By Robert Bruce

(Editor’s Note: SAR is taking a different approach this year in presenting coverage of the National Defense Industrial Association’s annual Joint Services Small Arms Systems Symposium. This prestigious gathering of top names in weaponry from industry, government, military, and law enforcement offers up so much information and hardware that an entire issue would be required to do it justice.

Military Affairs Correspondent Robert Bruce’s assignment was to find and report on what’s new and exciting then shoot as many photos as possible covering all aspects of the event. The pictures appearing here have been carefully selected from more than 160 submitted.)

“Achieving a secure environment for the American people requires a strong resolve in the diplomatic arena and a stronger fortitude to back it up. Facing terrorist forces from MOUT to the open battlefield, American forces, both military and law enforcement alike, require the best equipment available. Only through the efforts of government and industry focusing together on the immediate needs of current operations and ‘lessons learned’ and applying the emerging advanced technology and system integration approaches will the tools necessary to support our warriors now and in the future will be realized.” Objective Statement – NDIA Joint Services Small Arms Systems 2007 Annual Symposium, Exhibition and Firing Demonstration

It’s all here for “warriors now and in the future.” NDIA Small Arms Systems is once again hosting what is arguably the most exciting, most exclusive and most important annual gathering for those whose purpose in professional life is to arm the free world’s defenders with the best that men can build and money can buy. Technical presentations, hardware exhibits and thundering live fire demonstrations are jam-packed into three days at the Virginia Beach Convention Center and on the ranges at Blackwater USA.

Symposium Schoolhouse

Formal presentations are essential to the event, providing an opportunity for hundreds of attendees to get the latest information on major government initiatives, military want lists and industry solutions.

Briefings by members of the Joint Services Small Arms Synchronization Team were perfectly scheduled to kick off the first day’s symposium. JSSAT’s mission is to harmonize as much as possible the often divergent needs of all five branches of the US Armed Forces as well as Special Operations Command.

When these men talk, everyone listens closely. Some even rush outside to call the office with breaking news.

We learned that the Army still officially loves the M4 carbine, further dampening the hopes of advocates of piston-driven upper kits, SCARs, XM8s and such. Big Army is well along in improving reliability of the M249 SAW, lightening the M240, moving toward a QCB M2HB, and has been directed by Congress to “green” its ammo. This presumably so that the environment outside enemy bodies will not be contaminated by lead.

Oh, and it may field a better handgun and/or Personal Defense Weapon in the next few years. For more on this go right to the USAF section. The Navy is phasing out obsolete M14s in favor of more M16s, as well as sometimes troublesome Miniguns in favor of twin-mounted M240s. The crunch in full scale range real estate is driving a move to use of more electronic simulators, supplemented by live fire training on shorter ranges with reduced-power ammo.

Its partner, the Marine Corps, is leading the charge toward an Infantry Automatic Rifle, lighter than the current M249 SAW and holding the line until LSAT (see sidebar) is fielded. The Corps, considered by many to be the most serious about cutting red tape to put good stuff in the hands of grunts, is also looking for new Long Range Sniper weapons and solutions to “emerging requirements TBA.”

Alternative caliber and weapon advocates leaned way forward to catch each word about the Leatherneck leadership’s plans to “evaluate alternatives to 5.56mm ammunition and weapons.”

Don’t make the mistake of looking at the Coast Guard as harbor cops. Coasties are America’s first line of defense against seaborne terrorism at home and many places abroad. Armament upgrades continue, most notably in transition to new .50 cal Barretts and 7.62mm MK11s from Knight’s. They don’t need a new handgun because almost all their puny 9mm Berettas are overboard now, replaced by hard-hitting .40 S&W SIGs.

Airmen are directly involved in more ground combat than ever before. USAF Security Forces are growing by leaps and bounds in weapon requirements and quantities, filled mostly by Army standard hardware like M16 rifles, M240 machine guns and M9 pistols. However, the AF apparently takes sidearms seriously and now has the lead in the search for JSSAP’s on-again, off-again Future Handgun program.

Colonel Charles Beck explained that the program is funded and underway now, looking for an off-the-shelf pistol chambered for a “readily available military cartridge” that is “non-expanding” but yielding a “wound channel increase.” So, the race is on again for all those hopeful manufacturers who had lined up last year for the USSOCOM trials that never happened.

SAR’s readers can sit in free at this and other notable presentations by accessing proceedings on Defense Technical Information Center’s website at www.dtic.mil/ndia/2007smallarms/2007smallarms.html where slides from most of the briefings are posted.

All are organized in chronological order and grouped by specific themes including Individual Weapons, Ammunition, Joint Services Small Arms Program (JSSAP) Update, Activities in NATO, Crew Served Weapons, Modeling and Simulation, as well as Less Than Lethal Systems.

Exhibits

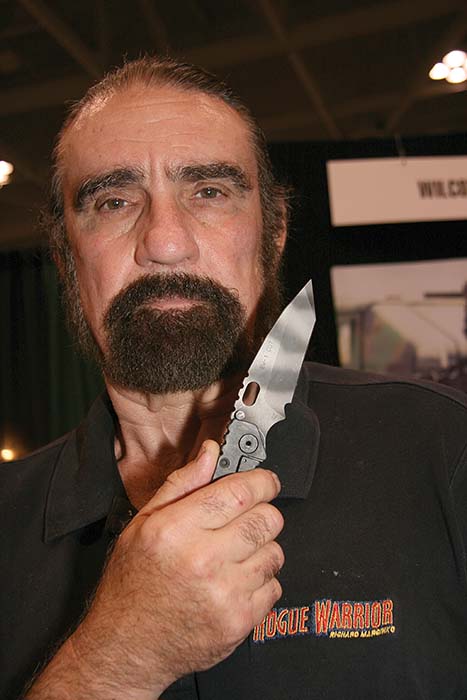

The opportunity to pick up and examine cutting edge hardware is essential to the conference mix and more than 80 exhibitors were on hand with the latest in guns, gear and ammo. In stark contrast to the more commercial trade shows, NDIA Small Arms is where attendees will most often find the men and women who are directly responsible for creating what’s on display.

Curious about the new barrel coupling system for the Army’s new M110 Semiauto Sniper Rifle? Talk to Dave Lutz at the Knight’s Armament booth. Tantalized by just a sneak peek at Magpul’s Masada rifle at SHOT? Rich Fitzpatrick and Drake Clark were giving muzzle to butt plate tours.

What’s with that trailer toting a big and heavily armored weapons station replicating that of a US Navy warship? Special Tactical Services’ Jerry Hurd will explain how the firm supplies full spectrum training and innovative hardware support for maritime and ground combat operations.

How about the latest hardware in use by Navy SEALs and others in Special Operations Command? Talk to NAVSEA Crane’s Barry Gatewood about Miniature Day/Night Sight developments or Jason Davis about on-weapon Shot Counters.

Customary exhibits from ARDEC/JSSAP/PM Soldier Weapons, collectively the 800 pound gorilla of small arms development and fielding, were conspicuously absent this year. A spokesperson explained that budgets are tight right now so money is better spent in direct support of war fighters – a decision that we understand and endorse.

Not to worry, much of what would have been in the Army’s display could be found elsewhere in the large hall. Some examples include HK with the XM320 grenade launcher, General Dynamics with the QCB (Quick Change Barrel) M2E2 and convertible XM312/XM307 .50 cal./25mm machine gun, and show star LSAT at the AAI booth.

Range Day

After two and a half days of formal presentations and exhibit hall booth hopping, the opportunity to get out on the range is essential to maintain a real world perspective. Sal Fanelli, NDIA SA’s perennial volunteer Rangemeister, now with USMC Program Manager Infantry Weapons, was ably assisted this year by Jim Schatz, the long term HK veteran now enjoying his role in semiretirement as an independent industry consultant and Small Arms Review contributor.

(Robert Bruce)

With all military ranges in the greater Virginia Beach area fully booked with intensive GWOT training, Fanelli was fortunate to secure permission from Blackwater USA to utilize three of the dozens of ranges on its sprawling 6,000 acre complex, an hour’s drive south in Moyoc, North Carolina.

A notable downside of this arrangement was Blackwater’s necessarily strict OPSEC (operational security) rules that protect the identities of employees and trainees, many of whom are part of ultra-sensitive domestic and overseas operations. Most prominent was the near total ban on photography and all attendees got a stern warning to leave their cameras on the bus.

(Editor’s Note: SAR sends Fanelli a big thanks for certifying Military Affairs Editor Robert Bruce as NDIA’s “official range photographer” and to Blackwater’s Allen Livingstone for turning him loose on site with confidence in his promise to carefully avoid showing details of facilities and identities of non-NDIA personnel.)

Again by special arrangement, SAR got there early to observe industry teams as they prepared for the afternoon’s live fire demonstrations. This is invaluable for close-up photography of significant hardware in a way that doesn’t block spectator viewing and an extended period of relatively low stress to talk with the shooters.

Extended coverage of JSSAP’s LSAT is a prominent example for these reasons, providing ample time to discuss the finer points of the system’s experimental weapon and ammunition with AAI’s team leader Paul Shipley and his crew. Then, observing within an arms length the test firing for function and zero.

Other teams from FN, Knights, HK, Milkor, Colt, and the like were spread out along Range 5’s 30 meters of firing line, popping away with modular assault weapons, PDWs, and grenade launchers (sorry, dye marker rounds only).

On Range 4 next door, Remington’s Greg Baradat rehearsed door breaching with a stubby 870 MCS shotgun, and TDI’s Tim Lindsay conducted an invitation-only VIP demo for the KRISS submachine gun. Glock’s team searched the gravel in vain for an extractor lost from its crowd-pleasing Model 18 selective fire machine pistol. No problem, plenty of other Glock’s to show and shoot.

With a hour or so before arrival of the main body of event attendees, we took a somewhat leisurely stroll up the road about half a mile to Range 19. This is a KD (Known Distance) range with a 1,200 yard limit and suitable safety fan so the event’s sniper rifles and heavy machine guns could be accommodated.

This provided a look at a half dozen of Blackwater’s various specialized live fire training stations including multi-weapon CQB, an elaborate MOUT complex and K-9 facility.

All were bustling with activity and plenty of lead was flying. No comment on what organizations the trainees represented, but George Orwell’s oft-quoted observation comes to mind that, “People sleep peaceably in their beds at night only because rough men stand ready to do violence on their behalf.” Amen.

Arriving at the KD range we found Armalite’s Mark Westrom zeroing his Super SASS while some other guy was mounting a mean looking .50 cal. atop a camo painted honest-to-goodness GI HMMWV (not a silly civilian HUMMER) incongruously sporting Wisconsin license plates.

Turned out to be Ed Haywood, creator of Central Wisconsin Armory’s formidable new Dragon M50 high rate of fire machine gun, characterized by modifications allowing the gunner to select open or closed bolt operation utilizing the spade grips. This burly former Navy Gunners Mate had made the very long trip to Virginia in his personal war-surplus HMMWV, no small feat of endurance for man and machine.

Back at the main area chartered buses had deposited hordes of event attendees who, after a catered lunch, were gathering around at Range 4 for the handgun, submachine gun and shotgun demonstrations.

When the time came to move one range over, Jim Owens of FNH USA set the tone for several of the subsequent industry presentations by doing a quick briefing on the SCAR family of weapons but deferring live fire to later. The show, tell and sometimes shoot moved down the line in roughly five minute increments, ending with HK Defense’s Wayne Weber inflicting the always crowd-pleasing full immersion water and sand torture on an unstoppable HK 416.

Then the smorgasbord of small arms opened for business with attendees lining up behind their favorites for live fire action. Bragging rights aplenty come with hands-on time with exciting new and unusual weaponry like the 7.62mm FN SCAR Heavy, TSSI’s shoot-from-cover ParaScope, and Karl Lewis’ 40mm M203 pistol. Life doesn’t get much better than this with free ammo, expert coaching and somebody else has to clean the range and the weapons afterward.

Particularly noteworthy this year was the absence of any heartbreaking mechanical failures or heart-stopping safety violations by demonstrators or others. No rounds fired directly skyward, no commando rolls with loaded weapons and no recalcitrant robots. A big round of applause, please.

NDIA’s Joint Services Small Arms Systems

SAR strongly supports the work of the National Defense Industrial Association, readily accessed on the web at www.ndia.org. Make plans now to be at the 2008 Small Arms event in Atlantic City, New Jersey, May 12 to 15. The customary live fire demonstrations will be held at nearby Fort Dix and are likely to include some of JSSAP’s most interesting cutting edge hardware. Industry demonstrators will, no doubt, keep in mind draconian restrictions on transport of weapons and ammunition imposed in the Peoples Republic of New Jersey. Good luck guys!

Lightweight Small Arms Technologies (LSAT)

SAR Spotlight by Robert Bruce

SAR’s intense and sustained interest in the Joint Services Small Arms Program’s LSAT initiative was once again handsomely rewarded as government/industry team leaders Kori Spiegel and Paul Shipley charted a number of significant developments since last year’s presentation to this NDIA symposium.

While all combat infantrymen are overburdened, the problem tends to be particularly acute for SAW gunners in Army and Marine rifle squads. In addition to standard body armor, water, rations, and gear, these men carry a 17.5 pound M249 with 200 rounds of linked 5.56mm ammo (6.5 lbs.) and two extra 200 round bandoleers (13 lbs.).

While the SAW’s firepower is critical in many combat scenarios, the system’s weight has a decidedly detrimental effect on the speed and endurance of most gunners who carry it.

However, it will require something approaching a 50% reduction in combined weapon and ammo weight before the SAW gunner will have mobility on a par with his brother riflemen. How close to this ambitious goal can they get without sacrificing this essential weapon’s firepower, range and lethality?

While a definitive answer is several years away, parallel experimentation with both cased and caseless ammunition is progressing well, JSSAP’s Spiegel explained, and a prototype weapon, firing plastic cased telescoped 5.56mm ammunition, has been demonstrated in both laboratory and field firing.

The experimental demonstration weapon and its rapidly evolving ammunition were working so well in fact, that program officials were taking the calculated risk of conducting the system’s first “public” live fire demonstration at this event.

Traveling to Blackwater USA early Thursday morning in advance of the scheduled industry demonstrations, we caught up with LSAT industry team coordinator Paul Shipley of AAI and crewmembers Dennis Trump and Tim Livelsberger on Range 5. This was the perfect time to take a close look and get some photos of the weapon and ammunition.

The prototype light machine gun they brought was tried-and-true Serial Number 1, which has fired more than 3,000 rounds so far, starting with the initial “Spiral 1” cased telescoped ammo and has recently been converted to fire the reduced size “Spiral 2” cartridge.

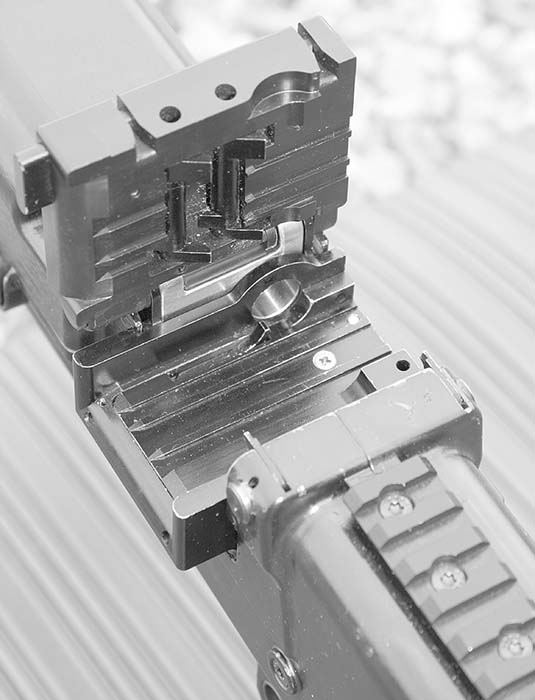

Its gas piston driven operating system has a cartridge rammer instead of a bolt and features a highly unusual oscillating chamber with push-through feed and ejection. While this is called a “rotating chamber” in program documentation, it doesn’t spin, but moves back and forth in an arc of approximately 90 degrees.

Program officials are understandably wary of disclosing too much technical detail, but official promotional/informational materials include simplified diagrams and evocative wording that might guide a reasonably knowledgeable person to informed speculation as follows.

Think of a clock face with the chamber (viewed from the rear of the weapon) at rest in the 12 o’clock position and the barrel waiting at 9 o’clock. The gunner cocks the action by pulling back on a charging handle and a spring loaded rammer is poised to push the first round forward into an empty chamber.

M249 SAW gunners know this as “open bolt” operation, essential “thermal management” to avoid problematic cookoffs.

Pulling the trigger releases the rammer to chamber a cartridge and this releases the chamber mechanism to rotate counter-clockwise down to the 9 o’clock position where it locks in line with the barrel. A conventional firing pin is released to initiate the primer, igniting the propellant powder. The plastic case is fully contained and supported in the cylindrical chamber so chamber pressure and resultant muzzle velocity equate that of conventional systems.

As the bullet passes the gas port inside the barrel some of the follow-on propellant gas is vented downward into an expansion tube where it meets the head of the piston. Kicked rearward, it causes the chamber mechanism to unlock and swing back down with the empty case in line for push-through ejection when the next round is fed.

“Dwell time” – milliseconds delay allowing the cartridge to deflate for ease of extraction – occurs during the chamber’s movement. Links are pushed out of the feedway as each new round moves into position.

In full auto burst fire, the action automatically repeats at a cyclic rate of approximately 650 rpm, similar to that of most conventional belt fed guns.

LSAT Heritage

Those who know about the Advanced Combat Rifle program circa 1990 will recognize some useful mechanical design principles carried forward from the ARES entry. This strikingly configured magazine fed bullpup featured a separate, moving chamber and push through feed and ejection of its lipstick tube polymer cased telescoped 5mm all-tracer cartridges.

The radically new ammo was developed back then in partnership with Olin. It is no coincidence that this famous firm, now known as St. Marks Powder, is now a prominent member of the new LSAT team.

Superior synergy, of course, as ARES is the program partner responsible for the launching platform and currently offers the TARG (Telescoped Ammunition Revolver Gun), a .50 caliber weapon firing caseless ammo from multiple chambers.

Institutional knowledge is invaluable and decades of direct experience plus engineering know-how at ARES and St. Marks – along with the rest of the program’s team – are no doubt saving plenty of time and money.

For example, the layout and lines of the prototype gun are unmistakably influenced by the Stoner-ARES Light Machine Gun, a more conventional 5.56mm SAW featuring a box receiver with in-line buttstock and under barrel piston gas system.

A follow-on inquiry to ARES, answered by Drew Kurtis, their top engineer on the LSAT project, revealed another specific aspect of Gene Stoner’s work on the earlier LMG that has been wisely utilized.

“The recoil scheme Mr. Stoner used in this gun is adapted to the LSAT,” he explained. “Feedback from the people who have fired it…has been extremely positive and feel the weapon is very controllable, especially given the light weight.”

LSAT Muzzle to Buttplate

The Cased Telescoped (CT) Weapon SN1 we observed at Blackwater has a 16.5 inch long smooth (unfluted) rifled steel barrel tipped with a standard GI birdcage flash suppressor/muzzle compensator.

The gas block (an interim configuration, Shipley says) is topped by a dovetail for a front sight if needed, and has what appears to be a conventional expansion chamber surrounding the piston.

The forward end of the receiver has stylishly angled multiple cooling slots on the sides above lengths of MIL STD 1913 rail used to mount various accessories. Another underneath serves as a sturdy anchor for an adjustable bipod. Hard mounting to test fixtures and tripods is facilitated by a pair of tubes attached underneath the receiver.

The pistol grip/trigger housing mechanism is of standard ergonomic design and the left side selector lever moves by downward thumb pressure in an arc with its indicator pointing in turn from SAFE to 1 (semi) and A (automatic).

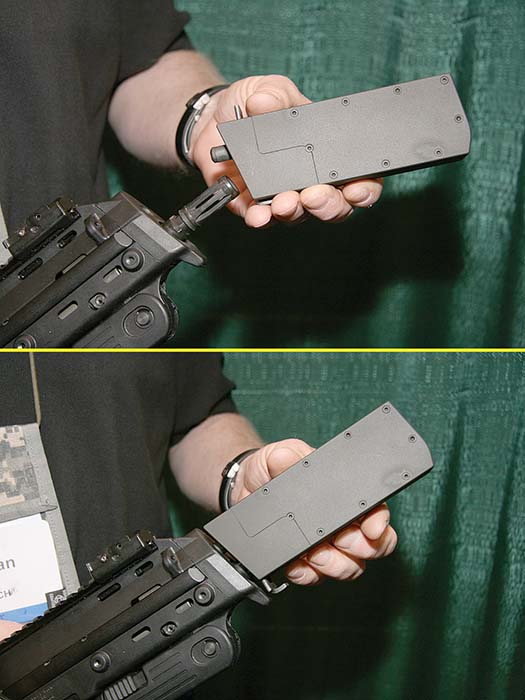

Feeding the plastic linked polymer cartridges takes place on the left side from an assault pouch attached underneath. On top is a hinged feed cover, roughly the size of a cigarette pack, which swings open to reveal a pair of conventional feed pawls that move the belted ammo in line with the chamber.

Ridges on the feedplate and inside of the cover provide low drag support to the ammunition. Stripped links drop out the right side as each round is rammed forward and another moves in line with the chamber.

A charging handle protrudes from its channel on the right side of the receiver, automatically returned to forward position by a coiled spring and guide rod and does not reciprocate on firing. A prominent rectangular port in front of the feedway allows ejection of spent cases as each is automatically pushed forward and out of the chamber by a new round.

Its skeletonized buttstock features a hinged shoulder rest on its butt plate and a good gripping surface up front for the nonfiring hand. It telescopes in the manner of an M4 carbine to adjust for body armor and different sized shooters and body armor.

A length of Picatinny Rail rigidly mounted to the top rear of the gun’s boxy receiver will accept most any type of sight. Trijicon’s Bill Taggart had thoughtfully provided a new piggyback combo sight to use in the demonstration, the company’s entry in the Army’s Rifle Combat Optic Program trials.

Based on extensive USSOCOM use, it features Trijicon’s 4 power ACOG TA31 Rifle Combat Optic fitted with distinctive honeycomb anti-reflective cover and laser filter. On top is a Docter red dot for fast CQB shooting, shielded by protective wings.

Livelsberger quickly clamped the combo’s A.R.M.S. Throw Lever mount in place and proceeded to achieve a suitable zero with just a few single shots. Nothing unusual was observed about the weapon’s muzzle blast sound level, propellant smoke or flash.

CT Ammo

While representative caseless telescoped (CT) ammunition may be seen in LSAT program literature and shown in actual sample cutaways, Shipley was not at liberty to allow detailed photos of the actual “Spiral 2” live rounds on hand for the demo. Agreeing to avoid close shots of the primer end, we were rewarded with the opportunity to photograph from the side and front the translucent polymer tubes with black plastic links.

Most notable are the copper-clad tips of conventional 5.56mm M855 ball projectiles seen behind black plastic end caps that retain and center each one, surrounded by granular propellant in the cylindrical case. Waterproofing has to be problematic but Shipley indicated that a configuration with molded in place end seal is nearing completion.

A ridge on the end cap at its junction with the case serves to position each featherweight and flexible plastic link. The combination is neat, compact and strikingly unusual.

It should be noted that team member St. Marks Powder recently completed development of a special reduced flash propellant tailored for LSAT that will replace the off the shelf powder in ammo used for the demonstration. A laboratory test video shown in the symposium briefing showed a dramatic decrease in muzzle flash in a darkened room.

Live Fire Demo

JSSAP’s LSAT team chief Kori Spiegel arrived and we spoke briefly with her about what she had in mind for the demonstration. She explained that the team was proud of the speed and scope of recent progress and it was time to show peers in military and industry what the system could do.

Ever mindful of “Murphy’s Law,” we asked about calculated risk. This produced a smile and a confident nod. “We’ll see,” she said.

When their turn came during the industry demos, Shipley introduced the weapon and its ammunition to a crowd of NDIA attendees, briefly explaining features, benefits and progress to date. On cue, Livelsberger loaded a forty round belt then took an offhand shooting stance, popping off several semi auto shots before extending the bipod and dropping to prone.

So far, so good. A deft thumb flick moved the selector to AUTO and he began a series of short cadenced bursts, ending in a twenty round sustained fire belt runout. All had been fired without a hiccup, prompting enthusiastic applause from the crowd and probably a considerable amount of relief to the LSAT team.

SAR sends congratulations to JSSAP and its LSAT industry partners AAI, ARES, ATK, Battelle, Omega, and St. Marks Powder for a job well done! And best wishes for success with the many challenges ahead on the long road to fielding in the not-too-distant future.

| This article first appeared in Small Arms Review V11N1 (October 2007) |