Introduced at SHOT Show 2014, the first Glock .380 Auto caliber pistol available to the American Market is the Glock 42. The pistol is manufactured at Glock USA, in Smyrna, Georgia.

By Christopher R. Bartocci

The Glock pistol has without a doubt become the preferred sidearm of many law enforcement agencies in the United States. The commercial market is just as large if not the largest in the country. Throughout the world the pistol has been adopted by Army and Special Forces units, law enforcement as well as competition, recreation and self-defense users. Here in the United States, Glock pistols have been sold in 9x19mm, .40, .357 SIG, 10mm, .45 Auto and .45 GAP. The reputation for durability and reliability is well documented and legendary throughout the world.

However, one very popular caliber is missing: the popular .380 Auto (9x17mm). Oddly enough, Glock has made pistols in this caliber for many years but they did not appear in the U.S. The models G25 and G28 never made it. Why was this?

In order to import pistols into the United States there is a point scale that they must reach (Please see Legally Armed in this issue, page 16). Caliber is part of the component of the point scale. The configuration of the pistol chambered in .380 Auto caliber did not accrue enough points to be considered importable due to the caliber. However for Glock Austria, this pistol was extremely exportable to many other countries. There are several countries throughout the world that prohibit their populous from having firearms chambered in military calibers. So a 9x19mm caliber pistol would be illegal, but you could have a 9x21mm or a 9x17mm. One such country is Italy. You may not own an AR-15 chambered in .223 Rem but you could purchase one in .222 Rem caliber. In fact, Colt manufactured rifles in this caliber specifically for this market. The same went for the pistols. The Italians were prohibited to have a 9mm pistol but they could in .380 Auto. The Glock 25 and Glock 28 pistols would come to be very popular in this country. In Central as well as South America, the market is very lucrative for the G25 and G28 pistols as well. Really, the United States is the only country this author knows of that the .380 Auto caliber Glocks are not available for individual civilian purchases. But as previously stated, one would have a very hard time justifying a less powerful cartridge in a pistol the exact same size. It would defy logic but you never know what the customer wants.

All Glock pistols fire from what Glock refers to as “Safe Action.” Due to the Glock pistols being striker fired, there is no need for an external hammer to cock and uncock. There is no lever to decock the striker. The main benefit to the Safe Action pistol is that every trigger pull from the first pull to lock back is the exact same trigger weight. Unlike more common double action / single action pistols, when the trigger is pulled for the first time the trigger pull is a heavy 12 or so pounds due to the hammer being cocked back. After the pistol fires, the trigger pull is approximately 6 lbs. The first shot you shoot low and the next shot you shoot high until you get the consistent single action pull. The Safe Action for some is much easier to shoot due to the consistent trigger pull. Also, once you get used to the trigger reset, the pistol excels at rapid fire. When the pistol is in the loaded condition, the position of the striker has about 1/4 load of the striker spring. As the trigger is pulled to the rear, the striker is drawn to the rear of the pistol fully compressing the striker spring until the trigger bar drops down off the drop safety, releasing the striker to hit the firing pin. The trigger pull is normally 5.5 pounds from the factory, but by altering the geometry of the connector and replacing the trigger return spring the trigger weight can be increased upwards of 10.5 pounds. Safe Action comprises of 3 different passive safeties. Passive meaning they are not mechanically engaged by a lever but when the trigger is pulled each one disengages in order and when the trigger is released they all re-engage in the reverse order. The first part of the Safe Action is the passive trigger safety. There is a small spring loaded tab in the center of the trigger that must be depressed before the trigger may have any rearward movement. Unless the trigger is manually pulled the tab blocks any rearward travel of the trigger. The second is the firing pin block. There is a mechanical steel plunger blocking the striker’s forward movement so it may not pass through the breech face to strike the primer. As the trigger is pulled, a tab on the trigger bar pushes upward disengaging the firing pin block. The third safety is what is called the drop safety. The trigger bar (cruciform) rides on the drop safety. When the trigger is pulled all the way to the rear the trigger bar drops down releasing the striker to fire the round. If the trigger is not pulled, there is no way for the trigger bar to release the striker. The drop safety prevents this. Only a full rearward movement of the trigger can drop the trigger bar off the drop safety to release the striker.

The Glock 25

The G25, introduced in 1995 is built on the exact same frame as the Glock 19, Glock’s compact version of the Glock 17. The G25 has been produced in both generation 2 and 3 variations. The overall length of the G25 is 7.36 inches with a height of 4.99 inches. The width of the slide is 1.18 inches. The barrel length is 4.01 inches in length and uses the same hammer forged polygonal rifling as the rest of the Glock family of weapons. The weight of the pistol is 23.30 oz unloaded and 31.70 oz loaded with 15 rounds of ammunition. Like its 9mm counterpart, the magazine capacity of the G25 is 15 rounds of .380 Auto caliber ammunition. The G25 is offered with standard or tritium night sights. All holsters and magazine pouches are compatible with any one that fits a G19/G23 or G38.

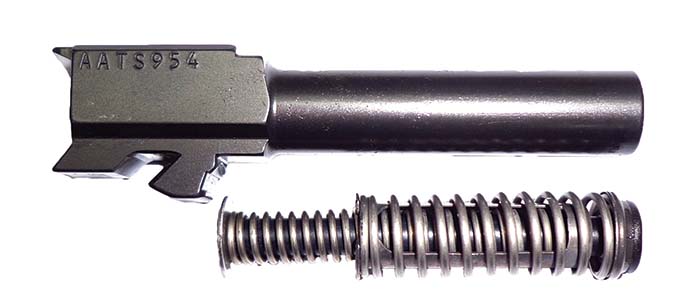

The major difference between the G19 and the G25 is not just the chamber dimensions and caliber but also the locking mechanism. Due to the relatively low slide thrust of the .380 Auto caliber cartridge, the standard locked-breech design of all the other Glock pistols had to be altered to a blowback design. To accomplish the change from locked to unlocked blowback operation the locking surfaces on the barrel were removed as well as the redesign of the locking block. Unlike the common blow back operated pistol the barrel of the Glock 25 is not fixed to the frame but assembles in the same fashion as all of the other Glock pistols. The slide moves rearward in recoil until it is tilted below the slide, similar to that of the standard locked breech mechanism. Other than the modifications to the chamber and locking surfaces of the barrel and slide, all of the other components are standard.

When looking at the G19 vs the G25 from an Americans perspective it is difficult to see why one would want the G25. To take two guns in the exact same size and have one a full powered 9mm and the other in the significantly lower .380 Auto caliber one would find it difficult to justify the .380 Auto. When firing each side by side, the recoil difference is really quite irrelevant as recoil is very similar. There are always those who want what is prohibited and that would more than likely explain the demand from American consumers for a .380 Auto caliber pistol.

The Glock 28

The G28, introduced in 1997, is built on the exact same frame as the Glock 26; Glock’s sub-compact version of the Glock 19. The G28 has been produced in generation 3 variations. The overall length of the G28 is 6.41 inches with a height of 4.17 inches. The width of the slide is 1.18 inches. The barrel length is 3.42 inches in length and uses the same hammer forged polygonal rifling as the rest of the Glock family of weapons. The weight of the pistol is 20.65 oz unloaded and 23.83oz loaded with 10 rounds of ammunition. Like its 9mm counterpart, the magazine capacity of the G25 is 10 rounds of .380 Auto caliber ammunition. The 15-round magazine from the G25 may also be used in this pistol although it may stick out of the magazine well. The overall thickness of the G28 really feels off for a pistol chambered in .380 Auto. The G25 has a more proportioned feel to it for a .380 Auto caliber pistol than that of the G25. The G25 really feels very large for such a small caliber pistol. This is from a personal perspective comparing two pistols of different size in the same smaller caliber.

The major difference between the G26 and the G28 is not just the chamber dimensions but also the locking mechanism. Due to the relatively low slide thrust of the .380 Auto caliber cartridge, the standard locked-breech design of all the other Glock pistols had to be altered to a blowback design. To accomplish the change from locked to unlocked blowback operation the locking surfaces on the barrel were removed as well as the redesign of the locking block. Unlike the common blowback operated pistol the barrel of the Glock 28 is not fixed to the frame but assembles in the same fashion as all of the other Glock pistols. The slide moves rearward in recoil until it is tilted below the slide, similar to that of the standard locked breech mechanism. Like the G26, G27 and G39, the recoil spring is altered. Due to the recoil spring compartment, a dual recoil spring is used. Although necessary for functioning reliably there is also an alteration of the recoil springs, along with a reduced feeling in recoil.

As previously stated with the G28, from an American perspective comparing the exact same size gun offered in .380 Auto, 9mm, .40 caliber, .45 GAP and .357 SIG there is no foreseeable benefit in going with the .380 Auto caliber pistol given the choice of all calibers. Comparing the .380 Auto to the 9mm NATO there is no recoil difference to speak of – certainly not enough to warrant the decrease in firepower from 9mm to .380 Auto. For those whom size is the issue and not recoil, the extremely effective .40 cal. and .357 SIG may even be more appealing. Please keep in mind this is if one is given the choice, which is not the case in every country throughout the world.

This author had the opportunity to test a G28 pistol several years ago when a Glock representative stopped by the Wisconsin Department of Justice State Crime Laboratory in Milwaukee, Wisconsin where this author held the position of a Forensic Firearms Examiner. First look at the pistol looked just like the G26/G27/G33 and G39. What stood out the most was the weird shape of the locking surfaces on the barrel. They were gone. When the slide was retracted the barrel did tilt giving the impression of unlocking but it was not. The magazine looked very distinctive. To differentiate the .380 Auto caliber magazine from the 9mm magazine the rear of the magazine was sunken in to accommodate the shorter .380 Auto cartridge.

The G28 was then completely disassembled. The same components were used in the G28 and the other models. The only noticeable differences was the barrel locking surfaces removed as well as the locking surface on the underside of the slide in the front of the ejection port. Otherwise, the same trigger group, same drop safety and the same firing pin block mechanism.

The pistol was then test fired with numerous types of ammunition. This included Federal American Eagle .380 Auto FMJ, Remington UMC .380 Auto FMJ, Federal Hydra-Shok, Winchester Silver Tip, Remington JHP, Wolf FMJ and CCI Gold Dot ammunition. All of this ammunition combined there were over 300 rounds fired through the G28. As one would expect from a Glock pistol there were no malfunctions at all. The range was limited to 10 yards and all groups were respectable off hand. Recoil was noticed to be on par with the 9mm NATO caliber. Direct blowback operated guns do generate more felt recoil compared to the same gun with a locking mechanism. When firing the G26 and the G28, they were compared side by side in all aspects. This included accuracy, recoil and reliability. Oddly enough they were the same in almost every way. Even in recoil. With some loads the .380 Auto caliber pistol barked just as much and in some cases more than the 9mm counterpart.

The Glock 42

At SHOT Show 2014, Glock introduced a new pistol to the American market. Many things were special about this pistol. First it was the first .380 Auto caliber Glock pistol to be made available to the American market. The second is the pistol was manufactured in the United States. This new pistol was introduced at SHOT Show 2014 as the Subcompact Slimline Glock 42.

To begin with, Glock, Inc. in Smyrna, Georgia has been a major assembly plant since it opened. Daily operations at this plant consisted of assembly, test firing, warranty repair and much more. Also, Glock USA sales and marketing operations are run out of the Smyrna, Georgia facility. All United States sales were handled through this office but engineering remained at the parent company in Austria. They had not manufactured anything. As of now, Glock manufactures all the major components for the G42 in house. This includes frames, slides and barrels. Due to EPA regulations, Glock USA is unable to use the Tennifer process so they had to adopt another treatment for the slide and barrel. As of this writing, Glock USA is producing G17, G19 and G42 for U.S. and export sales and has the capability of producing any Glock pistol currently on the market.

Why now can individual Americans own .380 Auto caliber Glock pistols and we could not before? All those ATF importation regulations do not apply to pistols manufactured in the United States. There is no point requirement. Thus, Glock USA is free to manufacture the .380 Auto caliber pistol without concern for the importation point restrictions. In fact there is a stamp on the barrel, slide and frame of the state of Georgia on the G42. Since the assault weapon importation ban, several foreign companies have set up production facilities here in the U.S. and began production of the rifles in the U.S. This has become commonplace in the industry. This is perfectly legal and gives customers the firearms they want.

The Glock 42 is truly a subcompact slimline pistol. When comparing it to the G28, the length of the G28 is 6.41 inches compared to the Glock 42 coming in at 5.94 inches. The real difference is in the width. The width of the G28 is 1.19 inches and the Glock 42 is .94 inches. This makes for an incredibly flat pistol that is comfortable to carry in a back pocket or a cargo pocket. The barrel length of the G28 is 3.42 inches compared to 3.25 inches. The overall weight of the G42 unloaded is 13.76 ounces and loaded with 6 rounds of .380 Auto caliber ammunition is 14.36 ounces. For comparison purposes the weight of the G28 is 20.65 oz unloaded and 23.83oz loaded with 10 rounds of ammunition. The magazine capacity of the G46 is six rounds and the magazine is single column. If one chooses, they could carry a total of 7 (6 rounds in the magazine plus one round in the chamber).

The narrow and lightweight Glock 42 pistol did require some redesign. The most notable change is the return back to a locked breech mechanism from the direct blowback of the G25 and G28. Due to the much lighter weight slide, the mass did not exist to keep the slide closed long enough for residual pressure to drop so the fired cartridge case could be safely and reliably extracted and ejected. The firing pin safety has been changed from the round shape to a more oval shape with much more bearing surface. Another change is the slide stop spring. There is only a trigger pin, so the spring of the original slide stop had nothing to grab to give tension. The G42 uses a coiled spring on the front of the slide stop to give spring tension.

The slide has the loaded chamber indicator on the extractor. As of this writing, only fixed sights are available. It is safe to assume that tritium night sights will be available in the near future. The recoil spring is similar to the Gen 4 subcompact using the dual recoil spring due to the limited size of the recoil spring compartment. When looking directly at the breech face the shape of the firing pin hole is more of a tear drop than a round or elliptical shape hole. The shape of the firing pin on the Glock 42 does not have the same elliptical shape of the other models. The firing pin itself is tear drop shaped. The top of the firing pin is round and the bottom has the tear drop shape and the bottom comes back at a rearward angle.

The American made frame itself has the same checkering of the Gen 4 series on the sides, front strap and back strap. There are thumb rest grooves on both sides of the frame. The magazine release is ambidextrous. It may be moved to the right or left side. Looking at the fire control mechanism, it looks like every other Glock but smaller. The trigger broke right at 5.75 pounds. The trigger has a smooth contour to it. The pistol disassembles for cleaning in the exact same way as its big brothers.

The Glock 42 pistol was tested with several types of ammunition to check for reliability. First ammunition tested was 200 rounds of Remington UMC .380 Auto FMJ and 200 rounds of Federal American Eagle FMJ. The pistol was also tested with 300 rounds of Black Hills Ammunition FMJ. There were no malfunctions at all with this ammunition. The same two magazines that came with the pistol were used for all testing. Federal Hydra-Shok was also tested. There were 20 rounds fired with no malfunctions of any kind. The next round was the Remington Golden Saber high performance hollow point (Brass Jacket). There were no malfunctions. The last were the Hornady Critical Defense. This was a particularly difficult load for the pistol. If the slide was locked to the rear, magazine inserted and the slide manually released the pistol would occasionally experience a failure to feed. However if the magazine was loaded with the slide closed and the slide pulled to the rear and released the malfunction did not seem to happen. When firing the pistol, this author only experienced one out of 40 failures to feed. The pistol was fired without lubricant.

The Glock 42 is an excellent choice for personal protection. Whether it be a back up pistol, carried concealed in a purse or holster or even a pocket the Glock 42 fits the bill. The pistol is short, flat and snag free. There are some guns on the market in the same caliber that are slightly shorter and others slightly larger. There are always tradeoffs. The locked breech will decrease recoil and increase reliability. The trade off may just be an extra half inch or so. The G42 is as reliable as can be. The family of weapons has built their name on durability and reliability. This pistol can do anything and more you would expect from it. Now is the real big question. This question I heard at the Glock booth at SHOT Show 2014, that is, “so when is the 9mm coming out in this size?” We will just have to wait and see. Scaling up to 9mm will not be so easy giving the significant increase in pressures and cartridge length. We will just have to wait and see what Gaston Glock comes out with at SHOT Show 2015. He never disappoints his customers.

| This article first appeared in Small Arms Review V19N4 (May 2015) |