By David Lake

Lewis Machine and Tool is rapidly approaching “alpha” status among small arms manufacturers. Their most recent distinction comes from New Zealand, where the Ministry of Defense has named LMT an official purveyor of small arms to the fighting soldiers of that island nation. Some years ago, Lewis Machine planted its flag on British soil, in the form of the L129A1 “Sharpshooter,” along with Law Enforcement International, Ltd.

What is noteworthy about these agreements with foreign governments is that the rifles demonstrated by LMT in these tests and trials were pitted against the presumed heavyweights in battle rifle design and manufacture. Major players like Fabrique Nacionale, Heckler and Koch, and Steyr had sent their best offerings to these trials, yet were not chosen when vying for favor of the selection committee. It would seem that the new battlefield is becoming more like the old battlefield; where the need for rugged simplicity has overshadowed the appeal of exciting, yet perhaps unproven or untrusted technology. Actual performance has trumped the promise of superiority. Enter the “Best of the Basics,” Lewis Machine and Tool, LM308MWS. It’s a cousin to the legendary Stoner SR-25, with some judicious adjustments to make it appropriate and expedient for today’s armed professional.

LMT’s approach to improving the AR based fighting rifle is based on sound and simple logic. A careful and nuanced approach has been adopted when revising or updating the battle rifle- LMT’s engineers exercise restraint and retain the good attributes of the original AR-15 and SR-25 designs. As updates and improvements are made, they really are improvements, in all sense of the word- not mere changes for the sake of boosting commercial sales. It is apparent that Lewis Machine and Tool is not in the business of fabricating and selling hype. LMT rifles come with some signature features, and a sterling reputation. And that’s sufficient for the best of us.

The most obvious and recurring design attributes that separate LMT from the competition are the MRP monolithic rail platform, and the SOPMOD stock system. The MRP allows for quick barrel changes (takes about a minute) that can be affected by addressing 2 torx screws. This design feature exploits the rigidity and accuracy potential of a unitized receiver and forearm structure by totally isolating the free-floated barrel from stresses applied to the forearm. The MRP system incorporates a massive barrel extension that further enhances accuracy by simply adding more mass and rigidity to the equation. The barrel is stable.

The SOPMOD stock was one of the first collapsible stocks to include waterproof storage compartments for batteries, ammunition and tools (also appropriately sized for a #40 cigar). The SOPMOD is loosely based on the old M4 or CAR stocks as we know them; it collapses in a similar manner. But LMT’s update deviates from the normal tubular shape of the comb and angle of the butt. This stock improves shooter comfort by way of a triangular comb, with deep flat sides that make for an ideal cheek weld. The SOPMOD is friendly to the tactical beard while most other modern enhancements to the collapsible stock tend to grab and pull facial hair. Also, the SOPMOD’s butt surface is perpendicular to the rifle’s axis and features a soft rubber pad with a wide radius around the corners. The M4 featured a negatively raked butt surface, a waffle-textured face, and nearly sharp corners around the edges. Also there is a touch of subtle genius in the SOPMOD stock. It does not wiggle or rattle like most collapsible stocks can. It rides on a few high spots that have been molded in at equally spaced contact patches around the receiver extension’s circumference. The stock seems to be molded a little bit undersized, and thus maintains just enough stretch to allow the stock to move freely, while remaining snug on the tube. So the stock is as solid as any other that may feature a mechanical lock, but the LMT stock maintains this rigidity and proper fit without separate complex locking structures. It’s just very well designed and well executed. It is the essence of genius in action- to enhance and simplify simultaneously.

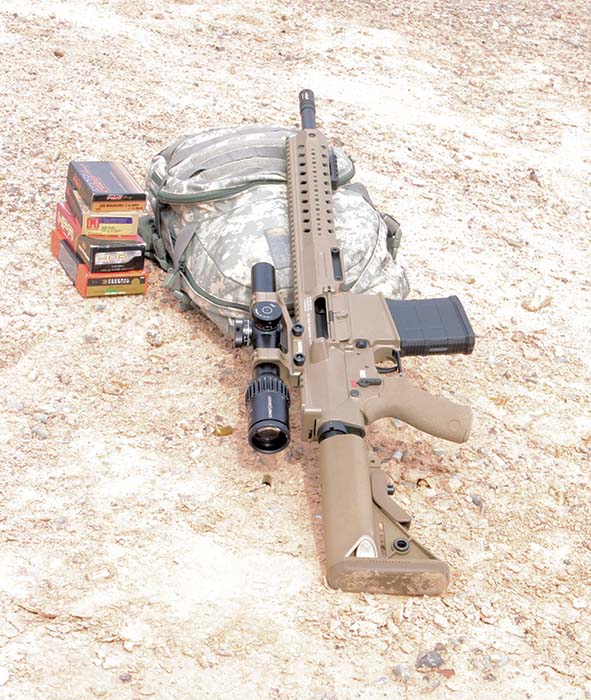

This rifle is put together with much consideration. All of the incidental and common parts, at close inspection, are a little bit “better” than the norm. All of the small parts are made to order. The trigger is a fixed two stage unit. It gives positive control and feedback when slow, aimed, controlled fire is required. The second stage is short and only requires an extra pound of force past the initial take-up, so during rapid fire, as the trigger is yanked or slapped, there’s no perceived hesitation or delay. The safety selector is a rock hard piece of investment cast steel, and features a hard detent. The magazine catch can be operated from either side; by the trigger finger as usual or the “forward hand” can release the magazine by depressing a protected paddle on the left side of the receiver. The bolt catch has been maximized to survive the abuse imposed by the operator and mechanism alike. The charge handle is overbuilt as well. It features a “dam” on the rear face to help divert gasses and debris that might otherwise exit the rear of the upper receiver. The latch itself is slightly extended and shaped into a paddle on the leading edge to facilitate easier operation; the buffer spring is quite stout and much force is required to charge the weapon. The buffer is an H3, as required for the extra speed and load on the action the 7.62 Nato round creates. The Ceracoat finish is superb. It is applied to all external surfaces for elemental protection and camouflage. The sheen and “Dark Earth” color are perfectly suited against desert soil and rock and dry vegetation. The internal surfaces all exhibit a matte black finish; assumed to be hard anodizing. The application of the ceracoat is nearly perfect. There’s no hard masking line between internal and external surfaces, and zero visible defects in the finish. In fact, the Ceracoat finish on the face of the shell deflector is undamaged after firing 140 rounds. There is only a dark rub mark on the finish, but the Ceracoat film is intact. The grip on this rifle is made by Ergo. It is rubber coated, features shallow ginger grooves and fits the hand perfectly. The rifle includes a standard P-Mag and 2 QD flush cup sling loops and a set of hard sights as standard kit. The barrel on this rifle is made from cryogenically stress relieved ordnance steel and features hard chrome lining over the 1-10” twist rifled bore. Though not advertised as such, the rifling is of a “polygonal” profile. Polygonal (or improved) rifling is known by many names (5R being the most ubiquitous) but all brands and types boast the same advantages of a cleaner, cooler, more accurate and longer lasting barrel. The only room for improvement was found at the muzzle. The LM308MWS comes fitted with a basic old fashioned A2 style flash hider. When used with a .308, it is not especially effective at mitigating muzzle flash. It is even less impressive for recoil control. This rifle needs a better device on the business end. The Brits decided to affix a Surefire as part of their kit. Being intended for domestic civilian hobby use, this rifle could do well with a muzzle brake- of any kind. Recoil generated by this rifle just crosses the line between fun and discomfort. After a day out, it is taxing on the body.

The rifle seen on these pages is the LM308MWS. It is very similar to the model that Lewis Machine and Tool demonstrated to her Majesty’s Ministry of Defense in 2009. Of course, the Royal MoD did ultimately request some changes to the original entry, which resulted in the creation of the L129A1. This new service rifle was selected to serve in the role of “sharpshooter.” This role describes duties and demands similar to those of the “designated marksman” found among US forces. The relevance and need for the sharpshooter has been well demonstrated over the last 15 years of fighting in the Middle East. The sharpshooter is expected to operate in close contact and support of general infantry; so his rifle must serve in the capacity of a basic assault rifle. At the same time, the sharpshooter must be able to engage enemy snipers at range, or behind hard cover; so the sharpshooter and his rifle must be able to interdict at great distance, and with great power and penetration. The sharpshooter receives marksmanship training and is as capable of ranged precision fire like the scout sniper, but without the added time and expense of training in the complete fieldcraft of the sniper.

This breed of dual role battle rifle must be no larger than a typical assault rifle. It must not be significantly heavier than a basic infantry rifle. It must be able to sustain fire for prolonged engagements, and maintain accuracy and reliability. It must be able to deliver the accuracy, power, and distance analogous to a sniper rifle. That sounds like a dare more than a list of realistic qualifying criteria established by Military’s top brass. It’s a challenge, to be sure, but little by little, this dual role rifle has come into being. Digital and print media are full of ignorant conjecture and compelling support, valid opinion and intolerant retort made on the subject and interpretation of what’s become known as the “DMR” or Designated Marksman’s Rifle. This designation has evolved to be the label for any (intended) fighting rifle that has been purpose built…to serve 2 purposes- that of assault rifle and precision rifle. Many firearms makers list a “DMR” on their menu. Not many can actually deliver the gear that satisfies the call. It is the informed opinion of Small Arms Review that this LMT rifle does indeed perform in this requisite capacity.

Our LM308MWS was sent out into the rough desert of southern Utah for some field testing. A Warne Gen 2 MSR Mount wrapped around a Schmidt and Bender 1-8 Short-Dot would serve as the user’s visual interface. The rifle would be tested against close to medium range practical targets (IPSC metric silhouettes) from arm’s reach up to 40 yards and distant “hard” targets (12” steel plates) at ranges up to 500 yards. For the close targets, a shot clock was employed to measure time between shots. For long range targets, only a backpack was used for a rest, to simulate expedient field conditions. And for comparison’s sake, an M1A Scout and a basic M4 (type) carbine were present at our evaluation. The LMT’s recoil, control and shot-to-shot recovery and transitions between targets were more labored than with the M4 at close range as we expected. It’s a heavier and more powerful gun. Shot splits on target averaged .7 second, while the M4 was only .3 second apart. These times were not measured merely how fast the trigger could be pulled, but how fast a target could be hit at 40 yards. But then consider that most targets won’t need to be hit twice with a .308 round; shot-to-shot control becomes less of a concern. At ranged targets, the LMT’s first shot hit percentage was 20% higher than our M1A. Consecutive shots placed 40% better with the LMT. There are 2 reasons for this improved long range performance. The free-floating barrel of the LMT eliminates point-of-impact shift caused by heat and harmonics, and due to its improved ergonomics and more balanced operating system, the LMT allowed for a more manageable sight picture under recoil when fired rested from a prone position. When making follow-up and correction shots to compensate for wind and drop, it is important to maintain sight picture in order to get visual feedback from previous shots fired. Because the user can keep a visual on the target, and can see the “splash” from bullet impact downrange, he can make instant corrections before sending the next round. This is why the LMT returned a greater probability of landing hits at range. The LMT was also fired from a solid rest at 200 yards to test its inherent accuracy. We used 4 types of ammo; from 147 up to 175 grain bullet weights. The 1-10 twist rate of the rifle showed preference for the 168 and 175 grain pills. Match grade 155 grain ammo did not return optimal results. Ball 147 grain ammo was adequate on our steel targets up to 200 yards (for hit or miss). Shot groups sizes will not be represented here; as they just don’t apply to this rifle or its intended role. It is not a match rifle and should not be compared to such. To generalize- with the right ammo, and careful control and coordination, this rifle can be expected to hit 2 MOA targets up to the 308’s limited range.

We found the LMT to be plainly superior in some capacities and a worthwhile compromise in others. Handling speed and control on close targets was faster, and making good hits on distant targets was easier than with the M1A. When compared to the M4, the LMT was not measurably faster, but was indeed fast enough in control and handing to bring a prompt and decisive end to a close quarter insurgency of cardboard targets. Overall, the LMT had the advantage in the field.

Lewis Machine and Tool is an industry master at building rifles up to a standard, not down to a compromise. And they don’t build rifles to fill popular consumer demand; instead they just build as good a rifle as they can. In a market where the amateur or hobby-level consumer seeks out the “mil-spec” designation as a guarantee of performance or mark of quality, too many companies are content with simply applying a label to a rifle as proof of its pedigree. The well-informed will find real quality and performance from the likes of LMT. There are no claims and no promises made- just a statement, “Failure is not an option.” That is the LMT mantra. They make premium weapons that will do what they are intended to do and they will execute without excuse or exception. This brand is trusted and used by real professionals- those who put themselves in harm’s way and use their rifle as a tool of their craft. This rifle boldly represents the quality and performance and presence of Lewis Machine and Tool.

| This article first appeared in Small Arms Review V19N10 (December 2015) |