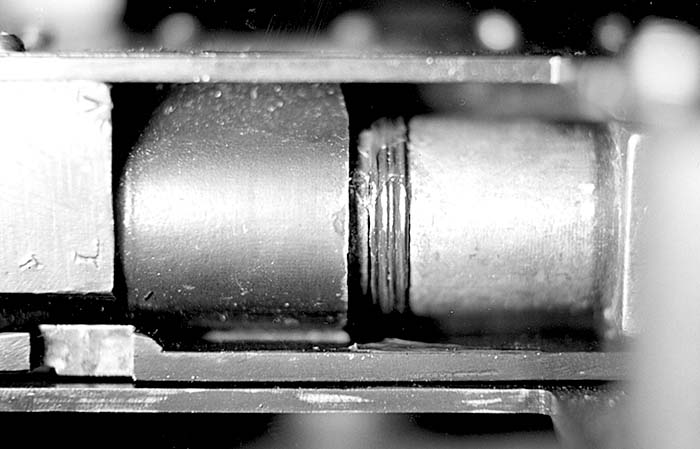

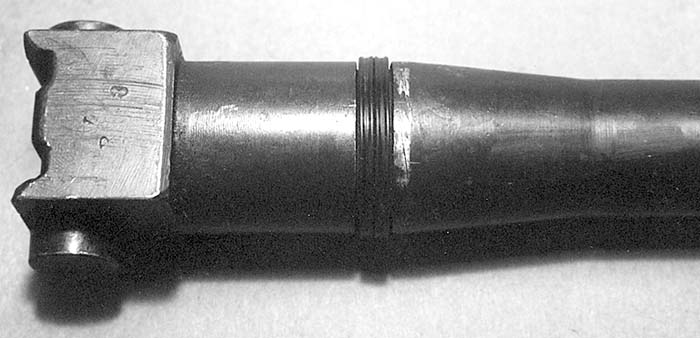

1919 barrel altered for a 1917. It is shown with a single O ring in place. This was turned to fit the 1917 BMG prior to cutting the groove for the O ring.

By Dr. Ed Weitzman

When I fired my first water-cooled MG, I looked the same way I did after my first swimming lesson, as there was very little left of the original packing material to keep the water in the gun. Attempts at finding a suitable replacement for the asbestos twine (wouldn’t want my MG declared a toxic waste site by the EPA) led me to a modern alternative, the O-ring. This has proven to be a reliable, inexpensive and effective substitute for asbestos packing.

A Browning 1917, and a MkI Vickers were converted to O-ring barrel seals. It has shown to be superior to the traditional methods of keeping the coolant in the gun. No modification to the gun is required but access to a lathe will be needed.

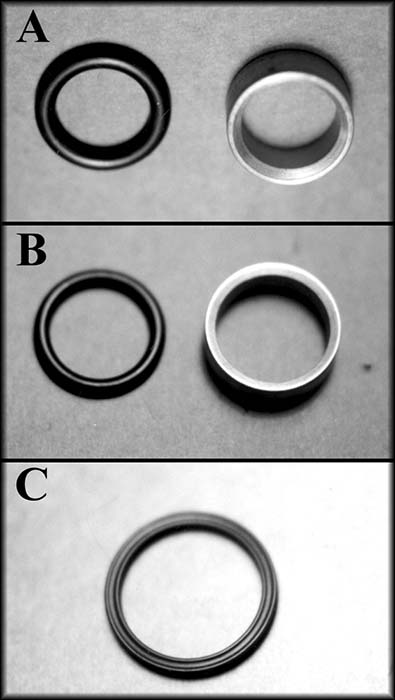

The first step is to obtain the proper size O-rings. Both the Browning and the Vickers take the same size rear O-rings. I use a double seal, Buena-N O- ring (shaped in cross section like a 4 leaf clover ) dash No. 119 (3/32 x 15/16 x 1 1/8). For the front, I recommend the use of Viton as these withstand high temperatures better than neoprene. The Browning muzzle requires a dash No. 115 O-ring (3/32 x 1 1/16 x 7/8) and the Vickers, a dash No. 208 (1/8 x 5/8 x 7/8).

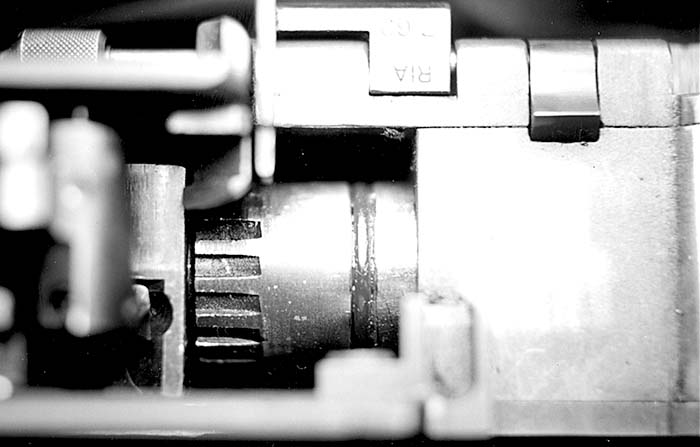

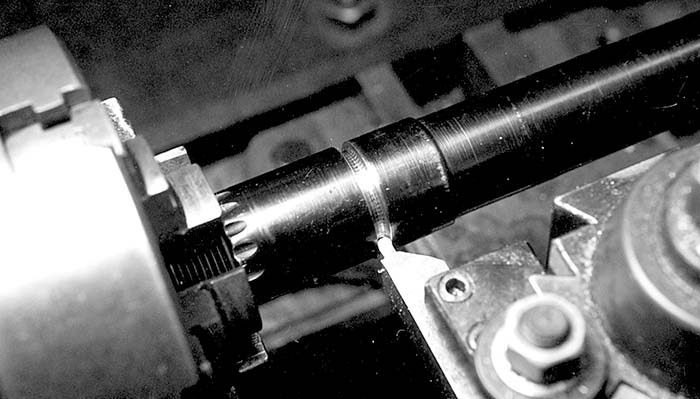

The packing groove in the barrel is wide enough to accommodate two rings side by side but not deep enough. Here is where our lathe comes into play. First remove and discard the old packing, then, with a sharp cut-off tool, you must deepen the packing groove until the barrel with the O-rings in place is a sliding fit in the trunion of the gun. It should just slide out when the gun is vertical. Take it slow, just taking a few thousandths at a time and the proper fit will be obtained. Apply a coat of high temp grease to the O-rings before attempting to fit them to the gun.

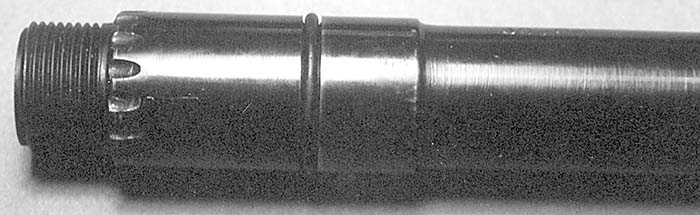

Don’t turn off the lathe yet, you still have a front spacer to make. The original front packing is much wider than the O-ring that will replace it and the spacer fills in the void. The easiest material to use is brass. The Browning spacer is .8175 OD x. 6875 ID x .280 wide. The one for the Vickers is .825 OD x .640 ID x .280 wide. You may have to experiment with the width to obtain a size that just compresses the O-ring when the muzzle gland is tight. The edge of the spacer that contacts the O-ring should have a 45-degree bevel.

The old front barrel packing is removed and the barrel is placed into the gun .The proper size greased O-ring is then placed on the muzzle of the barrel followed by the brass spacer. These are pushed into place and the muzzle gland is then tightened until it is snug. With the Vickers gun, the O-ring is placed in the packing cavity before the barrel is put into the gun. Next, the water jacket filled with water (or a coolant mixture of soluble oil and water), and your shooting session can begin. This shouldn’t leave you looking like you just had a swimming lesson.

All materials except the spacer, are available from McMaster-Carr Supply Co, PO Box 440, New Brunswick, N.J. (732-329-6666) nj.sales@mcmaster.com

Viton O-ring 115 #9464K28

Viton O-ring 208 #9464K67

Buena N O-ring #90025K248

Water soluble oil #1310K1

Hi temp silicone grease #1252K32

| This article first appeared in Small Arms Review V3N7 (April 2000) |