By Jon Miller

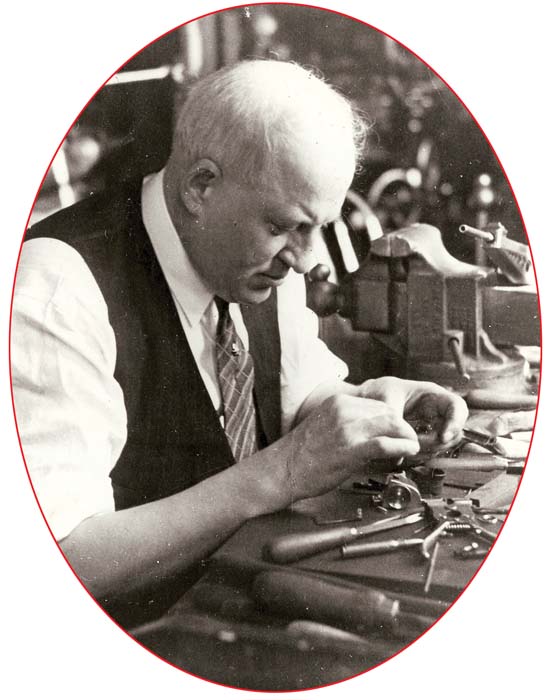

On April 19, 1879 Carl Gustave Swebilius was born in Vingaker, Sweden. He was one of five children of the town watch maker. He grew up working with his father and learning his love of precision machinery. At age 18, Gus immigrated to the United States and lived with his eldest sister in New Haven, Connecticut.

His first job in the U.S. was making barrels for Marlin firearms company. He was quickly promoted to foreman of that department. He continued to attract notice and was promoted to the tool room. After three years, he was transferred to gun design where he was working at the outbreak of World War I.

While there he modified the Browning .30 caliber machine gun for use on aircraft by lightening it from 35 to around 19 pounds and increasing the rate for fire from 400 to 900 rounds per minute. He finished that task in less than a month.

Swebilius was the first American to perfect the cam system sending bullets between spinning propeller blades and the first to synchronize a gas operated machine gun. His design was used on propeller aircraft through World War Two.

Major George Chinn, author of the classic tome The Machine Gun, recognizes Swebilius as second only to John Browning in early design of machine guns. Coincidentally, Swebilius worked with Browning during World War I. Following World War I, Swebilius worked as chief designer at Marlin and then at Winchester until 1939.

Swebilius worked not only at Marlin and Winchester, but also on a side venture producing high quality barrels and barrel drilling equipment. In 1932, Swebilius, Gustave Beck (a partner in the barrel drilling business) and three other investors bought the defunct Hartford Arms company lock, stock, barrel and manufacturing tools for $800.

The deal included enough partially assembled pistols and parts to complete around 800 pistols. George Wilson, Sr. was hired as foreman to assemble the pistols. Swebilius sold them to Galefs Hardware and Sporting Goods stores. They made enough money on the deal to pay off the note and they had the equipment to produce more pistols. This was the way Swebilius did business.

After some modifications by Wilson, the Hartford semiautomatic became the High Standard Model B starting with serial number 5000. The business was successful. Swebilius hired new Swedish immigrants whenever possible. When the United States entered World War II business skyrocketed. Initially the military used the model B for a machine gun sub-caliber firing device.

Pistols: Model B and Model B-US

From the beginning of the war there was a demand for .22 caliber pistols to train new recruits in marksmanship. The .22 was cheaper to shoot and had less recoil and report than the standard issue .45 caliber M1911.

In 1942, the War Department purchased Model Bs in mass quantity with deliveries beginning in May and June. Every model Swebilius had in inventory regardless of model or barrel length went to the military. The first pistol, a Model E serial number 95215, was shipped on March 10, 1942. Model B, Model A, Model D, Model E, Model H-B, Model H-A Model H-D and Model H-E pistols all went to the War Department.

Most early pistols were commercial Model Bs. Many survivors have the US Ordnance acceptance markings. At the request of the military, the Model B was modified to become the Model B-US. All barrels were cut to 4.5 inches to conserve steel. The frame was modified to more closely resemble the 1911 Colt in the web space of the hand. “Property of US” was roll stamped along the top of the barrel and on the right side of the frame over the trigger guard. A crossed cannon ordnance acceptance cartouche is also found on the right side of the frame. All had the standard ten round magazines. 14,000 Model B-US pistols were produced between 1942 and June 1943. Model Bs were also exported to England under Lend Lease. Several were silenced. One is in the Imperial War Museum in London and others have been located in Scandinavia.

Model H-D and USA Model H-D

The Model B-US was supplanted by a George Wilson designed exposed hammer Model H-D which was further modified into the USA Model H-D. The commercial Model H-D had the adjustable rear sight replaced by a fixed sight and the addition of an external safety. All barrels were 4.5 inches. US Property and ordnance marks were stamped like the B-US. This modified pistol was dubbed the USA Model H-D. About 34,000 were produced between 1943 and 1945. Early guns had the typical High Standard deep blue luster finish while later ones were Parkerized to save money. All grips were plastic.

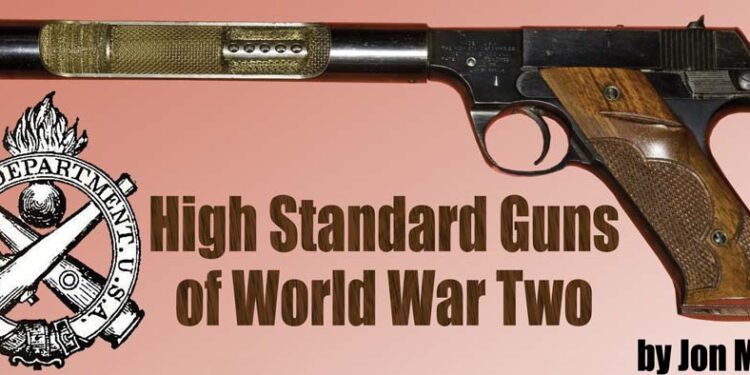

USA Model H-D M/S

While the USA Model H-D was being produced for the military, the Office of Strategic Services (OSS) had need for a silenced pistol for use on clandestine missions.

They contracted with Western Electric Bell Laboratories for the suppressor design. Bell chose the Kulikowski (Polish) silencer as its model. Several pistols including the Colt Woodsman, High Standard Model B, C, D, E and USA Model H-D were tested at Aberdeen. The USA H-D was selected. High Standard assembled and delivered 2,620 pistols to the War Department during World War II.

The classified pistol was officially named the USA Model H-D M(ilitary)/S(ilenced). Its code production name was the “Impact Testing Machine.”

The first batch of around 1,400 had blued frames with Parkerized suppressors. The second order came out with both frame and suppressor Parkerized. These were all shipped in black High Standard boxes. There have been several runs since then. One Parkerized batch was delivered to the CIA in plain brown Kraft boxes.

Most of the early guns were serial numbered and entered into the shipping books, although there were some missed numbers and blanks in the records. OSS/CIA reportedly had a special batch made without any markings. These were referred to as “sterile.”

The M/S had an exciting career. Soon after the first run production was completed, the head of the OSS “Wild Bill” Donovan took a sand bag and an M/S into the Oval Office. The story goes that upon his arrival President Roosevelt was doing some dictation. Reportedly, Donovan emptied the ten-round magazine into the sand bag in a trash can unnoticed by either the President or the guard outside the door. Whereupon Donovan offered the empty gun to the President with an explanation of what had just transpired. Roosevelt reportedly said, “Donovan, you are the only (expletive deleted) Republican I would trust to do such a thing.”

Roosevelt kept the pistol on display at Hyde Park until it was discovered that it was a classified weapon. It was promptly returned to Donovan’s aide.

That is a charming story and something like it probably did happen. But even a slightly hard of hearing sixty plus year old man can hear a suppressed pistol go off in a closed room at close range. The firearm reports are suppressed, not entirely and completely silenced. ALL guns make noise. The break of the trigger, fall of the hammer, movement and impact of the slide all make sounds. The escape of burning propellant gases into the atmosphere and the crack of a bullet breaking the speed of sound make even louder noises. How are they suppressed?

On the M/S, the slide can be locked in place by a disabled slide safety. The sound of the trigger break and hammer fall, while unavoidable, are fortunately negligible.

The last and greatest problem is the escaping burning propellants. In the M/S, most of the expanding gases are vented and captured in the first stage of the suppressor. The barrel has been turned down to 0.406 inch diameter and ported with four rows of eight perpendicularly oriented holes in the early versions and eleven holes in the final model. Gases behind the bullet escape through the ports and are captured in a roll of zinc plated bronze mesh. The mesh acts as a heat sink that cools and slows the gases before they escape.

The suppressor is divided into a first and then a second chamber by a brass washer. The front chamber is beyond the muzzle of the barrel. It is filled with stacked brass or bronze wire doughnuts, which capture gases escaping the muzzle.

For optimal results the weapon is prepared in advance. A liquid such as oil, water, insect repellant or optimally Burma-Shave is introduced into and allowed to fill the suppressor through the muzzle opening. Excess fluid is drained by gravity to prevent barrel blockage. A loaded magazine is inserted and the gun is then fired.

The muzzle end is then quickly sealed with a piece of masking or cello tape. The chamber end is sealed by the next bullet. This excludes oxygen from the tube thus preventing combustion of any propellant trapped in the tube. The liquid serves the same purpose and also acts as a heat sink absorbing energy while passing from liquid into a gas phase. The tape on the muzzle acts as a wipe making maximum contact with the bullet and thereby impeding remaining gas escape.

To maximize effect the muzzle should be in direct contact with the target. In that fashion, the inevitable escaping gases will follow the tract of the bullet penetrating the skin (and hopefully the skull contents). The cavitation and tissue disruption of the bullet will be multiplied by the expanding gases trapped inside the closed container.

There was little worry of fouling the rolled mesh in the M/S suppressor as it was meant to be replaced every couple of hundred rounds. Extra rolls were included in the box along with assembly instructions and a special wire brush meant for use in cleaning the weapon. The brush was usually discarded.

There was a glitch with the M/S ammunition. Standard .22 caliber bullets were in contravention to the Hague convention as they were not jacketed ammunition. As such, they were not supposed to be used in war time. A communiqué was sent out to all troops to stop use of the M/S until proper ammunition in the form of the T-42 could be supplied. The order was of course ignored.

High Standard wasn’t alone in making the M/S. Armorers in Viet Nam reverse engineered the pistol and produced an untold number of copies for use by troops and Special Ops teams. What better way to silence watchdogs (Hush Puppies?) when entering a village in the middle of the night?

During World War II, the Russians became aware of the M/S and requested samples. As we were at that time fighting a common enemy the request could not be ignored. Churchill suggested however, that the guns be shipped without the screens – which is what happened.

The Soviets had more experience with the M/S later when they shot down a U-2 piloted by Francis Gary Powers over Sverdlovsk on the First of May 1960. Powers was on what was already scheduled to be the last U-2 reconnaissance flight over Russia. The integrity of his plane was disrupted when a surface to air missile exploded in his immediate vicinity. He ejected from the aircraft at high altitude carrying several survival items including a sheath knife, suicide device disguised as an American silver dollar and a High Standard USA M/S serial number 120046.

Much to the chagrin of the Eisenhower White House, Powers was captured intact and alive. The pistol, items listed and parts of the U-2 were paraded through a propaganda trial meant to embarrass the USA. The M/S has since been known as the “Powers Pistol.”

The Powers Pistol along with other evidence is still on display in the KGB Museum in Lubyanka Prison on Lubyanka Square in Moscow. The Lubyanka Prison is notorious in Russia as it was KGB headquarters where people were taken for interrogation, torture and execution.

After the OSS was disbanded, the CIA and military operations inherited most of the remaining stock. As late as year 2000, there were still over 400 of the original guns on inventory at CIA Langley. Several had been issued to Special Ops in Kosovo.

People report coming across them while decommissioning navy ships or in the survival pack of the B-52 bombers. Dozens spilled out of a 55 gallon oil drum at an American air base in Thailand in 1966 or 1967. Some were reported in Korean CIA bases.

Many USA Model H-D M/Ss disappeared into duffle bags after the war. Some disappeared when the OSS was disbanded. At least two of those were converted back to USA Model H-Ds. There are possibly a dozen original M/Ss that were Amnesty registered and are legal for civilian ownership.

Model P-380 (.380 caliber)

Despite the efficiency with the M/S, the OSS wanted a more robust silenced weapon. The SOE had the Welrod in .32 ACP and in 9mm. It was quiet, but it was a manually operated, magazine fed, single shot pistol. The OSS wanted a magazine fed semiautomatic .25, .32 or .380 caliber silenced pistol. Colt was approached initially, but after negotiations failed the contract went to High Standard. The contract for 1,000 guns at $57 each was signed on 23 April 1945. A one month production run was scheduled to begin on 24 August 1945 but there were delays. The revised date of production was set for 15 September. The war ended in the interval and the contract was cancelled. One gun was delivered to the OSS but there may be others.

High Standard was compensated for the contract cancellation. Swebilius had the balance of frames after the contract was cancelled, so he replaced the silencer with a standard .380 barrel and marketed it as the G-380.

.25 Caliber

The prototype suppressed .25 caliber pistol serial number “1” survives. The silenced .25 caliber pistol disappeared from the inventory near the end of the war but later surfaced and was confiscated by police in New Jersey. It was transferred to a private collector “in return for favors.”

In the 1960s, ATF agents approached Harry Sefried while he was working at his desk at High Standard. The .25 prototype was on his desk. The agents inquired regarding its ownership. Sefried replied, “Depends”. “On what?” they asked. “Well if it’s legal its mine, if not it belongs to the company.” While the agents went to the front office to search through the paperwork, Sefried took the pistol to the machine shop, removed the baffles and had the left side of the suppressor milled exposing the ported barrel. When the agents returned they informed him that the company’s Title II paperwork had expired. They would therefore confiscate it as an illegal silenced pistol. Sefried protested that it was no longer suppressed as the tube had been milled. To prove that, he positioned the agents on the milled side of the pistol and fired it. All present agreed that it was not suppressed and Sefried kept the pistol. That pistol and the .32 caliber prototype are now privately owned.

Model P-22

The OSS requested another modification. They wanted a pistol which could be quickly converted from standard commercial to suppressed configuration. High Standard complied with the quick change lever placed forward of the trigger guard. By depressing the lever either barrel could be slid forward and removed allowing interchange. Four prototype .22 calibers were produced in this configuration. That lever takedown was found on the P (later G)-380 and subsequent G series commercial pistols.

.50 Caliber Browning Machine Gun

As mentioned earlier, Swebilius left Winchester in 1939 to work full time at his new company at about the time war broke out in Europe. England was in desperate need of all guns and especially machine guns for aircraft. Swebilius had secured a reputation in the field in the last war. A friend, John Owsley, convinced the British Purchasing Commission that Swebilius could supply the goods.

In November, 1940, the first contract was signed for 12,000 .50 caliber aircraft machine guns and spare parts. Initial delivery was expected in ten months. Swebilius had nothing. He had no land, no plant, no men and no tools. Worse, most tools had already been snatched up by other manufacturers. Gordon Wilson and Charles Liedke scoured the east coast for any usable machinery buying anything available. It is reported that they even went to silk weaving factories and bought outdated pieces from storage. Everything was sent back to the new Waterfront plant in East Haven where Swebilius and his crews reworked the machinery to specifications.

The first machine gun came off the line on 19 April 1941, five months after the contract was signed. Newspapers and Time magazine wrote articles acclaiming the feat as a miracle. There is a photo that shows Swebilius by a chrome plated .50 caliber proclaiming it to be the 10,000th off the line seven months ahead of schedule. There had been only one reject up to that point. A total of 228,000 guns with extra parts were produced for the Allies and another 25,000 were also refurbished.

United Defense Model 42

Swebilius was a proven genius in design of firearms, especially machine guns. He designed what was to be the UD 42 prior to World War II. It was designed to replace the venerable but weighty and labor intensive Thompson .45 caliber submachine gun. The new gun was designed to fire 750 rounds per minute and quickly convert from the European 9mm cartridge to the American .45 caliber ACP. It was one of the finest and most innovative firearms designed for World War II.

Applications for patent were submitted October 15, 1940 and four patents were issued to Swebilius for the UD 42. Another patent was issued to his friend, coworker and High Standard vice president, John Owsley, for his innovative back to back style of magazines.

Although designed by Swebilius, High Standard was dedicated to barrel and machine gun production and was unable to produce the new weapons. Marlin won the Netherlands Commission contract and manufactured 15,000 submachine guns for use in Dutch Indonesia. High Standard received a 10% royalty of $7.50 per gun.

Japan invaded Indonesia before the guns were delivered. The United States bought all the guns and transferred them to the Office of Strategic Services for overseas use. All guns were issued except 800 held back by the Dutch. In 1944, many ’42s were airdropped into the European Theater of Operations where they were used with success. They were also used in the Mediterranean and Far East theaters where they were met with favor. Later they were used in China and in Africa.

US Army Ordnance informally tested the UD 42 in August 1940 and found it acceptable. It was resubmitted for formal testing in November, 1941 with suggested modifications. It was found to be reliable, accurate and controllable. At about this time, the Ml Thompson had become available. Ordnance found the UD 42 to have “no requirement.” Development of the .45 caliber version was halted after the production of six prototypes.

In 1948 Marlin acquired exclusive rights to produce the UD 42 with royalty rights to High Standard. The Netherlands and Argentina expressed some interest but sales never materialized. The UD 42 was used through the early ’70s in Southeast Asia and Africa. Some made it back to the US but they are not common. There is rumor of a limited offshore stockpile still in Cosmoline as late as 1998.

Other Swebilius Designed Firearms

.30 Caliber Carbine

Swebilius designed .30 caliber carbines for infantry use. The Ordnance Department tested them in both semi and full automatic versions. The carbines were found to be light, accurate, reliable and easy to maintain. Although they performed well, the Winchester submission was chosen to become the M1 carbine.

M3 Grease Gun Silencers

In early November, 1942, the Maxim Silencer Company (also located in Hartford) offered to make silencers for .45 caliber M3 submachine guns. A booklet entitled Design of Silencer for M3 Cal. .45 SMG was completed in November, 1943. Trials showed that noise was reduced to only a few decibels above the mechanical action of the gun. In May, 1944 High Standard received a contract to produce 1,000 silencers for $12,970. Barrels were to be provided by General Motors Guide Lamp division.

After some delay, the first barrels arrived, but were defective as the threads had burrs and thread tolerances were not as specified. High Standard received a separate contract to remove the burrs. The first silencers were shipped in August, 1944. The silencers were used in Europe, Southeast Asia and the Pacific theaters to good effect. Beyond noise suppression, the silencer also reduced barrel flash and rise making the gun more accurate.

A second $73,440 contract for 4,000 silencers and barrels was placed in December 1944. This time the barrels were produced by High Standard. Shipment was completed by September, 1944. None of the second contract silencers were issued as there were 4,100 still in stock at the end of the war. Some were still in storage at the beginning of the Vietnam war.

High Standard also tested the M3 silencer in 9mm but found it unsatisfactory.

Barrels

High Standard Manufacturing Corporation, 1817 Dixwell Ave. Hamden, Connecticut was the pistol company. In addition to the Model B, Model B-US and USA Model H-D, it also produced barrels for the Model 1919 .30 caliber machine gun, barrels for the model 1911A1 .45 caliber pistol, the 1903, Model 1903A1 .30 caliber rifle with and without sights, the model 1903A3 .30 caliber rifle, Model 1917 .30 caliber rifle barrels and the M2 .50 caliber machine gun.

.45 Caliber Pistol Barrels

High Standard made .45 M1911A1 barrels during WWII under a “Government Free Issue” contract for Remington Rand, Ithaca and US&S as these pistol makers did not make their own barrels.

Production/procurement records show:

Remington and Ithaca used some (a few) Colt barrels in the early production days and some Flannery barrels in 1944 and 1945. If you estimate they made spares before production was halted at war’s end, you can easily argue 1,000,000 to 1,200,000 were made.

Miscellaneous Related Ordnance

High Standard also had contracts for bomb fuse bodies, bomb fuze striker, flash hiders, yoke rod ends, deep hole drills and numerous other small contracts. They continued to produce machine gun barrels and parts until the 1970s.

High Standard Manufacturing Company. Inc, 1337 Dixwell Avenue, Hamden, Connecticut was the machine gun factory. There was also a plant at 100 Waterfront in East Haven, Connecticut.

Both of these companies were paying engineering fees to a parent company called Dixwell Corporation, which was controlled by Swebilius. The officers and directors of all three companies were similar if not the same.

At fiscal year ending November 30, 1945, Swebilius personally owned 127,155 of the 150,000 shares issued (85%) for the pistol company. With the stock owned by his sons, the controlling percentage rises to almost 89%.

Epilogue

At war’s end, Gus Swebilius was second only to Louis B. Mayer as the highest paid executive in the United States. There were charges of war profiteering. The investigation board not only cleared Swebilius, but commended him for saving the United States government millions of dollars in his contracts and the production methods adopted by other companies.

Swebilius health was failing. He died of throat cancer October 18, 1948. After providing for his widow and sons, he left much of his personal fortune to cancer and epilepsy research. His legacy still provides research grants today.

(Personal correspondence from and special thanks to: John Brunner, Bill Jenkins, Charles Petty, John Stimson, and Bob Waldridge.)

| This article first appeared in Small Arms Review V13N2 (November 2009) |