By Paolo Ortenzi & Gabriele Tansella (A.A.I.)

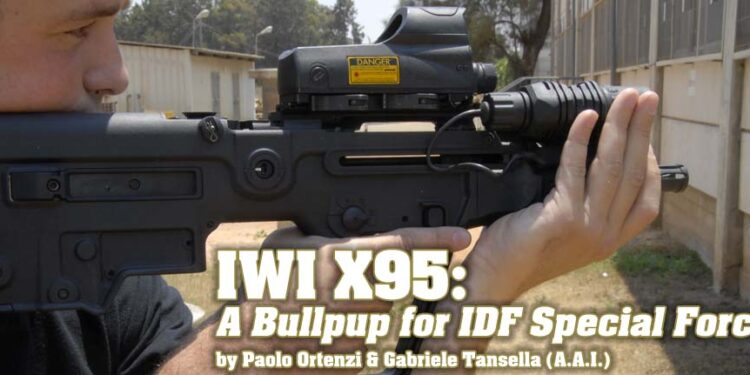

A direct derivation from the TAR-21 Tavor bullpup rifle, adopted in 2003 by the Israel Defence Forces, we are going to introduce to SAR readers the version designed for the Sayeret (Special Forces) units, a shorter and more modular rifle that, in case of need, can be converted into an SMG.

The TAR-21 project in Ramat Hasharon was started in 1995 when the Israeli company name was still IMI (Israel Military Industries). In recent times, IMI ownership has been handed over from the State of Israel to a private company, the Samy Katsav Group (the same holding that includes also Meprolight, Selectron International Optronics and Global Shields) and changed its name to Israel Weapon Industries or IWI.

It was the intention of IWI that the new rifle design would have to satisfy the needs of the Israeli infantryman due to the most recent battlefield requirements. A large majority of the combat actions of the IDF happened in urban areas, where soldiers must fight in harsh CQB conditions: apartments, narrow roads, restricted spaces typical of small villages where the terrorist enemy have their site and hold their positions.

Another tactical consideration comes from the fact that IDF is a highly mechanized army. Even if the Israeli soldiers, during their GIBUSH (the selection for the combat units), are trained to cover long distances marching by feet, it is an operative reality that most of their movements on the battlefield are done travelling by APCs, IFVs or by helicopters. This requires them to have the equipment, including the assault rifle, as compact as possible. IDF learned this lesson when they adopted the FN FAL, in the 1960s. Aside from reliability problems they had with this rifle, the FN FAL was a very long rifle and very uncomfortable to carry inside an armoured vehicle or to be handled inside a helicopter during an airborne infiltration behind enemy lines.

Currently IDF is armed with a very small quantity of IMI Glilon (the Galil short version), and mainly with M16A1s, refitted with round handguards and different sling system, and Colt M16A1 Carbines, with old style polymer collapsible stocks, both with fixed carrying handle on the upper receiver. Only in recent times has the series 900 Colt M4A1 carbines been issued. According to battlefield reports, even the M4A1 has been judged by the Israelis as too long to fit the need of the Israel mechanized infantry.

The solution chosen by IWI engineers was to design a bullpup rifle; to have a short rifle without limiting the ballistic of the 5.56mm cartridge because of very short barrels. The result was the TAR-21 rifle (the acronym stands for Tavor Assault Rifle – 21st Century), officially adopted in 2003 by the IDF.

Due to the high number of Elite and Recon units in the IDF, IWI was requested by TSAHA’L to modify the TAR-21 design for its own special forces. The Micro Tavor was born, and after some intensive field testing, the design was refined and modified into the last version, currently delivered to the Israeli army: the IWI X95 Special Forces carbine.

The X95 is really compact: only 590 mm long with its 13 inch barrel. To make a fast comparison, an M4A1 with fully extended stock and a 14.5 inch barrel is 880 mm long.

The rifle is built around a backbone made of a “U” shaped steel rail, where its mechanics move and the polymer receiver is fixed. It’s hard to say that the X95 is beautiful, but its appearance, in the gray-black polymer livery, is very aggressive and martial and less “toy” looking than the previous green polymer. The change reflects the fact that the polymer chosen for building the external body of the carbine has been changed from the previous models.

The old greenish polymer was designed to be rigid and impact resistant as much as possible. With the frequent use during field testing, the main problem was that even if it was able to absorb hard shocks, the polymer was not able to last: after a while cracks in the body started to appear, compromising structural integrity of the weapon. The solution was to adopt another polymer, the current black gray looking one that was “softer” but did not show cracks after intensive use, being also more resistant to the strong UV middle-east sun radiation.

The X95 operates with two different mechanics: the 5.56×45 carbine with gas recovery system and 9×19 caliber blowback operated submachine gun, both using the same body.

The 5.56 carbine uses a long stroke gas recovery mechanism. During the shoot sequence, the bullet in the barrel uncovers a hole, the gas port, which blows high pressure gases into a tube where there is a gas piston that starts to move rearward due the effects of the gases. The gas piston is permanently locked with the prismatic bolt carrier, that starts, in its turn, to move rearward too, and so doing, due to a cam on the bolt carrier body, causes the bolt head to rotate and unlock the breech only when gas pressures are on safe values. The group bolt-bolt carrier keeps travelling rearward for about 70 mm, compressing the recoil spring and ejecting the spent brass. When the kinetic force of the shot ends, the recoil spring pushes forward the bolt-bolt carrier group, feeding a fresh cartridge from the magazine, chambering it and locking again the bolt in the breech locking lugs.

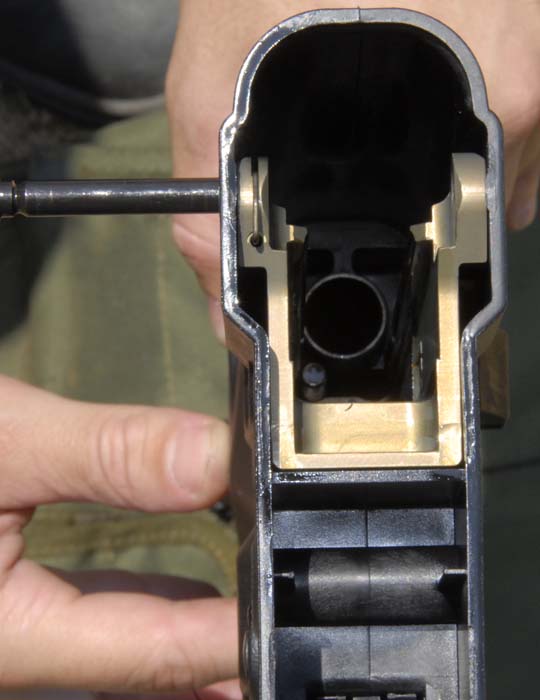

When shooting the 9×19 SMG version instead, it is only the prismatic bolt weight and the force of the recoil springs that define the bolt opening delay to ensure a safe opening of the breech, the rest of the operation sequence being identical to the 5.56 version.

The X95 barrel is produced using a cold hammer forging process, with 6 right-hand grooves, 1:7 twist. This is quite curious since the IDF uses both M193 and M855 ammunitions. The explanation is due to the IDF doctrine, since they do not want to renounce to the better terminal effects given by the 55 grs ball, and reserve the heavier 62 grs ball ammunition only for squad sharpshooters. On the muzzle end of the barrel is mounted a flashider with 5 radial slots located only in the upper portion of it, while the lower part is closed, being this solution identical to the one adopted on the American M16A2 assault rifle.

The gas port is located 187 mm from the end of the barrel extension. On the breech is mounted the barrel extension, with the locking lugs for the bolt. The bolt face presents a singular asymmetric locking lug configuration: the three locking lugs, in fact, are located at 12 o’clock, 4 o’clock and 7 o’clock. This last one, in its turn, is split into two smaller ones. The bolt face is hollow, to create a belt that completely surrounds the cartridge rim ensuring a level of safety in case of gas leak from a broken primer or shell rupture.

On the bolt face there are also a big extractor claw that engages the cartridge rim for almost one quarter of the diameter, and a spring loaded ejector pin. To reverse the spent case ejection, the bolt head must be replaced – an operation that must be performed by the unit armourer.

The bolt carrier is a prismatic rectangular shaped block of steel CNC machined to accept the cam and the bolt head. Protruding from the upper front of the bolt carrier body there is the integral operating rod, ending with the stainless steel terminal of the self adjusting gas valve. Internally the operating rod is hollow to accommodate the recoil spring and the recoil spring rod. The bolt, bolt carrier, recoil spring and spring rod are permanently joined and do not need to be separated during field maintenance. The bolt carrier side walls are straight, sealing the ejection port on the polymer body, avoiding the need of a ejection port lid to keep dust and debris out of the action.

The X95 body is realized in a black-dark gray highly UV and impact resistant polymer plastic. While the rear portion of the body is identical to the standard TAR-21 rifles, the front and middle portion differ greatly for their shapes and commands collocation.

The front handguard has a round section, with ribs on the lower part to give the shooter a better grip. The front and upper part has ventilation holes to allow air to circulate and cool the barrel. At the upper tip of the front handguard there are the backup front sights, realized in polymer and adjustable only for windage. After the backup front sights there is a short Picatinny rail to allow accessories to be mounted. Standard configurations foresee for X95s a tactical lamp, with its PTT button strapped with Velcro on the front handguard.

In the middle portion of the X95 body there is the charging handle. This item is not reciprocating with the bolt movement (on the TAR-21, the charging handle is located in the upper portion of the front handguard) and can be reversed on the opposite side at the shooter’s choice.

Just behind the slot where the charging handle travels, there is a round hole showing a slot to operate a latch. A unit armourer, with a simple tool, can disengage the latch and remove a damaged barrel in minutes.

On the upper part there is another portion of Picatinny rail where the primary sight system is locked. The X95 is normally delivered with the Mepro MOR reflex sight that allows having a red dot sight and a visible/IR laser target pointer (the equivalent of a M68 CQB sight and of the AN/PEQ2) in one compact unit. Lasers can be activated by another PTT button, with its cable placed at operator convenience and strapped to the weapon with another Velcro ribbon.

At the rear end of the main Picatinny rail there are the rear flip up backup sights, integral to the polymer body and built in the same material. Those sights are battle zeroed at 300 meters from the factory and are intended to be used only in case of failure of the primary optronic sighting system.

Behind the backup sights there is a polymer proprietary mount, designed to accept several accessories: the Meprolight MX3, a 3x magnifying riflescope to extend the range of shooting of an infantryman, the Mepro GLS, the Tritium reflex sight for the 40mm grenade launcher (not used on the X95 but on the GTAR-21 rifle), and the Mepro Minimon-I, a II Gen monocular light intensification night vision device compatible with the daylight reflex sight.

IDF prefers to use II Gen NVD, instead of III Gen, because their battlefields are more often urban areas, where there is some degree of artificial illumination, than open rural areas, where night vision must rely only on stellar light.

The trigger guard is very wide, protecting the hand of the operator and allowing him to use it to distribute the weight of the weapon in a more comfortable way than traditional assault rifles. The weight and mass balance of the X95, together with the compact size and central position of the pistol grip, allows an operator to shoot even in full auto the weapon holding it with only one hand, as in the case of shooting around a corner without exposing the rest of the body or the head to enemy fire. The trigger guard can be replaced, on request, with a more traditional one, more suited for operators wearing scuba gloves, such as Shayetet 13 IDF Navy commando units.

Just above the trigger, reachable by the shooter’s index finger, is the ambidextrous magazine release button. The location of this button demands a long rod to transmit the movement to the mag catch, since the magazine well in the bullpup configuration is in the rear portion of the stock and not immediately near to the release button as in traditional rifles.

Immediately to the rear of the trigger guard, easily operated by the shooter’s thumb, is the ambidextrous safety/fire selector with three positions: “S” for safety, “R” for semiautomatic fire (it stands for “Repetition” taken from the FN FAL British nomenclature) and “A” for full auto.

In the rear part of the body, in the middle of the stock at the height of the cheekpiece, there are two wide ejection ports, one for each side. For a right handed shooter, for example, the right ejection port will be left open, and a brass deflector will be mounted with one hex head screw. On the other side, the ejection port will be closed with a plastic lid fixed also with another hex head screw. Set up of ejection ports is done by the unit armourer on the field.

At the bottom of the stock is the magazine well and, behind it, a big hidden button to operate the hold open: when a fresh magazine is inserted, the shooter can press the button with the thumb of the same hand and the bolt will be released, closing the rifle action and chambering a unfired cartridge.

The buttstock is covered with a rubber pad, to help the shooter to keep the rifle on the shoulder and to absorb the recoil.

he trigger group, with the mechanics similar to the AK47, of course is not located in proximity of the trigger, but behind it, in the gap between the pistol grip and the magazine well. IWI has designed it as a whole modular unit to make maintenance easy by both the shooter and the unit armourer. Replacing the trigger group is easy and takes only few seconds: just push out the two big pins before the magazine well and tilt the trigger group module until it is possible to remove it.

All the X95s, and the TAR-21s rifles, are designed to keep essential maintenance as fast and simple as possible, keeping the logistic at field unit level. Only in a few malfunction cases will the rifle be sent to a superior level of maintenance.

The X95 magazines are the usual 30-round M16 magazines, STANAG 4179. This has been done to maintain compatibility with the existing logistic chain. Changing magazines while in battle, for soldiers used to the M16, could be a little bit awkward and slower, but this is a common problem for all the bullpup configuration rifles and can be improved only with training.

Since the TAR-21 rifles have been started to be deployed in IDF combat units, recruits are no longer trained with the M16s, but directly with the new rifles, to avoid problem with manipulation under the stressful conditions of the battlefield, when only muscular memory of movements repeated hundreds of times when performing training drills will drive the soldier to make the right thing in the right moment.

Field stripping the X95 is really easy. After magazine removal and the safety checks to ensure that the carbine is clear with no round chambered, just put the rifle with the muzzle down and have the rubber buttstock in front of your eyes. Push the upper pin at the end of the stock out and open the rubber buttstock like a lid. The buttstock cavity will now be accessible. With two fingers pick the polymer pad, where the recoil spring and the recoil spring rod are attached, and pull it out. Done.

Basically, the X95, and all the TAR-21 rifles and carbines, after field stripping are divided into only two subassemblies: the rifle and the bolt group. That’s all the soldier is requested to deal with. No more pins or small parts that can be lost and make the weapon inoperable.

The X95 can be produced also as a 9×19 caliber SMG. This is the case, for example, of the X95 silenced version, with integral silencer that does not need subsonic ammunitions but uses the ordinary 9 Parabellum ammunition. But in case the mission profile needs it, the 5.56 carbine can be converted into a blowback SMG that shoots from closed bolt position. The kit includes the barrel, the bolt, an insert that will fit the X95 standard M16 magazine well and, of course, 32-round Uzi magazines for the 9mm ammunitions.

The 9mm Parabellum barrel has no gas port and is the same length but has a different rifling twist: 1:10” 4 RH grooves, specific for the 9mm heavier bullets.

The bolt group has no rotating bolt. The bolt, with its extractor and ejector, is integral to the bolt carrier body and machined into it.

The magazine well for the Uzi magazine is a polymer-metallic insert that has the same external dimensions of the 5.56 magazine. It’s a drop-in item that will lock to the normal magazine catch. To operate the 9mm magazine release the operators will use the same magazine release button used for the 5.56 magazines.

The purpose of the 9mm conversion is not only to use a different cartridge when the mission profile requires it, but also to use less expensive ammunitions for training purposes maintaining the same ergonomics.

The X95, in the IWI and Israel Defence Forces, is the next generation of Special Forces assault rifle that combines its compact size and light weight keeping the same ballistics of much longer military selective fire carbines.

It has been designed and developed with the close collaboration of IDF Special Forces, but it can offer a good use potential for all those military/police forces that need for some reason a flexible, modular and compact carbine that can be switched into a pistol caliber SMG.

Battlefield reports, during IDF “Cast Lead” operation in late 2008, have been quite promising, showing that the X95 and the TAR-21 weapon family have a very good reliability record and can stand the ruggedness of real combat.

IWI X95 Specifications

Model: X95

Manufacturer: Israel Weapon Industries (IWI)

Type: Bullpup selective fire carbine (5.56mm) or SMG (9mm)

Rate of fire: 700-1,000 rpm (5.56 version); 750-1,200 rpm (9mm version)

Caliber: 5.56 x 45 or 9 x 19

Action:

Rotating bolt, gas operated by long stroke piston (5.56 version)

or blowback (9mm version)

Barrel: Chrome lined, 6 RH 1:7 twist

(5.56 version); 4 RH 1:10 twist

(9mm version); length: 330 mm for both versions.

Magazine: STANAG 4179 30-round magazine (5.56 version); 32-round Uzi magazine (9mm version)

FCG: Internal hammer, single action, selective fire (safety, semiauto, full auto positions); closed bolt design for both versions.

Sights: Primary sights: reflex optronic sights on Picatinny mounts; backup sights: fixed front polymer sights, rear flip up polymer sights.

Materials: Body: Reinforced, UV and impact resistant injection molded technopolymer; internal chassis, barrel/bolt/carrier: forged steel CNC machined.

Overall Length: 590 mm

Weight: 2,980 grams (5.56 version); 2,900 grams (9mm version); both without magazines.

| This article first appeared in Small Arms Review V16N3 (September 2012) |