Firearms ownership has an amazing potential for personal growth. Some people are satisfied with buying a new gun on occasion and only shoot once in a while. Some people shoot a large amount of ammo to become proficient and take up hunting or competitive shooting to test and build their abilities. Some make the next step to loading their own ammo, either for enjoyment, cost savings or improved accuracy. The pinnacle for many serious firearms enthusiasts is when you can actually build your own custom gun. With modular systems like the AR-15, M16, M4 family it is easy to do, with numerous parts built to similar specs for simple assembly into different configurations. Other guns are not quite as easy to build and start with pieces of metal, commonly called receiver tubes or flats. They are not even finished to the point of being considered a firearm and usually require an extensive amount of bending, cutting, welding and drilling. Some of the more common home builds include MAC family firearms from flats, Sten family guns from pieces of tube, and AK47 family firearms from flats. Although a little beyond the ability of many weekend recreational shooters, they are not uncommon to see and several templates, bending jigs and drilling fixtures are available to help the advanced builder. In this issue we are going to go a step beyond the more common home builds and manufacture a firearm a little more complicated and extremely desirable. How about actually building your own MP5 clone from a non-gun receiver flat? Thanks to LSC Manufacturing, LLC. it’s a project much closer to the abilities of an advanced builder than ever before.

The Legal Stuff

The heart of any firearm is the receiver. This is the piece or part that is actually considered “the firearm.” While gun parts are typically unrestricted and readily available, it is the actual receiver that requires a transfer through a licensed federal firearms dealer and the necessity of the form 4473 and NICS check to obtain. Under federal law an individual can build their own firearm, but aside from assembling a few parts into a different configuration on an already manufactured receiver, few people actually build their own gun from scratch.

If the gun is going to be a standard rifle, shotgun or pistol, federal law doesn’t require any special forms or previous “permission” to partake such a project. If the end project is going to be an NFA firearm, such as a short-barreled rifle or a silencer, it requires preapproval on a BATFE Form 1. It is a registration form and is almost identical to the BATFE Form 4 used to transfer an NFA firearm and has a fee of $200. It is important to determine the type of firearm you are building before starting out to determine if it requires preapproval and NFA registration. The build we are completing in this article is a short-barreled rifle so if you wish to duplicate it and are not a Title II Manufacturer, you must have an approved BATFE Form 1 prior to beginning. The author is the proprietor of Small Arms Research, a licensed Title II Manufacturer, and chose to manufacture this project as a Short Barreled Rifle, and it was registered as such.

If you are manufacturing a rifle, either a Title I gun or a Title II Short Barreled Rifle you must comply with 922(r) and make certain you have the appropriate number of United States manufactured parts in your build. You can have no more than 10 imported parts. The appropriate parts may be obtained from several dealers, and some are listed at the end of this article in the “sources” section. If you are building this as a pistol, 922(r) does not apply and end caps are available to replace the rear stock for your pistol build directly from LSC.

In the Beginning…

Since we are building a firearm we need the ability to manufacture the previously mentioned receiver. With the earlier examples (Sten, AK47, M11, etc.) this starts with either a steel tube for rounded receiver guns, or a flat stamped out piece of metal that is folded and welded in a way that it will resemble an original receiver. They are not uncomplicated because everything has to fit to a specific tolerance but they are usually strait forward with 90º bends. Because this build is for an MP5-type gun, the receiver is almost a combination of a tube and a flat due to the bolt design and numerous bends necessary to accommodate the firing mechanism. Actually “making” this receiver used to take much more machinery than found in the average enthusiasts workshop. Enter LSC Manufacturing.

LSC Manufacturing is a small company with old-fashioned values, an eye for detail and they pride themselves on their customer service. Throughout this build project we needed to contact LSC several times to coordinate shipments and update progress. They were always available and happy to assist us at every turn. Their goal is to bring back OEM specifications to the HK build community and from the experience we have gained thus far, they are well on their way. LSC Manufacturing has several new products in many different phases and we will be watching for their introductions as they are announced.

Much to the delight of the “build it yourself” firearms enthusiasts, LSC Manufacturing debuted their BATFE approved “non-gun” receiver flats at SAR Show West, on December 5, 2008. These U.S. made flats incorporate a clamshell design where many of the critical and difficult bends are already incorporated in the flat. When it is lined up properly on a special jig and bent in a shop press, it can be welded to form the general receiver section. There is plenty of work to do even after this has been bent and welded but it starts to take shape fast, in a way that was once reserved only for those far beyond the “hobby builder” category.

A major feature that sets the LSC Flat apart from many other “flat build” projects, and makes a difficult build like an MP5 type firearm possible, is the LSC flat is preformed with the magazine-well and spine, as well as all surface areas surrounding the bolt carrier once properly folded and welded.

There are several steps involved to build a functioning firearm from its non-gun flat state, but due to the quality and pre-planning in the flat, it is a project in reach for many of us. In addition to the actual bending and welding of the flat itself, there are several parts that must be drilled, cut, precision fit and/or welded in place. All the small parts are supplied with the receiver flat as a “weld up kit” and include the shelf block for use with a semiautomatic trigger group, the case deflector, the rear stock bushing, the small, flat scope mounting piece for the top of the receiver, the rear site base, and the sling clip.

Out with the Old

A key component we have yet to mention is something that is absolutely essential to assembling your own rifle. You need a demilled MP5 parts kit to assemble on and around your new receiver. These can be obtained from many sources or you can purchase one directly from LSC, starting at $1,500 or so depending on the configuration and condition. You can get some necessary parts from www.HKSpecialist.net as well. Other places you can check are ad boards from popular Class III enthusiast websites like www.SubGuns.com and www.Sturmgewehr.com. A Class III dealer may enjoy getting some value from old dealer samples no longer being used in demonstrations or upon surrendering the license. They may have more value to someone as a parts kit once properly demilled than as a post 1986 dealer sample machine gun.

Once you get your parts kit it will be necessary to further disassemble it and prep the parts for use in your new build. This can be a painstakingly time consuming project because you want the parts to be in as good a condition as possible.

First, remove every part that will be needed for the new gun that only requires a simple detail disassembly. This would include all stocks and stock pins, bolt and carrier, cocking lever and pusher, bayonet lug cover, front and rear sights, trigger group and housing, selector, magazine release, etc. Clean, degrease and clean all these parts and put them in a big zip-loc bag or box and label them for new build.

The parts you can reuse from the receiver pieces you have left are the barreled trunnion, the cocking tube, and the rear sight base. These can be removed with a Dremel tool or with air tools by cleanly removing the factory welds. Extreme patience and caution should be used when removing them so you do not remove material from the parts you wish to reuse. Refer to the photos accompanying this article to see how we removed them.

An important note when prepping parts for the build involves the fully automatic fire control group (FCG) if one came with your parts kit, and if you are or are not going to need it. Once you bend and weld the receiver, being in possession of the fully automatic FCG can create legal constructive possession problems. If you plan to modify the original FCG to be used in the semiautomatic build we will address it later in this article.

On a final note in dealing with the original parts kit, when you are disassembling your demilled parts kit it is an ideal time to check the condition of all the parts. Look for anything that may have been cracked, broken or worn out. These parts can be changed out at the time of the new build and lessen the chance of having an unsafe condition with your new build. It can also lessen troubleshooting headaches if the new build is completed but does not perform to your expectations.

It is also a good time to check the headspace of the working relationship between the original bolt, locking piece, rollers and trunnion. The head-spacing can be checked with standard feeler gauges. Since you are going to be using and installing the same parts, and the optimal positioning for these parts will be in the same position with the same relationship once welded in your new receiver, you “should” find the same reading once you are done. To check the head-spacing with the demilled parts kit, with the bolt locked fully closed into the trunnion, you want to measure the space between the bolt and the bolt carrier. It is easy to check this relationship with a huge chunk of receiver missing or even peeled back from the old demilled receiver. When it is reassembled in your new receiver it is also easy to see this parts relationship from inside the mag-well, looking down from the top. With the bolt and carrier locked fully into battery inside the trunnion, the “gap” between the rear of the bolt and the front of the carrier should ideally be between .25mm (.010 inch) and .45mm (.018 inch). If it is outside those parameters it can be adjusted by replacing the rollers with either oversized or undersized rollers. Standard rollers are 8.0mm and can be purchased from 7.92mm to 8.04mm with an adjustment range of +.04mm to -.08mm so you have a fairly wide spectrum to choose from to obtain the proper headspace.

Modification of Original Parts

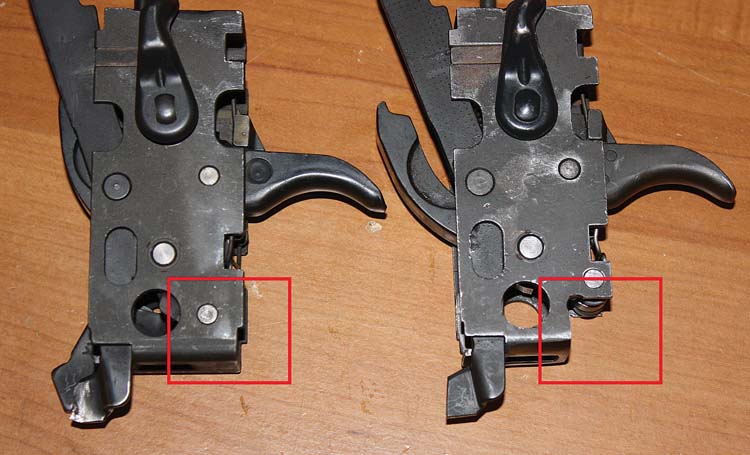

At the time of your build you will need a semiautomatic FCG to use with your finished product. Neither is it legal to install it in the semiautomatic build, nor will it actually even fit once the shelf is welded into the receiver. If you do not have a semiautomatic FCG you can modify a factory fully automatic FCG with a few more steps. We already had several semiautomatic FCGs to use from past projects so we didn’t get into the modification procedure but the directions are available from LSC on their website. If you do have a properly modified or semiautomatic FCG it is best to just discard the one that came with the demilled kit. Any Title II manufacturer will be happy to take it off your hands or someone with a registered “push-pin” machine gun may be able to use it.

Even if you have a semiautomatic FCG you may wish to use a factory fully automatic grip frame for aesthetics. It is not a violation to have a grip frame marked with the fully automatic (or burst) position and will look much more like a factory MP5 if that is the look you are after. To use the frame supplied with your parts kit, or any other factory fully automatic frame it will need to be modified. Since factory grip frames are attached with a pushpin and the semiautomatic version uses a shelf with no hole for attachment, it will not simply slip on.

The shelf used on the semiautomatic is wider than the space available between the pushpin ears. To put it plainly, it won’t fit. The fast and easy way to resolve this issue is to simply cut the ears for use with the original pushpins right off. You can use a Dremel or even use a hacksaw to remove the ears and finish it up with a fine sanding bit, stone or file. If you want that “original” look, you have the option to measure the width of the new shelf and remove some material inside the ears to the fit over it. That is the direction we chose. If you want an even more realistic look and not have two empty holes in the ears you can cut off the ends of the original push-pin and glue one on each side giving the look of the pin being inserted.

The next change you will need to make to the original grip frame is to remove some material so it will slide over the new shelf and hold the frame and trigger pack in place. The original packs have a steel plate in the front that will not allow it to be used on a gun with a shelf. You will need to open the slot in this plate to allow it to slide over the new shelf. Since there are several builders of semiautomatic versions of these guns and have been making and converting them for many years, we have seen a few different methods relating to the attachment of the grip frame and the proper indexing of the trigger pack. We will leave the style you want to use to your discretion. Some manufacturers will modify the trigger pack so it actually sits on the new shelf inside the grip frame. This is done by removing a little extra material from the front of the grip frame, allowing the shelf to ride tightly under the trigger pack. In this case the critical dimension is the height of the cut on the trigger pack, as it will relate directly to the height of the shelf. The other method we often see is where the grip frame is cut to a precise height to rest directly on the shelf and a little extra material can be taken off the trigger pack since it never contacts the shelf directly. For this build we cut them both as even as possible to rest tightly on the shelf and it works fine.

In With the New

The first thing we did was mark the receiver. Small Arms Research uses a 3-axis CNC Engraver and it is much easier to clamp and engrave a flat surface than one with multiple contours such as an MP5. Regardless of the marking method you choose, this is the best time to mark the receiver with the least amount of trouble.

When you order your LSC receiver flat you will receive the “weld up kit.” It will provide you with a new rear sight base, which will save some prep time and the shelf for the semiautomatic trigger pack. You will also need the scope mounting piece, case deflector and rear stock bushing.

In order to effectively bend your receiver flat to the proper shape we would strongly recommend contacting Flat Solutions to purchase their bending jig. It is a simple and effective mechanism and we used it with ease. Those of you who are a little more adventurous than this writer may be able to fashion a jig yourself but since one was available we didn’t tempt fate any more than we needed to.

The receiver flat is provided with an “ear” at each end to drop over a guide rod and help it to stay centered while bending. A steel ramrod dowel also slides over these alignment pins after the receiver flat is inserted. This is the surface that will be pushing directly on the receiver flat and forcing it down into the jig.

Two ram legs are inserted into the ramrod and the main ram is inserted over the legs. The shop press pushes directly on this main ram and this ensures that pressure is exerted equally. As soon as you start putting pressure on it the receiver flat will start taking shape and if one end is curling up much faster than the other the jig can be repositioned in the press to distribute the pressure equally.

Pressure is slowly increased until the receiver sides are bent up and touching. If they are not lining up even it is easy to tweak it by gently “rolling” it in the press a tiny bit to help increase the lift on the slow side. When they are all touching and lined up, the front push rod will be inside the newly formed magazine-well and the rear will be inside the rear of the receiver in front of the rear stock attachment point where you will later weld in the takedown pin.

At this point we removed the receiver from the jig and clamped it together. We checked to make certain everything was true by sliding the bolt carrier through it, making sure it slid freely without hanging up on anything. At this time you can also check the fit of your rear stock after snipping the guide ear at the rear. The front guide ear may also be snipped off at this point. A small file will smooth the surface on both ends.

After clamping and testing the shape of the receiver we slowly started the welding process to completely close the flat and attach it at all points. Several times during this process we stopped to recheck the fit of the bolt carrier to make sure it moved freely. We had no problem with it at this point so everything was smooth but if you do have any issues where it is snug, the easiest time to tweak the receiver is before it is fully bent and welded for obvious reasons. To this point, if we could recommend anything to Flat Solutions to make the build easier it would be the addition of a mandrel that mimics the shape of the bolt carrier, but much longer and heavier. This would allow the manufacturer a tool to use for checking the inside diameter without the extra wear and tear on the original bolt carrier. If it were heavy enough it would also serve to assist in tweaking the receiver in the early stages of the build, and possibly even help to “form fit” the welded receiver should a small alignment issue arise.

After welding the receiver we needed to add the shelf to hold the new FCG. The placement of the shelf requires a precise measurement where it covers the area that the hole for the original push-pin would be on an original submachine gun. After giving it some deep thought we simply fitted the shelf to the proper fit inside the grip frame with the trigger pack inside and held it up to the receiver so it fit snug and flush with the receiver using the rear stock takedown pin hole for alignment. We marked the proper location for the shelf and proceeded to make a small tack weld after squaring it up. At this point we slid the grip frame and trigger pack over the shelf and slid the stock over it to make sure everything fit correctly before completely welding it in place. This method proved to work fine in our build project.

The next step was to weld in the case deflector that came with the LSC weld-up kit. It is placed inside the receiver and flushed to the top of the squared slot directly to the rear of the ejection port. While it may be welded in at an earlier time in the build we chose to do it at this time. Two small plug weld holes were drilled in the receiver to weld the deflector in place and it was permanently attached. At this point we checked the internal fit once again for free movement of the bolt carrier and found it to be a little tight. We used some marking ink on the bolt carrier to see where it was dragging and used a fine stone on a long shaft to gently smooth out the interior of the receiver.

We were ready to fit the barreled trunnion at this point. We drilled four plug weld holes in the receiver to weld in the trunnion. We made sure to choose different locations from the original welds on the factory demilled parts kit we removed it from. The front alignment ear was also snipped from the top of the receiver and the area smoothed up where the cocking tube would be inserted. Much to our delight the trunnion and cocking tube both slipped in and fit tight and snug. The alignment of the trunnion before welding it in place is very important to ensure proper function. Placement can easily be checked by making certain the barrel pin is aligned perfectly with the pre-cut holes in the receiver. Since we were using a barreled trunnion with the front sight post attached, we inserted the cocking tube in the receiver and also slid the trunnion into the receiver while sliding the point it is inserted into its position in the front sight mechanism at the same time. To ensure proper alignment of the cocking tube since it is a much smaller diameter than the corresponding hole below the front sight we turned down a steel dowel on a lathe to act as an alignment pin. The small end of the dowel fit snugly inside the cocking tube and the large end fit snugly inside the tube it corresponds with; perfectly centered. With the alignment pin in place the cocking tube was welded to the receiver followed by the trunnion. Once again everything was checked for alignment. At this point it is important to remember to insert the cocking handle and linkage before dropping the bolt and carrier into the receiver in case the roller lock mechanism on the bolt drops into the trunnion.

After ensuring proper alignment once again, the rear stock bushing was centered and welded into place, followed by the rear sight base and the small flat scope-mounting piece.

This would conclude the welding. The last step would be opening up the section of the receiver to accept the magazine release and installing the components. The receiver flat is partially pre-cut in this area but must be finished to fit. To ensure we had the proper placement of the mag-catch we brought several plastic “snap caps” to cycle through the feeding mechanism so we would know the magazine locked in at precisely the right height in relation to the bolt. Most people reading this magazine are aware of the headaches that can be caused when a magazine doesn’t fit just right and lock in at the right height. If the magazine is too high it can drag on the bolt creating cycling and feeding problems. If the magazine locks in too low it can have serious feeding problems. Both issues can create a situation where factory magazines must be altered to work properly and that is frustrating and time consuming to deal with. After several light cuts with a small file, the mag-catch was installed and it was time for the real test, live fire.

Off to the Range

After picking up the workshop and triple-checking everything again, the gun was cleaned of any debris and lightly lubricated. The remaining parts were installed and the furniture and sights were mounted. Everything cycled well and felt great but it was time for the true test of the project. Immediately upon arriving at the Small Arms Research Test Facility we loaded several magazines with numerous types of ammo and hung a test target. We started the live fire testing by loading a single round into a magazine. With great anticipation the trigger was squeezed and: BANG!

The gun was examined, the brass casing was collected and evaluated, and the target was inspected. The casing looked fine and the target had a clean, single hole just above the bulls-eye. So far, so good. This was repeated for several rounds with the same results when we started loading two rounds in the magazine. Most guns can fire a single round and still have serious problems, and even though we were delighted it was feeding the single round from the magazine and ejecting it correctly, the real test would come in repeated firing as it was designed and built to do.

The magazines, each with two rounds, were lined up on the bench and we inserted the first of them. The opened bolt was slammed shut and the first round was fired. With almost the same anticipation as the first shot, the trigger was slowly squeezed and BANG! It feeds, fires, ejects and feeds again. Now were getting confident that it was built correctly and the painstaking time we took to do things slowly and methodically was going to pay off. The range session ended with firing full magazines of several types of ammo without a stoppage, hiccup or failure of any kind.

What’s Next?

The gun was brought back to the shop and completely disassembled and inspected again. After finding no areas of wear or stress it was cleaned up, given a coat of flat black paint to protect the steel surfaces and it was time to choose a final finish. Since it was a complete “ground-up” custom build, a traditional finish was ruled out. We were building it to show that it (hopefully) could be done, not by professional gun builders, but by reasonably knowledgeable individuals (RKIs) with some basic skills. Since the thought of actually building an MP5 type gun from a receiver flat was so far from what used to be possible by people in our skill set, it was decided to try a new finishing process as well. It wasn’t a “normal” MP5 so a normal finish just wouldn’t do.

After doing a lot of research, we found a company in Florida (Hydro Print Services) specializing in Hydrographic printing, also known loosely as a “water dip finish.” Even though this is a time proven process, it is finally becoming available to single piece end users and no longer reserved for only huge runs by major manufacturers. That fits the theme of this build just fine.

In general terms the process works like this: Your gun (or knife or magazine or silencer, etc.) is cleaned and prepped and sprayed with a thin coat of base primer. As it is getting to the end of its drying cycle, your chosen finish pattern is cut to the proper size and actually laid to float on the surface of a water bath. The film is sprayed with an activator to dissolve the film and leave just the pattern material floating. The gun is immediately submerged in the water, right through the pattern, then immediately removed. After a quick wash to get rid of any residue, the gun is sprayed with a special urethane coating to protect the finish and it’s done.

The beauty of this finish is that it lends itself well to surfaces with numerous shapes, folds and bends, even compound curves as the floating pattern actually bonds to every surface evenly and flows around the intricate surfaces in places where a normal finish could never reach. The other real bonus is that it will adhere equally well to numerous types of materials as shown on our test piece where we had the finish applied to the gun, the plastic furniture, some magazines and even an old 3-lug silencer we have had for years. When it returned from the printing service we couldn’t have been more pleased with the end result and reasonable pricing.

There are several patterns available (over 300 at the time of this writing) to have for your final finish and while some are in the “traditional” category, some are WAY outside the box. These patterns look like they have a real 3-dimensional finish and the detail is amazing. This gun has been accused of being airbrushed by numerous people not yet familiar with the Hydrographic Printing process. That’s quite a complement to the detail and finish. Though there are several available patterns, I decided to let my 7-year old son pick out the one we would use on this gun, so it was done in “Reaper Black”, a pattern that looks like an urban snow camo from a distance, but actually numerous, highly detailed grey skulls on a black background. We wanted unique, and that’s exactly what we have. Patterns can be found online at the address following this article in the sources section.

With any finish, the single factor as important as what it looks like from the finisher is the durability it has. We are pleased to say that thus far (about a month of banging around in the safe) we have put almost 1,000-rounds through it and it has been taken apart and cleaned and lubricated 3 times with no degradation of the finish in any visible areas and not even any noticeable wear on the magazines where they are inserted and locked in over and over. It’s far from a long-term test, but so far it is very promising.

Observations and Conclusions

This was one heck of a project from start to finish. If we had been thinking, we would have had a stopwatch running for the entire build but it was an afterthought. Loosely keeping track of time, two of us spent approximately 16 hours between stripping and prepping the demilled parts gun for parts and bending, welding and fitting the new flat to a firing state. Some of this time was spent in shop set-up and some was spent in building the alignment dowel pin we created for aligning the cocking tube and barreled trunnion for welding. It was done slowly and methodically since it was a first-time build for both of us with few real written directions to go by. Many phases of the project were viewed by four eyes when only two were really necessary in hindsight. We also took longer than usual to document the build for publication, making notes and snapping photos in most phases. If we decided to build a few more we believe we could cut the overall prep and build time almost in half on any subsequent builds because we know the build order and could each strike off prepping and working on separate phases of the build at the same time.

The work is quite strait forward and the more familiar the builder is with the host family weapon the easier it will be. The learning curve drops fast when the parts relationship is already known. It may take someone who does not have much time on the MP5 platform a little longer. Since we used a semiautomatic fire control group we already had available, you can plan on spending a few more hours in converting the factory FCG for semiautomatic use if you choose that direction. Also, since this writer is an 07/SOT we didn’t have any wait time for approval in the SBR build, nor did we have to permanently pin a barrel extension to achieve the 16+-inch barrel length necessary to meet the Title I firearm criteria.

The end result is certainly something to be excited about. This single build has shown us that properly built, it functions on par with any of the numerous factory German guns this writer has had the pleasure to own and it is incredibly accurate. All who have had the chance to fire it, some with a great amount of time on the MP5 family of firearms, have commented on its accuracy and are surprised at the entire project. The flat and parts from LSC worked great and nothing was misrepresented at any level. Their staff was helpful in all questions. At a retail price of $199.95 for the flat and the weld-up kit we believe there will be several additional “to do” lists for our fellow RKIs in the coming months.

Tools of the Trade

This build isn’t a “no tools necessary assembly project” and we don’t want anyone caught by surprise. Here is a list of the tools needed to complete this build.

- Drill press (& drills)

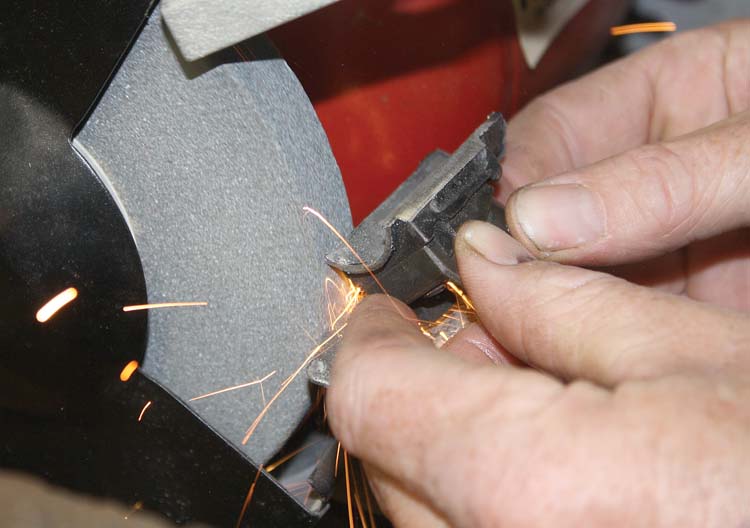

- Dremel Tool (and cutoff wheels, stones, sanders, etc.)

- Calipers

- C-Clamps (several and assorted sizes)

- Vice grips

- 6-inch vise

- 12-ton shop press

- TIG welder

- Tin snips

- Belt sander

- Aluminum barrel blocks for vice

- Large flat file

- Assortment of needle files

- Air compressor (and cut off wheel, air gun, grinding stones and wheels, etc.)

- Machinist (or felt tip) marker

- Hack saw with fine metal blade

- Hammers, punches, screw drivers, etc.

Sources

MP5 Flats & Parts Kits

LSC Manufacturing, LLC.

P.O. Box 521 Pacific Palisades, CA 90272

Ph: (310) 699-9150

Email: info@LSCManufacturing.com

www.LSCManufacturing.com

Parts Kits

www.HKSpecialist.net

www.Subguns.com

www.Sturmgewehr.com

Flat Bending Jig

Flat Solutions

Flatsolutions@yahoo.com

Hydro Print Finishes

Hydro Print Services

5400 Park Blvd.

Pinellas Park, FL 33781

Ph: (727) 544-7935

www.HydroPrintServices.com

| This article first appeared in Small Arms Review V14N8 (May 2011) |