By Christopher R. Bartocci

Over the past 10 years the industry has seen several new weapon systems emerge with the older piston technology making a comeback. Due to the campaign of certain manufacturing firms, the consensus is that the older retro piston operating system is superior to the current direct gas system of the current issue M16 and M4 weapon systems. While no statistical data has come forth to support the claim, several manufacturers are coming out with piston operated 5.56mm weapon systems including Colt, POF, Heckler & Koch, LWRC and, now, Magpul Military Industries.

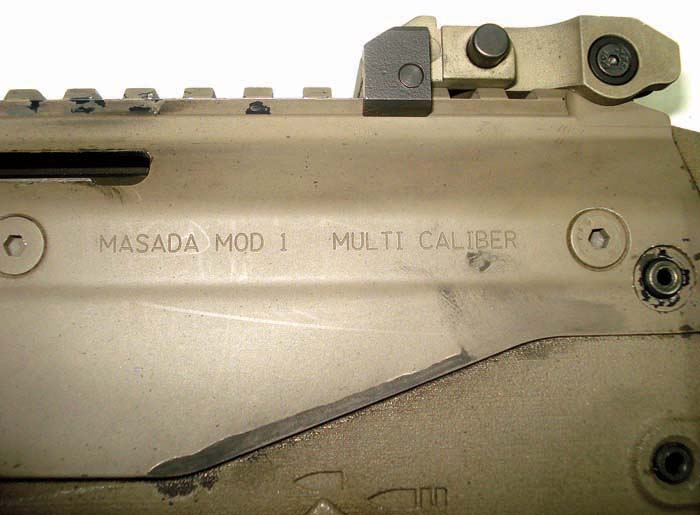

Magpul introduced their Masada Adaptive Combat Weapon System at the 2007 SHOT Show. There was quite a buzz around the booth from both the introduction of the Masada as well as their revolutionary new PMag polymer magazine. The Masada is, of the entire current available piston operated 5.56mm weapon systems, the most advanced and conceptually new weapon system out in the market. Unlike the POF, Heckler & Koch and LWRC models, the Masada is not based off of existing M4 weapon platforms. Like the Heckler & Koch XM8/G36 weapon systems and the British SA80 weapon systems, the Masada uses technology borrowed from the Stoner/Sullivan/Miller designed AR-18/AR-180 weapon systems of the early 1960s. The Masada however, takes it to the next level.

The Masada name comes from the battle of Masada where the Roman X Legion laid siege to the Jews in 72 AD. The fortress stood on top of a plateau and had a secure source of fresh water. Due to this, the Romans were forced to build a ramp to permit their formations to attack the fortress without breaking ranks. With the ramp being nearly complete, the Jewish defenders decided to end their existence rather than come under Roman rule. The citizens of Masada left their food out in plain view so the Romans could see they were in no danger of starving and through this act of defiance, the citizens of Masada decided they would kill themselves rather than have their women and children raped and enslaved by the Romans. Controlling their own destiny, the entire town perished by their own hand. Magpul found the story of Masada a bold example of defiance. Most weapon systems bear the name of their designer or manufacturer; the Masada name is more of a symbol of defiance.

The Masada is the first weapon system to be developed by Magpul. Conceptually, Magpul had thought of a firearm design for several years; however it was not until 2006 when pen went to paper. Magpul’s Mike Mayberry headed the Masada design team and it was designed in only four months time. Like many other firms, their initial goal was to take the current successful M16/M4 weapon systems and incorporate those desirable traits into their weapon system offering potential users an easier transition. During the developmental stages, many weapon systems were examined and Magpul was able to extract what they felt were the benefits of each design and would incorporate those into their final design. Magpul was able to keep some parts commonality with AR-15/M16 components that included the barrel and barrel extension, trigger, disconnector, hammer assembly, hammer/trigger pins, trigger spring, front sight assembly, extractor pin/spring/plunger, ejector/spring and retaining pin.

Magpul found that to retrofit the standard M16/M4 weapon system with their improvements would be quite difficult and costly. In March of 2006, the decision was made to abandon the retrofit design and start from a clean sheet of paper with the project commencing in the fall of 2006 from scratch. As previously stated, they would model the mechanics of the operating system of the AR-18/AR-180 making many modifications from that design. The AR-18/AR-180 was not a combat proven design by any means. The ArmaLite rifles were never manufactured in quantity for military sales, only commercial sales. The first military production of this system was the British SA80 which was a disaster and still considered one by some. The H&K XM8 was never fielded and the G36 has seen limited use.

The Masada was not designed to fit any military requirement so Magpul had freedom to do what they wanted in order to build their own vision of a durable and reliable weapon system. Military weapons programs will often mandate parts interchangeability with current systems, which are good for the supply channels but do not allow the weapon to perform to its capabilities.

The final design shows clear M16 influence in the way the weapon breaks open for maintenance, the bolt and the fire control group. The standard M16 NATO magazine is used which we will discuss later. However, Magpul has integrated several of their trademark enhancements into the Masada including the ability of the pistol grip to accept MIAD cores, Enhanced Trigger Guard, UBR Stock concept and PMag. The Masada will allow the user to be able to change calibers by simply changing the bolt and barrel and, depending on the cartridge, the lower receiver magazine well. The 7.62x39mm Masada will use a special lower receiver enabling it to accept standard AK47 magazines. The Masada will be available in 5.56x45mm, 5.45x39mm, 6.8 SPC, 6.5 Grendel and 7.62x39mm calibers. Magpul will make available barrels, bolts and if needed, lower receivers to let the customers convert their Masada to a different caliber.

Upper Receiver and Handguards

The Masada utilizes a one-piece upper receiver. Throughout the industry, several companies have designed one-piece upper receivers including Colt, LMT, VLTOR, FN and more and the benefits are many. One of the first things an operator will do when he gets a weapon is to procure a quad rail system. Often, the addition of an aftermarket rail system will increase weight. Many of these are not going to free float the barrel and will transfer heat from the front sight assembly back into the receiver. Additionally the extra weight put on the barrel from the addition of optics, lasers, flashlights and vertical pistol grips may cause accuracy issues and, in extreme cases, the barrels to bend. Free floating handguards assist with both accuracy and cooling. The Masada’s upper receiver is manufactured from high-strength 7000-series aluminum alloy and extruded in a closed box profile. There is a fired cartridge case deflector at the rear of the ejection port to prevent left handed shooters from being struck in the face with a hot cartridge case. On the top is a 37-slot Mil-Std-1913 rail. Magpul provides a front sight that is identical in length to standard M16 front sights permitting the use of a standard BUIS (Back-Up Folding Sight). No BUIS is provided and the user may use any commercially made M16/M4 BUIS. The Masada uses a steel-on-steel interface. Bolted into the receiver are internal receiver rails that guide the bolt carrier group. Bolted and pinned into the receiver is a steel alloy barrel trunnion that is heat treated to cope with the heat caused from high firing schedules. The receiver will accept a 40mm grenade launcher.

The handguard (lower) is injected molded from high strength polymer with the ability to accept Mil-Std-1913 rails at the 3, 6 and 9 o’clock positions. There are two lengths of handguards. The standard length allows 11.5+ inch barrel lengths while the short handguard permits the use of a 10.5 inch CQB barrel.

Bolt Carrier Group

The bolt carrier group is esthetically similar to that of the AR-18/AR-180. A captive recoil spring is designed to stay in the carrier once removed to prevent loss from cleaning in the field. No tools are required to perform routine field maintenance. The bolt is the standard M16/AR-18/AR-180 eight lug profile. The barrel extension on the barrel is the standard M16 barrel extension. The firing pin has the addition of a return spring to prevent slam-fires from the inertia of the bolt closing on a commercial cartridge with a soft primer. The charging handle is both ambidextrous and non-reciprocating. To change the location of the charging handle, the rifle is broken open and the bolt carrier group removed and the charging handle is pulled out and inserted on the opposite side. Currently, Magpul is working on charging handle location changes to enhance user friendliness.

Lower Receiver

The lower receiver is made of injection molded polymer. The bolt catch, magazine release and selector lever are fully ambidextrous. The lower receiver accepts standard GI NATO M16 magazines. However, Magpul uses their advanced polymer PMags with the weapon system, which is a great improvement in reliability over the standard GI aluminum magazine. The fire control group is a drop-in pack that contains standard M16 fire control components (hammer, trigger, disconnector) as well as the bolt catch. The bolt catch lever is located in front of the bottom of the trigger guard. Upon firing the last cartridge, the follower of the magazine elevates the bolt catch. To release the bolt, the operator merely pushes downward on the bolt catch with his trigger finger to release it. All of the receiver takedown pins are captured preventing them from being lost in the field. The trigger guard is modeled after Magpul’s trademark enhanced trigger guard that allows the shooter to easily fire the weapon with heavy gloves. The pistol grip is modeled after the medium Magpul MIAD pistol grip profile. The removable cores will allow the operator to carry two N, CR123, AA or AAA batteries. Another core will permit three additional 5.56mm cartridges and a bolt/firing pin. Part of the modularity of the Masada is the ability to change calibers. The lower receiver is a replaceable component. Currently, a second lower receiver has been designed to allow the rifle to fire the 7.62x39mm cartridge.

Stock Assemblies

Magpul has completed the design of two stock assemblies for the Masada. The first is a Magpul folding stock design that takes the best design features from two other Magpul designs: the UBR (Utility Battle Rifle) and the PRS (Precision Rifle Sniper) stocks. The UBR allows the stock to be extended without changing the cheek weld. The stock has seven adjustable length-of-pull positions that amount to 3 inches of possible adjustment in length. The stock is equipped with a rubber buttpad. The stock can be fitted with a single point sling mount on the left side. The cheek-weld portion of the stock is stationary. The Masada stock has the advanced features of the PRS stock as well that include an adjustable cheek-weld height. The stock folds to the right of the weapon and does not interfere with the ejection of the fired cartridge cases. In the front of the stock (when folded) is a water proof battery compartment that holds two AA or two CR123 batteries.

The second stock is the Precision Rifle (fine adjustment for sniper/target use). This is a fixed stock with 1.3 inches of length-of-pull adjustment and 1.8 inches of cheek-weld height adjustment. This stock has two different lengths of rubber butt pads and will accept a monopod.

Barrel and Operating Characteristics

The Masada uses standard AR-15/M16/M4 barrels, which have a modified front gas block and gas port. Therefore, any AR-15/M16-type barrel can be modified to work on the Masada. The standard handguard will permit any barrel length above 11.5 inches. If the 10.5 inch barrel is required, a modified shorter handguard is available. There are no tools required to change the barrels out. The mechanism is an interrupted Acme-type thread in conjunction with a spring loaded detent to operate. To change the barrel, the bottom handguard is removed, the spring loaded detent is depressed, rotate the lever to the right and the locking mechanism comes off and the barrel is pulled out of the receiver. The piston op rod and associated assembly remains part of the barrel. The gas piston system is Magpul’s very own design based on the AR-18/AR-180 Stoner design. The front sight base has an adjustable gas regulator with three settings: “S” for suppressor, “R” for normal use and “H” for high altitude, extreme cold or fouled/impaired function conditions.

The weapon’s cycle of operation consists of the hammer striking the firing pin which detonates the primer in the cartridge igniting the propellant. Expanding gasses drive the bullet down the bore and as the bullet passes the gas port, gas is bled into the expansion chamber creating a blow to the face of the operating rod driving it rearward. The rear of the operating rod strikes the face of the bolt carrier driving it rearward unlocking the bolt, extracting and ejecting the fired cartridge case. The operating rod spring, now compressed, returns the operating rod into the gas block, the recoil spring returns the bolt forward stripping a cartridge off of the magazine. The cartridge feeds into the chamber and the bolt locks into the barrel extension and the next cartridge is ready to fire.

Shooting Impressions

There are, as of this writing, only six Masada prototype rifles. Two of them made their way to Rochester, New York for test and evaluation along with Magpul’s Drake Clark. First examination of the two rifles showed an extreme amount of wear. These rifles have been shot countless numbers of times. Both were dirty and dry. All shooting was done with Federal American Eagle and Remington UMC .223 Rem ammunition loaded in Magpul PMags. Magpul claims the Masada has been tested with a wide variety of commercial and military production ammunition and their experience is the Masada is not sensitive to ammunition. First shots were fired with the AAC 416 sound suppressor installed and the rifle functioned flawlessly with the sound suppressor on it. The controls were easy to manipulate due to their similar locations to the M16. The bolt catch took a little getting use to due to its location and how it was engaged. Once used to it, the bolt catch was fast and easy to use. The Masada was designed so reloading could be done while the rifle was still on the shooters shoulder. Once the loaded magazine was inserted, the bolt was quickly released by taking the trigger finger and pushing downward on the bolt release. For a 6.7 pound lightweight rifle, the Masada was easy to control and the cyclic rate was around 700 rounds per minute enhancing controllability on fully automatic fire. Approximately 500 rounds were fired within 45 minutes through the two rifles that were dry with no lubricant and dirty. All shooting was done at 25 yards in CQB type scenarios. It was easy to get off 3 to 5-round bursts and that was center mass on a standard law enforcement silhouette target. The adjustable stock was greatly appreciated. Of the six shooters firing the Masada, we ranged from small stature, medium build to large frame/long arms and various thicknesses of jackets. Everyone got comfortable with the Masada. The overall length of the 14.5 inch Masada is 32.5 inches with the stock in the fully closed position. With the stock fully extended the rifle is 35.5 inches in length. With the stock folded, the Masada was only 26 inches in length.

The Masada is probably the most advanced of any of the piston guns available on the market today. Although not expected to be in production until mid-2008, the Masada has turned a lot of heads by keeping with the combat proven piston operation but going with next generation synthetic furniture. The quick-change barrel will allow a modular firearm that will allow caliber changes quickly by only replacing the barrel and bolt with no need for an entire new upper half. The Masada is geared for the commercial market, but you just never know what military unit may think when they get their hands on one. Drake Clark was assuring that the production rifles will have several improvements over the prototypes and that even when the rifle is released for sale, it will not be considered a done project as Magpul plans to continue to evolve and improve their new weapon system.

(Editor’s note: Subsequent to this article being written, the following press release was received and says in part: “Bushmaster Firearms International, LLC (BFI) announced today that it has signed an exclusive license deal with Magpul Industries Corp. for the production, future development, and sales of Magpul’s prototype MASADA weapon system. The Bushmaster ACR (Adaptive Combat Rifle) will initially be offered in 5.56 NATO, available for law enforcement and civilian purchase second quarter 2008. This release will be followed by military ACR versions in the 3rd quarter of 2008. The Bushmaster ACR will initially be available in 3 SKUS: Standard Carbine with fixed stock, Entry Carbine with folding stock, and Special Purpose Rifle with Precision Rifle Stock.”)

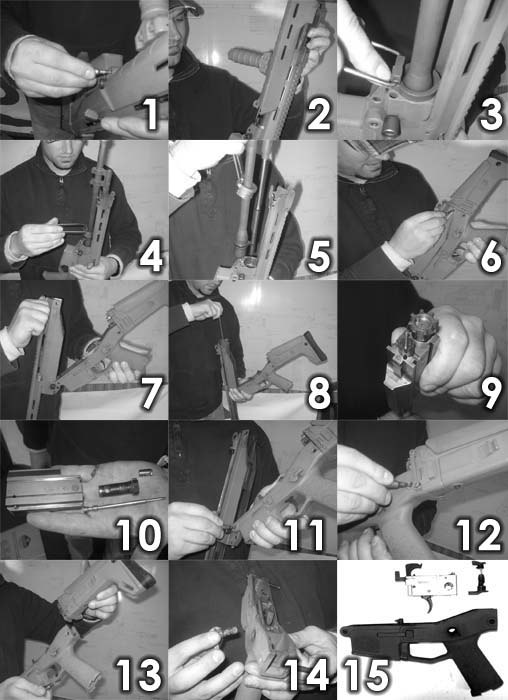

MASADA DISASSEMBLY

•1 Remove the magazine and check the chamber to make sure the gun is clear. With the tip of a cartridge (or any other tool) push inward on the handguard pin and pull from the right side until the pin stops.

•2 Pull the handguard free from the receiver.

•3 Depress the barrel nut locking button.

•4 Rotate the barrel nut 1/4 turn counter-clockwise to unlock the barrel from the trunnion and pull barrel nut free from the trunnion.

•5 Pull the barrel assembly free of the receiver.

•6 Depress the rear takedown pin from the left and pull out the right side until it stops.

•7 The receiver will break open in the same fashion as the M16 family of weapons.

•8 Get a hold of the recoil spring and pull the bolt carrier group from the receiver.

•9 To remove the recoil spring from the bolt carrier, push inward on the recoil spring and align the end of the recoil spring guide with the grooves cut into the bolt carrier and pull the recoil spring free.

•10 The bolt assembly comes apart similar to the standard AR-15/AR-180 carrier. Pull the firing pin retaining pin out from the bolt carrier. Remove the firing pin and firing pin spring from the rear of the bolt carrier. Pull the cam pin out and pull the bolt out the front of the carrier. Remove the extractor pin and then remove the extractor.

•11 Depress the front pivot pin and pull out to the right side until the pin stops and separate the upper from the lower receiver.

•12 To remove the stock, depress the pin and pull it out from the right side until it stops.

•13 Lift the stock assembly out of the receiver.

•14 Remove the selector right wing and remove the lever from the left side of the receiver

•15 Pull the trigger group/bolt catch pack out of the receiver.

| This article first appeared in Small Arms Review V11N8 (May 2008) |