By Frank Iannamico

During the Second World War, Germany fielded a number of new weapons produced from simple sheet metal stampings. The German 9mm MP40 machine pistol was the first successful sheet metal weapon to be made in large numbers followed by the German MG42 machine gun, and the Sturmgewehr. The MP40 weapon started a world revolution in small arms design. The methods and materials used allowed weapons to be manufactured cheaply and very quickly in large numbers – very advantageous during a large scale war. Weapons manufactured by these methods proved as durable as their labor-intensive counterparts made primarily of milled steel. One of the first designs fielded by the Allies was the 9mm British Sten Mark I in 1941. This was soon followed by the even more utilitarian Mark II and III Sten models.

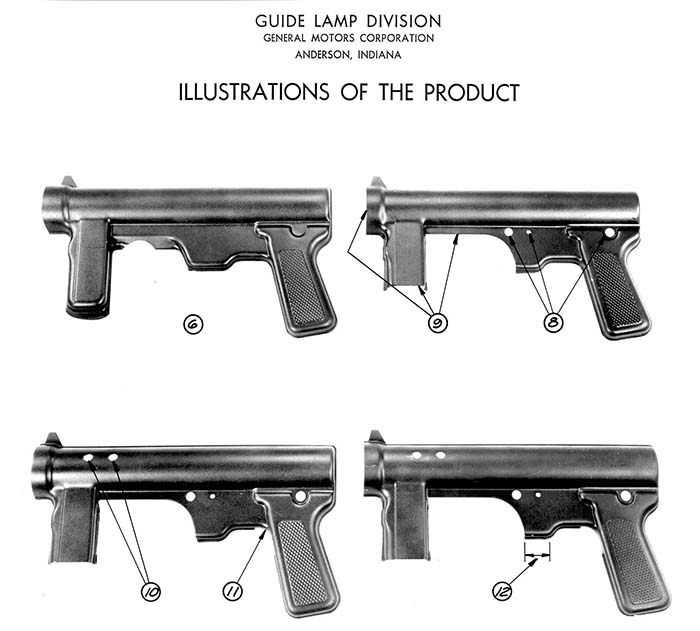

Seeing the benefits of such a design, the United States Ordnance Department began to develop a similar submachine gun that was to be fabricated from mild steel sheet metal. After an in-depth study of the German MP40 and the British Sten by the Ordnance Department engineers, the requirements for a similar U.S. weapon were established on 6 February 1941. Development began by the Small Arms Development Branch of the Ordnance Department with assistance from the Inland Division of the General Motors Corporation. One of the first new submachine gun models to be designed was the T15 submachine gun. The T15 was a .45 caliber weapon that featured a straight open-bolt blow back operation commonly used in most submachine gun designs. The T15 quickly evolved into the simplified T20 model after several requirements were revised. One of the design changes was the elimination of semiautomatic function, and a requirement for the weapon to be easily converted to fire 9mm Parabellum ammunition. Because of the slow cyclic rate of the weapon it was decided that there was no need for a semiautomatic feature thus allowing the design to be further simplified.

The T20 had one very unique design feature that separated it from all other submachine guns of the day. On virtually all previous submachine gun designs, the bearing surfaces of the bolt would move forward and rearward supported by the inside surfaces of the receiver. On the T20 weapon, the bolt was designed with two horizontal holes that ran through the entire length of the bolt. The bolt then rode on two steel rods that were inserted into the holes, and were held in place by a steel plate oriented by two holes located in the rear of the receiver. Each guide rod had its own separate recoil spring. The steel guide rods were supported at the front by a steel guide plate that was indexed in the receiver by two integral tabs on the plate. A spring steel circular clip kept the bolt, guide rods and recoil spring assembly together until the barrel could be screwed onto the receiver. The front guide plate was secured to the receiver by the tightening of the barrel nut assembly. The primary advantage to the design was that the bolt never contacted the inside surfaces of the receiver. The unique arrangement made the T20 submachine gun nearly impervious to stoppages from dust, mud water or even sand. The T20 was one of the few weapons that was able to successfully pass the Ordnance Department’s rigorous mud and dust tests.

The receiver design of the U.S. T20 prototypes also differed radically from other submachine guns that used a simple circular tube for the basic receiver. When a tube receiver was used, a separate housing for containing the trigger and sear assembly needed to be designed and attached to the main tube. This would complicate manufacture somewhat as the two pieces would need to be accurately oriented to each other. In the design of the T20, the receiver was constructed by joining two separate stamped sheet metal pieces by welding. The receiver, the housing for the trigger and sear assembly, and pistol grip were all an integral part of the single assembly. The only other separate parts required were a dust cover/ejector housing for the trigger mechanism and a simple spring steel trigger guard that also held the cover in place. Other parts like the barrel bushing, sights and ejection port cover were attached to the receiver assembly by rivets or welding, no threaded fasteners were used.

The method of manufacturing barrels was borrowed from the British, who produced their Sten machine carbine barrels by the cold swaging method. The M3 barrel was also manufactured by cold swaging, a process that saved a significant amount of production hours. The steel tubing for the barrel would first be reamed to the correct inside diameter. The rifling would then be pressed into the barrel by inserting a mandrel and compressing the tube as it was forced through the die. The 40-inch piece of tubing would then be cut in sections to produce five M3 barrels. This barrel making process was much faster and less expensive than broaching or other methods. Accuracy of fire remained well within the requirements established by the U.S. Ordnance Department for submachine guns.

The T20 was recommended for adoption as the Caliber .45 Submachine Gun, M3 on December 24, 1942. The contract for manufacture of the M3 was awarded to the Guide Lamp Division of General Motors who were experts in sheet steel fabrication for the automobile industry. However, there were several problems encountered during initial manufacture of the M3. One of the problems was being able to accurately join the two receiver halves together by welding. A second problem was the thin sheet metal receiver halves were warping from the heat generated by the welding process. While Company and Ordnance engineers were engaged in resolving these problems, the Ordnance Department ordered the resumption of M1A1 Thompson Submachine Gun production.

The original M3 submachine gun production schedule had planned for 20,000 units to be produced by July 1943, but only 900 acceptable units had been completed. Before long the welding problems of the receiver were solved and the M3 was in full production. At the height of production in 1944 one-thousand M3 submachine guns were being produced every twenty-four hours.

The Guide Lamp initial contract price for the manufacture of the U.S. M3 was $18.36 per unit after being adjusted to cover the cost of minor production changes, and the packing of the completed units. There were a large number of subcontractors involved that supplied various small parts to Guide Lamp. The only major part that was subcontracted out was the bolt assembly, which was manufactured by the Buffalo Arms Company of New York. The manufacture of the M3 submachine gun was further simplified with the introduction of the M3A1 model in 1945.

While the unique design of the M3-M3A1 receiver made the weapons extraordinarily reliable, the design of the magazine proved problematic. It remains a mystery as to why the U.S. M3-M3A1 submachine gun was not configured to use the existing and excellent double stack-double feed magazine from the Thompson. The Thompson magazine was a proven design and already in production. Instead, the 30-cartridge M3-M3A1 magazine was a double stack, single feed design that contributed to stoppages when exposed to dust and mud. The single feed configuration had previously proved troublesome when used in both the British Sten and the German MP40 weapons. While the M3 was undergoing Ordnance testing, virtually all jams and stoppages were attributed to the weapon’s magazine. During testing of the M3 by the Infantry Board, they had suggested a few ways to improve the magazine’s reliability, but the problems were never addressed. The only fix was a rubber and eventually a plastic cap to keep dirt and debris out of the magazine. The cap was to be kept on the magazine until it was ready to be placed into the weapon.

Although many martial arms collectors of today are put off by the U.S. M3 and M3A1 submachine gun’s appearance and slow cyclic rate, the weapons were very cleverly designed. The M3-M3A1 has often unjustly received criticism based solely on its utilitarian toy-like appearance. The M3 and M3A1 submachine gun remained in U.S. service many years after most foreign and domestic World War II era weapons were declared obsolete.

| This article first appeared in Small Arms Review V9N3 (December 2005) |