by J.M. Ramos

Fourteen years ago, I attended the Columbus gun show in Ohio, touted as the Mecca of military gun buffs and enthusiasts in North America. The early 1970s up to the late 1980s can be considered the decades of exotic guns in America. The weapon covered in this article is a rare find, probably the only one in existence. From the hundreds of very interesting weaponry I have seen at the show, this particular piece really caught my curiosity and interest. I convinced the owner to permit me to conduct a test and evaluation on the piece. I bought 500 rounds of hot CCI Stinger ammo in anticipation of the live-fire evaluation.

When we arrived at the test site, the owner already had a table set up for photography as well as targets at the side of an old barn. After I finished taking exterior photos of the gun, the owner removed the top cover of the gun to show me the internal mechanism. This is where my excitement begun. I have examined and tested many exotic rimfire weapons in the past 25 years but this little bullpup machinegun really caught my attention. Let’s take a close look at what makes this rimfire contender a cut above the rest.

FUTURISTIC BULLPUP CONFIGURATION

This radical .22 was made by Armi Jager, the Italian gunmaker famous for its rimfire look-alikes most notably it’s AR-15 and AK-47 clones. The AR-15 look-alikes (AP-74) are imported into the USA by EMF Company, while the AK-22 (AP-80) and Galil-22 (AP-84) were imported by Mitchell Arms. Both companies were based in Southern California. Mitchell Arms has since gone out of business in the mid 90’s while EMF is still in operation. The Jager rimfire AKs are also available in calibre .22 Magnum boasting a 15-shot capacity. The model 85 bullpup is the last look-alike produced by Jager introduced in 1985. When I first saw the gun at the show, I thought it was just an ordinary AP-85 having seen samples in the stores prior to the Columbus show. The Bullpup .22 is what really caught my attention among the many fabulous items Bill had on display on his table. After noticing what appears to be a three position fire selector above the pistol grip, something different from what I saw on the regular semi-auto variant before. This prototype gun will be appreciated by those who share my enthusiasm that rimfire class battle weapons with selective fire capability are the ultimate all purpose close-quarter combat arm. It can deliver as many projectiles as a 12-gauge shotgun with its 1,500 rpm cyclic rate. In addition, its easy-to-control, extremely light and portable and can be effectively employed by users ranging from 7 to 70 years old with a minimum of training and shooting experience. Above all, ammunition is cheap and readily available everywhere with dozens of brands and power levels to choose from.

There is no question that bullpup type weapons are the wave of the future. The Jager AP-85 shares the same basic characteristics found on these futuristic full-bore military counterparts. It’s compact, perfectly balanced and easy to deploy in both confined and open spaces. As a close-quarter battle gun, the rimfire bullpup has a few advantages over larger caliber versions. The exterior configuration of the AP-85 is reminiscent of the FAMAS assault rifle. There is a .22 rimfire French-made version of the military-issue caliber 5.56x45mm FAMAS called the F-11. This clone is made by Manufacture D’Armes Des Pyrenees. The F-11 was imported into the US by Beeman Precision Arms of San Rafael, California. The cost of this gun was double that of the Jager version. The outer shell of the F-11 is mainly plastic just like its military brother, while the Jager AP-85 is a combination of cast alloy for the actual receiver, enclosed by a stamped sheet metal pressing to form its bullpup configuration. A wooden buttstock is mounted at the rear of the gun secured by two long cross bolt screws and doubled as connectors for the rear sling attachment. The matching wooden pistol grip and foregrip are the same as those used in the AK-22 version.

The sighting system is definitely borrowed from the FAMAS design. It is in the form of a long plane that rides over the top of the gun. It doubles as a carrying handle. Both rear and front sights are mounted inside the sighting plane’s channel. The rear sight is a flip-up-type and can be set from 50 to 100 meters. It is windage adjustable. The front sight is post type and is elevation adjustable. A combination tool to adjust both sights is included in the package. The gun comes complete with a scope base. It locks over the sighting channel tightened into position by a large screw that connects through a hole underneath the channel. The scope mount is machined from solid steel and has a built-in groove allowing the shooter to be able to use the regular iron sights without removing the mount itself. To complement its military styling, the AP-85 comes complete with an attractive flash suppressor. As we clearly see at this point, the Jager gun is really a Hybrid between the AK and FAMAS configuration combining the use of steel and wood rather than all-plastic exterior. It’s a nice blend and solidly built throughout.

THE TRIGGER LOCKWORK

The original AP-85 fired semiautomatic-only utilizing a pivoting hammer design; the same system employed basically in the earlier AR-15, AK-22 and Galil 22 look-alikes with small variations to fit each model’s external configurations. Wood or plastic furniture patterns also differ slightly on these models following closely to the original battle weapon they emulate. Internally, the full-auto prototype is completely different from the semiautomatic-only model. The former fires from the open-bolt position utilizing a fixed firing pin. The cocking handle is a non-reciprocating type like that of the Uzi SMG. It’s an excellent feature that eliminates distraction while shooting the gun. Undoubtedly, some will question the advantage of the open-bolt system employed in this gun versus a close-bolt one for accurate shooting. Open-bolt SMGs have been criticized for the heavy slamming action of the bolt, which affects accurate aimed fire in semiautomatic fire. Large-caliber SMGs that operate on the blowback principle require massive heavy bolts to overcome the resistance generated by the power of the cartridge when fired. Rimfire guns have lighter recoil springs, smaller bolts and very short recoil. As a consequence, there is little movement generated by the counter-recoil stroke. In addition, .22-rimfire open-bolt SMGs minimize the chance of “cook-offs,” as the chamber cools faster between shooting intervals. Rimfire shells are much thinner than their center-fire counterparts and definitely more susceptible to blowing itself up when loaded to a very hot chamber.

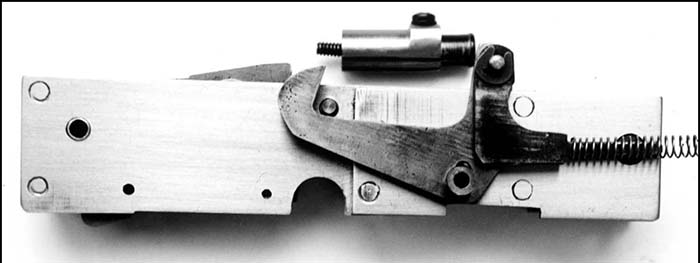

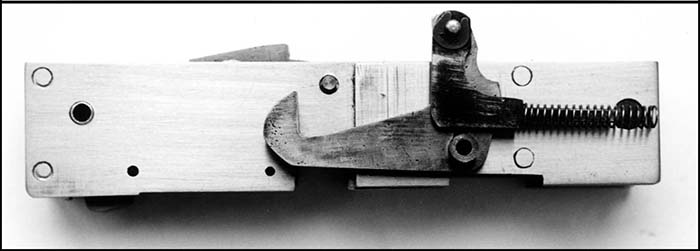

The prototype gun employed a modular trigger arrangement. The module contained the complete trigger mechanism minus the actual trigger, which is mounted at the front of the gun. The trigger bar is in the form of a long rod mounted at the right side of the internal alloy receiver. It connects the trigger to the trip arm inside the module. Pre-assembled in the module are the massive sear, the trip arm that contained the tripper and disconnector assembly. The recoil spring assembly is captive with a built-in buffer system in the form of a large coil spring added at the rear.

CYCLIC RATE RETARDER

Among the many interesting features of the gun is its cyclic rate retarder. Rimfire machineguns normally fire with an average cyclic rate of 1,500 rpm or higher. The early Spanish Broomhandle machine pistols, Czech Skorpion and Star 1911 machine pistols as well as various submachine guns in World War II were equipped with cyclic rate retarders to slow down the rate of fire primarily to conserve ammo and allow better control of the weapon in full auto. Retarders fitted to these weapons were usually complicated and/or fragile. Modern submachine guns and assault rifles incorporate burst control devices instead of a retarder mechanism to get the same effect.

While this is not the first time I have examined such a device employed in a full-auto gun, the retarder in this bullpup is no doubt the simplest I have ever seen. The arrangement is so clever, yet so simple and workable. The mechanism consisted of a large hook mounted at the left side of the sear. It pivots along with the trip arm. A light spring is mounted at the rear of the module to keep the hook down when not activated. The rear of the bolt has a thick plate mounted unto it. On the left side of the plate was a large plunger powered by a strong spring. As the bolt nears the end of the recoil, the plunger head will butt against the rear bent of the hook forcing the part to rotate rearward which in turn causes the hook to pivot upward locking up against the underside shoulder of the bolt rear plate. As the plunger’s powerful spring compresses, the pressure increases and evenly distributed against the bolt to the front and to the vertical bent of the hook to the rear. This action delays the forward recoil of the bolt until it is finally overcome with the help of the recoil spring also. Only a small Allen wrench is required to remove the large captive plunger at the rear of the bolt that activates the retarder hook. It takes just over a minute to remove this component. Since the hook is always kept on its downward position by the its own return spring, it remains inactive during battery until the large plunger that activates it is connected to the bolt. This is an excellent feature that gives the operator the option to select the cyclic rate required for any given circumstances.

THE FIRE SELECTOR

The fire selector is mounted on the left side of the gun just above the pistol grip. It has three-position indexing. The middle (vertical) position is SAFE – blocking the movement of the trigger. With lever pointing to the rear it delivers SEMIAUTOMATIC. In this mode, the trigger pull is restricted only halfway – just enough for the sear to release the bolt forward. The disconnector head remains level with the rear underside of the bolt allowing it to push the disconnector head rearward as the bolt reaches the end of recoil causing the disconnection between the sear and tripper hook. To fire the next round, the trigger must be released to allow sear and trip hook re-engagement. On full forward position, the gun fires FULL-AUTO. In this sequence, the deep notch of the selector pivot pin allows longer pull, that in turn causes the trip hook to pull the sear further downward. With it, the disconnector head (top part of the tripper) also move down deeper away from bolt reach precluding the usual disengagement between the sear and the tripper hook resulting in full-auto fire. The fire selector can be made ambidextrous.

LIVE FIRE TEST

Firing a rimfire full-auto is a pure delight. These types of guns are truly unique when compared to their full-bore counterparts. The gun balanced so perfectly that aligning its sights came naturally. I also liked its very compact configuration and styling. The quality of workmanship is superb. There are no shortcuts in the making of this prototype inside and out.

Targets were set up at 25 yards. Thirty- and 15-round magazines were used alternately during the test using only CCI Stingers. I wanted to test the durability of the gun. Many guns I have tested, suffered receiver cracks and broke small parts within just a few hundred rounds. The gun was fired first without the cyclic rate retarder. On semiautomatic, it printed a decent group of 2-3 inches with 30 rounds as fast as I could manipulate the trigger. I set the selector to full-auto and emptied the 30-round magazine. Group dispersion was reduced to less than 2 inches, with bullets tearing a nice hole in the middle of the target. The gun was noticeably loud, but with very little recoil or muzzle climb in this long burst. With a fully loaded 30-round magazine, I fired the gun and quickly released the pull to get the shortest burst possible without the retarder in place. I could only manage 3-4 pauses on the trigger and the 30-shot magazine was empty. No malfunctions occurred with 230 rounds fired so far.

The cyclic rate retarder was re-installed for comparison purposes. Starting again in the semiautomatic mode, I now felt more familiar with the gun and my groups improved considerably. After firing 60 rounds in this mode, it was time to check the effectiveness of the retarder. With the selector set at full-auto and using the same technique of quick trigger pull release to attain a short burst, I managed to get off 2 to 3 rounds with each pull of the trigger. I was shooting at two targets, alternately firing short burst as quickly as I could and the rounds printed exactly where I wanted them. I fired 120 rounds in this mode with the last 30 shots in one full-auto burst. The rattle is definitely slower than without the retarder in place. Good group, no malfunction but now I started to feel the heat of the stamped receiver cover in my cheek as I aimed the gun onto the target. I paused for 15 minutes as the gun already consumed over 400 rounds. This is a drawback of the design that can be easily corrected by incorporating a polymer liner over the sheet metal cover to protect the shooter’s face from heat build-up. The gun worked flawlessly from start to finish without any cleaning whatsoever. After field stripping, I examined all the parts – no breakage, just black residue all over. What I saw and tested that day is truly among the finest in its class. This prototype rimfire submachine gun is possibly the last contender in its class that evolved from generations of proven designs.

| This article first appeared in Small Arms Review V7N4 (January 2004) |