By Christopher R. Bartocci

Laser sighting has come a long way in the firearms industry. They have become stronger, smaller, more accurate and cheaper so they are more affordable to law enforcement and military personnel. The newer generation of laser sights are mostly attached to the trigger guard; whether by the trigger guard, or a laser aiming module attached to an accessory rail, part of the grip pane, or built into the frame of the firearm. Although many are very high quality, the one disadvantage is the fact that all of the firearms require special made holsters for the bulky laser. The external mounting has made many of these designs prone to damage or susceptible to misalignment due to the sight being knocked around, or the firearm being dropped.

There are many advantages of having a laser sight. However, first and foremost is not accuracy: it is the intimidation factor. By having a laser and placing it on the adversary, the adversary may think twice about what he is doing and comply. Everyone leaves safely without a shot ever being fired. Sometimes, the most effective firearm is the one you do not have to shoot. The next major benefit for law enforcement and military personnel is the ability to shoot around shields and to fire accurately from the hip. Under stress and when time is of the essence, quick drawing with a laser sight allows the shooter to keep his eye on the target rather than on the sights of his firearm. As soon as that dot comes on target, he can rapidly engage the target. The next major benefit is actually training. When training new shooters, the use of a laser sight can help a trainer and shooter diagnose problems rapidly. By staggering dummy rounds in the magazine at random, when the shooter comes upon a dummy, the laser will show if he is flinching, pulling or jerking the trigger. Lastly, depending on the particular laser sight, is the accuracy.

In 1989, a Rochester, New York-based laser company came up with a new concept in the application of micro-laser diodes for the firearms industry. LaserMax, Inc. was co-founded by Will Houde-Walter, a laser product developer, and Dr. Susan Houde-Walter, a Professor of Optical Engineering, for the purpose of designing laser handgun sights; but also design and develop industrial lasers as well. The first prototype laser sight became a specially made spring guide that installed inside the pistol. LaserMax, already an industry leader in small circuit board and mini-diode technology, had arrived at their destiny. The power came from batteries stored between the magazine well and the rear of the pistol and a wire went from the battery compartment to the inside of the gun. The firearm chosen for this project was a Glock semiautomatic pistol. The laser was actuated by a button cut into the frame. Will, then CEO of LaserMax, took his design to Gaston Glock to show him the concept. Mr. Glock looked at the cut up gun and asked, “What have you done to my gun?” This comment prompted Will to think there had to be a better way; perhaps to make the unit more compact and, more importantly, a drop-in unit.

The LMS-1000 Series Laser Sight

The design Will had come up with was indeed the answer to Mr.Glock’s concern. LaserMax developed a laser spring guide assembly that would house the laser and batteries into one component. On March 31, 1989, U.S. Patent Number 4,934,086 was granted to William Houde-Walter. The spring guide tube would contain a rear cap (synthetic), which is actuated by the on/off switch, batteries, circuit board, laser diode, lens and recoil spring. The switch would become the slide lock lever on the Glock pistol. By increasing the length of the slide lock and using a new spring; the switch worked in a three position fashion. Ambidextrous activation turns the laser on and the center position rests the unit in the off position. The original offering was 670nm red laser dot. Not to long after was the “hi-bright” 635nm orange laser.

Installation could be accomplished by the end user. The slide stop and spring are removed and replaced with the LaserMax replicas. The batteries are inserted into the back of the laser spring guide assembly, cap installed and the recoil spring is slid over the tube and the painted red end of the spring is lined up with the red dot painted on the cap. The laser spring guide is inserted into the frame and the gun is reassembled. Unless you are looking at the business end of the firearm, you would not know the laser was in the pistol. The laser itself was also unique in the fact that the dot pulsated and was not on continuously. This was done for two reasons. First, making the laser pulsate added speed to target and enhanced visibility. This is not a new theory founded by LaserMax. Active lights have played a significant part in the attractiveness of emergency vehicles and dangerous intersections for years. Secondly, LaserMax found the battery life was significantly enhanced.

The sight is zeroed at the factory and no adjustments are needed on the laser sight. LaserMax has sighting fixtures that accurately perform zero right out of the box to ± 2 inches at 20 yards. This will guarantee a center mass hit on a human target at such distance. The LMS-1911 laser sights are designed to be adjustable for the users. The LaserMax LMS-1000 series laser sight is closer in line with the barrel than any other laser sight on the market. The average M1911 shooter would not tolerate anything more than pin-point precision.

The batteries used in all of the LaserMax sights are various hearing aid/watch batteries. LaserMax shrink wraps the appropriate amount of batteries together for easy installation, but the batteries can be stacked into the compartment as well.

A pistol equipped with a LMS-1000 series laser sight would require no special holster. Engineering tests have been conducted with numerous types of duty and concealed carry holsters. The handguns were placed in the holsters and dropped on both sides to insure the laser switch would not be actuated causing an unwanted red dot on the ground as well as dead batteries.

The laser sight tested for this article was the LMS-1441 installed in a Beretta 92FS Brigadier pistol. The laser came in a kit containing the laser sight, battery pack, laser sight cap, disassembly latch and release button/spring. This particular laser sight used the standard factory recoil spring.

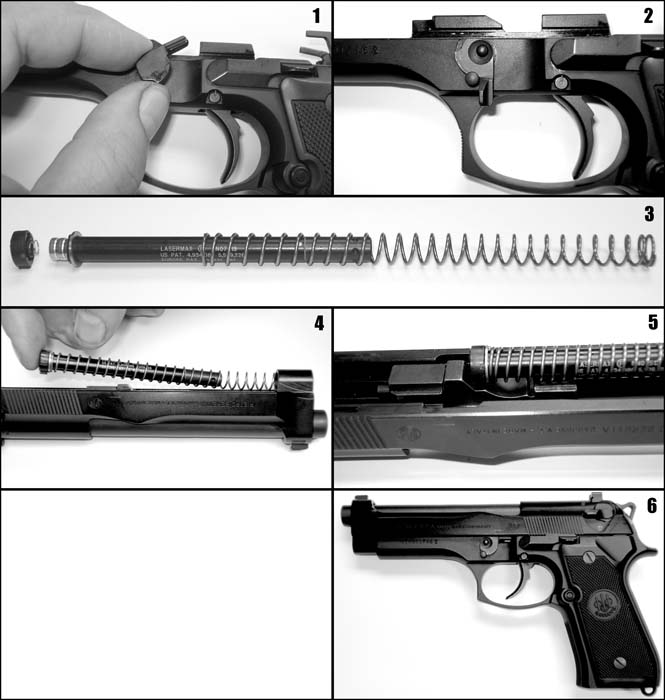

Installation was simple. The battery pack was inserted into the laser spring guide and the cap installed. The pistol was field stripped by depressing the disassembly latch release button and rotating the latch 1/4 turn. The slide was then slid off the frame. The recoil spring and guide were removed. The spring was removed from the spring guide and slid over the laser spring guide. To install the switch/disassembly latch, depress the disassembly latch release button and lift upward on the latch until it stops and then pull it out from the right side of the frame. Now the button is pulled from the left side of the frame. The LaserMax button and spring are installed in the left side of the frame. The only difference between the two is the LaserMax button has a cant to the front to allow easier access to the switch for left handed shooters. Now the button is pushed all the way in and the LaserMax disassembly latch is installed into the right side of the frame and placed with the latch in the 6 o’clock position. The spring and laser spring guide are installed the same way as the standard Beretta components.

To actuate the laser, the switch is pressed in from either the right or left side of the pistol. The center is the off position. The location of the switch also provides safety for the shooter. As the pistol is drawn from the holster, the shooter’s trigger finger will automatically be on the switch keeping the finger off the trigger until the shooter is actually ready to fire.

Live fire showed with Winchester M882 Ball ammunition, the pistol was able to shoot nearly to the exact point of aim at 15 yards with the group measuring approximately 2 inches. More than 300 rounds were fired without any change in impact of the laser. LaserMax has performed life testing on this laser sight to exceed 10,000 rounds, which is more than the military specification of the Beretta M9 service pistol, which is 6,000 rounds.

LaserMax manufactured internal laser sights for all Glock models, Beretta 92/96 Series, SIG P220 series, Smith & Wesson Sigma series, various M1911 models as well as the Springfield XD pistols. All are drop in by the user and require no zeroing with the only exception being the M1911 series.

The Uni-Max Laser Sight

For those shooters who do not have any of the mentioned firearms, there is another option LaserMax offers. If the pistol sports a Mil-Std-1913 accessory rail, LaserMax just released their Uni-Max laser sight. This is a very small laser in a black polymer case that is powered by a battery (357 Silver Oxide). This laser attaches directly to the rail and has a toggle switch on the rear of the sight and can be actuated from the left or right. The center is off. The Uni-Max can also be equipped with a pressure pad switch for mounting the Uni-Max on the rail system of a rifle or a carbine. LaserMax has done extensive testing of the Uni-Max on the M4 carbine and a sample sight was tested on one of the author’s Colt LE6920 Law Enforcement Carbines. It was mounted to an A.R.M., Inc. SIR (Selective Integrated Rail) system. The pressure pad was mounted by Velcro to a Grip Pod vertical pistol grip/bipod combination. The Uni-max is sighted in by the user with a small Allen wrench. Due to the vast number of firearms the Uni-Max could be used on, it would be impossible to zero it at the factory. The Uni-Max has an accessory Mil-Std-1913 rail on it as well so the shooter could mount a flashlight to the pistol as well.

In late 2007, LaserMax introduced the first 532nm green laser. The green laser is significantly brighter under any condition than the red or orange laser. The human eye is more sensitive to green than any other color.

The LMS-JMX

Even though the revolver is seen less popular in the market, the small frame .38 Special revolvers are still a personal defense weapon of choice. For the occasional shooter, or one who only keeps the firearm for an emergency, the revolver’s simplicity is a much better choice. Semiautomatic pistols require more range time and training to be proficient and clear possible malfunctions. LaserMax offers the same sighting technology to revolver shooters as well. The LMS-JMXH and NH fit to the Smith & Wesson round butt J-frame revolvers. The grips are replaced with a recoil absorbing Santoprene grip. The laser itself sits in line with the top of the bore on the right-hand side of the revolver. The laser is zeroed in by the shooter due to the various models of J-frame revolvers. The laser is actuated by pressing in on either of the touch buttons located on the grip. Due to the way the sight is mounted, the revolver can use a standard holster with no special accommodations needed.

Laser sighting systems have come a long way. The technology has become more compact and so much more efficient. Now, the laser sight has shrunk out of sight. The LMS-1000 series of sights is designed for law enforcement and military personnel and designed with durability and compactness in mind. The sights have been in use with military, police and SWAT teams all over the world. LaserMax has also made infrared sights for use with night vision for special use. Their applications are endless.

Installing LMS-1401

| This article first appeared in Small Arms Review V12N1 (October 2008) |