yet not interchangeable types of Glauberyt magazines at the same time – one for the Police PM-98, and one for the Military PM-84P. That wasn’t dangerous when both SMGs were used by separate services, but for a while it seemed like the Army would buy PM-98s to replace aging PM-84Ps, which were no longer manufactured after the original ZM Lucznik SA went bankrupt in 2000. The new company, Fabryka Broni Lucznik-Radom, which was taking up traditions of the original Radom factory (opened in 1927 to manufacture Polish Mauser carbines and later on the famous Radom pistol, known in Poland as the Vis wz.), only tooled up for the PM-98 and flatly refused to retrace its steps. This was one of the reasons behind the recent replacement of the worn-out Glauberyt in the Army with the 5.56mm Mini-Beryl.

BRS

For its virtual absence in the Polish civilian market, strictly regulated by the Police, the Glauberyt has an astounding variety of civilian-legal semiautomatic only versions. As early as 1990, the emerging PM-84 already had a variant like that, called the PM-84 Semi-Automat. Also the PM-84P had similar Semi-Automat version, and in 1999 a civilian-legal model of the PM-98 appeared, called the BRS-99. This differed much from the previous semiautomatics, though. Those earlier ones were nothing more than a military-finish SMGs with alternative trigger mechanism and words SEMI-AUTOMAT impressed on the side, while the BRS-99 was intended for the U.S. civilian market and so it sported a 16.1-inch barrel and an entirely different lower receiver to keep users from installing military selective fire ones.

Despite all this effort, the BRS did not become an export hit while a mere two dozen were sold on the civilian market in Poland. This was due to the intervention by the Radom District Police HQ, which contrary to the level of internal changes, labeled the BRS as a reworked fully-automatic weapon, which is against Polish gun laws. Later on, the same interpretation stifled the civilian-legal Beryl-IPSC rifle and any other attempt at manufacturing civilian versions of any AK-platform weapons.

Several of the civilian owners got into serious trouble over that matter, and thereafter only security companies were able to buy the BRS legally. In the death throes of the former Lucznik factory, sometimes these civilian guns sold to the security companies were mixed up from everything that was on hand. The author once shot a PM-84 Semi-Automat in 9×18, but fitted with the BRS (or PM-98) stock. Several shooting clubs licensed to train security personnel were also able to buy some of these guns and one of Warsaw’s clubs had an even stranger combination: a PM-84P emblazoned with SEMI-AUTOMAT in block capital letters on the side of the upper receiver, which came from the factory fitted with a selective fire lower.

The BRS, as a modification of the PM-98 design, were retained in the production program of Fabryka Broni (FB). Since 2001, FB is offering the FX Simmunition force-on-force mock combat gun, called the BRS-00, being a selective fire military and police training firearm. Before the advent of the fixed Simmunition BRS-00-FX, the FX conversion units for the Glauberyts were made by BUOS of Warsaw and FB. Having to convert a lethal-force weapon and using that for force-on-force training was found disconcerting by the officials responsible for training, and so an FX-only gun was introduced instead, to avoid possibly dangerous mistakes. The BRS-00-FX has a standard receiver, marked for the FX ammunition, with a lightened bolt inside, propelled by only one (left) of the two parallel return springs – and of course a different barrel, preventing a live round from being chambered, fired and exiting the restricted bore. All FX-specific parts are clearly marked with a coating of sky-blue paint.

PM-98S and PM-06

Soon after the PM-98 was introduced, the world has gone through a bout of Picatinny-fever, starting in 1994 with the introduction of the world’s first standardized accessory mounting rail, the Mil-Std 1913 or Picatinny Rail. Polish police also felt the urge to festoon all firearms with endless lengths of “ribs” and demanded a mounting rail to be incorporated into the design, to enable it to choose changing tactical lights and laser sights, instead of being married once-and-for-always to a specific unit fitting into the fore-end socket.

At the turn of the century, the renewed Fabryka Broni started to develop a series of Glauberyt knock-offs for the Army and Police Special Forces. At first it was not an unqualified success – quite the contrary in fact. One of these early attempts was the PM-98S (like “Szybkostrzelny”, or Fast Firing). This version was simplified by abolishing it’s rate of fire reducer, after which the rate of fire rose from 640 rpm to 770 rpm. What amounted to a serious sin of wasting ammunition in regular military service was a virtue of higher firepower for the SF people. The S variant (also known as the “Specjalny”, or Special) has a different front sight protector – a full enclosed ring instead of the military model’s protective wings. One of the S version models was fitted with a 16-inch barrel (possibly a first BRS left-over) with a flash hider from the Beryl rifle. This “Pinocchio” variant, as it was mockingly known (just like with Pinocchio from the children’s tale, its nose rose from the not entirely truthful promises) was in fact ordered by several units for evaluation, and had spawned a heir: a PM-06S with 250 mm long barrel, fitted with external thread for the B&T Impuls II muzzle suppressor.

After these experiments a second wave of SF Glauberyts came, this time with the rails. At first, in 2002, as was the case with the first Beryl rails, these were rather of the Weaver, than true Picatinny profile. Because of the problems with access to the cocking handle the rail itself was put on the high support bracket over the front sight, which after fitting an already high EOTech holosight gained it the nickname of “the Rhino.” The Rhino was a disaster as it was clumsy, unbalanced, and worst of all, it made the shooter stretch his neck high, and lean forward at the same time, close to the ejection opening and – especially with a suppressor on the muzzle – the powder fumes blowing right into his eyes. It wasn’t also healthy for the sight itself, exposing it for the knocks and muzzle blast. In 2004, the next model was introduced, this time with the rail welded to the rear top cover, behind the ejection opening. Most of the Rhino problems were thus solved – only to be replaced by the new ones. This time it was hard to cock the bolt with the rail in place and again the rail made the shooter stretch his neck – but now to the rear. The sight had to be installed on the extreme rear of the rail to clear fingers cocking the bolt, or the cocking handle itself, if the sight had a side-sticking clamping knob. After another two years this problem was addressed by altering the cocking handle again – this time it was bent flat to the side, and a full-length rail was welded on top of the cover.

This wasn’t the end, however, as the Fabryka Broni was not relenting in their pursuit of better Glauberyt. During the 2006 MSPO arms fair in Kielce, Poland, a new variant was unveiled, called the PM-06. Though basic design of the submachine gun remained unchanged, many of the annoying details were put right at last. The receiver cover was made of thicker gauge sheet metal, being stiffer and vibrating less during the shooting. The safety-selector lever was made ambidextrous, and most importantly, the stock was redesigned to allow the optoelectronic sight as the main one. The old model of the stock was sliding out and dropping at the hinge, after being extended fully. This was made to allow the shooter to use the low mechanical sights placed at the level of the receiver top cover. With the coming of the rail mounted red dot sight, the gun, and subsequently the sight’s optical axis, were far too high for comfort, forcing the operator to stretch his neck in order to see through the sight, destroying what little the extended wire stock-struts offered in the way of stock weld. Moreover, the old style stock had to be either extended all the way, dropped and locked, or collapsed all the way and offered no rest at all. This was no longer suiting the tactical doctrine: first, modern tactical shooting stance doctrine called for shooting on the move with a gun held directly in front of the operator, not sideways from the short stops – which was the main type of shooting at the time when the stock was designed. As a consequence, the stock was too long for comfortable use. Second, SWAT teams operated in bulletproof vests full-time, which made a stock all the more uncomfortably long. As a result, a new stock was designed allowing it to lock in three positions along the stock struts. This, coupled with extended sheet-metal guiding tubes at the sides of the PM-06 receiver gave the operators a degree of latitude in setting the length according to the tactical needs. It can be extended all the way, beyond the guiding tubes, dropped and locked as in the old stock design for open sights shooting, but also it can be extended half-way or two-thirds length and locked in a straight line, to allow shorter straight stock compensating for red dot’s height, and front stance and/or vest shooting.

The 30-Years War

The development of the Glauberyt took more than 30 years and the end is nowhere near in sight. The basic design is getting older and dropping more and more from contact with modern technology or tactical requirements for this kind of a weapon. Right from the start this meant-to-be-compact PDW submachine gun had no chance to lead the way towards modernity, as it was marrying ideas taken from two designs that were respectively a quarter of a century (Uzi) and 30 years old (Skorpion). The Glauberyt was thus at least two decades late at the time of its birth – better and more technological submachine guns were not able to shake this kind of a handicap.

Moreover, the quality of the 50,000 PM-84Ps making up a lion’s share of all Glauberyts ever manufactured, had left much to be desired. ZM Lucznik SA was undergoing a particularly bumpy period of transition while making these – and it shows much. The PM-98, manufactured by the re-born Fabryka Broni has gone a long way towards repairing the lost reputation of the Glauberyt, but these are only used by the Police, Border Guards and the military Special Forces. A limited amount was exported: 3,000 were bought by the Iraqi National Police and several dozen were sold to an Indonesian Special Police Unit. The 9×18 variant displayed at the 2005 MSPO fair was a prototype of the model offered to (rumors had it) the Ukrainian Police, but no contract was signed eventually.

Today, many of the Glauberyt SMG flaws have finally been ironed out, but ironically nobody seems to care any more, as the days of the submachine gun in both military and law enforcement service appear to be numbered – and even if they’re not, a better and more modern design should replace the Glauberyt. The sooner, the better.

Glauberyt Field Stripping Procedure: For Series PM-84P, PM-84P Semi-Automat, PM-98, BRS-99 and PM-06

Before starting to field-strip any firearm, clear, check and double check the firearm. During the field-stripping strive to maintain muzzle awareness and point your muzzle in a safe direction at all times.

To unload and clear the weapon, first detach the magazine (PM-84, 84P and derivatives: magazine catch is situated at the heel of the pistol grip, and has to be operated by the supporting hand; PM-98 and derivatives: magazine catch is situated at the side of the pistol grip, can be operated with the thumb of the shooting hand – provided it is a right one) and cycle the action several times with trigger finger indexed outside the trigger guard. The bolt can be latched open for chamber inspection by rotating the hold-open button up with the bolt retracted.

Upon clearing the gun allow the bolt to close and remove the receiver top cover by pushing forward on the side projections of the bolt bumper plate until they clear the horizontal leg of the inverted L-shaped channel in the cover latching projection, then lift the cover (rear end up), rotating until the front end clears the front sight base.

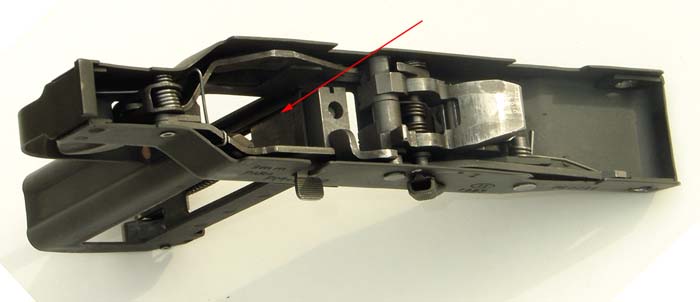

Detach the return spring unit by pressing the latching projections against the springs until they clear the horizontal leg of another L-shaped cutout, this time in the receiver, lift, ease out the compressed springs and withdraw the complete return unit (bumper plate with spring rods and springs) out of the receiver.

Retract the bolt all the way back and lift by the cocking handle(s).

Depress the barrel nut latch and rotate the nut. After two revolutions it will clear the latch and can be eased off. After the nut comes off, take the barrel out of the front of the receiver.

Disconnecting the lower receiver is the part of the routine field stripping procedure. In a PM-84/84P one has first to unfold the foregrip (press the latch button on the left side of the hinge and rotate the foregrip down) and retract the stock by one-third (press the latch button on the left rear and pull on the serrated parts of the stock rods) until the folded butt-plate clears the lower receiver. In PM-98 no preparations are needed. Press both pins (first inner, then outer) of the rear connecting bolt out of the receiver in opposite directions. Both pins are symmetrical and they can be assembled in either direction. After withdrawing the bolt, pull down the lower receiver by the pistol grip, and continue rotating it until the front of the lower receiver separates from the upper receiver.

| This article first appeared in Small Arms Review V16N3 (September 2012) |