Background

For 18 years the U.S. Army Yuma Proving Grounds (YPG) made special arrangements with a group of forensic firearms examiners from Arizona and California to utilize a tracking Doppler radar system for a wide variety of exterior ballistic projects. This technology is far more than a very sophisticated chronograph. It is capable of tracking small arms projectiles out to several thousand yards. Depending on the operator’s wishes, the data acquired by the system can provide 3-coordinate positional and velocity information for the projectile at millisecond intervals. Moreover, drag and deceleration (negative acceleration) data in both tabular and graphic forms are generated for each shot. All of these combined provide great insight into the exterior ballistic performance and behavior of the projectile at any point in time or space as well as the overall flight of the projectile. Downrange velocity at most any point in time or distance throughout a projectile’s flight is probably the most popular parameter generated from which traditional ballistic coefficient values can be derived. These values can then be used with most contemporary exterior ballistic programs for PCs to carry out computations of interest to the user. The BC values derived from actual test firings can also be compared to published values for the same bullet. Here one is apt to discover the influence of marketing in some manufacturers’ listings.

Additional capabilities of ballistic tracking radar systems include the determination of maximum range for small arms projectiles, the velocity of falling bullets, the velocity loss experienced by ricocheting bullets, bullets that perforate selected materials (e.g., glass, wood, sheet metal, dry wall) and the subsequent exterior ballistic behavior of the departing bullets. The results of many of these tests have been published in scientific journals such as that of the Association of Firearm and Tool Mark Examiners by one of the authors (Haag).

A Useful Example

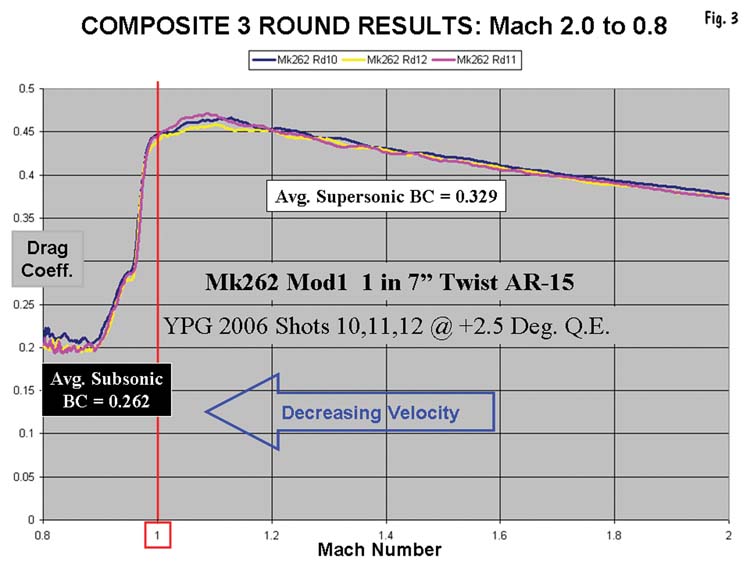

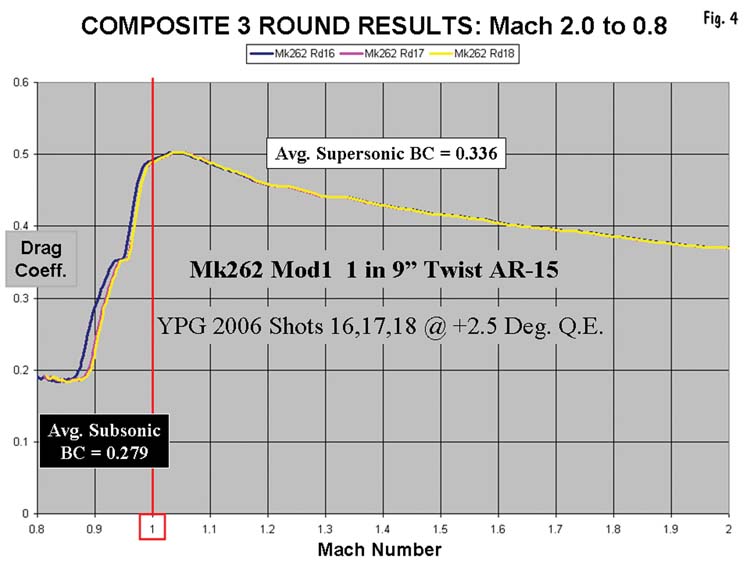

The following description and practical application of ballistic Doppler radar to a relatively new 5.56mm military cartridge, the Mk262 Mod.1 5.56mm cartridge, should be of value in understanding and appreciating the capabilities of this technology. This cartridge is loaded with a 77-gr Sierra JHP-BT MatchKing target bullet. The ammunition fired and tracked out to 1,500 yards at the Yuma Proving Grounds was loaded by Black Hills Ammunition, lot number BLH03F024-001. Figure 1 provides a visual comparison between the traditional 5.56mm service bullets, the Mk262 Mod. 1 bullet and the parent Sierra bullet from which the Mk262 came. The proprietary ball powder loaded in these cartridges produced an average muzzle velocity of 2,885 f/s from a 20-inch AR-15 with a 1 in 7-inch twist and 2,740 f/s from a 16.5-inch AR-15 with a 1 in 9-inch twist. Figure 2 shows the special fixture at the Yuma Proving Grounds for securing rifles at specific departure and azimuth angles. The tracking antenna can be seen in the background. Figure 3 provides a composite plot of 3 shots from a 20-inch, 1 in 7 twist AR-15. Figure 4 shows a composite plot of 3 shots from a 16.5-inch AR-15 with the 1 in 9-inch twist along with other data of interest. This type of plot may not be familiar to many readers consequently some explanation is warranted. It is a plot of the drag coefficient (CD) calculated by the system’s software vs. Mach Number and reads from right to left. Mach 1 represents the speed of sound under the site conditions at the time of the test and has been flagged with a vertical red line. Those readers who wish to gain a greater understanding of drag coefficient are urged to use the Internet for a wealth of information well beyond the scope of this article. (Try RSI-Exterior Ballistic Coefficients) Suffice it here to say that a properly designed, properly manufactured and properly spin-stabilized bullet will display a smooth and regular ‘S’-shaped plot over the supersonic, trans-sonic and sub-sonic regions. There is a specific shape and series of CD values for each projectile design and weight.

The reader should take away several interesting observations from Figure 3 and Figure 4. First of all the 1 in 9 twist barrel was able to spin stabilize this rather long bullet. In fact, based on these very limited tests of 3 shots each, it did a slightly better job of doing so than the 1 in 7 twist barrel. This came as a surprise since Sierra Bullets notes “7 to 8” twist only” on their component box for this bullet. Secondly, the calculated G1 BC values in the supersonic region were quite different than in the subsonic region. This is because the shape of this bullet bears little resemblance to the Standard G1 bullet upon which nearly every contemporary exterior ballistics program is based. This is also the reason why Sierra Bullets provides users of their EB programs with multiple BCs over specific velocity regimes.

The Issue at Hand

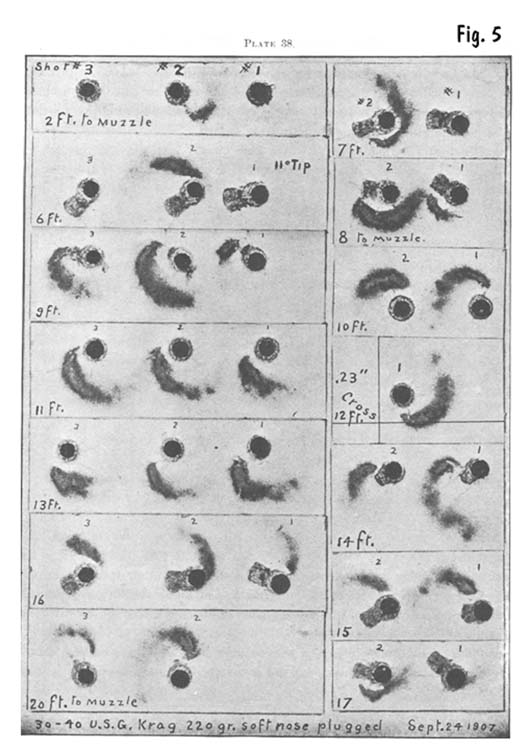

This project evaluated a claim purportedly coming out of Iraq by U.S. troops that M855 bullets become very unstable and inaccurate after sustained, full automatic fire (100 to 200 rounds) when fired from an FN Minimi/M249 5.56mm Squad Automatic Weapon (SAW). The prevailing theory was that the purported instability was a consequence of these bullets acquiring molten cores due to the high temperatures acquired by these bullets when fired through a very hot barrel. No hard evidence existed however as to either of these claims i.e., instability after sustained full-auto fire and/or molten cores being the cause of such instability. On the other hand, F.W. Mann in his classic 1909 book, The Bullet’s Flight from Powder to Target, showed that the lead immediately next to the jacket of lead core jacketed .30-caliber rifle bullets becomes momentarily melted from the transference of frictional heating of the bullet jacket during its journey through the bore. He demonstrated this by drilling a small hole through bullet jackets near the base of 220-gr, .30-caliber jacketed bullets and firing them through multiple cardstock witness panels located at selected distances in front of the test rifle (a .30-40 Krag). Figure 5 reproduced from this book illustrate the results of multiple shots by Dr. Mann. Deposits of vaporous lead can easily be seen at one side of the bullet holes in the witness panels. More recently Haag and Thompson demonstrated what they called the vortex effect for certain thinly jacketed pistol bullets. With these bullets, molten and vaporous lead emerged from slits in these bullets’ jackets and produced spiral patterns at close ranges using a particular brand of ammunition. This was due to the rifling cutting through the jacketing and exposing the lead core to the frictional and thermal effects of firing. The lead at these sites and immediately below the bullet jacket was, in fact emerging in a molten state as proven by an examination of the deposits under a scanning electron microscope. Figure 6 provides two examples of such patterns around bullet holes produced in cardstock at close range by two bullets from a large caliber right twist pistol.

The FN Minimi/M249 5.56mm SAW

The firearm used in this experiment is worthy of some description and opinion by the authors. It is a Belgian manufactured (as opposed to the American or other licensee) FN Minimi, which is the FN firm’s name for what we in America call the M249 Squad Automatic Weapon. Developed over many years from a design attributed to F.N.’s Ernest Vervier, it is a relatively early production model, as was used by American military forces in Operation Desert Storm in Kuwait and Iraq in 1991. It has the fixed position barrel carrying handle, exposed barrel fore end, floating spring loaded feed cover, tubular butt stock, and the 2 position, adjustable gas system of the early American issue model. It weighs 14.5 lbs. (6.5kg) unloaded, overall length is 39.75 inches (101cm.), with a barrel length of 18.43 inches (46.85 cm.). The cyclic rate for this early model was listed as 750 rpm to 1,250 rpm, depending on the gas system position selected and numerous other varying factors. These include lubrication of the action, amount of powder residue/jacket fouling in the gas system, number of rounds in the belt or magazine at a given moment, degree of chamber polish which affects frictional resistance to cartridge case extraction, and most importantly, the individual characteristics of cartridges being used, including bullet weight, powder type and charge, primer variation and case metallurgy. The mounting system/operator firing position used, ambient temperature and other external factors, also contribute to average cyclic rate in an individual situation. So any cyclic rate figure given should be taken as a general guideline and not as a fixed figure, for any full automatic firearm, much like E.P.A. gas mileage estimates on an individual automobile. When researched for this article, the Minimi/M249 was being used by the armed forces of at least 45 different nations.

This particular FN Minimi was purchased from Ohio Ordnance some years ago, reportedly having been sold to Israel originally and Israel having subsequently sold it to Ohio Ordnance, who reconditioned it. The barrel is chambered for the SS109 variant of the 5.56x45mm cartridge, of which the U.S. military designation is M855. The M855 bullet weighs 62 grains and is intended to be stabilized by the barrel’s 1 in 7 inch twist. The older M193 variant of this cartridge, firing the 55 grain bullet, can be fired with this twist, but accuracy is theoretically lessened, as the 55 grain bullet was intended for the 1 in 12 inch twist. But at realistic ranges, that the impact of the bullets can be noted, (which mostly does not exceed distances in excess of 300 meters), the theoretical accuracy differences noted are negligible, particularly when fired from the bipod, or offhand. The open bolt design of the Minimi/M249 SAW together with the mid-barrel point mounting position of the bipod, causes considerable dispersion of bullet impacts, greater than the width and height of a standing man’s body, at more than submachine gun ranges, unless the M249/Minimi is shot from a tight, weighted, or firmly dug in tripod. This matter of relative accuracy depends more on operator skill and the range from the shooter to target engaged, than any other factor. Examining the finely calibrated rear sight on the M249 might lead someone not experienced with this machine gun, to believe that these sights and their calibration selected can make much of a difference in accuracy, at 300 meters or less distance. But experience in firing offhand or from the bipod has shown the rear sight design to be mostly wishful thinking. With the more than adequate sighting radius of the Minimi/M249 standard model, taken with the barrel weight and sight design, one wonders why a trigger/sear system that would have given closed bolt operation on semiautomatic and open bolt operation on full automatic, (like the 70 year old Johnson and German FG42 automatic rifle designs), might not have been featured in this design, (or any design), of squad automatic weapon: especially as the Minimi/M249 seems to be issued as an individual and not a crew served weapon. And the ammunition an individual dismounted soldier can carry is finite. Anyone shooting this class of firearm, who wants to hit a small target at distance, with a minimum of cartridges expended, can understand this question and the need for accurate single shots.

The Minimi/M249 can be fired from either the M16 box magazine (which increases the cyclic rate noticeably), or from an M27 disintegrating link belt that is intended for use from a 200 round box or pouch, as well as from special Beta C magazines designed for this machine gun. Besides the experiment noted in this article, the authors have fired this particular Minimi/M249 over several years, somewhere between 5 to 10 thousand rounds total, with irregular cleaning, lubrication and barrel changes, various commercial and military manufacture ammunition used, of both the M855 and M193 type, including tracer and ball, steel and brass case construction with offhand and prone bipod firing positions used, and usually with large amounts of Arizona desert airborne dust and/or sand present. Having read many complaints about reliability issues on the Internet coming from Iraq and Afghanistan, we can report that this Fabrique Nationale in Herstal, Belgium, Minimi/M249’s reliability has been excellent, with no memorable stoppages or parts breakage in this author’s (Greenberg) experience.

Procedure at the Yuma Proving Grounds

The initial cold bore shots were fired through author Greenberg’s FN Minimi/M249 equipped with a new, chrome-lined barrel at an ambient temperature of approximately 72 degrees F. This FN-manufactured barrel had a twist rate of 1 turn in 7 inches. The lead photo on page 38 shows Idan Greenberg firing the FN Minimi/M249 assisted by David Fisher. Mr. Fisher’s role was to insure that the ammunition belt fed correctly and without any stoppages for the lengthy full-automatic discharges.

The ammunition employed in these tests was U.S. military M855 ammunition manufactured at the Lake City facility in 2000 (lot number LC-00B106-438). The projectiles loaded in these cartridges consist of a 62-gr. FMJ-BT gilding metal jacketed bullets with lead cores and hardened steel penetrators in the tips. This bullet can be seen in Figure 1. Two good radar tracks were obtained and a subsequent inspection of the data files showed that these “cold bore” bullets were well stabilized.

Several LC M855 bullets were also fired through a thin (0.015” thick) white cardstock witness panel to produce ‘normal’ bullet holes for later comparison and chemical testing with a specific chemical reagent for lead known as sodium rhodizonate. This reagent will react with traces of lead around the margin of a bullet hole producing a bright pink color. If molten or vaporous lead were to emanate from the open base of a “hot bullet,” a foggy deposit of vaporous lead would appear around the bullet hole. To look for this and any evidence of bullet instability, a second cardstock witness panel was positioned down range as a ‘target’ for the full automatic bursts.

A disintegrating belt was loaded with 100 rounds of ammunition and fired without stoppages in full-automatic fire. Immediately following this, a magazine with a single round of LC M855 ammunition was inserted in the gun, fired and tracked with the Doppler radar system. Radar tracking and subsequent data was obtained for this hot bore shot.

A second 100-round belt of ammunition was fired through the gun as soon as the radar operator was satisfied that he had acquired and stored the data from the first ‘hot bore’ shot. This required about 30 seconds. After this second full-auto burst of 100 rounds, another single round of LC M855 ammunition discharged and the bullet tracked with the Doppler radar.

The external barrel temperature just forward of the chamber was measured with a Model 42529 Extech infrared sensing device. This indicated an external surface temperature of 580(F within 1-2 minutes after the second 100-round burst.

The perforated cardstock witness panels from these shots (normal, cold bore vs. full-auto bursts) were subsequently examined for any evidence of bullet yaw and then treated with the sodium rhodizonate reagent on site in an effort to detect any corona of separated or molten lead from the cores of these bullets. No evidence of bullet instability or vaporous lead leaking out of the open bases of these bullets was detected with this highly sensitive reagent.

Exterior Ballistic Results

No stoppages occurred during the two, 100-round full auto bursts. A PACT timer showed a cyclic rate of 708 rounds per minute for the first burst and 697 RPM for the second burst. The discharge of the first 100 rounds required 8.386 seconds. The second burst required 8.517 seconds. The highest and lowest shot-to-shot intervals were 0.092 seconds and 0.060 seconds respectively.

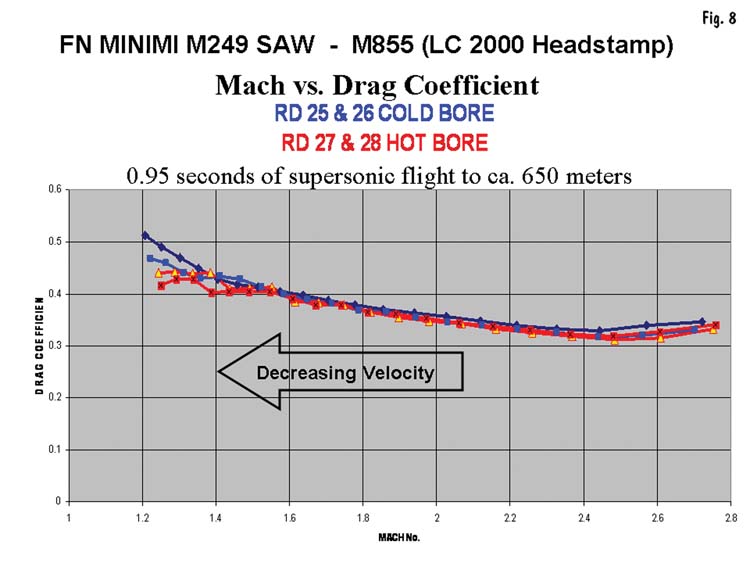

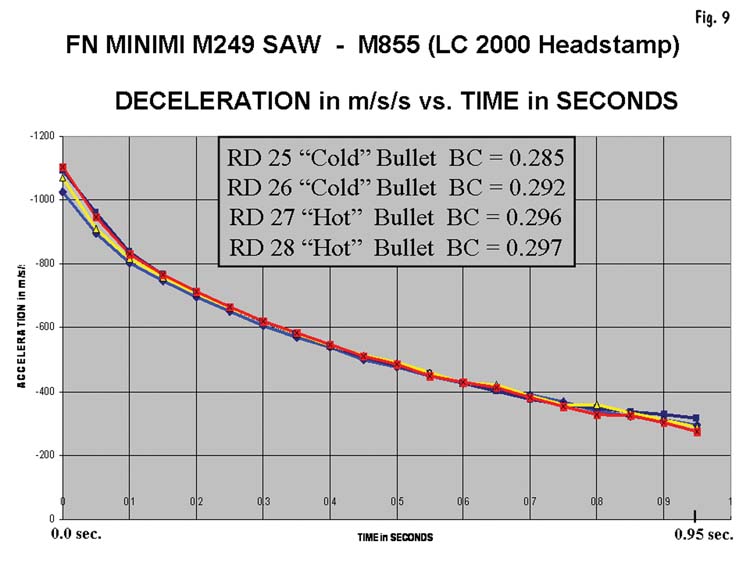

The rate of fire noticeably increased towards the end of the belt as resistance to its passage through the action of the gun due to lessening drag and weight. Good radar tracks (reliable data) were obtained for both ‘hot barrel’ shots. Plots of Drag Coefficient vs. Mach Number for these two shots were compared to the two ambient temperature shots. This graphic is reproduced here as Figure 8. Figure 9 shows a combined plot of Deceleration vs. Time for these four shots. Both of these graphics reveal very little difference in exterior ballistic performance for the two bullets from a cold bore vs. the two bullets from a very hot bore. In fact, the “hot” bullets appeared to perform very slightly better as they approached Mach 1 than the “cold” bullets. This is reflected in the calculated ballistic coefficient values given below.

An inspection of the ‘cold bore’ and ‘hot bore’ data files revealed only a slight difference in muzzle velocities between the cold bore shots (3,038 f/s and 3,058 f/s) and the ‘hot bore’ shots (3,093 f/s and 3,099 f/s).

The effect G1 ballistic coefficients for these bullets were calculated over the distance between 45 meters downrange and 600 meters downrange and are incorporated in Figure 8. The average value for the 4 shots was 0.293. The literature value given for the Speer 62-gr. FMJ-BT (SS109 bullets manufactured by IMI) in the Sierra Infinity-6 program is 0.307. This is not a significant difference. The calculated 300-yard velocity for this bullet launched under standard conditions with a muzzle velocity of 2,800 fps using the published 0.307 BC value yields 1,976 fps. The same calculation with using a BC of 0.293 produces a 300-yard velocity of 1,941 fps and a point of impact 0.32-inches low.

Summary

The notion or suggestion that standard issue lead core military ammunition fired from this 5.56mm squad automatic weapon (SAW) becomes unstable after sustained full-automatic fire was not born out by these tests. No degradation in exterior ballistic performance; and clearly no molten or vaporous lead emerged from the open bases of these bullets after sustained full-automatic fire of 100 to 200 rounds of service ammunition.

References

Mann, F.W., The Bullet’s Flight from Powder to Target (republished by Wolfe Publishing, Prescott, AZ (1980) plate 38 p. 333

Haag, L.C. and E. Thompson, “Comet Tail / Vortex Effect”, AFTE Jour. 41:3 (Summer 2009) pp. 257-267

Lucien C. Haag is a Criminalist/Forensic Firearm Examiner at Forensic Science Services, Inc. in Carefree, AZ

Idan Greenberg is a Firearms Adviser in Phoenix, AZ

| This article first appeared in Small Arms Review V15N4 (January 2012) |