By Al Paulson

As the dawn of a new millennium approaches, small-arms designers and military planners around the world are developing new cartridges and individual weapons for the coming century. One of the most thought-provoking concepts for a new military rifle cartridge comes Finland. Viewed by its designer, Juha Hartikka, as the next logical step in the evolution of assault rifle cartridges, the new round incorporates such interesting concepts as a straight case, a standard projectile diameter of between 4 and 5 millimeters, a bore diameter of 9 to 10 mm, and a screaming muzzle velocity of 1,500 to 2,000 meters per second (circa 4,900 to 6,500 fps). This round should be lighter than current assault rifle ammunition and it should be cheaper to produce. The same case design is loaded with a heavy 9-10 mm projectile to produce a subsonic round for use with a sound suppressor. The same barrel would be used for firing both ultra-high velocity 5 mm projectiles as well as subsonic 10 mm projectiles without any modification whatsoever. Furthermore, a rifle designed for this cartridge should be simpler and cheaper to manufacture than a weapon designed for the 5.56x45mm round. Clearly, these are ambitious design goals.

The M/2030 cartridge incorporates some novel and some well-established design concepts. The two key elements to Hartikka’s cartridge design are a countersunk base in the cartridge case and a subcaliber bullet with sabot. Hartikka envisions a remarkably simple and inexpensive weapon for this cartridge that operates from the straight blowback principle. The rifle would fire using two different ignition modes depending upon whether semiautomatic or full-auto fire is selected. The weapon would fire from the closed bolt for semiautomatic fire to optimize single shot accuracy, while it would fire from an unusual open-bolt design for full-auto fire to minimize recoil and shot dispersion. Open-bolt firing would feature advanced ignition within a very long chamber before the bolt reaches battery position for smooth full-auto fire. After discussing each of Hartikka’s cartridge design elements in some detail, we’ll take a look at how the overall cartridge design will impact weapon design.

Cartridge Design

The projectile for the standard ultra-high velocity M/2030 round—which one might term a hypersonic cartridge—looks rather like a plastic 10mm hollow point bullet with a large pointed spike sticking out of the cavity. The spike is manufactured from a hard metal alloy or ceramic, while the surrounding accelerator or sabot is fabricated from plastic. The light weight of the plastic accelerator—combined with the plastic’s low coefficient of friction with the barrel—enables the subcaliber bullet and sabot to reach very high velocity before reaching the muzzle.

Using a discarding sabot is a relatively old concept, dating back at least to the 1940s, when German designers developed a new artillery round called the Peenemunder Pfeilgeschoss (the Peenemunde Arrow Projectile). Modern ultra-high speed, fin-stabilized subcaliber arrow-shaped penetrator rounds are based upon the Pfeilgeschoss concept. While these tank rounds are extremely accurate, the discarding sabot concept has not been as successful thus far when applied to ammunition of rifle rather than cannon caliber, due somewhat disappointing accuracy.

A notable exception to such accuracy problems is Winchester/Olin Corporation’s Saboted Light Armor Penetrating cartridge or SLAP for short. Variants are available in 7.62x51mm (U.S. military designation M948) and .50 BMG (12.7x99mm, military designation M903 for the .50 caliber SLAP and M962 for the .50 caliber SLAP-Tracer). The 7.62mm rounds function reliably in most weapons, including bolt-action rifles, the M60 machine gun, the M134 Gatling gun, and the M240 machine gun. The M903 SLAP round is particularly relevant to the present discussion, since it delivers comparable accuracy to 7.62x51mm match-grade ammunition. Winchester’s success with this SLAP round clearly demonstrates that it is, indeed, possible to make a saboted cartridge of rifle caliber that will deliver acceptable and even outstanding accuracy. Winchester’s success with the SLAP round provides encouragement that Hartikka’s concept of a saboted round may be viable (for more information on Winchester’s SLAP rounds, visit the website at http://www.army-technology.com/contractors/ammunition/winchester/index.html).

The conical bullet of the Hartikka’s M/2030 hypersonic round has a caliber about half the diameter of the bore. A sabot seals the bore ahead of the combustion gases, carrying and guiding the bullet down the barrel, after which air resistance discards the sabot from the bullet. Since the subcaliber projectile neither centers itself in the bore nor slides down the rifling of the bore, it can be designed for optimum flight characteristics at supersonic speeds. This means using straight, smooth surfaces. While a teardrop shape is the ideal form (in terms of exterior ballistics) for projectiles traveling at subsonic velocities, this is a poor shape at supersonic speeds. Based on wind tunnel tests leading to the design of the Concorde supersonic passenger jet, Hartikka believes a bullet tip shaped like a straight, sharp cone is best. A shorter cone makes an efficient base at these velocities.

If this double cone bullet leaves the muzzle at Mach 6 (six times the speed of sound), Hartikka’s research suggests the projectile will fly 300 to 500 meters in almost a straight line until the bullet goes transonic. Once this bullet becomes subsonic, it destabilizes, tumbles, and drops suddenly. The net result is a cartridge that shoots to point of aim out to half a kilometer, while providing a shorter danger zone beyond the weapon’s effective range, minimizing the potential of collateral noncombatant casualties.

The same case can be loaded with a full caliber rather than subcaliber projectile to produce a subsonic cartridge similar in performance and recoil characteristics to a 9x19mm or .40 S&W submachine gun round. In fact, the full caliber case for the M/2030 is designed to produce muzzle velocities ranging from 290 mps (951 fps) to 450 mps (1,476 fps) depending on bullet weight, so this round could be tailored to give .357 Magnum-like performance out of a straight blowback rifle.

Thus a single weapon could be used as a Personal Defense Weapon (PDW) or an Objective Personal Weapon (OPW).

Weapon Design

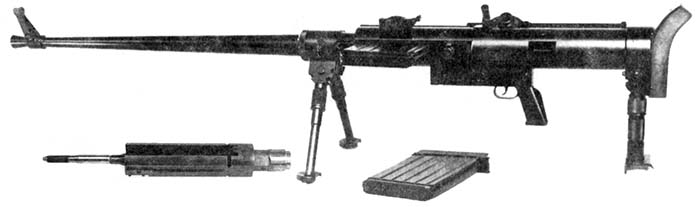

The weapon Hartikka envisions for the M/2030 cartridge draws its inspiration from World War I, when the Coenders brothers of Germany developed a 20mm automatic aircraft cannon for Reinhold Becker using a novel design that used an unusually long chamber and a bolt that actually entered the chamber. German and U.S. patent applications date from the first year of the war, 1914, and U.S. Patent 1,144,285 was issued in June 1915. Manufactured by Stahlwerke Becker of Reinickendorf, Germany, the Becker automatic cannon featured simple blowback operation, inertial locking, a remarkably light weight of just 66 pounds (30 kg), a 12-round detachable box magazine, a barrel length of 40 calibers, a cyclic rate of 400 rpm, and a muzzle velocity of 1,570 fps (479 mps). While designed expressly for use from aircraft, the successful Becker design was also pressed into an anti-aircraft role late in the war.

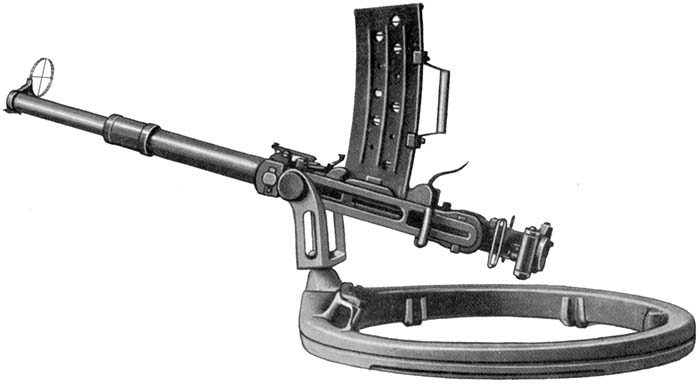

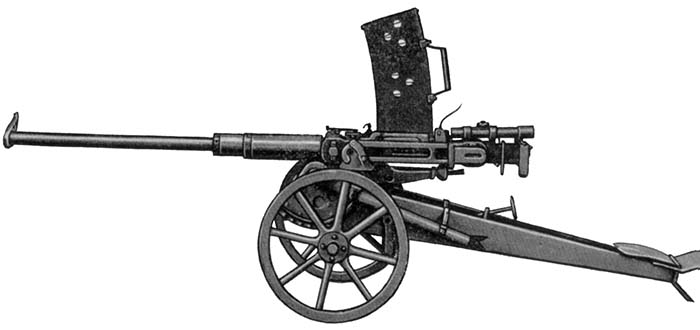

After the cessation of hostilities, the design was licensed to the Swiss automotive company Seeback Maschinenbau Aktien Gesellschaft (Semag) near Zurich in order to circumvent the terms of the Treat of Versailles. Using German financial backing and personnel, Semag modified the design to incorporate a longer cartridge and barrel to achieve higher average muzzle velocity of 2,247 fps (685 mps). This weapon was mounted on a wheeled cart with seat for the gunner, and was marketed in 1921 as the Semag Infantry Gun. Years later, this weapon was still in service and saw combat during the Spanish Civil War of 1936-1939 and during the Sino-Japanese War of 1937-1945. Both the 20mm Becker aircraft gun and the 20mm Semag infantry gun were a success on the battlefield. But Semag overreached the technology in 1923, when the company upsized the Becker design to fire a 25mm round. The resulting automatic cannon was too heavy for infantry use and the company foundered.

The Swiss firm Werkzeug Maschinenfabrik Oerlikon subsequently took over the rights to Becker’s patents, and by 1935 Oerlikon was producing a new family of 20mm automatic cannons—using three different 20mm cartridges—based on the innovative Becker design. Germany adopted the Model S aircraft variant of the Oerlikon, and this Becker-type automatic cannon served the Luftwaffe with distinction through the Battle of Britain. Oerlikon also adapted the Becker design for its 20mm anti-tank rifle, the SSG36.

Operating by the straight blowback principle, the original Becker cannon fielded so successfully during World War I uses a 20mm round with almost a straight cartridge case. The cartridge features a rebated base that enabled the use of a slimmer bolt face that could follow the cartridge into the weapon’s unusually deep chamber.

A striker hits the primer about a half inch (a bit more than one centimeter) before the cartridge is fully seated in the weapon’s chamber, a practice commonly called “advanced ignition” or “floating fire” in various languages. The Becker design is particularly innovative since the cartridge is already completely surrounded by the very long chamber at the moment of ignition, so the combustion gases cannot burst the case before the bolt has reached battery position.

An instant after primer ignition, bolt momentum pushes the rebated cartridge to the front end of the barrel’s extra-long chamber so the expanding case can seal against the rearward pressure of the expanding combustion gases. Gas pressure then pushes the empty case rearward through the long chamber until the projectile emerges from the muzzle and gas pressure drops to a safe level.

Using very high bolt velocity as a substitute for a securely locked breech has three principal advantages: (1) it enables the construction of a lightweight cannon, (2) it dampens weapon recoil considerably, and (3) it dramatically reduces vibration during full-auto fire since the bolt is effectively buffered at both ends of its cycle. This latter phenomenon occurs because advanced ignition within the long chamber buffers the bolt’s forward movement, while the long main operating (recoil) spring buffers the rearward movement.

Like the Becker cannon of 1914, a 21st century weapon designed for Juha Hartikka’s new M/2030 round would feature simple blowback operation and an extra-long chamber to support the cartridge case from the moment of advanced ignition until the bolt reaches the battery position when full-auto fire is selected. Unlike the Becker cannon, Hartikka’s assault rifle would fire from the closed bolt when semiautomatic fire is selected. The long chamber would support the fired case during the subsequent first phase of bolt movement out of battery.

One of Hartikka’s principal innovations is that the bolt head and extractor would push into the base of the M/2030 cartridge case, rather than using a more conventional design where the bolt slides over the base of the cartridge. This approach facilitates sealing the extra-long chamber of the simple blowback assault rifle. This concept also enables looser tolerances on the bolt, since it will self-center on the hollow cartridge base.

Thanks to the relatively light projectile weight of this hypersonic cartridge, ultra-high projectile velocity does not require ultra-high chamber pressure. A subcaliber projectile that is half the bore diameter should be able to achieve about four times the acceleration of a bullet that is twice the diameter without raising chamber pressure. This will probably require the development of a faster powder than is currently being produced to achieve hypersonic (Mach 5) velocities, but very fast powders are now available for experimenting with M/2030-style saboted cartridges. The plastic case of the hypersonic round would feature a metal primer cup to reinforce the base of the cartridge, and a novel primer of neither Boxer nor Berdan type that sits directly against the powder.

Using a plastic case requires forming the powder into a compressed briquette that fits snugly in the case, in order to provide enough case rigidity for proper magazine functioning. When the primer ignites, it forces the saboted bullet forward into the rifling of the bore uniformly and at low velocity before the powder briquette ignites. This eliminates the initial instability normally associated with a saboted rifle projectile as it detaches from the cartridge case, thus eliminating one of the factors contributing to the relative inaccuracy commonly seen in saboted rifle cartridges. It is worth noting that compressing nitrocellulose powder into a solid briquette using solvents for gluing the grains together is established technology. Lapua, for example, was using compressed powder for unbulleted cartridges as early as the 1980s.

The subsonic M/2030 round uses conventional powder, bullet, and Boxer or Berdan priming, while its hollow base cartridge case is made out of brass rather than plastic.

Since the hypersonic M/2030 round uses a plastic case and subcaliber projectile, these will be relatively inexpensive and lightweight cartridges. Furthermore, the countersunk cartridge base of both the hypersonic and subsonic rounds enables the use of a very simple and inexpensive weapon design not unlike the Sten submachine gun. In fact, a Sten could be modified into a proof of concept gun by adding a new barrel, bolt and magazine. Juha Hartikka, who has designed and built more than 300 different silencer variants since 1990 (many of which are marketed by Asesep„nliike BR-Tuote Ky, Sahamyllynkatu 33, 80170 Joensuu, Finland), has also developed the design for a specially reinforced sound suppressor capable of handling both the subsonic and saboted hypersonic M/2030 rounds. Using a saboted round with a suppressor not expressly designed to deal with a discarding sabot could lead to catastrophic structural failure.

While the terminal ballistics of the hypersonic round remain unproven and an ideal powder for the hypersonic round is not yet available, the innovative concept of the dual performance hypersonic and subsonic M/2030 rounds is thought-provoking to say the least. Developed with input from Finnish ammunition and small-arms guru P.T. Kekkonen (whom I view as a “Living National Treasure” of Finland), Juha Hartikka has spawned a concept which has some fascinating implications for the future of small-arms design. Hartikka is continuing the development of this countersunk cartridge base, hypersonic projectile concept. The latest iteration is called the M/2060 cartridge. But that’s another story. Meanwhile, anyone interested in learning more about Hartikka’s work can visit his website (http:/www.personal.inet.fi/business/reflex.suppressors), e-mail him (j_hartikka@hotmail.com), or write him (Juha Hartikka, 83430 Käsämä, Finland).

| This article first appeared in Small Arms Review V3N3 (December 1999) |