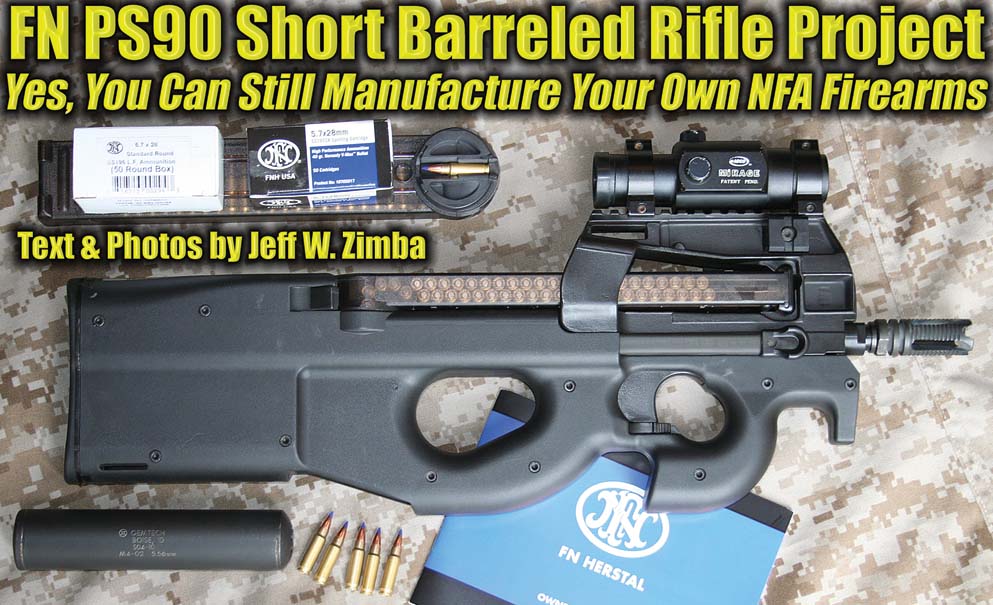

Text & Photos by Jeff W. Zimba

There are many semiautomatic variants of newly manufactured NFA firearms available to the military firearms enthusiast. Most people can live with the fact that they are operationally different due to the 1986 ban on the manufacture of machine guns for civilian ownership. Other changes, much more noticeable, also take place to meet the other Title I requirements including barrel length and overall length.

While the semiautomatic mechanism is currently “written in stone” at the present time, there is no prohibition on the civilian manufacture of any other NFA category, including silencers, destructive devices (DD), Any Other Weapons (AOW), Short Barreled Shotguns (SBS), and the focus of this article, Short Barreled Rifles (SBR). While you can’t alter the function, you can certainly get it back to that look you would like, simply by registering it as a Title II firearm prior to making any modifications.

Some popular rifles that get “altered back” to their more original look by using the same barrel length as their fully automatic brethren include the AR-15 and all its variants, and the Uzi carbine. Both are quite simple by mechanical standards and only require a swap in parts with minimal tooling, if any, being necessary. The FN PS90, which seems to be growing in popularity by enormous proportions, looks great with a shorter barrel as well; just like the original P90. The physical swap, while not beyond the abilities of many serious enthusiasts, is much more entailed than those previously mentioned and is thus the subject of this article.

The Legal Stuff Must be Taken Care of First

Before altering any firearm from a Title I to a Title II firearm, it is most important that prior approval from the Bureau of Alcohol, Tobacco, Firearms & Explosives be obtained. It is even necessary to obtain their approval before purchasing the parts to complete the conversion and own them in conjunction with your host firearm.

The form an individual will be using to register and “manufacture” the SBR will be an ATF Form 1 (5320.1) Application to Make and Register a Firearm. It is extremely similar in appearance to the familiar Form 4 used to transfer a machine gun to an individual. The basic information is the same, except you determine the information to be filled in regarding the firearm. If you are starting with an existing firearm, as is the case of our PS90 example, the original manufacturer and serial number is used. Any changes you propose to make will be listed in the new description, including barrel length, caliber, overall length, etc.

You will need to affix a recent passport photograph to the completed form and obtain a Law Enforcement Certification, again, just like the Form 4. It must be submitted in duplicate and accompanied by a pair of BATFE NFA Fingerprint cards (available from most local Class III Dealers or can be obtained directly from BATFE) as well as the Certification of Compliance with 18U.S.C. 922(g)(5)(B) (BATFE Form 5330.20). This form is often referred to as the Citizenship Certification. With the exception of the Fingerprint cards, all these forms can be obtained from the BATFE Website www.atf.gov or from the extremely beneficial website www.TitleII.com, formerly known as Danbrew’s PDF Document Center.

Include a check in the amount of $200 for the manufacturing fee payable to “The Department of Justice” with your package, and you can start your planning. Your approved form can show up anytime from 6 weeks to 12 weeks from mailing, and at that point you can start procuring the parts needed to undertake your project and start assembling the new configuration.

Getting to know the PS90

The FN PS90 is a compact Bullpup design with a very short overall length. This makes it even more attractive to bring through the Registered SBR process. With the short barrel, it is extremely compact and packs a big punch compared to similar sized firearms, usually available in pistol calibers. Its slim aesthetics are only exemplified by the unique, horizontal magazine, which lies flat, snapped over the top of the action with absolutely no protrusion in any direction. Basic disassembly for normal maintenance is very simple and requires no tools.

The PS90 is divided into 4 major components; the barreled receiver, the bolt group, the stock and the hammer pack. To field strip the PS90 the first thing you do is remove the magazine, inspect and clear the action and make sure no ammo is present. The next step is to pull the cocking handle rearward to cock the hammer, and than let the handle return to its forward position. Depress the barrel support lock located forward of the chamber area and slide the barrel and receiver assembly completely out the front. Next, tip the receiver down towards the front and slide the bolt group out the same opening as the receiver. Then, slide the butt plate at the rear of the firearm up, and off. The last thing to remove is the hammer pack located under the butt plate you just removed. The hammer group release lever is lifted up and the entire self-contained hammer pack is removed by sliding rearward from the stock. At this point the FN PS90 is field stripped enough for general maintenance and is quickly and easily reassembled.

SBR’ing the FN PS90

The PS90 is a very different creature from most other systems on the market. With many firearms, when factory short barrels are not an option, most people just cut the original barrel to the desired length, re-crown and thread if desired. In the case of the PS90, this isn’t the only option. The barrel on this gun is actually hidden under a much larger barrel shroud, and is blind pinned behind the flash hider. This shroud, from the barrel locking nut area, all the way to the tip of the flash hider is a one-piece unit and must be completely removed before proceeding. The original barrel is only usable again for your project if you cut it to the right length, re-crown and re-thread it for the proper barrel nut. Your other option is to procure a correct length barrel and correct barrel nut to finish your project and save the other parts for future projects or trading materials. Either way, you will need a new barrel nut as the old shroud is no longer useful in any capacity. Everything necessary to complete this project came directly from CMMG (www.cmmginc.com) including excellent directions with all questions asked. A new barrel was installed and a special barrel nut was supplied and utilized, converting the threads to the popular 1/2×28 to allow use of common muzzle accessories. The original barrel nut with the original P90 Flash Hider is also available to complete that “factory look” if that is what you are going for.

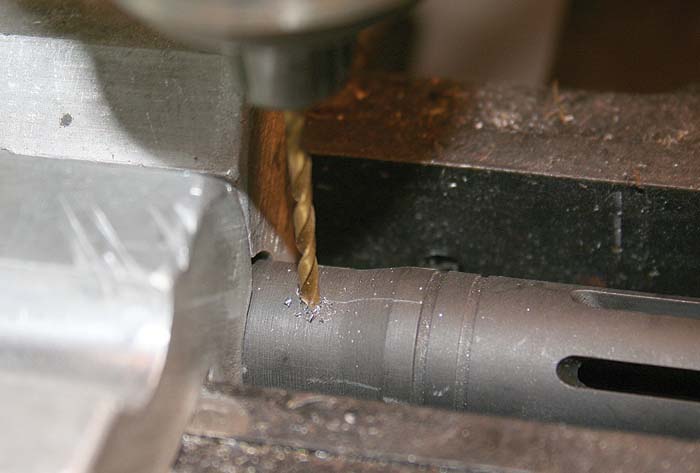

If you do wish to try and salvage your original barrel for future use or other projects you can drill out the blind pin located directly behind the flash hider. After removing this pin, the sleeve, also acting as the barrel retaining nut, can be removed and the barrel is allowed to be slid out through the rear of the receiver. If you don’t care about salvaging the barrel and sleeve for future replacement as is, you can simply cut through the barrel and sleeve behind the flash hider, remove the barrel sleeve to the front and remove the barrel through the rear of the receiver. The barrel will still be usable for a short barrel project in the future.

Special Tools & Flying Springs

No one likes flying springs, especially when we don’t know where they came from in the first place, what they looked like, or how to replace them even if we did find them. The special tools refer to some minor modifications necessary to some common wrenches to allow them to fit in the confined spaces of the barrel and the barrel nut.

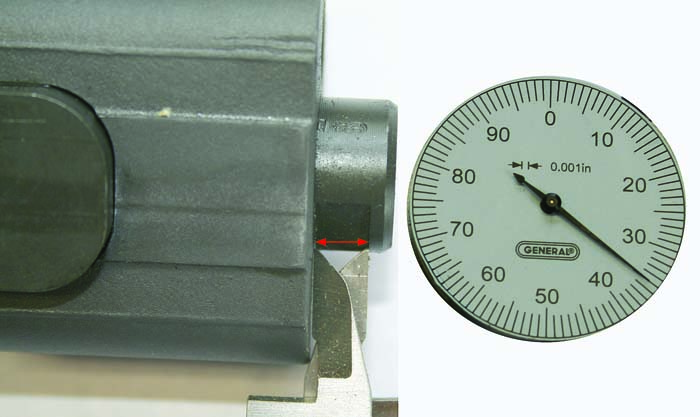

We will discuss the necessary modified tools first. The two wrenches that needed to be modified for this project include a metric 15mm and a 19mm. Since the spaces they need to fit are very thin, some material must be removed from the width of most standard wrenches. This can be accomplished with a bench mounted belt sander in short order. For a point of reference, the space the 15mm wrench needed to fit in measured only .235 inches wide while the unmodified wrench dialed in at .290 inches wide.

For the flying springs, it is important to know that the barrel, when in place, acts as a host for 3 captive springs. If the old barrel were to be quickly withdrawn from the rear of the receiver there would be nothing to hold the springs in their necessary position and have the potential to create a major problem. To address the spring placement concern, a range rod of a similar diameter can be used pushing the old barrel out (from front to back) with it, while capturing all the springs in their normal position. When the new barrel is inserted from the rear of the receiver, it slowly pushes the range rod out (to the front), recapturing the springs in their intended location again. With the new, short barrel in place the barrel nut was added at the front of the receiver and the barrel was tightened from the rear of the receiver while the front nut was held captive in the receiver and assisted with the 19mm wrench. With a tightening of the barrel nut, and reassembling the PS90, your SBR project is complete.

Do It Yourself or Hire a Pro?

Even though it is completely legal to manufacture your own SBR, some people choose to have a licensed Title II Manufacturer do the work for them. There are a few key reasons it may be advantageous to subcontract this work out. First, once you are approved by BATFE to complete your SBR, you must engrave your name on the receiver as the new manufacturer. Some people don’t want their own name engraved on a firearm as the manufacturer for reasons of liability or for concern about possible future sale. Others choose to have someone else do the work for them just because of time or mechanical constraints.

The process of hiring a licensed Title II Manufacturer to do this work for you is almost as easy as building it yourself on the Form 1 earlier described. In this case, the gun is sent to the manufacturer with a request to remanufacture it to an SBR, and a BAFTE Form 4 is completed to transfer the gun back to you once completed. It is the same federal tax ($200) and approximately the same time frame. The form is almost identical and the Title II Manufacturer is the one who engraves their business name on your firearm. Some manufacturers who do this work are CMMG, Inc. and TROSUSA, both well known in the FN arena.

Online Support

As the author was researching sources of information for this project, several businesses and helpful online communities were discovered. If you have any questions about the FN PS90, or are simply a new fan, you can visit either of the following websites that contain a lot of information: www.fnforum.com and www.fivesevenforum.com. Both were very helpful. For BATFE forms to complete the legal registration before engaging in the project, you will find everything you need at www.titleii.com. For general questions about NFA, the folks at “Tom Bowers Board” www.subguns.com are always happy to help out. For parts, accessories and heavy technical support we highly recommend CMMG at www.cmmginc.com.

PS90 Parts & Accessories

CMMG, Inc

Ph: (660) 248-2293

Fax: (660) 248-2290

www.cmmginc.com

SBR Conversions & Accessories

Mark McWillis

P.O. Box 680

Clackamas, OR 97015

Ph: (503) 358-3708

www.trosusa.com

| This article first appeared in Small Arms Review V11N12 (September 2008) |