By Anders Thygesen

It was a shameful day when the Germans occupied Denmark on April 9, 1940. The government surrendered after only a few hours of fighting and the chance of recognition as an ally of England was not to be in this round. However, not all good Danes accepted the government’s recommendation of accepting the presence of the occupying force without sword blows, and on the very next day, April 10, 1940, the first illegal sabotage strike was dealt with the blast from a Danish hand grenade M23.

The day prior, Danish engineer Erik Olsen from Odense’s electrical plant obtained the hand grenade from the Odense army barracks and subsequently threw it at a German troop transport train near Marslev. It was hardly an act that kept the German occupying force awake at night; nevertheless it was the opening salvo in a long line of sabotage missions conducted by a growing and extraordinarily effective resistance movement.

The Different Models

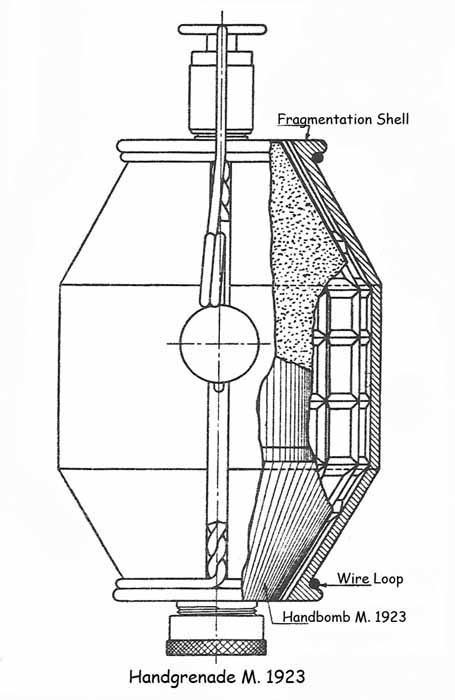

The basic version was the Hand Bomb M23 (offensive). Enveloped in an additional pair of cast iron fragmentation shells, manually attachable with steel wire, the Hand Bomb would become the Hand Grenade M23 (defensive). Both grenades were painted grey and some had a yellow band painted around the body of the grenade.

The construction of the practice version of the M23 differed slightly from the live version in that it was made from thicker steel as it had to withstand multiple impacts with the ground from throwing practice. A special cartridge containing a small black powder charge to simulate a detonation had to be inserted and it could be reloaded and thrown multiple times. The drawback was that it had to be returned to the manufacturer for reassembly of the fuse section. All the practice M23s were painted yellow or grey; the grey with a black band painted on the top cone.

In 1941 a new variant of the practice grenade, called the Blank Hand Bomb M41, was introduced for use in combat drill scenarios. The top 2/3 was made from wood and the bottom 1/3 from a cardboard tube filled with black powder. Just like the yellow practice grenade it could be reloaded but it also had to be returned to the manufacturer for reassembly.

A blank Hand Bomb/Hand Grenade M23 made from wood and steel was also used but no pyrotechnics were involved and it was only used to practice throwing an object with similar weight and shape.

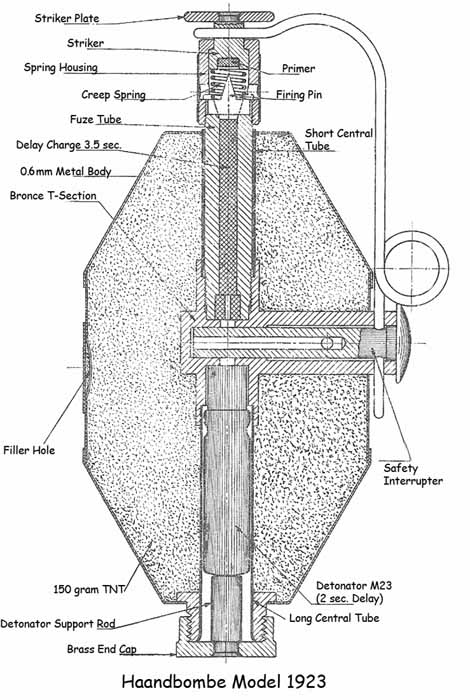

The grenade body consists of a 0.6 millimeter (0.0236 inch) thick steel cylinder with conical cups soldered to each end. The top cone houses the fuse and striker which are threaded into a central tube running through the whole length of the grenade body, ending up protruding from the bottom cone. The detonator designated Taendpatron M. 23 was enclosed inside the other end of the tube behind the knurled brass end cap.

The fuse, from which the striker protrudes, has four vent holes positioned 90 degrees apart in the housing. One end of a safety wire extends through a hole in the striker and the other end extends through a hole in the safety interrupter tube and the safety interrupter. The safety interrupter rests in a tubed T-section inserted in the centre of the well thereby separating the delay charge from the flash channel leading to the detonator. On the opposite side of the safety interrupter there is a rectangular cover plate soldered over the filler hole.

The interrupter assures that the grenade doesn’t detonate prematurely due to a defective delay charge or before it has been thrown to a safe distance.

If the delay charge burns through with the interrupter still in place, the spark will be stopped before reaching the 2-second delay flash channel. The interrupter has a channel drilled lengthwise about 3/4 deep and it ends up in a vent hole. This is so the hot expanding gasses from the burning fuse can escape via the channel and out through the vent hole, into the interrupter tube and out without making contact with the 2-second fuse below.

One of the obvious drawbacks to this design is that the grenade is extremely sensitive to water and even just moisture, hence every single grenade was packed in a wax sealed cardboard box. The moisture sensitivity problem in combination with the complex functionality and cumbersome design made it no match compared to the British and U.S. pineapple or the German M24 stick grenade.

In order to throw the grenade, a firm grip around the grenade body with the thumb resting on the interrupter, are advised. Then the safety wire going through the striker is pulled out and then the other end of the wire has to be pulled from the safety interrupter. Now hit the striker plate hard with the other hand or against any hard surface with enough force to overpower the creep spring holding the primer away from the fixed firing pin, thereby ramming the percussion primer into the firing pin, initiating the primer, which in turn ignites the delay charge. A hissing sound from the 3.5 second black powder delay fuse is heard and the lacquered paper covering the four vent holes will start burning away.

When thrown, the grenade will spin along the lengthwise axis like an American football, thereby causing the centrifugal power and gravity to pull out the interrupter from the grenade body. After about 3 meters (10 feet) of flight the interrupter will fall away and the grenade is now armed.

The grenade is filled with 150 grams (5.3 oz) of Trinitrotoluene (TNT), making the total weight of the grenade 350 grams (12.3 oz). The M23 offensive grenade has an effective range of only 4 meters (13 feet). The official safety distance is 60 meters (197 feet) but it is advised that unprotected personnel turn their back towards the detonation site or at least cover their faces.

The markings can vary from the number “23” or a letter “K” inside a 12 pointed star and “AK/B 1942” the number being the year of manufacture. Also the stenciled letters “AMA” can be found being the abbreviation for the Danish ammunition factory named AmMunitions Arsenalet. Additionally, many of them have a painted 3/4-inch wide yellow band.

The defensive Hand grenade M23 is basically a Hand Bomb M23 in disguise. Two fragmentation shells made from cast iron are attached to the grenade body with two wire loops. A cutout has been made in the two shells to make room for the safety interrupter and safety wire. According to the manual, the shells will fragment into 48 pieces weighing 3.2 grams (0.1129 oz) and 64 pieces weighing 2.3 grams (0.081 oz) the effective range being 10 to 15 meters (32 to 50 feet). The official safety distance is 150 meters (492 feet) but again it is advised that unprotected personnel turn their back towards the detonation site.

The shells weigh 150 grams (5.291 oz) each, almost doubling the weight of the grenade to a total of 650 grams (30 oz). The operational procedure for the defensive grenade is, for obvious reasons, exactly the same as for the offensive.

Taendpatron Model 1923/31/41 (Detonator)

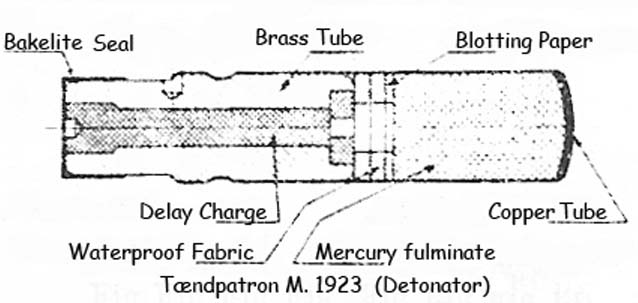

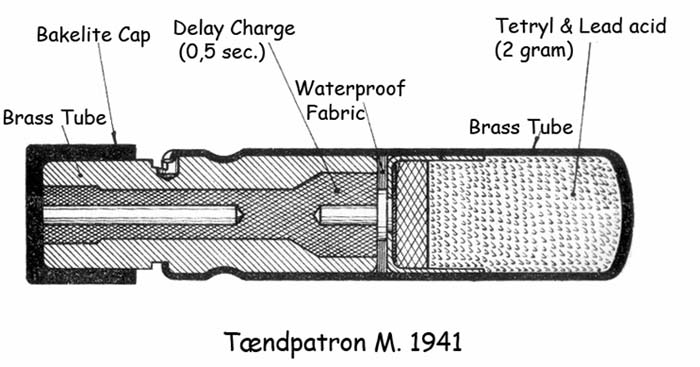

The detonator M23 consist of a brass section containing a 2 second black powder delay charge and a copper section containing 2 grams (0.0705 oz) of mercury fulminate explosive charge. The copper section is crimped to the brass section and the open end of the brass tube is sealed with a bakelite cap.

In 1931, the mercury fulminate was discontinued and replaced with Tetryl and lead acid, which is a more stable and powerful explosive. Also, both sections were made from brass. The diameter of the bakelite cap was increased from 9 mm to 10 mm to avoid the possible mistake of inserting the detonator with the bakelite seal still in place. Due to these modifications the nomenclature was changed to Taendpatron Model 1931.

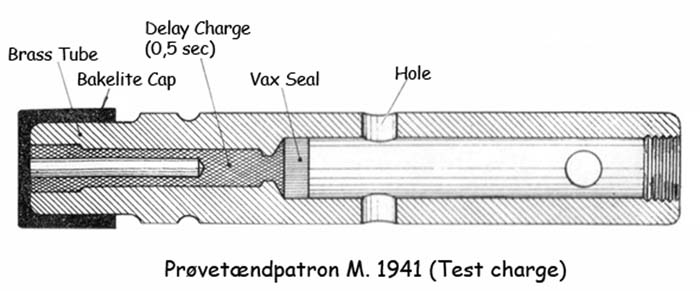

In 1941, it was found that the total delay time at 5.5 seconds (3.5 sec. + 2 sec.) was too long and a new Taendpatron (detonator) with a delay charge of only 0.5 second was introduced, reducing the total delay to 4 seconds (3.5 sec + 0.5 sec). This detonator received the nomenclature Taendpatron Model 1941.

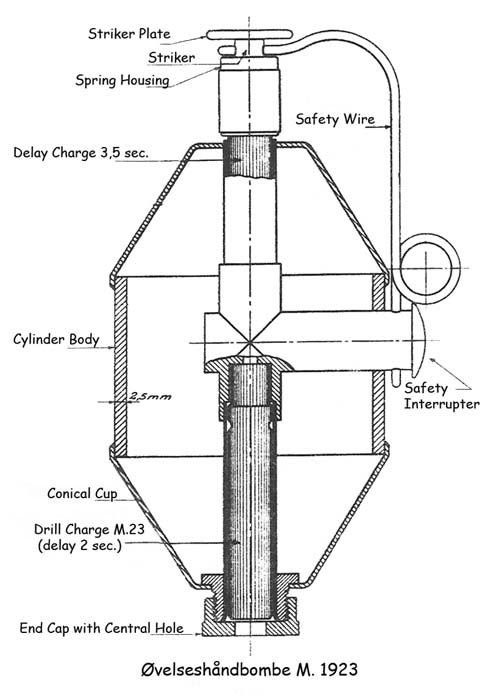

Hand Bomb Model 1923 (Practice)

The practice version of the M23 offensive grenade came in two different colors. One is painted yellow to distinguish it from the live grenade, and the other is grey with a 10 mm (0.3937 inch) black painted band around the top cone. Apart from the color, it differs by being thicker in the construction as the cylindrical mid section of the grenade body is made from 2.5 mm (0.09 inch) and the cones from 1 mm (0.039 inch) thick metal versus the 0.6 mm (0.0236 inch) on the live grenade. The alteration was solely made for reasons of durability and had no influence on the functionality or use of the grenade. Furthermore, the practice grenades have no filler hole or cover plate. Two small holes, one just below the safety interrupter and another one on the opposite side on the top of the cone, are drilled in the body to further tell them apart from the live grenades. Both holes are approximately 2.5 mm (0.09 inch) in diameter. Additionally, the knurled brass end caps on practice grenades have a central 6 mm exhaust hole so the gas and smoke from the spotter charge can escape. The practice grenades also usually have a string of dots from a mandrel on the mid cylinder just below the safety interrupter. The number of dots can vary from just one to numerous and they serve the purpose of telling how many times this particular grenade has been reloaded. Two fragmentation shells can of course be attached to the practice grenade in order to simulate the defensive Hand Grenade M23.

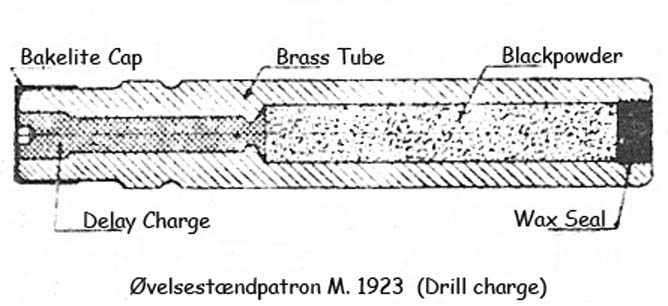

The grenade can be armed with two different charges. A black powder spotting charge called Ovelses Taendpatron M23 (drill charge M23) can be inserted into the detonator channel covered by the brass end cap.

The spotting charge is an enclosed unit containing the second delay fuse (2 sec.) along with a small 0.7 gram (11 grain) black powder charge sealed off with a lump of wax. When the charge fires the wax seal, the expanding gases and smoke escape through the 6 mm central hole in the end cap. To follow up on the modified detonator M41 the delay was reduced from 2 seconds to 0.5 seconds and now renamed Ovelses Taendpatron M41 (drill Charge M41). The drill charge is painted red, stamped with the Danish letter “Ø” meaning “Drill” and made from brass.

The other charge is a Provetaendpatron M23 (Test charge M23), which consists of only the black powder 2 second delay element. The grenade could then be test fired and demonstrated inside a class room. The test charge’s outer appearance is similar to the drill charge except it has four holes drilled from the side and one from the bottom. In 1941, the delay was reduced to 0.5 second and renamed Provetaendpatron M41 (Test Charge M41).

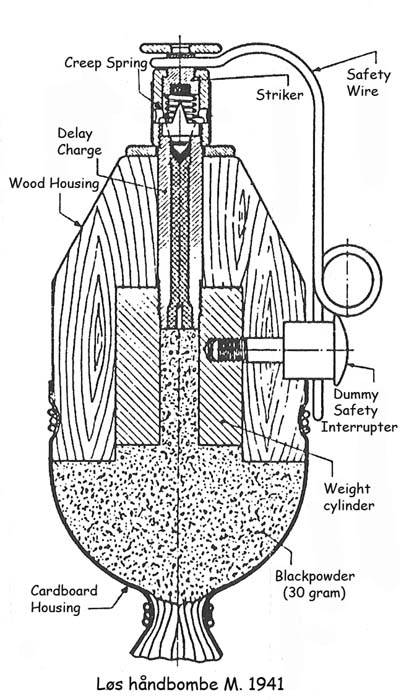

Hand Bomb Model 1941

In 1941 a new practice grenade called Los Haandbombe M41 (Blank Hand Bomb M41) was introduced. The top 2/3 is made from wood and has a steel cylinder inserted in order to gain weight equivalent to the live grenade. The bottom 1/3 is made from a cardboard tube and filled with 30 grams (1.058 oz) of black powder. The safety interrupter is non functional and only serves the purpose of resembling the live one. Because of the black powder charge, a safety distance of 3 meters (10 feet) was set. Just like the yellow and grey practice grenades it could be reloaded but it had to be returned to the manufacturer for reassembling. The first versions were unpainted wood and the cardboard were painted black; later the wood was painted white and finally the last versions were painted grey all over except for the black band around the top.

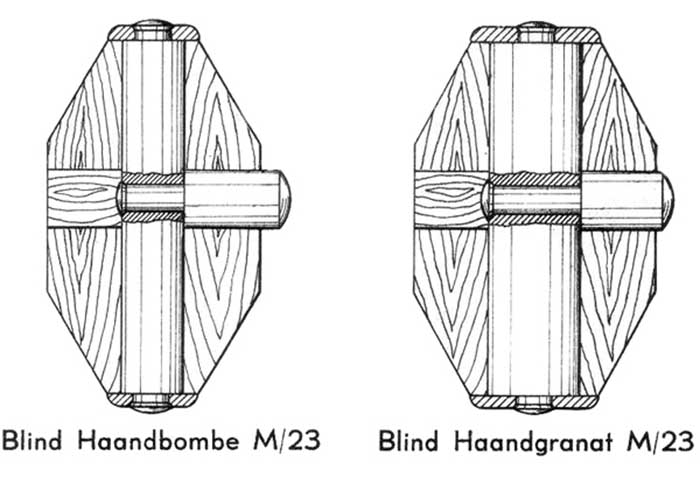

Hand Bomb/Hand Grenade Model 1923 (Blind)

A Blind Hand Bomb and Hand grenade M23 made from wood and steel were also used but no pyrotechnics were involved and it was only used to practice throwing an object with similar weight and shape as the live ones. It has a steel plate in each end. The plate on top has the word “OP” (UP) stamped, and a steel button is protruding from the side simulating the safety interrupter. The Blind Hand Bomb M23 weighs 350 grams (12.345 oz) and measures 10.5 cm (4.133 inch) long and 5.7 cm (2.244 inch) wide. The Blind Hand Grenade M23 weighs 650 grams (22.928 oz) and measures 10.5 cm (4.133 inch) long and 6.5 cm (2.559 inch) wide. The blind is painted white for ease of spotting and recovering in the terrain. Other versions are known to exist and cheap ones have been observed also made from wood but they had a 4 cm (1.57 inch) broad and 5 mm (0.1969 inch) thick iron ring attached to the body with a bolt that doubles as the interrupter knob. The grenades were painted silver grey.

The M23 and its variants have been obsolete for many years now. Exactly how many were used during World War II is unknown although a good portion certainly were used by the resistance movement. Unfortunately the Germans took over the production during the occupation and adopted it in the Wehrmacht and gave it the nomenclature respectively “Handgranaten 342(d) and 343(d).”

| This article first appeared in Small Arms Review V12N6 (March 2009) |