By Dan Shea

We at SADJ wanted to cover the history of U.S. grenade machine guns, and with a recent visit to US Ordnance, the prime manufacturer of the MK19 Mod 3, it seemed like a perfect time. Later in this article, we’ll cover the modern MK19 system and improvements in depth. But first, a look at where we’ve come from...

Throwing grenades is nothing new. Reports of tossing explosives at enemies go back to the dark ages and certainly many armies had “grenadiers” in the 1700s and 1800s; light the fuse, toss the grenade. It wasn’t until mechanical fuses and primer firing were evolved that the idea of launching grenades automatically occurred. There are many early patents for weapons designed to launch explosive devices, but until the 1950s, the U.S. didn’t take the idea too seriously. With the advent of the 40x46mm grenade and its legendary M79 launcher, wheels started turning in the minds of designers and soldiers alike. Evolution of the single shot launchers has been covered in-depth by SADJ in the past; it is the idea of the U.S. designed, belt-fed, quickly repeating launchers that is our subject.

A proper timeline would be in two lines; the 40x46mm low velocity rounds, and the 40x53mm high velocity rounds. LV rounds have a range of 350-400 meters and can be shoulder fired or fired in a vehicle-mounted full-auto launcher, the HV rounds can go out to 2200 meters and are not for shoulder fired launchers.

Approximate Milestones for 40×46 Low Velocity Development:

1950s: Development of the 40x46mm low velocity grenade, and M79 launcher.

1965: Development and deployment of the MK18 Mod 0 crank fired launcher.

1968-71: Development and deployment of the MK20 Mod 0 automatic launcher.

1968: Development and deployment of various XM174E2 launchers.

1968: Development and deployment of the dual caliber M129 helicopter gun.

Approximate Milestones for 40×53 High Velocity Development:

1964: Final evolution of the 40x53mm high velocity grenade.

1966: MK19 Mod 0 design at Naval Ordnance Station, Louisville.

1969-74: Development of the Hughes XM175 series of launchers.

1968: Deployment of the first MK19 Mod 0 to Vietnam.

1971: Deployment of the first MK19 Mod 1 to Vietnam.

1974: Development of the MK19 Mod 2, not fielded.

1970s (Approximate): 600 MK19 Mod 2 Aluminum receiver guns- Israel.

1984-1989: Final development and manufacture of the MK19 Mod 3 by Saco Defense, then 1990s General Dynamics, and currently US Ordnance.

“The Honeywell Gun,” variously called the XM172, or the MK18 Mod 0, this was a crank fired belt fed, with 40x46mm ammunition; the same ammunition used in the M203/M79/M320 system. The ammunition is pre-loaded into a tape that holds the case in line with the barrel. Two rounds were fired per full revolution of the belt, allowing for slow, ranging fire, or firing up to about 250 rounds per minute. Belts were 24- or 48-round lengths. This was into action in about 1965 and survived in various places for U.S. forces (Navy) in Vietnam, primarily on “PBRs” (patrol boat, river) although some use on Chinook helicopters working over landing zone perimeters was seen.

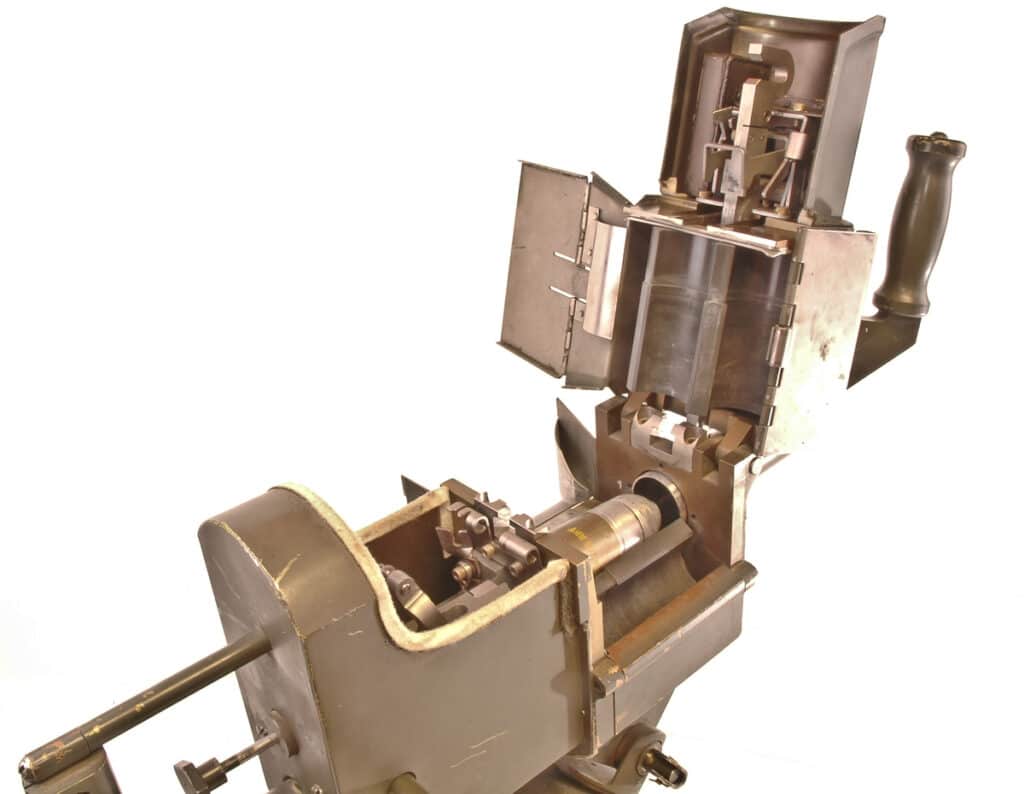

MK18 Mod 0 with the cover open, showing the lower rotor with a round in position, and the upper rotor inside the cover. The two rotors are keyed together so that when the top cover is down, each rotor makes half of the chamber. Since it is Hi-Low pressure, low velocity, the round can be fired like this, and much like a revolver, the projectile must enter a separate barrel. The rounds were initially held in a metallic tape, since they didn’t need to be extracted, the tape simply came through with empty cartridge cases in it. This was later changed to a reloadable Mylar backed fabric which, for many, doubled as a grenadier’s belt for the M79 shooters.

Around 1966, the Navy wanted a better system than hand-cranking. Colonel George M. Chinn, author of the famous five-volume series of books “The Machine Gun” was involved. His team at Naval Ordnance Station in Louisville, Kentucky was simultaneously involved in designing an automatic grenade launcher to replace the crank-fired MK18 and, by 1967, the team had the boxlike MK20 Mod 0 in 40x46mm, and was preparing for the new MK19 system in 40x53mm.

The MK20 is an unusual design, the cocking handle is pushed forward, and the barrel moves forward and stays “cocked.” On pushing the trigger, the barrel springs to the rear, over the grenade, pushing it onto the firing pin and the barrel moves forward with the projectile moving forward in its bore. The cycle repeats as long as the trigger is depressed. Production was ended in 1971, when Chinn’s group was advancing the MK19 system.

The MK19 Mod 0 was fielded, at first, in 1968 in small numbers in Vietnam, and was an unreliable system. It utilized the newly designed 40x53mm round, and fired from an “open bolt” but using ‘advance primer ignition’. This means the firing pin struck the primer before the cartridge was fully seated and in battery. The Mod 1 debuted as in this example in 1971 and, by 1974, it was evident that there were reliability issues and a “Mod 2” was designed but not implemented. These were all done by Colonel Chinn’s team at the Naval Ordnance Station in Louisville, Kentucky.

There was, in fact, a production of the Mod 2. The MK19 Mod 2 Israeli contract gun in 40x53mm with an aluminum receiver. Approximately 600 were made. There’s no clear historical evidence pointing to the location of actual manufacture; at Naval Ordnance, or as a technical data package exported to Israel, perhaps with parts for assembly abroad.

In any event, these functioned but were not advanced into larger production and the MK19 Mod 3 replaced them in service. The Israeli Mod 2s were sold on the surplus market, and the parts were initially offered as “MK19 Mod 3” replacement parts in the mid-2000s, but of course none of the parts interchanged with the Mod 3 guns. Some steel receivers were made and project guns tested in the U.S. by a variety of smaller manufacturers, but there was a clear size and parts difference with the issue MK19 Mod 3. Today, it appears these parts are offered as “MK19 Mod 2.5” complete guns in a modern production, new receiver program. Not to discourage potential end users, but these are not compatible with the MK19 Mod 3 system, which is physically larger and does not interchange parts. It would be inadvisable to mix the systems and support, so if the Mod 2.5 is chosen, it should be supported on its own and verification of spare parts supply should be done.

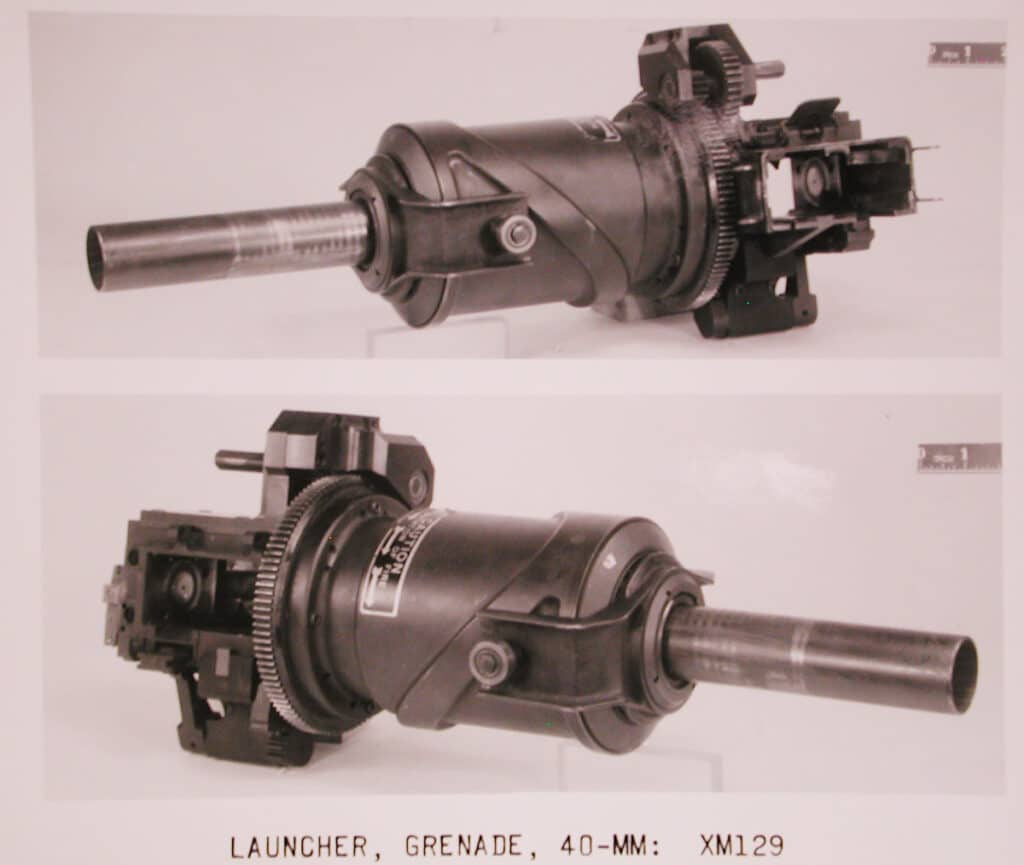

M129: This is a unique electrically operated system that had a cam path in the receiver housing, but instead of the bolt traveling in that path like a Gatling or an M134, the barrel reciprocated. The barrel would start in the forward position, and when fired would cam back over the round, fire it, then move forward for extraction. These were mounted in chin pods on the front of many Huey gunships in Vietnam as well as other rotary winged aircraft. It replaced the very similar M75 system which had accuracy issues, among other problems. The M129 could fire either 40x46mm or 40x53mm grenades, depending on how the feed was set up.

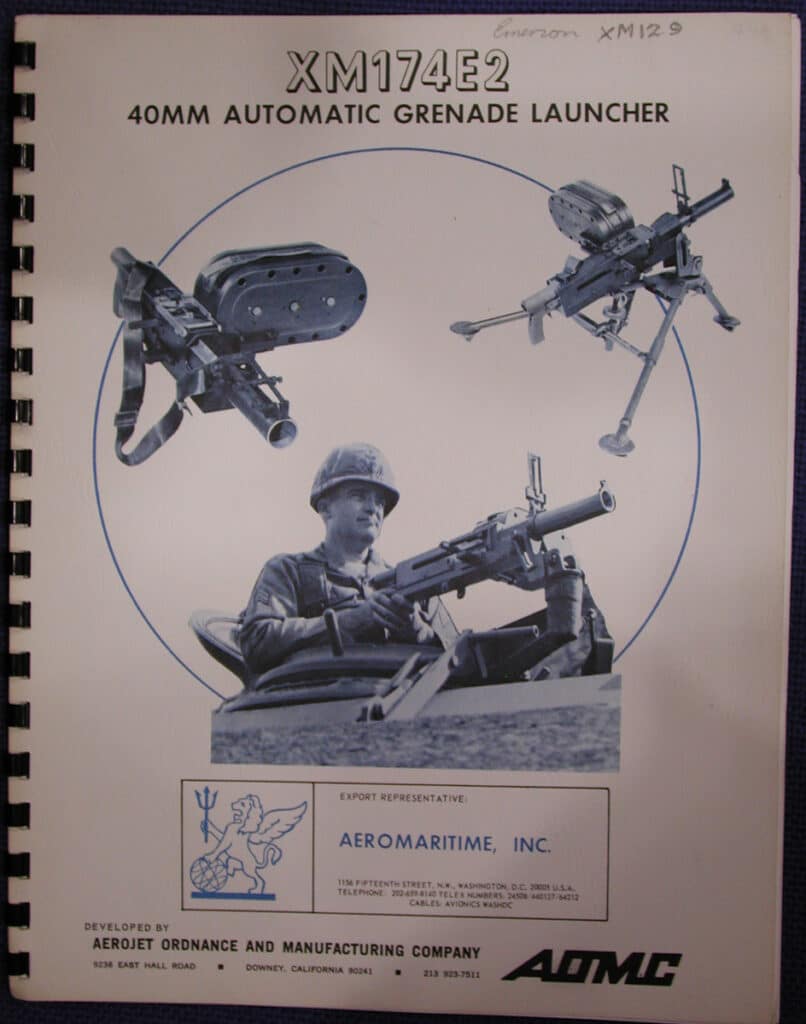

The XM174E2 was a drum fed 40x46mm automatic gun on tripod that was made in very small quantity in the late 1960s by Aerojet Ordnance & Manufacturing Company. These made a shadowy appearance in Vietnam: Colonel David Lutz, USMC ret’d, told this author once of how he’d found two of these XM174E2s with drum feeds at a base armory and took them to his area of operations in the A Shau valley. He and his men were quite impressed with the accuracy and firepower in fighting the Vietcong and NVA, and wanted more of them. As Colonel Lutz (Lt. Lutz at the time) stated it “Then, adult supervision showed up, demanded to know where we had gotten these, and took them away in that time-honored military tradition of if it works well, you can’t have it.”

In the late 1960s and early 1970s, there were two versions of the M175 40x53mm grenade machine gun; first was the XM175AL (above, left) which had a milled, rounded receiver, and the second version XM175ST (above, right) had a boxlike sheet metal receiver. Hughes Gun Systems in Culver City, California was the design group and manufacturer. Both were open bolt firing, link-belt fed, could be converted to be right- or left-feed, and did not require external power like the M129. The M175 was designed initially for ground vehicle use, and then the vision changed for it to become a manually operated helicopter door gun.

More on the MK19 in the Modern Day….

In the 1980s, FNMI in South Carolina was awarded the contracts for the M16A2, the M249 SAW, the M240G, and the MK19 Mod 3, all at the same time. Chief Engineer George Kontis described the situation, “We knew we could not properly perform all four of the contracts simultaneously, and the contracting officer did as well, and offered our choice of three—leave one behind. After a full review, I determined that the MK19 Mod 3 TDP and learning curve would be the hardest, so FNMI withdrew from the MK19.”

Saco Defense was awarded the contract for MK19 Mod 3, and it took almost six years to develop the TDP and production process on the especially difficult receiver and bolt production. We visited the Saco facility numerous times during this period and tested the weapon in many of the phases of production along with the M6E4 program run by Marc Desrochers. Kevin Sullivan of today’s Nostromo company was project manager in the mid to later MK19 program success. Saco was bought out by General Dynamics, and the GD MK19 Mod 3 production was in full delivery for many years. Several other companies have tried to go into production, but the advantage goes to larger companies, and indeed the U.S. DoD wanted a secondary manufacturer capability during the Iraq and Afghanistan wars; ATK was awarded this, with FN Manufacturing as a subcontractor on the receivers and bolt bodies.

In the 1990s, I was involved in importation of special tripods and mounts from Vinghog of Norway for my USG customers. At that time, the accepted first burst hit probability at 1000 meters for the MK19 Mod 3 on M3 tripod with fixed cradle was approximately 53%. In our testing for U.S. government agencies, we ascertained that the HK GMG had a much higher first burst hit probability, and much of that advantage was in the tripod and soft mount as well as a good sighting system. (GMG testing for this author started in 1993 and continued through the Yuma Proving Ground tests in 1996-97. It’s a fine GMG but not the subject of this article).

The customers wanted to retrofit their MK19s to gain similar accuracy. With the addition of the special Norwegian soft mount, the Adjustable Sight Mounting Bracket and some rudimentary head’s up sights with 40mm gradients, we brought the MK19 Mod 3 reliability to about 85% for first burst at 1000m. My point? The MK19 Mod 3 is an excellent grenade machine gun that needs mount stability and proper sighting. The advancements since that time have been by leaps and bounds, with the ability to land short bursts at long ranges increasing exponentially.

The MWO

There is a program that came out of the accuracy testing that was done. In June of 2002, a five-year plan was adopted for the MK19 Mod 3s in the U.S. Army system. MWO 9-1010-230-50-1 was implemented with an expected completion date of June 2007. However, that was only in the U.S. Army and later USMC/USN inventories; there are still tens of thousands of MK19 Mod 3 around the world that need this upgrade.

The purpose of this particular modification work order (MWO) is to convert the MK19 Mod 3 Grenade Machine Gun, to the MK19 Mod 3 with Adjustable Sight Mounting Bracket. Maintenance time is reduced and there is now a structural mounting point for fire control devices. The previous “sight mount” was a half-step, providing a not very secure rail base to the existing rear sight body. With this new purpose-designed mounting base, a variety of enhanced sighting devices can finally be used. The modification kit has the trapezoidal mounting base & screws, along with directions, and, for the armory, a fixture for drilling. This MWO was used as a vehicle to provide some upgrading of other parts, in particular the firing pin, firing pin sear, cam cocking, cocking lever and an adjustable secondary drive lever.

US Ordnance has the contracts for the M60E4 (the Navy SEALs’ MK43), the US M2A1 .50 caliber, as well as M240 series and other M2 guns. After several years of research and prototyping, then going into production, US Ordnance perfected their MK19 Mod 3 manufacturing procedures. They had also inherited one of the original technical data packages (TDPs) that came from Colonel Chinn, and benefitted from employees who worked the original Saco and General Dynamics programs. In their arrangements with General Dynamics and the U.S. government, US Ordnance contracted to be the manufacturer of the MK19 Mod 3 grenade machine gun. They are the official U.S. government contractor for this system, as well as for foreign military sales (FMS) and sales to allied buyers. SADJ toured the manufacturing facility recently, and with the new U.S. government contract to supply all MK19 Mod 3 and repair parts, US Ordnance is preparing for a full mil-spec live-fire test, which we will participate in and bring the report to our readers. There is a complete upgrade program that should be available to most longtime users of the MK19 Mod 3 system. Rather, it is available, but many end users are not aware of it. I have participated in several over the years, but US Ordnance is the primary on this type of project. They can gauge your existing guns, recommend the upgrades, perform them in the factory or set up on site programs. This will not work on the MK19 Mod 1, Mod 2, or the “Mod 2.5” as can be seen in the history of the development, they are different guns from the most prolific and reliable Mod 3. Contrary to some advertising and “internet wizards,” the parts of those other models do not interchange with the MK19 Mod 3 40mm Grenade Machine Gun, and it is our sincere hope that this guide will help identify what systems are in place, and how to upgrade, repair, and maintain them.

Meanwhile, in the USSR…

While the U.S. was developing the 40x46mm and 40x53mm grenade machine guns, the Soviets were designing, as well. In 1965 the AGS concept was born and by 1971, production had begun. The AGS-17 30x29mm Grenade Machine Gun is a lightweight, tripod or vehicle mounted open bolt grenade launcher. It’s quite effective, and the smaller diameter, longer grenades have an almost spear-like travel to target. However, at 1700 meters range the time to target is very long, due to the high trajectory arc. Typically, the AGS is drum fed with 29 linked rounds per drum. SADJ has covered these extensively in the past and the analysis can be found at our websites.

Grenade Launcher Ammunition

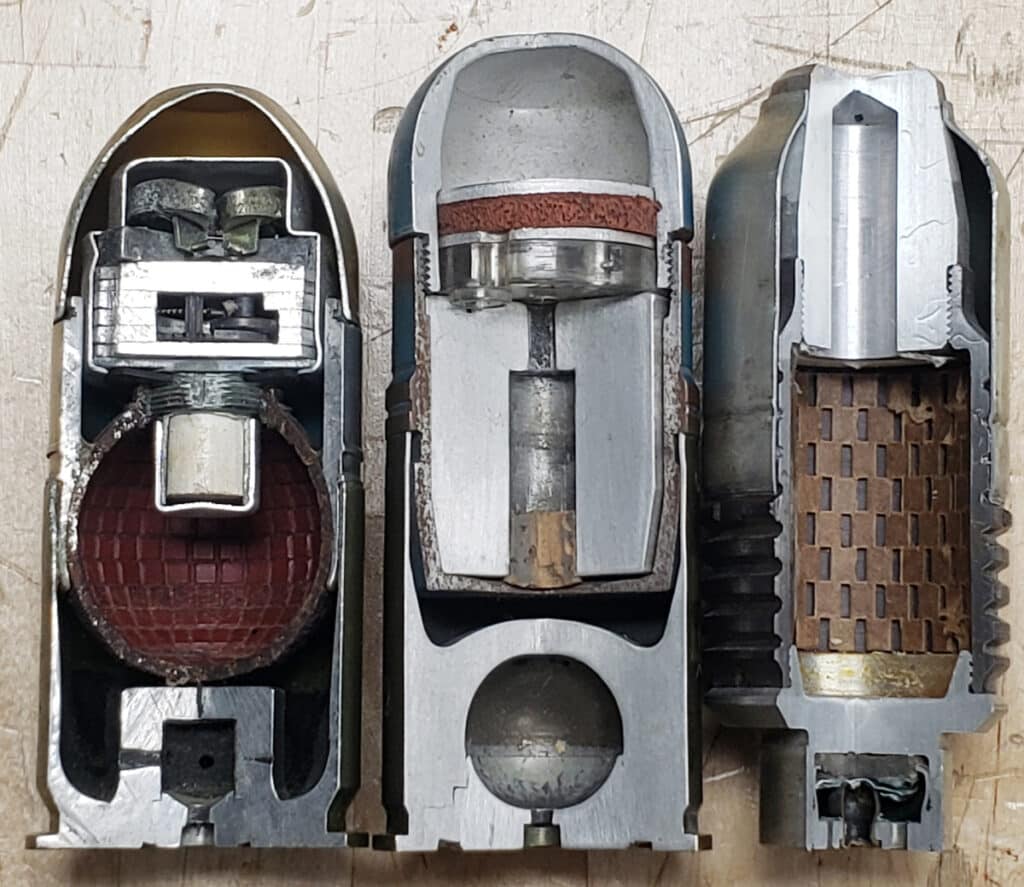

40x46mm HE Fragmentation Hi-Low pressure, low velocity cutaway round for the M203/M79/M320 type launchers. The multiple fuses are in the front, the fragmentation ball is in the center (without energetics), and the base shows how the Hi-Low pressure system works. The primer is fired, igniting propellant in the central chamber which expands. When it reaches X pressure, it blows out through the vent holes into the sides into a much larger expansion chamber, creating a lower pressure that “pushes” the grenade into the barrel and downrange. Range is 350-400 meters.

At center is the 40x53mm Hi-Low pressure, high velocity cutaway round for the MK19/GMG and other Grenade Machine Gun systems, it is evident from the thick walls of the spherical chamber that there is much more pressure involved here. The cartridge case is 9mm longer than the 40×46 low velocity (M203) round, and the 40x53mm round cannot be chambered in the shoulder fired launchers. Range is out to 2200 meters, depending on firing platform.

Right is the VOG-25 40mm grenade, a “caseless” round that is front loaded into the barrel of the GP-25/30/34 underbarrel launchers. When the primer is struck, it ignites the propellant in the chamber at the very bottom, the expanding propellant gasses vent out into the base of the launcher forming the secondary low-pressure chamber and drive the grenade down the bore and downrange. There is no cartridge case left, it has all left the launcher downrange. Range is 350-400 meters.